Rotating cross-flow flat ceramic membrane separation turntable

A rotating cross-flow and ceramic membrane technology, which is applied in the direction of semi-permeable membrane separation, membrane technology, chemical instruments and methods, etc., can solve the problem that flat organic membranes cannot withstand high-pressure backwashing, hollow fiber membranes are prone to fouling, and the scope of application is limited. problems, to achieve the effect of convenient implementation of high-pressure backwashing, easy cleaning, and reduction of membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

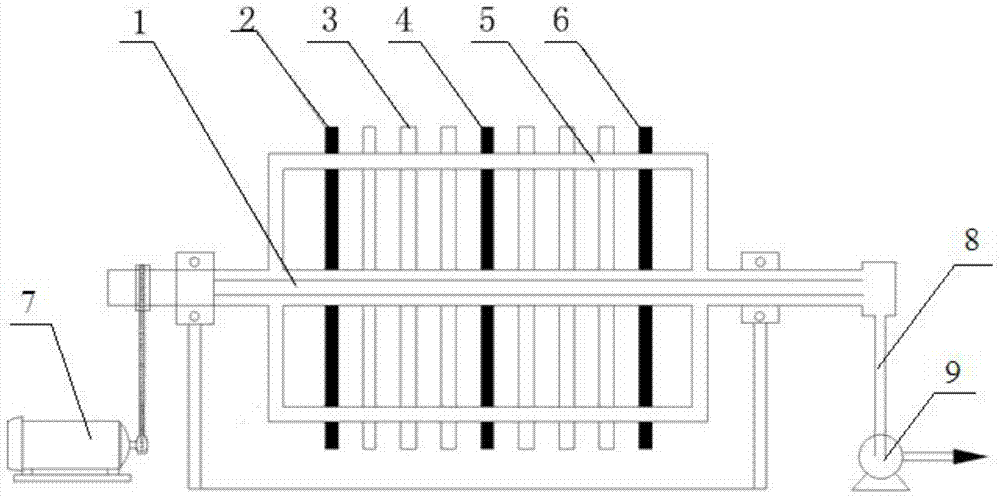

[0028] Such as figure 1 As shown, this embodiment discloses a rotating cross-flow flat ceramic membrane separation turntable, which includes: a hollow central shaft 1, a support assembly fixed on the hollow central shaft 1, and several flat plates supported by the above support assembly. A type ceramic membrane component 3 , a drive mechanism (motor) 7 for driving the rotation of the hollow central shaft 1 , and a liquid collecting pipe 5 .

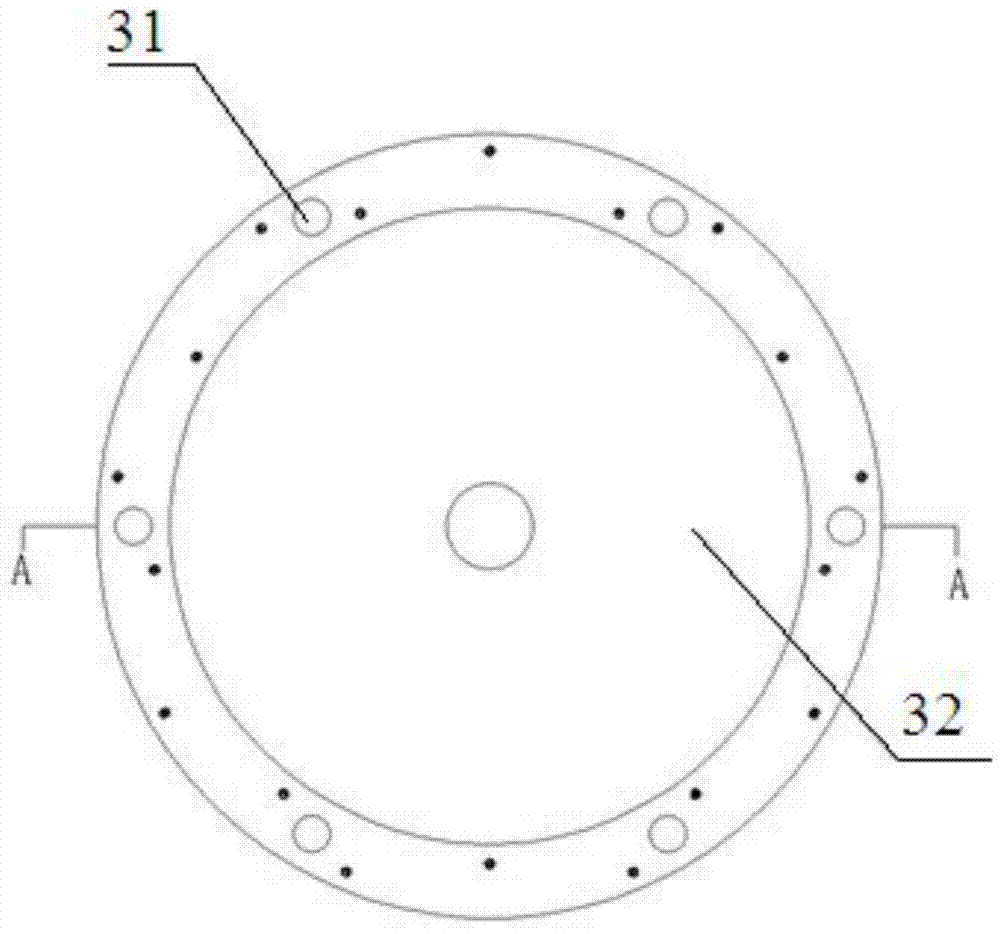

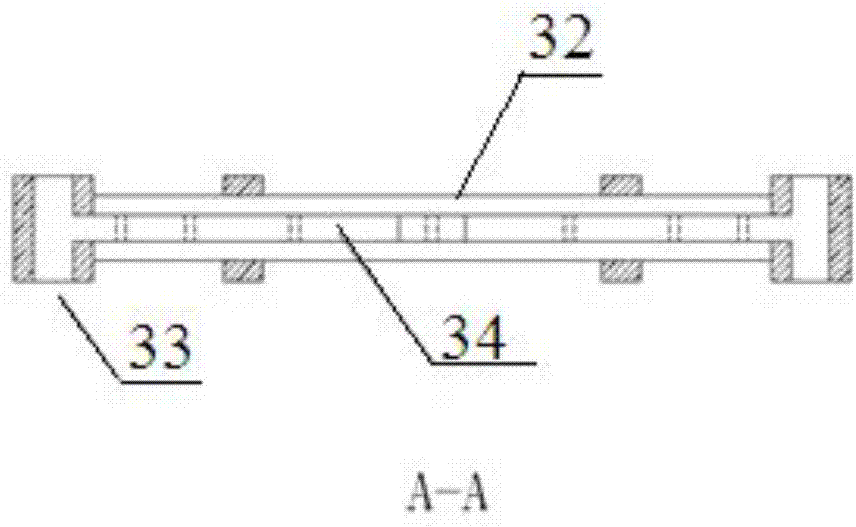

[0029] Such as Figure 2-3 As shown, the above-mentioned flat ceramic membrane component 3 includes a hollow cavity flat ceramic diaphragm 32, and the above hollow cavity flat ceramic diaphragm 32 includes two separated film layers, which is an external pressure and internal suction structure. A plurality of liquid sink cavities 33 and liquid outlet holes 31 are arranged around the cavity-type flat ceramic diaphragm 32 , and a plurality of cavities 34 are arranged inside the hollow-type flat ceramic diaphragm.

[0030] The liquid collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com