Preparation method for constructing super-hydrophobic structure on surface of aluminum alloy

A super-hydrophobic technology on the surface of aluminum alloy, which is applied in the field of preparation of super-hydrophobic structure on the surface of aluminum alloy, can solve the problems of high cost and difficult industrialization, and achieve good reproducibility, easy industrialization, and simple operation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

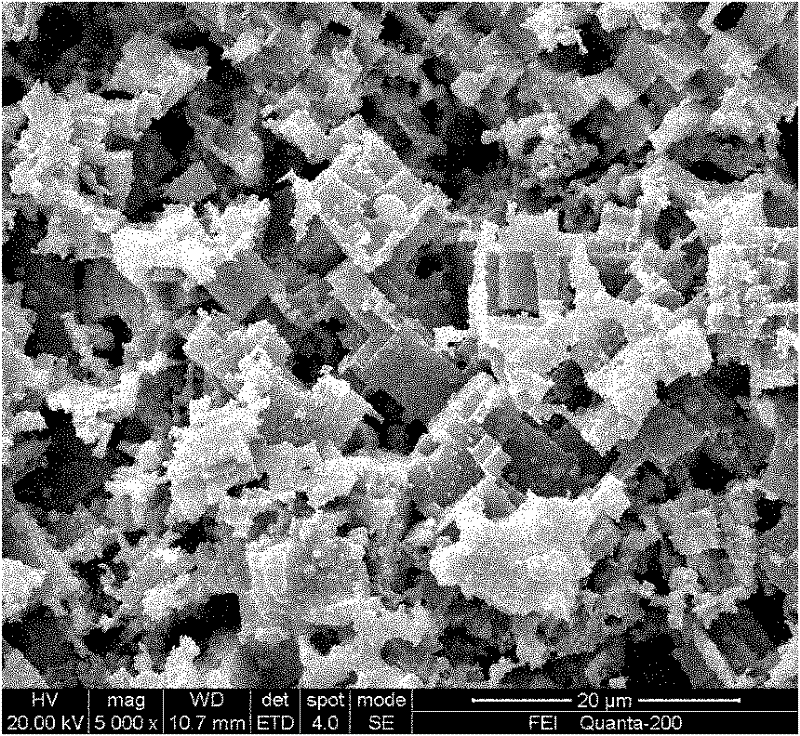

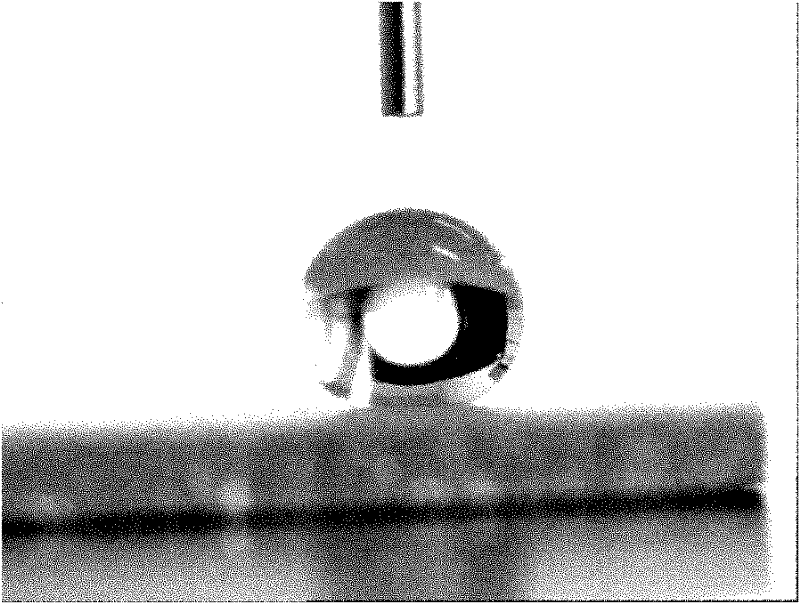

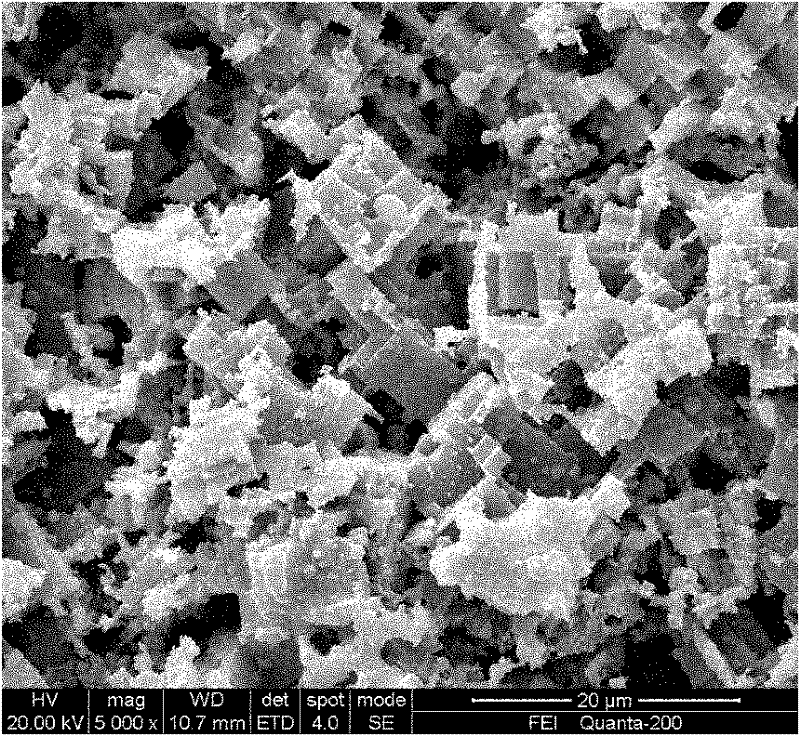

[0018] First, the aluminum alloy plate is mechanically polished and polished to remove surface defects and oxide films, and then cleaned with deionized water. 0.08mol / L oxalic acid solution and 1mol / L hydrochloric acid solution with a mass concentration of 3.7% were mixed in a volume ratio of 1:1 and fully stirred to form a mixed acid solution; then the aluminum alloy plate was immersed in the mixed acid solution for 15 hours, and then Take out the aluminum alloy plate and wash it thoroughly with deionized water, then immerse it in 0.5mol / L potassium permanganate solution for 1 hour, then wash it with deionized water, and dry it in a furnace at 100°C for 1 hour. The aluminum alloy superhydrophobic surface can be prepared by immersing in stearic acid ethanol solution with a mass fraction of 1% for 30 minutes, drying at room temperature and air for 24 hours at a relative humidity of 75%. Test the wettability of the coating surface with OCA20 contact angle tester, see figure 1 a...

Embodiment 2

[0020] First, the aluminum alloy plate is mechanically polished and polished to remove surface defects and oxide films, and then cleaned with deionized water. 0.08mol / L oxalic acid solution and 1mol / L hydrochloric acid solution with a mass concentration of 3.7% were mixed in a volume ratio of 1:1 and fully stirred to form a mixed acid solution; then the aluminum alloy plate was immersed in the mixed acid solution for 12 hours, and then Take out the aluminum alloy sheet and wash it thoroughly with deionized water, then immerse it in 0.5mol / L potassium permanganate solution for 2 hours, then wash it with deionized water, and dry it in a furnace at 80°C for 1.5 hours. The aluminum alloy superhydrophobic surface can be prepared by immersing in stearic acid ethanol solution with a mass fraction of 1% for 25 minutes, drying at room temperature and atmospheric environment at a relative humidity of 60% for 20 hours.

Embodiment 3

[0022] First, the aluminum alloy plate is mechanically polished and polished to remove surface defects and oxide films, and then cleaned with deionized water. 0.08mol / L oxalic acid solution and 1mol / L hydrochloric acid solution with a mass concentration of 3.7% were mixed in a volume ratio of 1:1 and fully stirred to form a mixed acid solution; then the aluminum alloy plate was immersed in the mixed acid solution for 14 hours, and then Take out the aluminum alloy sheet and wash it thoroughly with deionized water, then soak it in 0.5mol / L potassium permanganate solution for 1.5 hours, then wash it with deionized water, and dry it in a furnace at 100°C for 0.5 hours. The aluminum alloy superhydrophobic surface can be prepared by immersing in stearic acid ethanol solution with a mass fraction of 1% for 28 minutes, drying at room temperature and atmospheric environment at a relative humidity of 70% for 22 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com