Self-bonding layer strip material with environmental protection and wide temperature change

A self-adhesive layer, temperature change technology, applied in building insulation materials, film/sheet adhesives, adhesives, etc., can solve the problem of increasing product material cost and production cost, low bonding strength, and decreased viscosity quality, etc. problems, achieve good practical value and social benefits, benefit the environment and society, and improve the bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

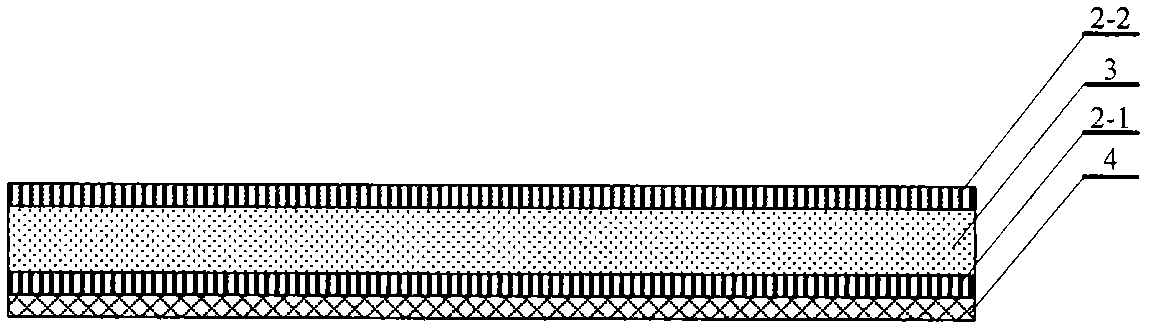

[0061] refer to figure 1 , in conjunction with the production process of the self-adhesive layer tape with environmental protection and wide temperature change of the present invention, the structure of the self-adhesive layer tape of this embodiment will be described in detail.

[0062] The process of manual coating is as follows: First, spread the non-woven polyester cloth on the countertop or clean ground, use a brush to evenly apply the adhesive to the surface of the base layer 3, and wait for natural drying or artificial heating and drying. (that is, the first adhesive layer 2-1), on its surface, one layer of base film 4 as a separator is pressed. Then, the self-adhesive layer that has coated one side of the adhesive and the composite base film 4 is reversed, and then glued and dried in the same way (being the second adhesive layer 2-2). Then, roll up the self-adhesive layer strip material coated on both sides and put it in a packaging bag, which can be implemented by th...

Embodiment 2

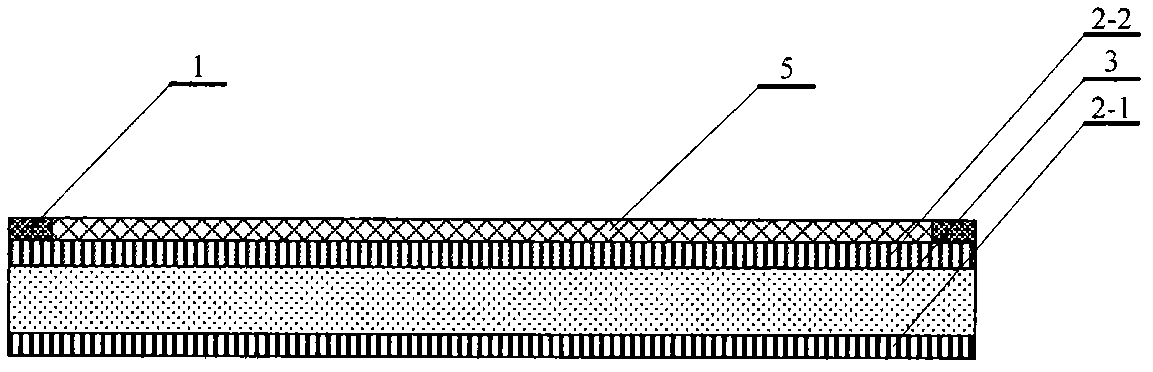

[0075] refer to figure 2 , the present embodiment has the self-adhesive layer tape material of environmental protection wide temperature change, is coated with the mask 5 of the barrier film by the kraft paper material of silicone oil on one side, and the kraft paper material that is coated with silicone oil on both sides is used as edge film 1, and this mask 5 and the edge The films 1 are all purchased on the market, and the width of the edge film 1 is 10cm.

[0076] The tire base layer 3 is made of non-woven polyester cloth material, and the thickness of the tire base layer 3 is 0.76mm.

[0077] The first adhesive layer 2-1 with a thickness of 0.02mm and the second adhesive layer 2-2 with a thickness of 0.02mm are respectively coated on the two surfaces of the base layer 3, and the first adhesive layer 2-1 or the second adhesive layer 2-1 The other side of the second adhesive layer 2-2 re-presses a layer of facial film 5, wherein, the re-pressing leaves a blank strip on bo...

Embodiment 3

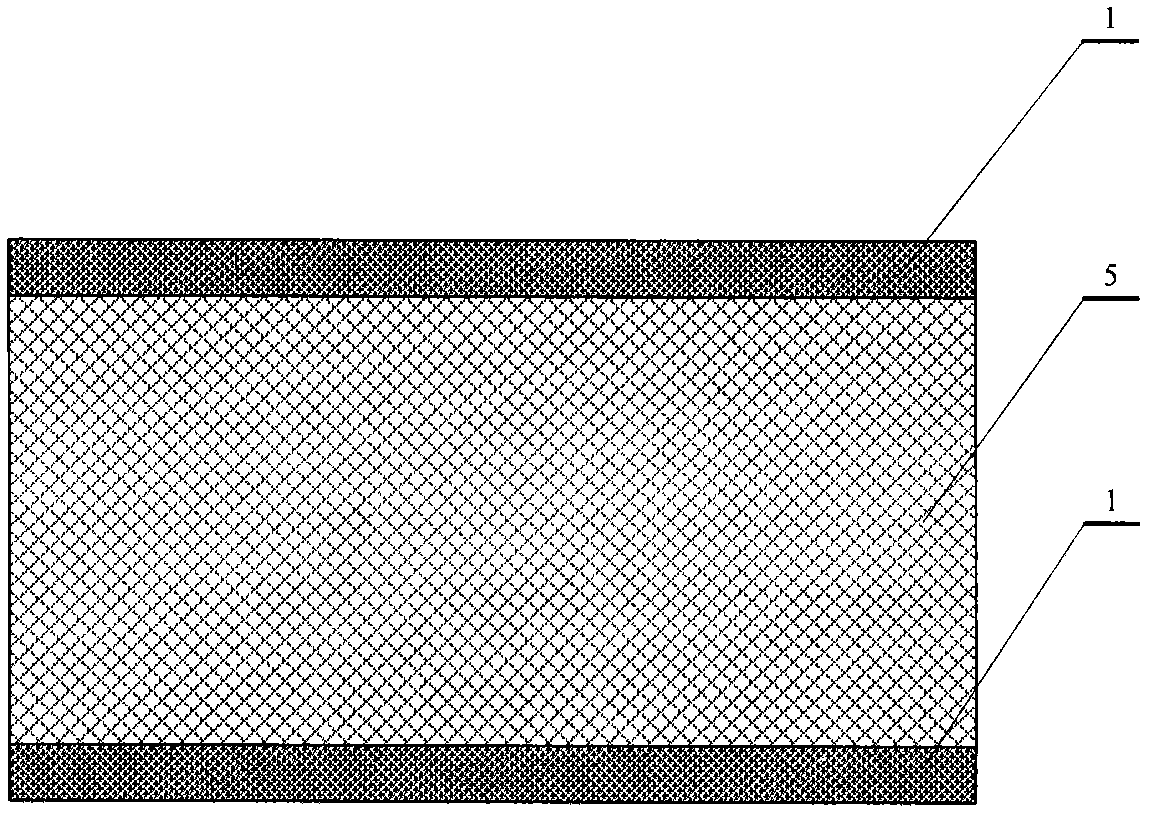

[0090] refer to figure 1 and image 3 , the production process of making the self-adhesive layer of the self-adhesive waterproof roll material of the present invention is:

[0091] First of all, the tire base layer 3 is put on the shelf, after buffer adjustment, deviation correction, and drying, it enters the glue coating pool for gluing, and the glue in the pool is automatically replenished from the glue storage tank by the delivery pump according to the amount of glue in the pool. The finished base layer enters the drying furnace, and is automatically dried by electric heating according to the preset temperature. The temperature in the furnace is divided into three sections: high, medium and low. , the outlet is in the low temperature zone, and the distribution temperature of the three-stage control is high temperature zone: 160-130°C, medium temperature zone: 120-100°C, low temperature zone: 80-50°C, in order to shorten the drying time of the adhesive layer and reduce the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com