A continuous gluing device for bamboo and wood composite rods

A bamboo-wood composite and gluing device technology, applied in the direction of adhesive application device, lamination device, plywood press, etc., can solve the problems of low thermal conductivity, low productivity, high energy consumption, etc. Long life and rapid heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

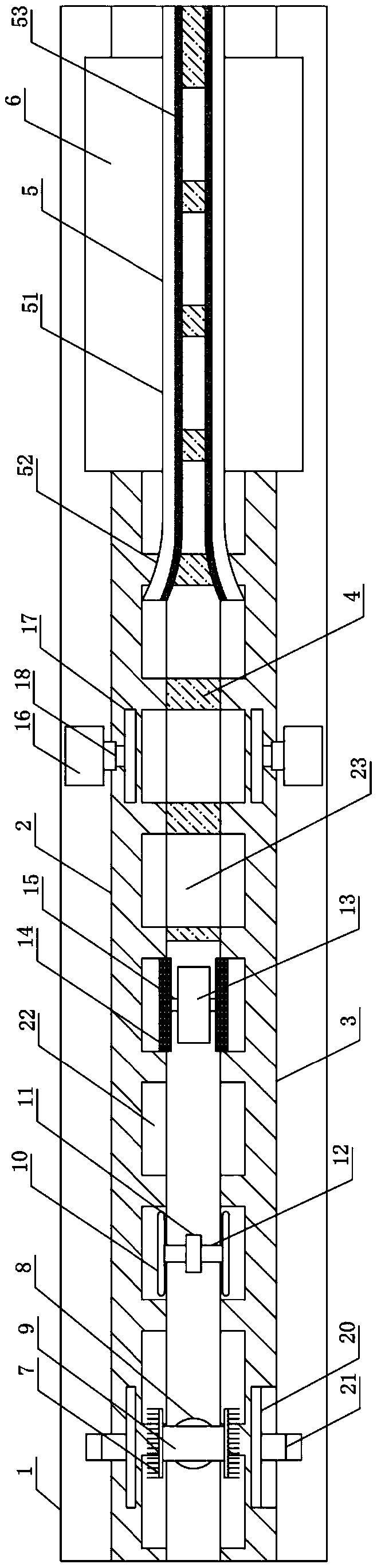

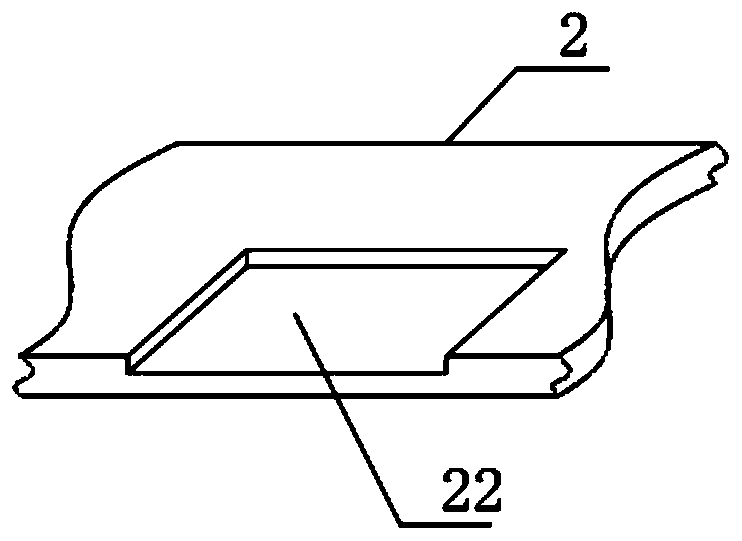

[0028] according to Figure 1-5 A continuous gluing device for bamboo-wood composite rods as shown, comprising a workbench 1, a transmission device, a cleaning device, a heating device, a gluing device and a hot pressing device, the cleaning device, a heating device, a gluing device and a hot pressing device Set on the top of the workbench 1 in turn, the conveying device includes a bamboo conveyor belt 2, a timber conveyor belt 3 and a bamboo-wood composite rod conveyor line 4, and the bamboo-wood composite rod conveyor line 4 is arranged on the bamboo conveyor belt 2 and the timber conveyor belt 3 on one side, the cleaning device, the heating device and the gluing device are arranged between the workbench 1 and the bamboo conveyor belt 2, and the bamboo-wood composite pole conveying line 4 is arranged on the gluing device side, and the hot pressing The device is arranged on both sides of the bamboo-wood composite rod conveying line 4, and the hot pressing device is arranged o...

Embodiment 3

[0033] Described heating device comprises PTC heater 10 and temperature control box 11, and described PTC heater 10 is arranged on temperature control box 11 top both sides, and PTC heater 10 is arranged on bamboo material conveyor belt 2 or wood conveyor belt 3 just above, Both sides of the temperature control box 11 are fixedly provided with second connecting rods 12, and the PTC heaters 10 on both sides are fixedly connected to the second connecting rods 12, and the PTC heater 10 is electrically connected with the temperature control box 11. The setting of the device is conducive to heating the side of the bamboo and wood to be composited, reducing the moisture content of the bamboo and wood, avoiding the effect of high moisture content on the quality of the glue, and through heating, the curing efficiency of the glue can be improved, thereby improving Production efficiency, and use the PTC heater 10 to set, the heat generated by the PTC heater 10 is rapid, the aluminum shee...

Embodiment 4

[0035] Described gluing device comprises pressurized rubber barrel 13 and glue sprayer 14, and described glue sprayer 14 is arranged on pressurized glue barrel 13 top both sides, and glue sprayer 14 is arranged on bamboo material conveyor belt 2 or wood conveyor belt 3 Directly above, a third connecting rod 15 is fixedly arranged on both sides of the pressurized rubber barrel 13, one end of the third connecting rod 15 is fixedly connected with the glue sprayer 14, and the output end of the pressurized glue barrel 13 is connected with the glue sprayer 14 input connections.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com