Superhydrophobic acrylic resin paint

An acrylic resin and super-hydrophobic technology, which is applied in coatings and other directions, can solve the problems of poor surface water resistance, no self-cleaning performance, and easy accumulation of dust, etc., and achieve the effect of low cost, good industrial application prospects, and simple construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Measure 30ml of acetone, 50ml of ethyl acetate and 20ml of ethanol with a graduated cylinder and add them to a 300ml beaker to form a mixed solvent;

[0025] (2) Take by weighing 20 grams of nano-calcium carbonate and 80 grams of nano-silicon dioxide respectively with an electronic analytical balance and join in the mixed solvent and stir with a magnetic stirrer for 30 minutes to form a solution composed of nanoparticles;

[0026] (3) 0.1 gram of silane coupling agent was added to the nanoparticle solution and continued to stir for 30 minutes;

[0027] (4) Weigh 3 grams of heptadecafluorotrimethoxyethoxysilane and add it to the nanoparticle solution and stir for 10 minutes;

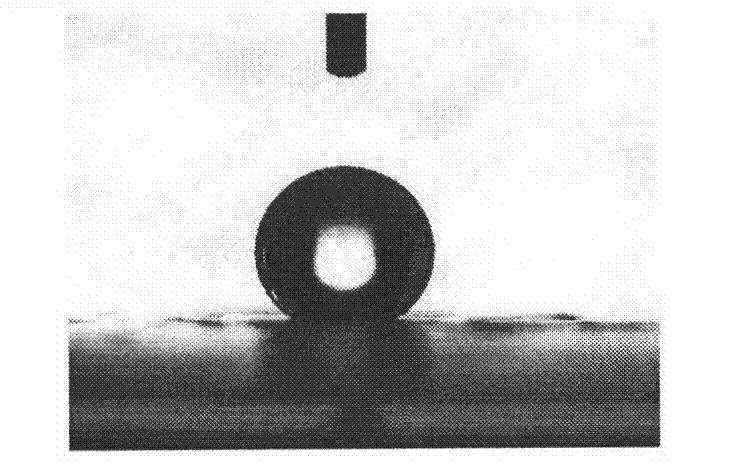

[0028] (5) Weigh 20 grams of acrylic resin and add it to the above nanoparticle solution and stir for 120 minutes to obtain a superhydrophobic acrylic resin coating; use a spray gun to spray the coating on a smooth ceramic surface and place it in an oven Cured at 100°C for 5 hours, after cooli...

Embodiment 2

[0030] (1) Measure 60ml of acetone, 100ml of ethyl acetate and 40ml of ethanol with a graduated cylinder and add them to a 500ml beaker to form a mixed solvent;

[0031] (2) Take by weighing 10 grams of nano-calcium carbonate and 90 grams of nano-silicon dioxide respectively with an electronic analytical balance and join in the mixed solvent and stir with a magnetic stirrer for 30 minutes to form a solution composed of nanoparticles;

[0032] (3) 0.2 gram of silane coupling agent was added to the nanoparticle solution and continued to stir for 30 minutes;

[0033] (4) Weigh 5 grams of heptadecafluorotrimethoxyethoxysilane and add it to the nanoparticle solution and stir for 10 minutes;

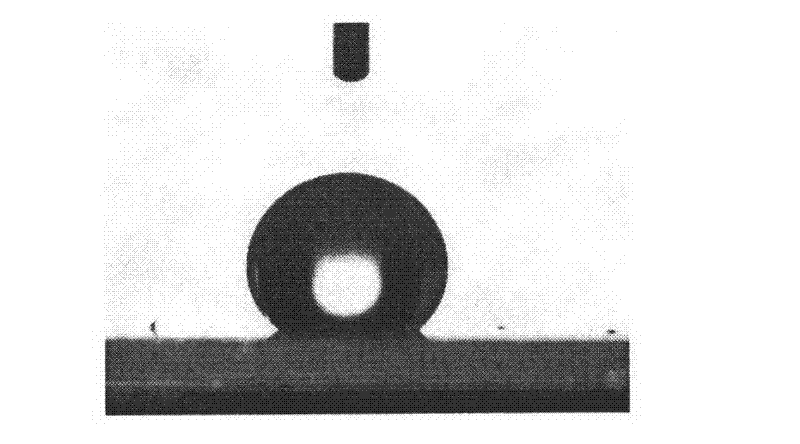

[0034] (5) Weigh 30 grams of acrylic resin and add it to the above-mentioned nanoparticle solution and stir for 120 minutes to obtain a superhydrophobic acrylic resin coating; use a spray gun to spray the coating on a smooth stainless steel surface and place it in an oven Cured at 100°C for 5...

Embodiment 3

[0036] (1) Measure 90ml of acetone, 150ml of ethyl acetate and 60ml of ethanol with a graduated cylinder and add them to a 1000ml beaker to form a mixed solvent;

[0037] (2) Take by weighing 10 grams of nano-calcium carbonate and 90 grams of nano-silicon dioxide respectively with an electronic analytical balance and join in the mixed solvent and stir with a magnetic stirrer for 30 minutes to form a solution composed of nanoparticles;

[0038] (3) 0.2 gram of silane coupling agent was added to the nanoparticle solution and continued to stir for 30 minutes;

[0039] (4) Weigh 10 grams of heptadecafluorotrimethoxyethoxysilane and add it to the nanoparticle solution and stir for 10 minutes;

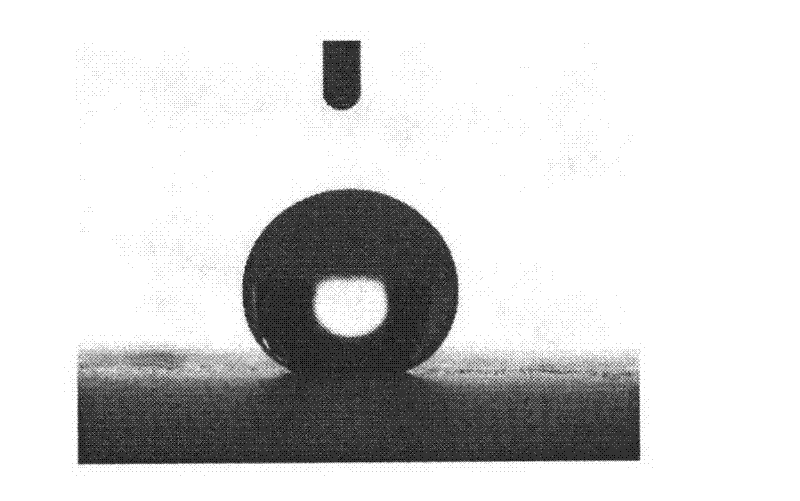

[0040] (5) Weigh 50 grams of acrylic resin and add it to the above nanoparticle solution and stir for 120 minutes to obtain a superhydrophobic acrylic resin coating; use a spray gun to spray the coating on a smooth glass surface and place it in an oven Cured at 100°C for 5 hours, after cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com