Surface skid resistance enhancing glazed tile adobe and preparation method thereof

A technology for anti-slip performance and glazed tiles, which is applied in the field of glazed tile blanks and their preparation, can solve the problems of worrying about the degree of anti-slip, and achieve the effects of increasing roughness, reducing dry materials and avoiding anti-fouling performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A kind of preparation method of the glazed brick that improves surface antiskid performance, comprises the following steps:

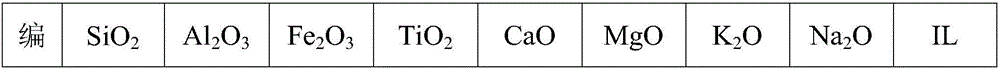

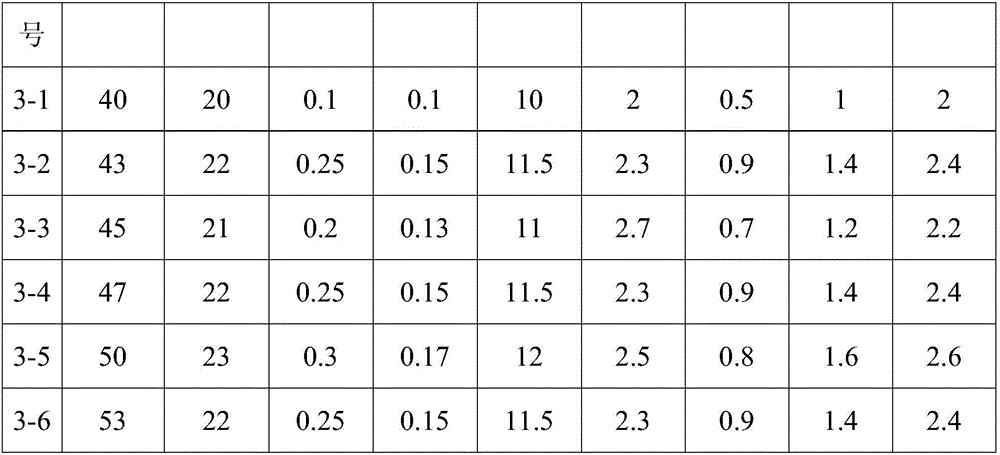

[0025] A. Preparation of rough glaze: take by weight 60-100 parts of Gaoming transparent frit powder, 25-35 parts of kaolin, and 1-2 parts of alumina, and then add water to the above raw materials to make a glaze slurry with a specific gravity less than 1.3. The chemical components of the above-mentioned high-temperature transparent frit powder are in parts by mass, including the following components: SiO 2 45-50 parts, Al 2 o 3 20-25 parts, Fe 2 o 3 0.1-0.4 parts, TiO 2 0.1-0.2 parts, CaO 10-13 parts, MgO 2-3 parts, K 2 O 0.5-1 part, Na 2 O 1-2 parts, IL 2-3 parts;

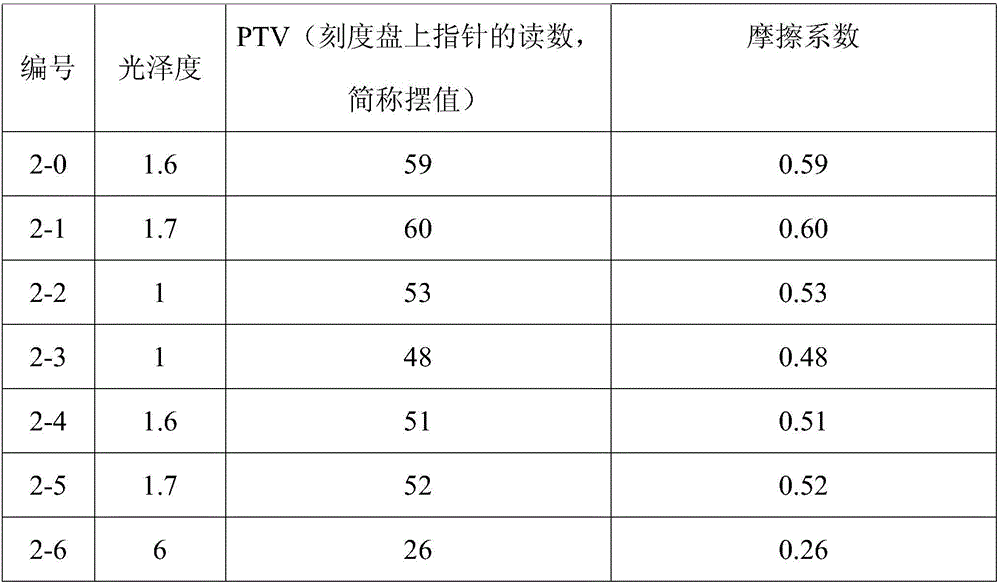

[0026] B. Preparation and firing of the product: apply anti-fouling underglaze on the surface of the brick, and then apply the rough glaze obtained in step A, and the glaze amount of the rough glaze is ≤0.5kg / m 2 , dried, fired, and finally polished to obtain the finishe...

Embodiment 1-1

[0039] A. Preparation of rough glaze: Weigh 100 parts of Gaoming transparent frit powder, 30 parts of kaolin, and 1.5 parts of aluminum oxide in parts by mass, and then add water to the above raw materials to make a glaze slurry with a specific gravity less than 1.3. The high-temperature transparent frit powder The chemical components are in parts by mass, including the following components: SiO 2 46.29 parts, Al 2 o 3 23.66 parts, Fe 2 o 3 0.27 parts, TiO 2 0.16 parts, CaO 11.25 parts, MgO 2.72 parts, K 2 O 0.88 parts, Na2 O 1.74 parts, IL 2.34 parts;

[0040] B. Preparation and firing of the product: apply anti-fouling underglaze on the surface of the brick, and then apply the rough glaze obtained in step A, and the glaze amount of the rough glaze is 0.5kg / m 2 , fired after drying, and finally polished to obtain the finished product. In the anti-skid performance test, the PTV (the reading of the pointer on the dial, referred to as the pendulum value) is 62, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com