Assembly machine for gas surface membrane component

A technology of assembling machine and membrane module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

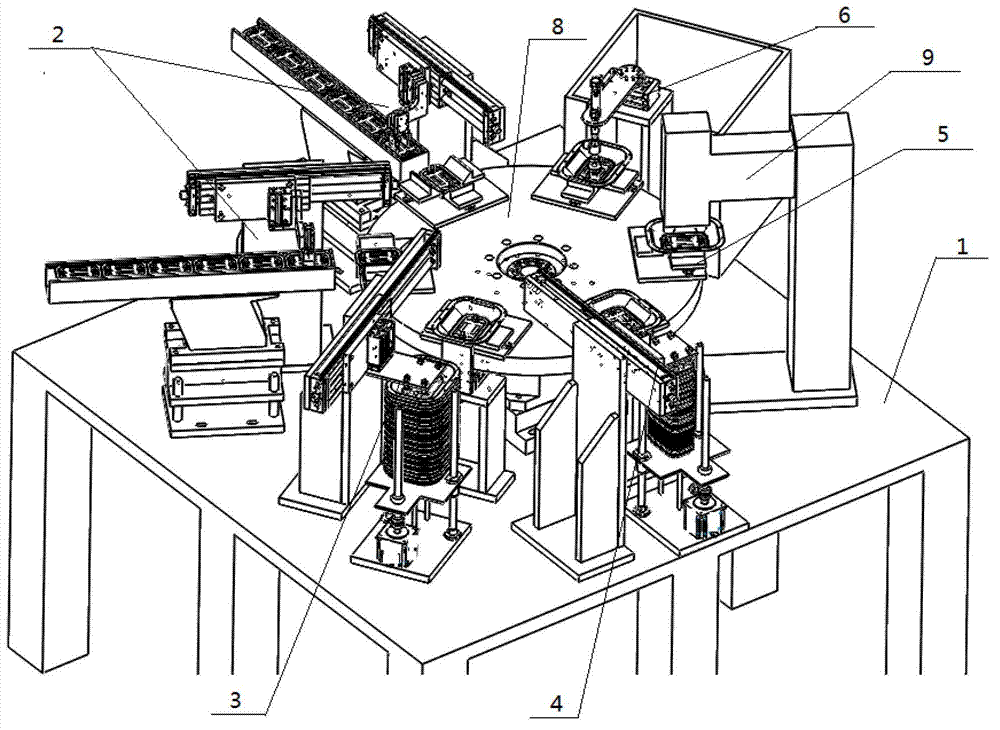

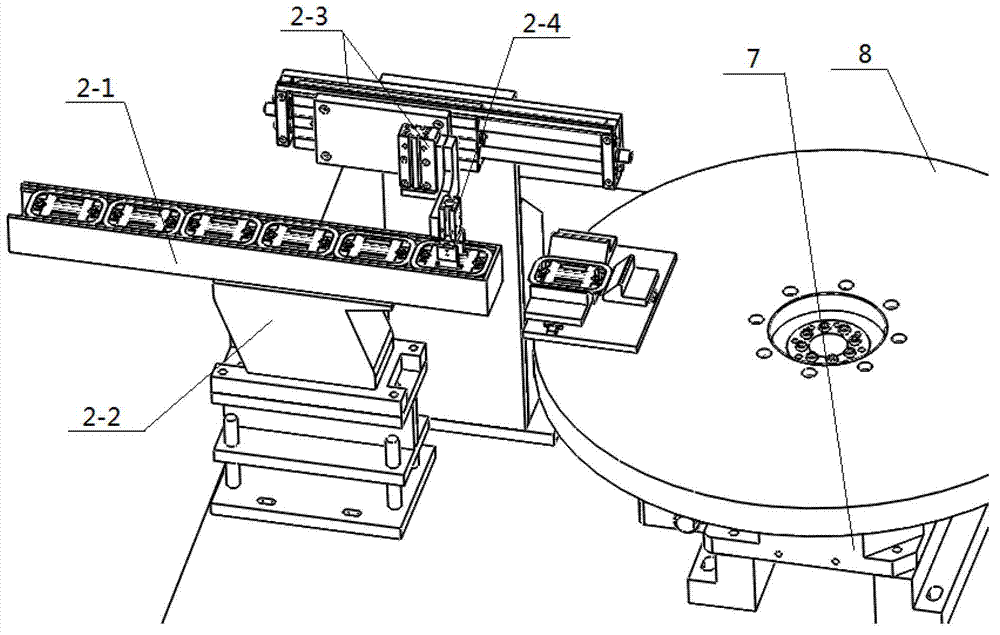

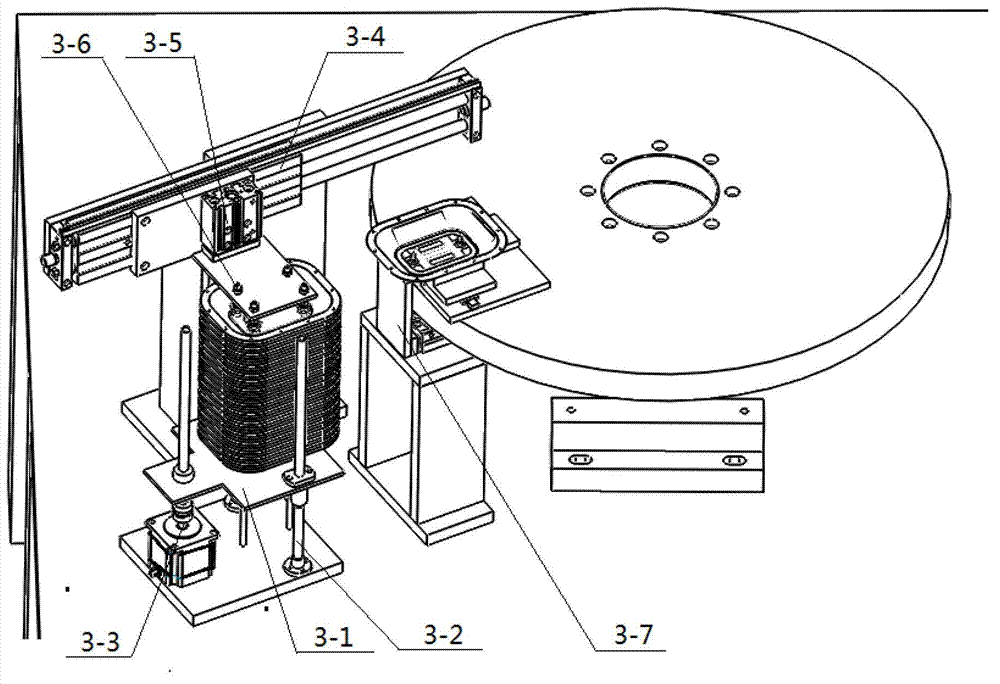

[0019] refer to Figure 1-Figure 5 , an assembly machine for a fuel gas surface membrane module, comprising a frame 1, a turntable indexing drive device, and a drive control module, and a six-station work area is evenly distributed outside the turntable indexing drive device, and the turntable indexing drive The device is fixed on the frame 1, including a drive motor, a divider 7 and a turntable 8, and six sets of adjustable clamps 9 are evenly distributed on the turntable, and the corresponding six-station working areas outside the turntable are two different specifications in sequence Plastic clip box assembly station 2, film assembly station 3, aluminum clip box assembly station 4, heat welding station 5, blanking station 6, the plastic clip box assembly station 2, film assembly station 3, The 4-station assembly of the aluminum clip box is composed of a parts sorti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com