Preparation method of porous super hydrophobic polypropylene film

A polypropylene film, super-hydrophobic technology, applied in the field of organic polymer polymer materials and their preparation, to achieve the effects of easy industrialization, good reproducibility, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

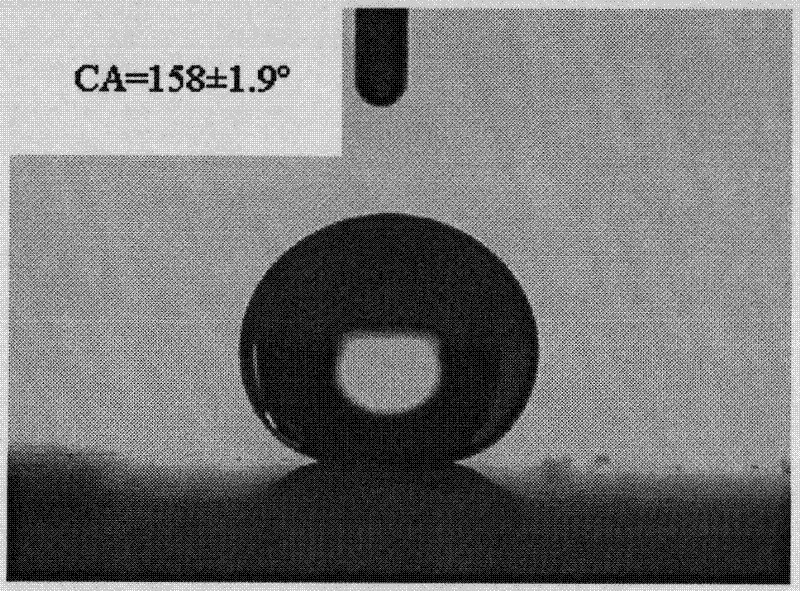

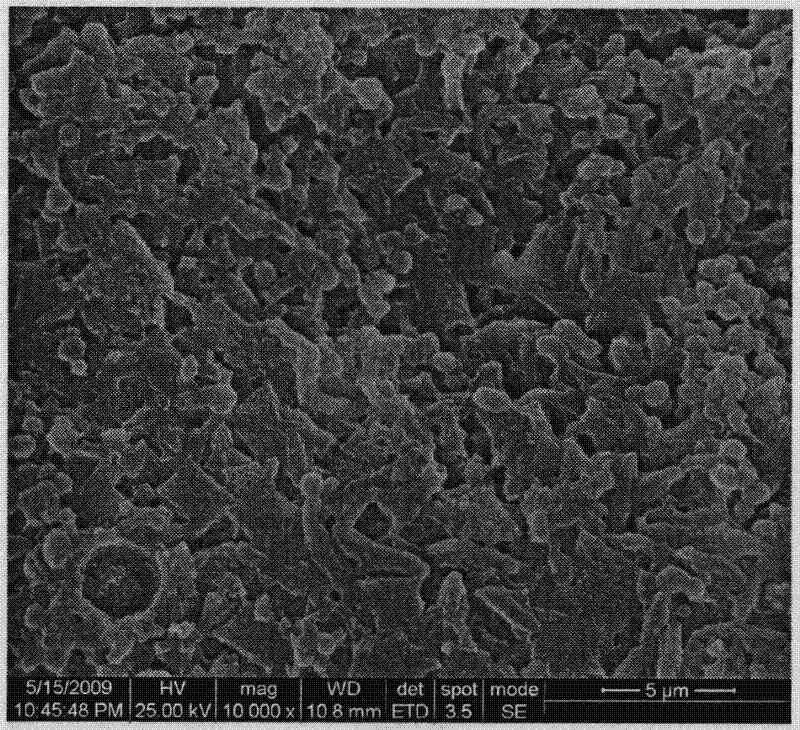

[0023] A porous super-hydrophobic polypropylene film of the present invention, the pore size distribution range of the surface of the porous super-hydrophobic polypropylene film is 100nm to 10 μm, the average pore size is 1 μm, and the contact angle between the surface of the porous super-hydrophobic polypropylene film and water is 158° ±1.9°, the rolling angle of water droplets on the surface of the porous superhydrophobic polypropylene film is 3°, and the thickness of the porous superhydrophobic polypropylene film is 0.2mm.

[0024] The above-mentioned porous superhydrophobic polypropylene film of this embodiment is prepared by the following steps: first, weigh 500g of polypropylene particles and 100g of polystyrene particles, and then weigh the polypropylene particles and polystyrene particles in the Mix the materials uniformly at 180°C for 30 minutes in the mixer, and then make the uniformly mixed mixture on the calender at 200°C to make a film semi-finished product with a ...

Embodiment 2

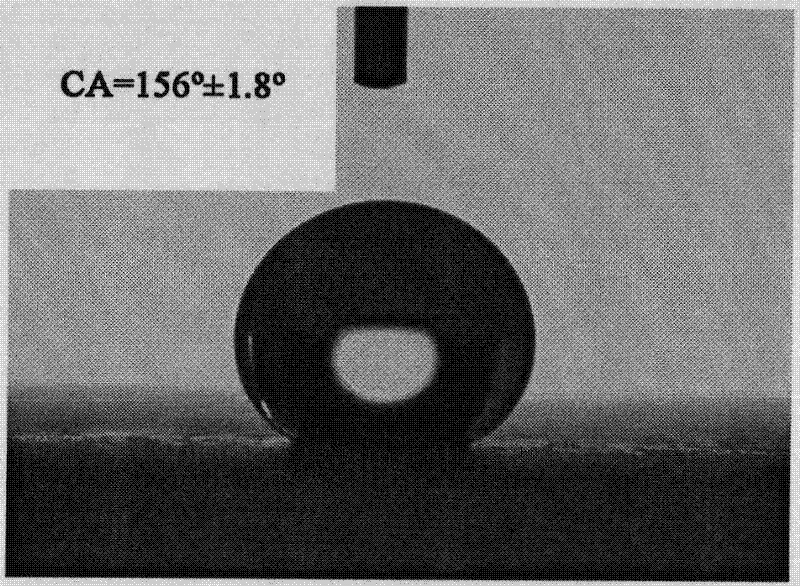

[0026] A porous super-hydrophobic polypropylene film of the present invention, the pore size distribution range of the surface of the porous super-hydrophobic polypropylene film is 100nm to 10 μm, the average pore size is 800nm, and the contact angle between the surface of the porous super-hydrophobic polypropylene film and water is 156° ±1.8°, the rolling angle of water droplets on the surface of the porous superhydrophobic polypropylene film is 5°, and the thickness of the porous superhydrophobic polypropylene film is 0.3mm.

[0027] The porous superhydrophobic polypropylene film of the above-mentioned present embodiment is prepared by the following steps: first, weigh 8 kg of polypropylene particles and 1 kg of polystyrene particles, and then weigh the polypropylene particles and polystyrene particles in the Mix the materials uniformly at 200°C for 60 minutes in the mixer, and then use the extruder at 200°C to make the uniformly mixed mixture into a film with a thickness of ...

Embodiment 3

[0029] A porous superhydrophobic polypropylene film of the present invention, the pore size distribution range of the surface of the porous superhydrophobic polypropylene film is 500nm to 5 μm, the average pore diameter is 1 μm, and the contact angle between the surface of the porous superhydrophobic polypropylene film and water is 159° ±1.6°, the rolling angle of water droplets on the surface of the porous superhydrophobic polypropylene film is 3°, and the thickness of the porous superhydrophobic polypropylene film is 0.01mm.

[0030] The above-mentioned porous superhydrophobic polypropylene film of this embodiment is prepared by the following steps: first, weigh 1.5kg of polypropylene particles and 200g of polystyrene particles, and then weigh the polypropylene particles and polystyrene particles Mix the materials uniformly in the mixer at 210°C for 60 minutes, and then use the tape casting method at 200°C to make the uniformly mixed mixture into a 0.01mm thick mixture of pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com