Patents

Literature

76results about How to "Comfortable and breathable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dyeing and finishing technology of blended fabric of tenel and cotton

InactiveCN101363158APromote migrationQuality improvementBiochemical fibre treatmentSingeingPulp and paper industrySurface-active agents

The invention discloses a dyeing and finishing technique of a tencel and cotton blended fabric. Firstly, textiles are treated by two positive and one reverse singeing, desizing and scouring and bleaching treatment, clipless mercerizing by a clipless mercerizing machine, and continuous open width pad dyeing, then loose color of the textiles and surface active agent are removed by washing to carry out easy care treatment, finally softening is carried out by adopting mechanical force. The invention has simple process. The invention greatly increases the strike immigration performance of the textiles and is easily dyed uniformly, thus improving the quality of tencel and cotton fabric and the product levels. The dyed surface fabric has good textural quality which is similar to tencel, soft hand feeling, soft light color, comfortable and breathable wear, easy care, and can be widely applied to shirt fabrics with top quality and home surface fabrics.

Owner:浙江誉华集团湖州印染有限公司

Preparation method of moisture-absorbing, sweat-permeable and anti-crease fabric

ActiveCN101949092AComfortable and breathableImprove wrinkle resistanceDyeing processWoven fabricsFiberColour fastness

The invention relates to a preparation method of a moisture-absorbing, sweat-permeable and anti-crease fabric, which comprises the following steps: weaving combed long stapled cotton and terylen fibers with grooves of a special shape into a base fabric by warp and weft interwaving based on a certain ratio, and enduing the fabric with the soft and air-permeable natural texture and permanent moisture-absorbing, sweat-permeable and anti-crease functions based on the physical structures of the raw materials; and dyeing the base fabric at high pressure and high temperature, carrying out a post-treatment on the fabric with a finishing liquid mixed according to a ratio of a special formula, and chemically finishing to enable the fabric to have high color fastness and feel soft and comfortable while having the moisture-absorbing, sweat-permeable and anti-crease functions. Thus, the invention meets the requirements for the moisture-absorbing, sweat-permeable and anti-crease fabric in the market, especially the requirements for outdoor clothes such as police uniforms, sports wears and the like.

Owner:江苏恒润盛鑫纺织实业有限公司

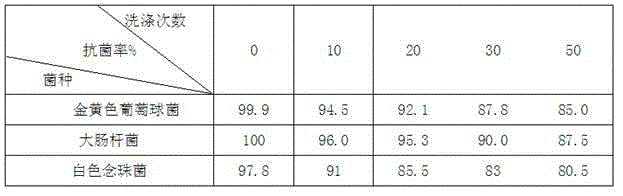

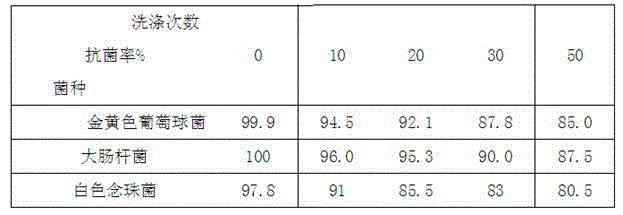

Tea tree oil microcapsule antibacterial healthcare fiber and preparation method thereof

The invention discloses a preparation method of tea tree oil microcapsule antibacterial healthcare fibers. The preparation method comprises the following steps of 1, preparing tea tree oil emulsified dispersion liquid; 2, preparing a mixed dispersion system of core materials and wall materials; 3, enabling the mixed dispersion system of the core materials and the wall materials to be subject to complex coacervation reaction; 4, preparing tea tree oil microcapsule dispersion liquid; 5, preparing tea tree oil microcapsule antibacterial healthcare fiber finishing agent; and 6, preparing antibacterial healthcare fabrics which load tea tree oil microcapsules: using the prepared tea tree oil microcapsule antibacterial healthcare fiber finishing agent for the pretreatment or post-treatment of the fabrics to obtain the antibacterial healthcare fabrics which load the tea tree oil microcapsules. The invention additionally discloses a tea tree oil microcapsule antibacterial healthcare fiber which is prepared by adopting the method. By adopting the preparation method, not only can the component of tea tree oil be stabilized, can the release of the tea tree oil be controlled and can the efficacy period of the tea tree oil be prolonged, but also convenient and comfortable treatment and healthcare functions are realized by taking the fabrics as media. The fiber disclosed by the invention additionally has antibacterial, healthcare, comfortable and ventilation functions.

Owner:JIANGSU YDTEX GRP LTD

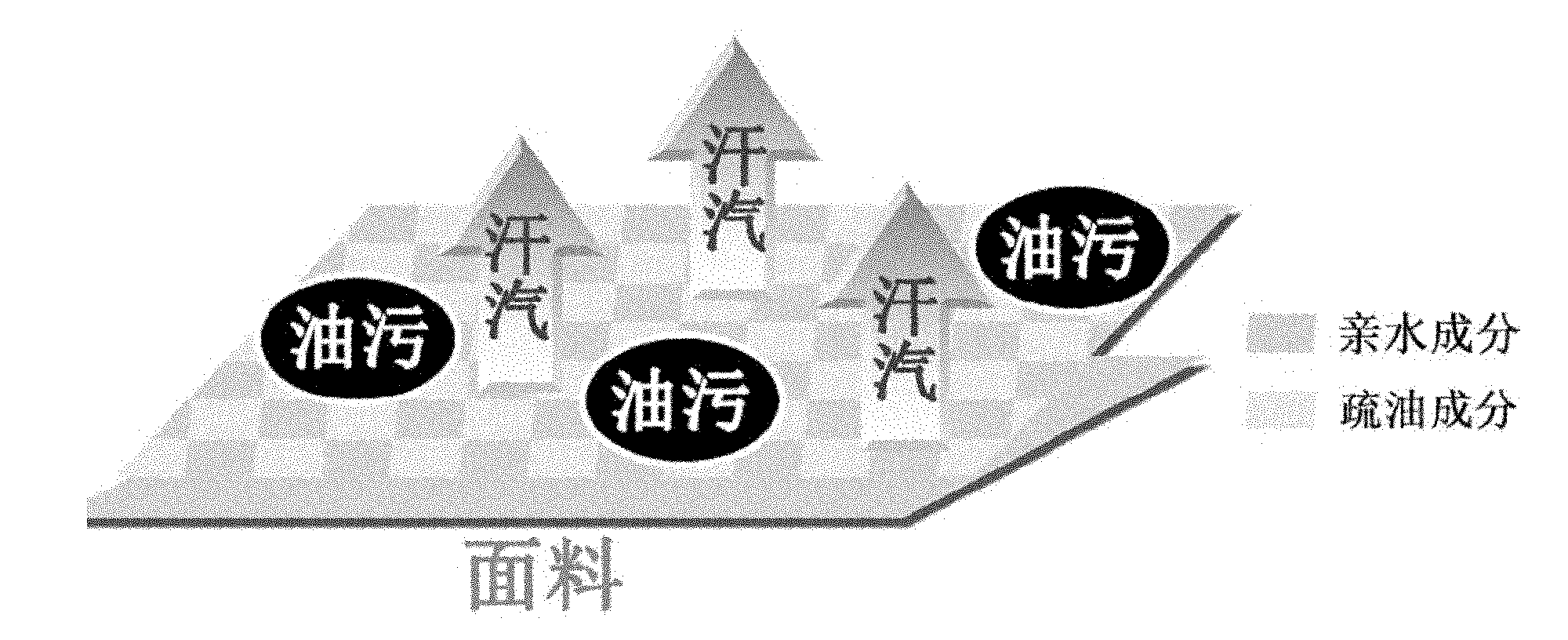

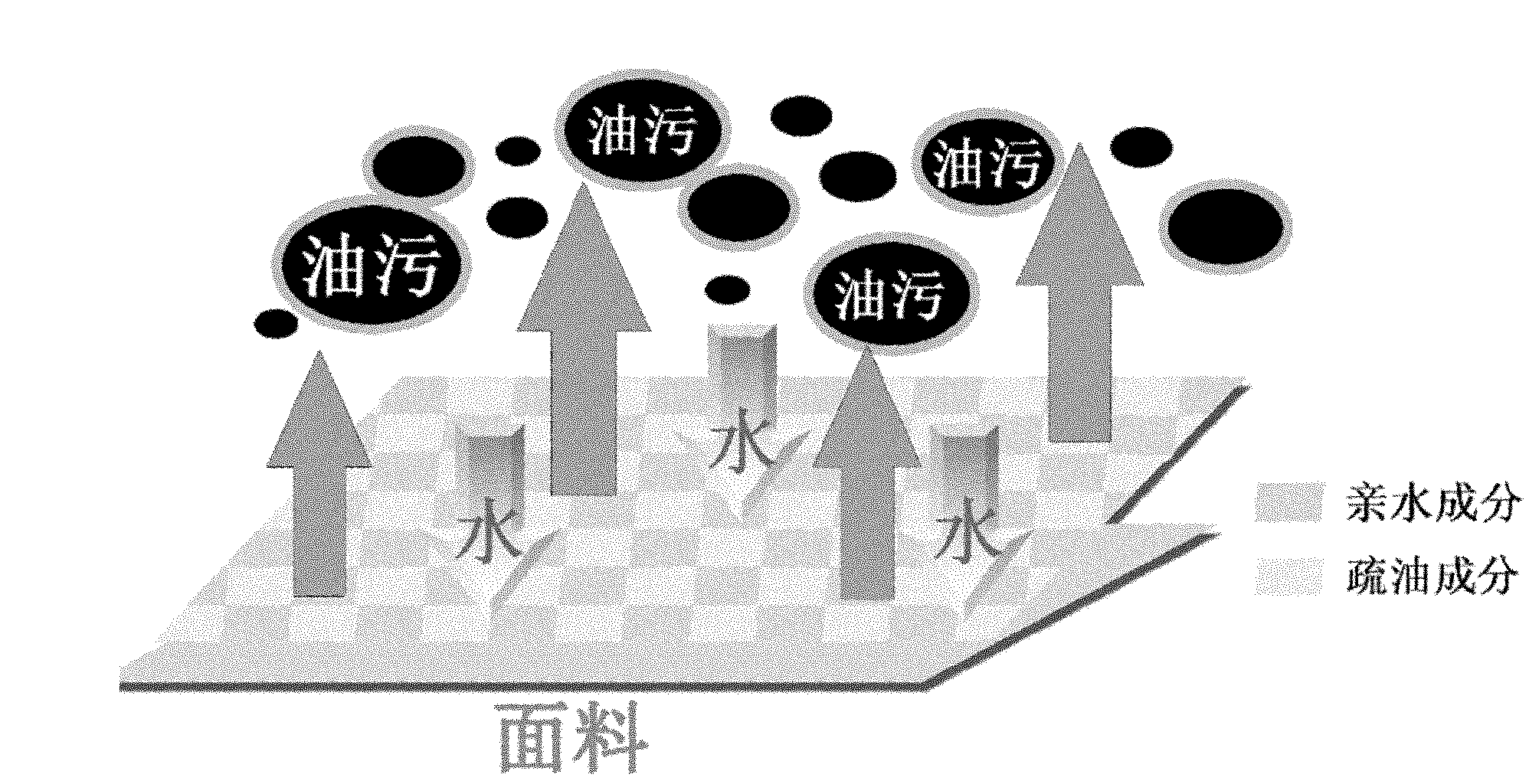

Finishing method of fiber product free of cleaning by detergent

InactiveCN102041685AImprove wettabilityReduce interfacial energyBiochemical fibre treatmentSingeingFiberPre treatment

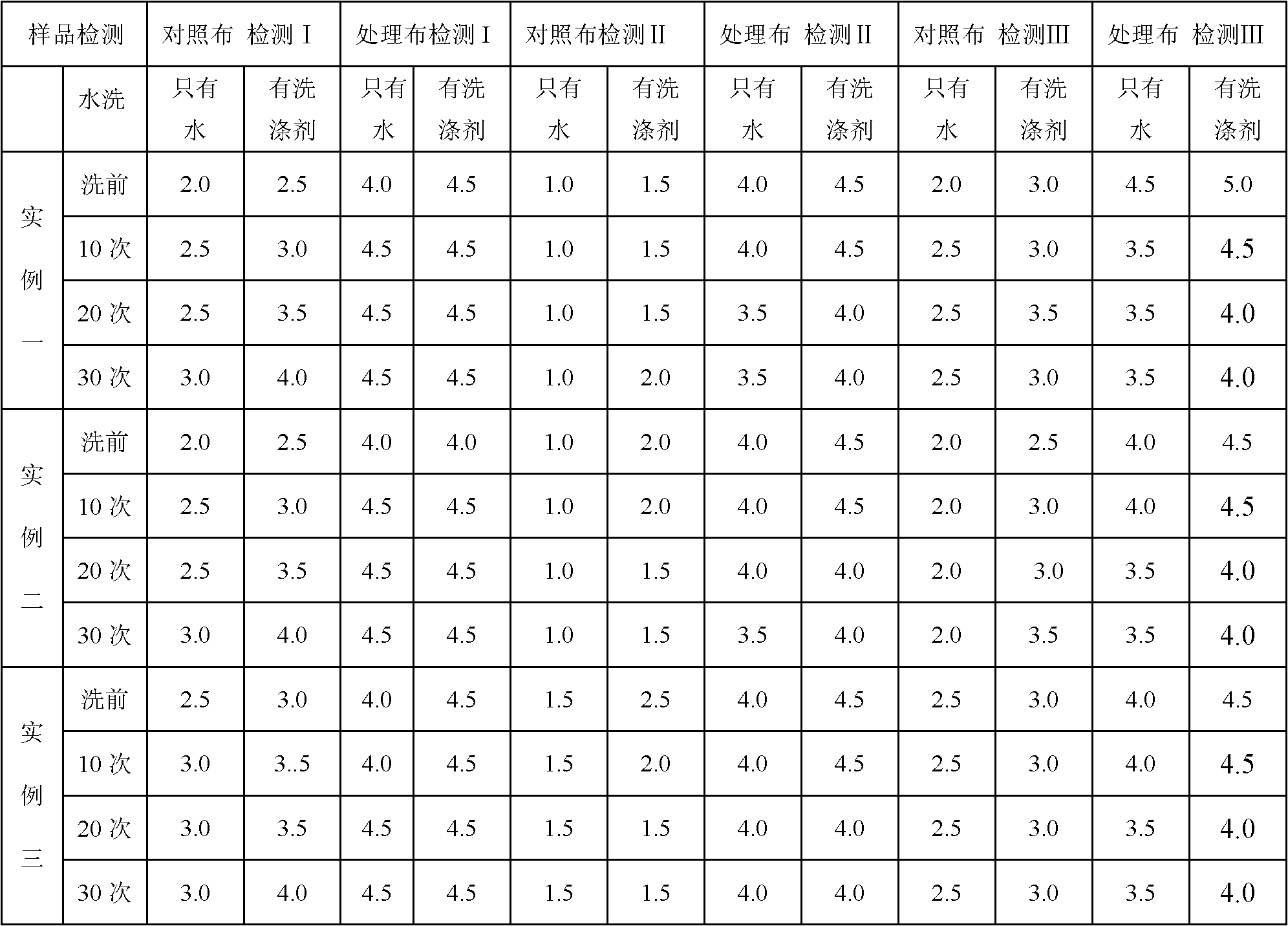

The invention provides a finishing method of a fiber product free of cleaning by a detergent. The technical process comprises singeing, desizing, mercerizing, tentering and preshrinking. The finishing method is characterized in that enzyme piling is added between the singeing and the desizing; a high-efficiency desizing technique is adopted in desizing; liquid ammonia finish and pretreatment are added between the mercerizing and tentering; baking finish is added between the tentering and preshrinking so as to lead the whole technical process to be singeing, enzyme piling, desizing, mercerizing, liquid ammonia finish, pretreatment, tentering, baking and preshrinking. Textiles manufactured by adopting the technique is not cleaned by using the detergent for cleaning, has basically the same cleaning effect with that of cleaning during which the detergent is added, also can not generate secondary dirt in cleaning; and simultaneously, the textile manufactured by using the method has the functions of fouling resistance and easy decontamination, proper oil-proof function, excellent multiple functions of water absorption, air permeability, washing resistance and electrostatic resistance, meets the requirements of people and belongs to an ideal high-grade textile which is energy-saving, environment-friendly and low-carbon.

Owner:LUTAI TEXTILE

Production process of cotton leno yarn dyed fabric

The invention discloses a production process of a cotton leno yarn-dyed fabric with good comfort and air permeability, soft feeling, and excellent water absorbability and wet permeability. The production process comprises the following steps: cotton yarn bleaching - dyeing - warping - sizing - weaving - grey cloth reconditioning - singeing -desizing - mercerizing - forming -pre-shrinking. The production process is characterized in that: in the weaving process: (1) pressurization and letoff are performed on a hollow part by a small shaft; (2) a doup release device is adopted to ensure the tension of the small shaft part to be the same as that of the upper yarn and the lower yarn of ground weave when doup warps fully open, and the warp end release amount is controlled at 2.5-3cm; (3) doup yarns are 0.5-1.0cm higher than ground harnesses at heald level time; and (4) a wefting mode is a large wefting travel mode with the inserting angle being 60-65 degrees and withdrawing angle being 310-315 degrees. In the singeing process, the direction of burner flame is changed into tangential singeing; and a mid-high alkali concentration singeing method and a three-step expanding adjustment method are adopted in the mercerizing and forming processes.

Owner:张家港市金陵纺织有限公司

Tencel nylon iridescent fabric and processing method thereof

The invention discloses a tencel nylon iridescent fabric and a processing method thereof, wherein the iridescent fabric is prepared by adopting A-100 type tencel fibers with the specification of 1.4 dtex*38mm to spin a yarn of 14.8 tex and then stranding the yarn of 14.8tex with a 30D single trilobal nylon long yarn. The product adopts 2 / 1 twill-weave, and has two warp yarns, one is of LY14.8 tex, and the other one is of 81 / 19 (LY14.8 tex + N30D). A manufacturing method adopts a unique process. The invention has the advantages that: the fabric belongs to polynary blend fabric and is novel and unique; the flash effect is gleaming; the excellent properties of the tencel and the nylon are integrated to make the fabric have exquisite quality, soft handfeel, and comfortable and breathable wearing; the fabric is a high-grade apparel fabric; and the processing method for the fabric adopts a special technique in processes of spinning, warping, sizing, healding, weaving and the like, thereby guaranteeing the quality of products, and obviously improving the quality and grade of products.

Owner:TIANJIN TIANFANG INVESTMENT HLDG

Multifunctional inherent-flame-retardant viscose blended yarn, fabric and yarn preparation method

InactiveCN105483890ALow fabric costCost-effectiveWoven fabricsYarnTemperature resistanceElectric arc

The invention provides multifunctional inherent-flame-retardant viscose blended yarn, fabric and a yarn preparation method. The viscose blended yarn comprises 50wt%-80wt% of flame-retardant viscose fibers, 20wt%-50wt% of aromatic polyamide fibers and 0-5wt% of antistatic fibers. The multifunctional inherent-flame-retardant viscose blended yarn has the multiple advantages of electric arc resistance, high temperature resistance, heat insulation, comfort, breathability and the like; the fabric is low in cost, high in cost performance and excellent in protective performance and has the performance of high fiber strength, tearing resistance, excellent wear resistance, good flame retardance, high-temperature resistance, heat insulation and the like. Therefore, the industrial enlarged production requirement is sufficiently met, and personal safety of a worker can be sufficiently guaranteed.

Owner:CHANGSHU BAOFENG SPECIAL FIBER

Preparation method of anti-electrostatic fabric

InactiveCN107460726ASoft touchHigh strengthDry-cleaning apparatus for textilesWoven fabricsEngineeringAramid

The invention provides a preparation method of anti-electrostatic fabric and relates to the technical field of textile materials. The preparation method of the anti-electrostatic fabric comprises the following steps: preparing raw materials: S1, preparing electroconductive aramid fiber and selecting high-strength polyester fiber and cotton fiber; S2, weaving fabric: weaving the fabric by a plane weave structure of warp yarns and weft yarns, wherein the warp yarns adopt electroconductive fibers and high-strength polyester filament yarns which are arranged according to the ratio of 1:4, and the weft yarns adopt mixed weft yarns comprising electroconductive fibers and the cotton fibers according to the ratio of 1:1; S3, performing decontamination treatment: preparing decontamination liquid, soaking the fabric obtained in the step S2 into the decontamination liquid, dipping at 30 to 35 DEG C for 20 to 25 minutes and then washing with water; S4, performing anti-electrostatic treatment: preparing anti-electrostatic treatment liquid, soaking the fabric washed with water in the step S3 into the anti-electrostatic treatment liquid, dipping for twice and rolling for twice, wherein the rolling allowance is 80 percent; and drying and shaping: drying the fabric subjected to anti-electrostatic treatment in the step S4 into a drying box, and performing tenter setting after drying to obtain the anti-electrostatic fabric. The fabric prepared by the invention has high anti-electrostatic performance.

Owner:丹阳新星服饰有限公司

Chinese herbal medicinal liquid and antibacterial knitted underwear

InactiveCN101612258AStrong antibacterial effectComfortable and breathableAntibacterial agentsHydroxy compound active ingredientsBorneolChinese herbs

The invention discloses a Chinese herbal medicinal liquid and antibacterial knitted underwear. The antibacterial knitted underwear is soaked in the Chinese herbal medicinal liquid. The Chinese herbal medicinal liquid comprises the following components in percentage by weight: 20 to 25 percent of daphne odora, 10 to 15 percent of common cnidium fruits, 12 to 16 percent of sophora flavescens, 16 to 20 percent of phellodendron, 12 to 16 percent of gentiana, 16 to 20 percent of mint, and 11 to 15 percent of borneol. A method for making the antibacterial knitted underwear comprises the following steps: (1) soaking the underwear in water between 60 and 70 DEG C for 25 to 35 minutes and rinsing 2 to 3 times for 5 to 10 minutes each time; (2) soaking the underwear in the Chinese herbal medicinal liquid for 10 to 15 minutes at a temperature between 110 and 130 DEG C; (3) performing bundle-drying and drying the underwear at 150 DEG C; (4) soaking the underwear in the Chinese herbal medicinal liquid for 5 to 10 minutes at a temperature between 100 and 110 DEG C; and (5) performing bundle-drying and drying the underwear at 120 DEG C. The underwear has strong antibacterial effect and is comfortable to wear.

Owner:黄叶清

Mulcel fiber/far-infrared fiber high-grade knitted fabric

The invention relates to mulcel fiber / far-infrared fiber high-grade knitted fabric, belonging to the technical field of spinning. The fabric is woven by yarn constituted by mulcel fiber and far-infrared fiber, the yarn is mulcel fiber and far-infrared fiber blended yarn, the mulcel fiber and far-infrared fiber blended yarn is mulcel fiber and far-infrared viscose fiber blended yarn, the fabric is woven by yarn formed by dyeing gray yarn and then merging into the three-strand yarn, and the specification of the mulcel fiber and far-infrared fiber blended yarn is 32s / 3; and the blending ratio is as follow: the mulcel fiber accounts for 70%, and the far-infrared viscose fiber accounts for 30%. The fabric disclosed by the invention has good heat insulation property, anti-pilling property, comfort and softness, and can fully reflect salient moisture absorption gas permeability and natural antibacterial, anti-mite, anti-odor, anti-moth, anti-ultraviolet, antistatic and other performances; and the far-infrared fiber is natural, environment-friendly, bright in dyed color and unique in keeping warm, and can realize health care, improves blood micro-circulation and the like.

Owner:浙江森创服装股份有限公司

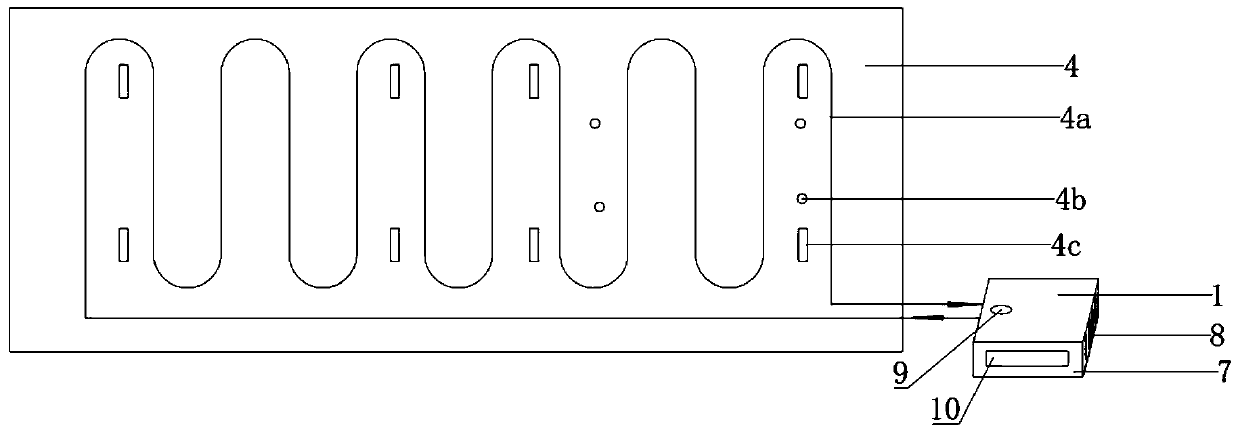

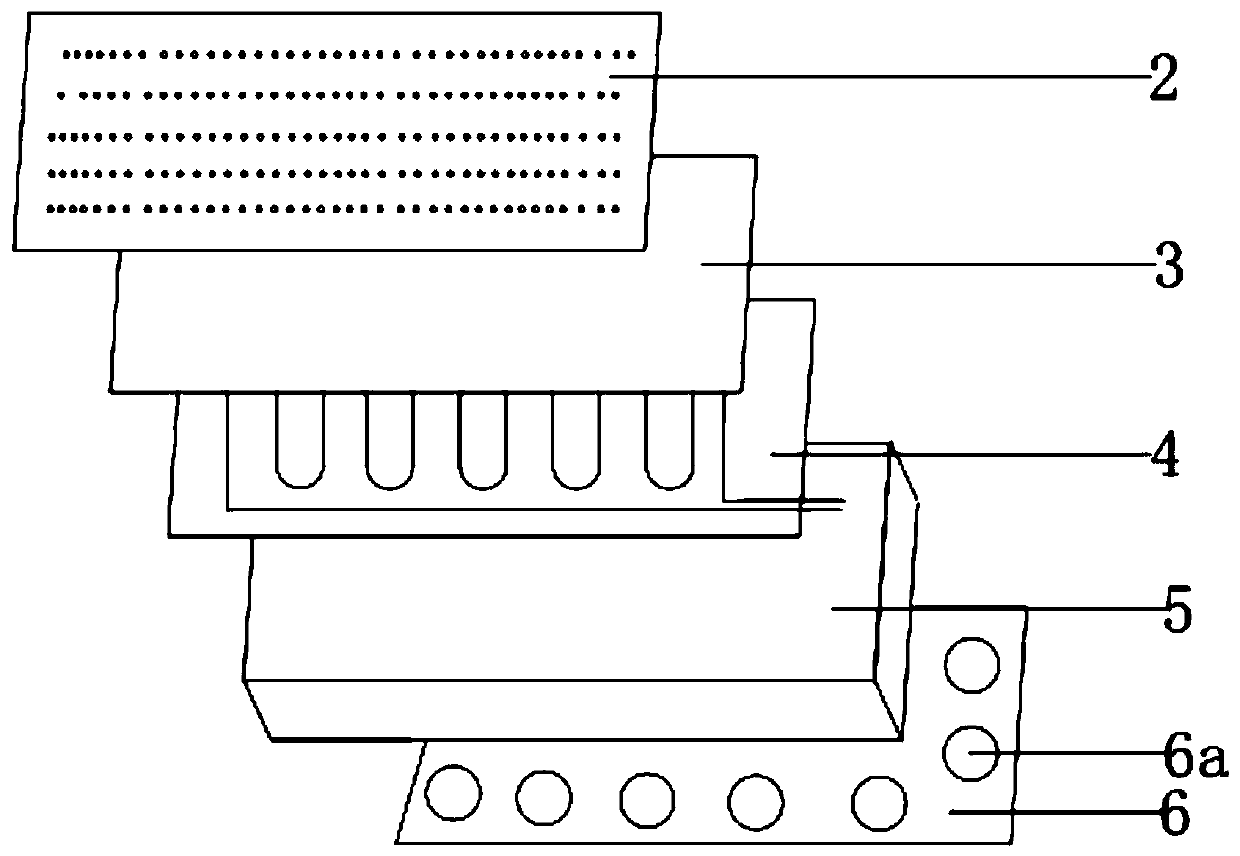

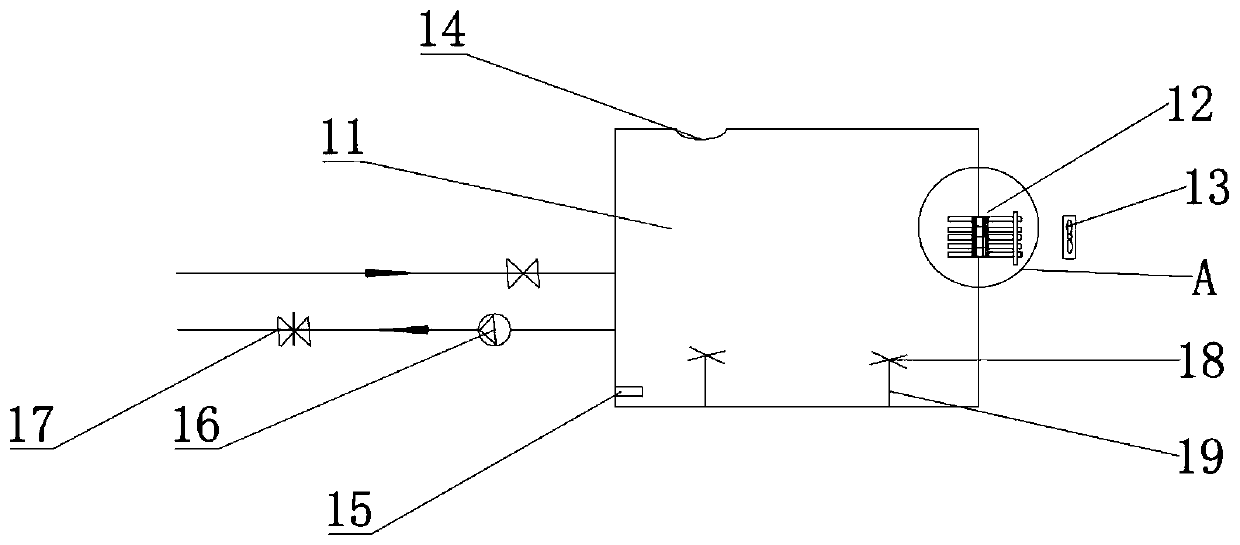

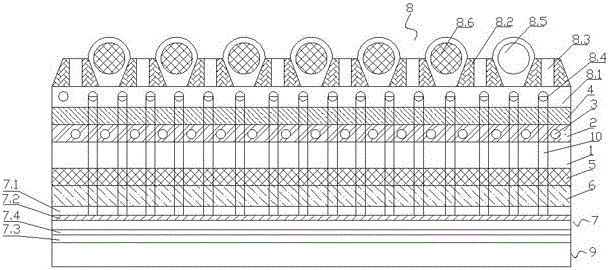

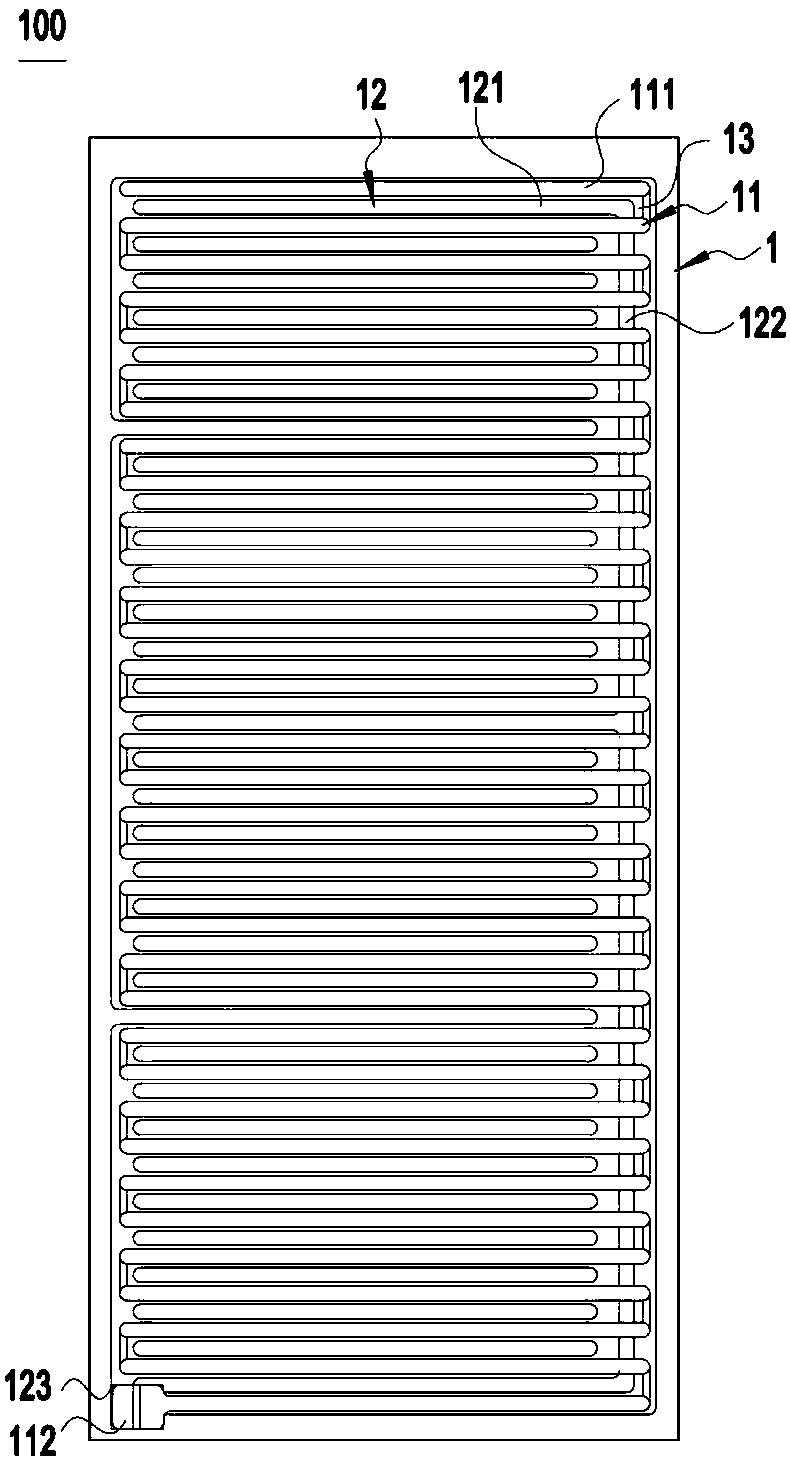

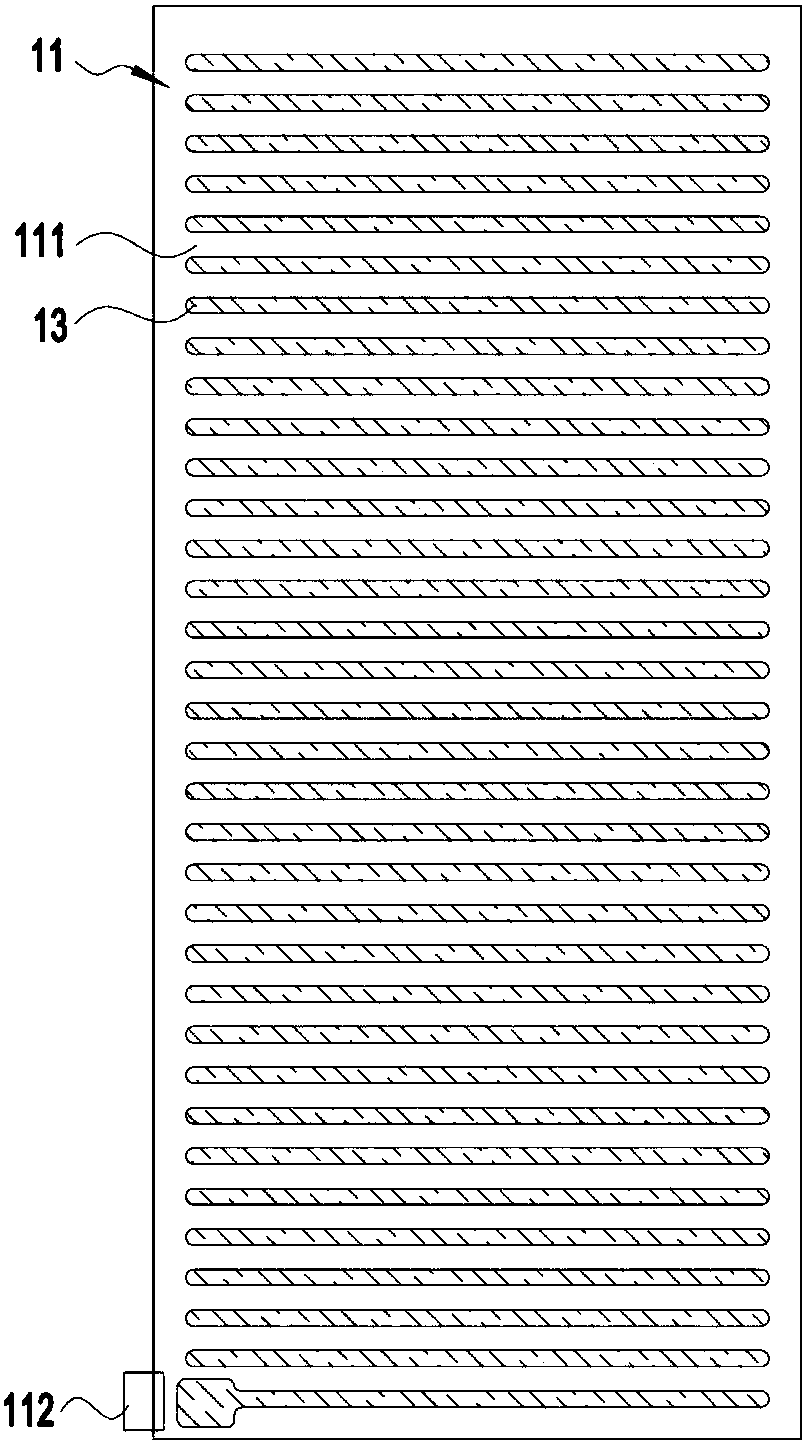

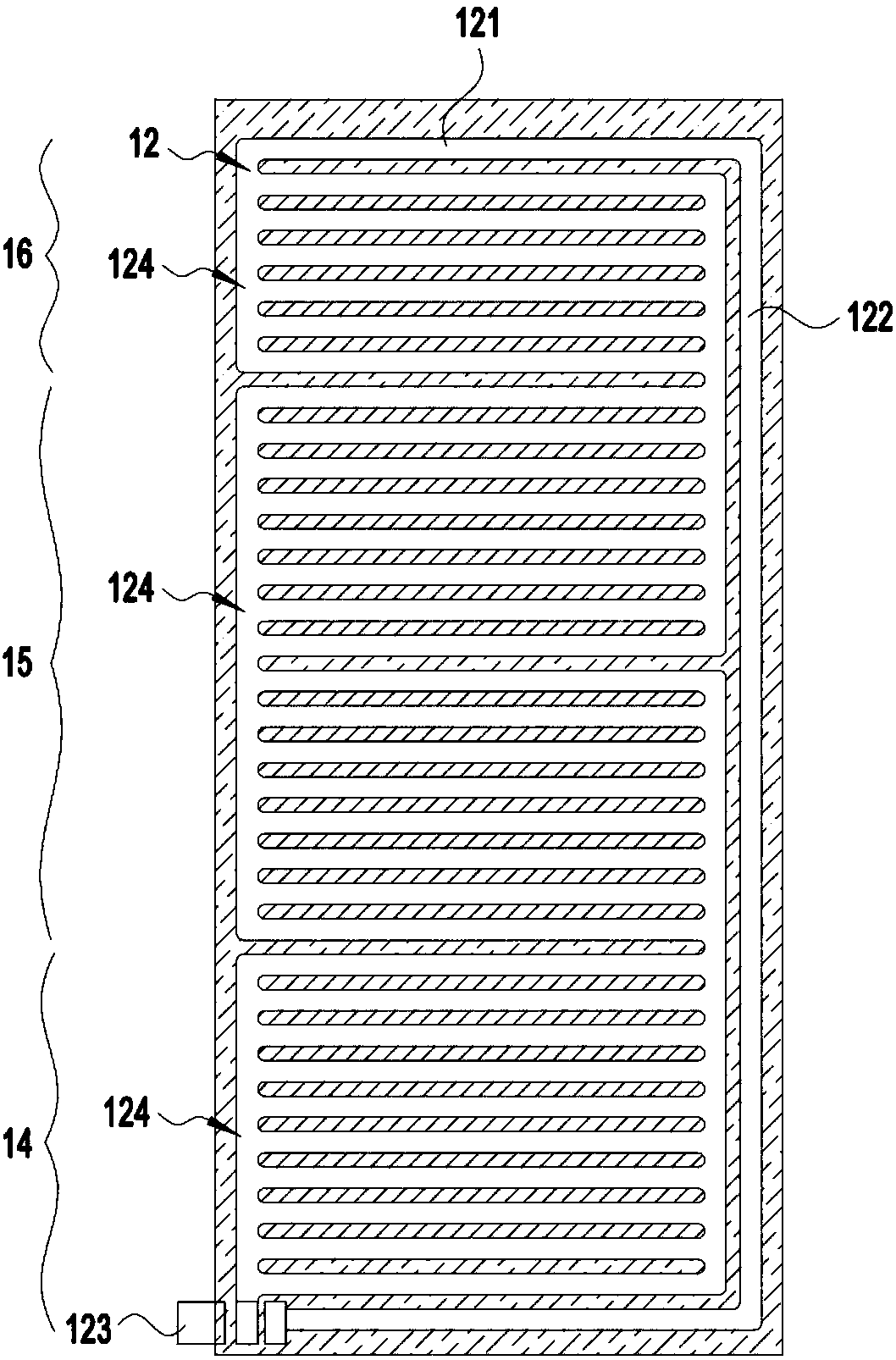

Intelligent temperature-control mattress

InactiveCN109907583ARefrigeration is difficultMeet warmingStuffed mattressesPhysical therapyTemperature controlLiquid-crystal display

The invention discloses an intelligent temperature-control mattress. The intelligent temperature-control mattress comprises a mattress body and a main engine, wherein the mattress body is provided with a ventilation layer, a lining layer, a temperature control layer, a filling layer and an anti-slip layer in sequence from top to bottom; a water circulation pipe is laid in the temperature control layer; the temperature control layer is provided with a sleep monitor and a first temperature sensor; the main engine comprises a water tank assembly, a control panel, a heat dissipation opening, a water feeding opening and a liquid crystal display screen arranged on the control panel; the water tank assembly comprises a water tank, a semiconductor cooler, a fan, a water feeding opening of a watertank, a second temperature sensor, a water pump, a self-operated electric control temperature adjusting valve and a stirring part. The intelligent temperature-control mattress disclosed by the invention has the advantages that the semiconductor cooler can meet the requirements of heating and cooling the mattress at the same time, and is simple in structure and good in safety.

Owner:深圳市弘楚源科技发展有限公司

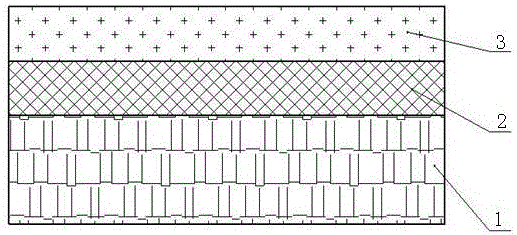

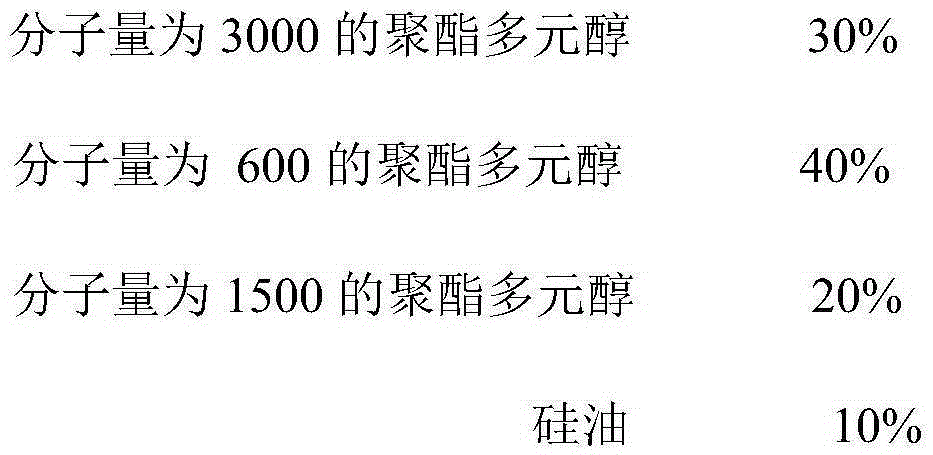

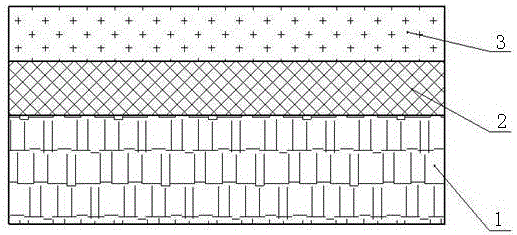

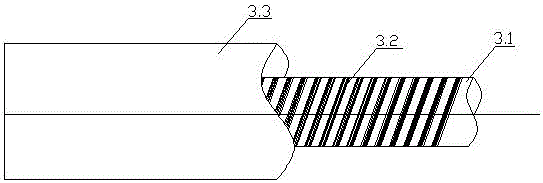

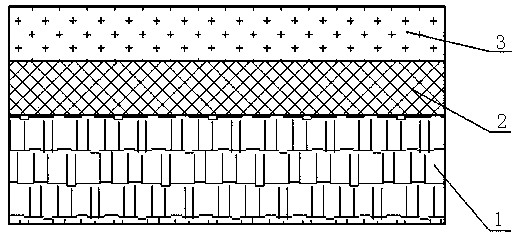

Waterproof fabric capable of reducing outward dissipation of heat

InactiveCN106240074AImprove waterproof performanceComfortable and breathableSynthetic resin layered productsClothingsThermoplastic polyurethaneMoisture absorption

The invention relates to a waterproof fabric capable of reducing outward dissipation of heat. The waterproof fabric comprises a base layer (1). An anti-microbial layer (2) and a waterproof layer (3) are sequentially arranged on the surface of the base layer (1). The anti-microbial layer (2) is made of bamboo fiber. The waterproof layer (3) is a TPU (Thermoplastic Polyurethane Elastomer) coating. A lining fabric layer is arranged on the back face of the base layer, and is at least provided with a temperature-adjusting fabric layer and a heat resistant layer; the material of the temperature-adjusting fabric layer has the characteristics of moisture absorption and heat generation; a difference value of moisture regain of the fabric at the relative humidity of 90 percent and 40 percent is ranged from 1 percent to 8 percent; the heat resistant layer is adjacent to the surface of the outer side of the temperature-adjusting fabric layer. The waterproof fabric provided by the invention is breathable, comfortable, waterproof and anti-microbial, and is capable of reducing outward dissipation of the heat.

Owner:JIANGSU HAIPENG SPECIAL VEHICLES

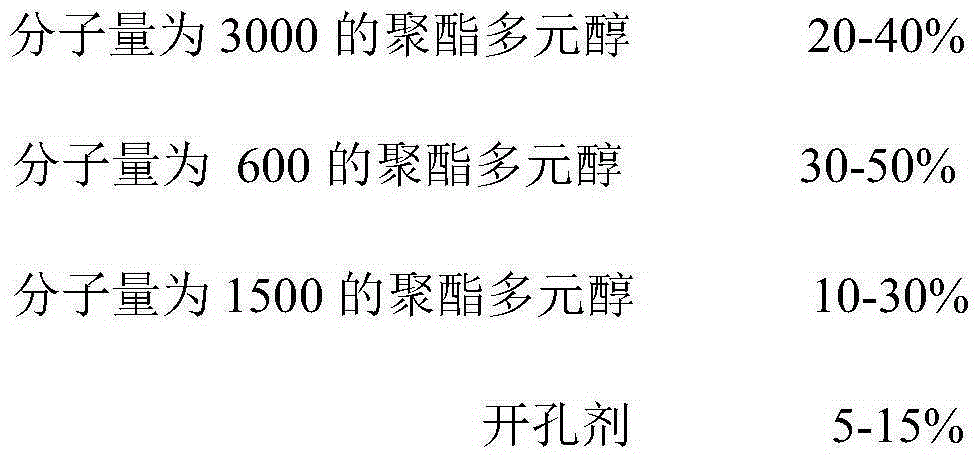

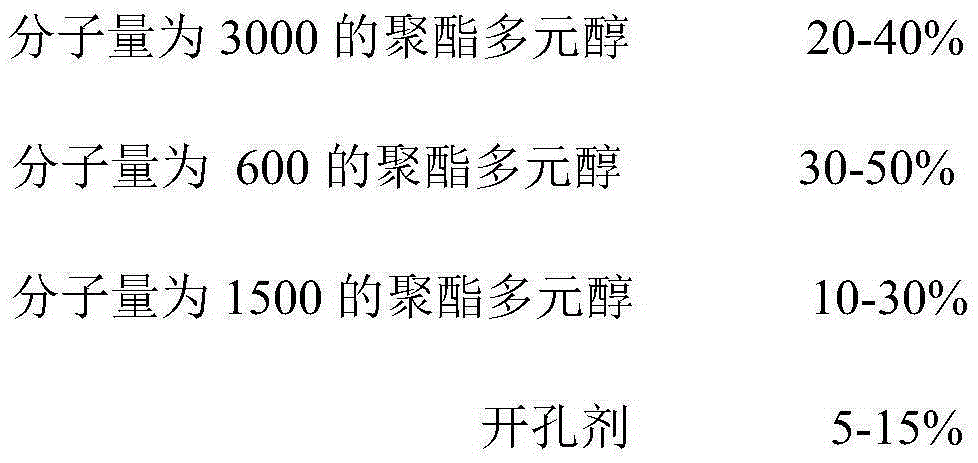

Preparation method for chronic springback resin material used for shoe sole

The invention discloses a preparation method for a chronic springback resin material used for a shoe sole. In the preparation method, the material is prepared from A and B raw materials, the A raw material comprises polyester polyol and an opening agent, the B raw material comprises polyisocyanate, and the reaction mole ratio of the A raw material to the B raw material is 1:1-5. The prepared chronic springback resin material has good tension, damping and ventilating effects, and is suitable for shoe sole products. Good protection is provided for feet of users, and comfortable wearing effects are provided.

Owner:黄瑞琦

Waterproof fabric capable of widening application range of yinmi health fiber

InactiveCN106218007AImprove waterproof performanceComfortable and breathableLayered productsClothingsFiberThermoplastic polyurethane

The invention relates to a waterproof fabric capable of widening the application range of yinmi health fiber. The waterproof fabric comprises a basal layer (1), wherein the surface of the basal layer (1) is sequentially provided with an antimicrobial layer (2) and a waterproof layer (3); the antimicrobial layer (2) is made of bamboo fiber; the waterproof layer (3) is a TPU (thermoplastic polyurethane) coating; the back surface of the basal layer is provided with a lining fabric layer; and the lining fabric layer is a warp knitting fabric, the warp knitting fabric is composed of yarns and filaments, the filaments are wrapped outside the yarns in a helical manner, the yarn comprises a heart yarn, the heart yarn is yinmi health fiber or a composite yarn of yinmi health fiber and other fiber, the other fiber is cotton, twine, wool, terylen, chinlon or spandex, and the filament is terylen or chinlon. According to the invention, the waterproof fabric is air-permeable, comfortable, waterproof and antimicrobial; and the application range of yinmi health fiber is widened.

Owner:JIANGYIN CHENGXIN SPECIAL PRINTING

Manufacturing and dyeing method of breathable fabric

InactiveCN105714423AThere will be no drilling phenomenonGuaranteed appearanceSucessive textile treatmentsCarbon fibresMarine engineeringPigment

The invention relates to the production and dyeing method of air-permeable fabrics. The fabrics are comfortable and breathable, and the fabrics usually do not have the phenomenon of drilling wool, which ensures the overall appearance and does not give people uncomfortable feelings. Through natural plant pigments and special preparation The advanced technology makes the dyeing agent of the fabric non-toxic and harmless and safe and comfortable to use, and there will be no drilling phenomenon, and it is comfortable and breathable to wear.

Owner:JIANGYIN DONGFA GARMENT MAKING

Blended comfort fiber fabric

InactiveCN103799588AImprove wear resistanceIncrease elasticityProtective garmentSpecial outerwear garmentsUltimate tensile strengthWear resistance

The invention discloses a blended comfort fiber fabric which is blended and woven from five fibers of a real silk fiber, an organic lifting wire cotton fiber, a superfine polyamide fiber, a superfine polyester fiber and a high count cotton fiber, wherein the real silk fiber accounts for 33%-36%, the organic lifting wire cotton fiber accounts for 14%-17%, the superfine polyamide fiber accounts for 19%-22%, the superfine polyester fiber accounts for 11%-14%, and the high count cotton fiber accounts for 11%-23% among the five components of the blended comfort fiber fabric according to weight percentages. The blended comfort fiber fabric is blended and woven from five fibers of the real silk fiber, the organic lifting wire cotton fiber, the superfine polyamide fiber, the superfine polyester fiber and the high count cotton fiber, and the woven fabric has the characteristics of softness, good wear resistance, high elastic recovery rate, high strength, fine and smooth hand feel, comfort and air permeability.

Owner:TAICANG SIXIN TEXTILE

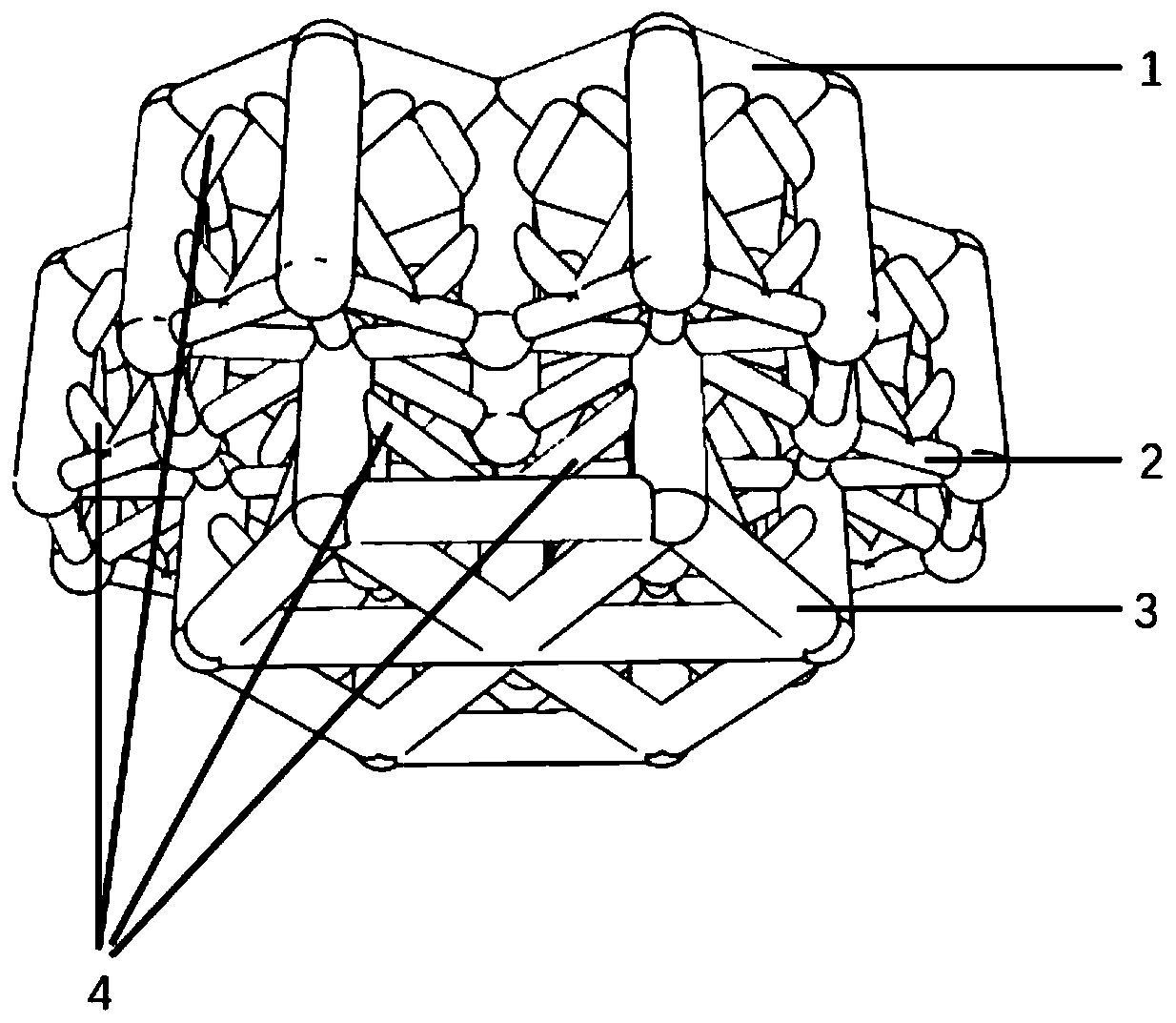

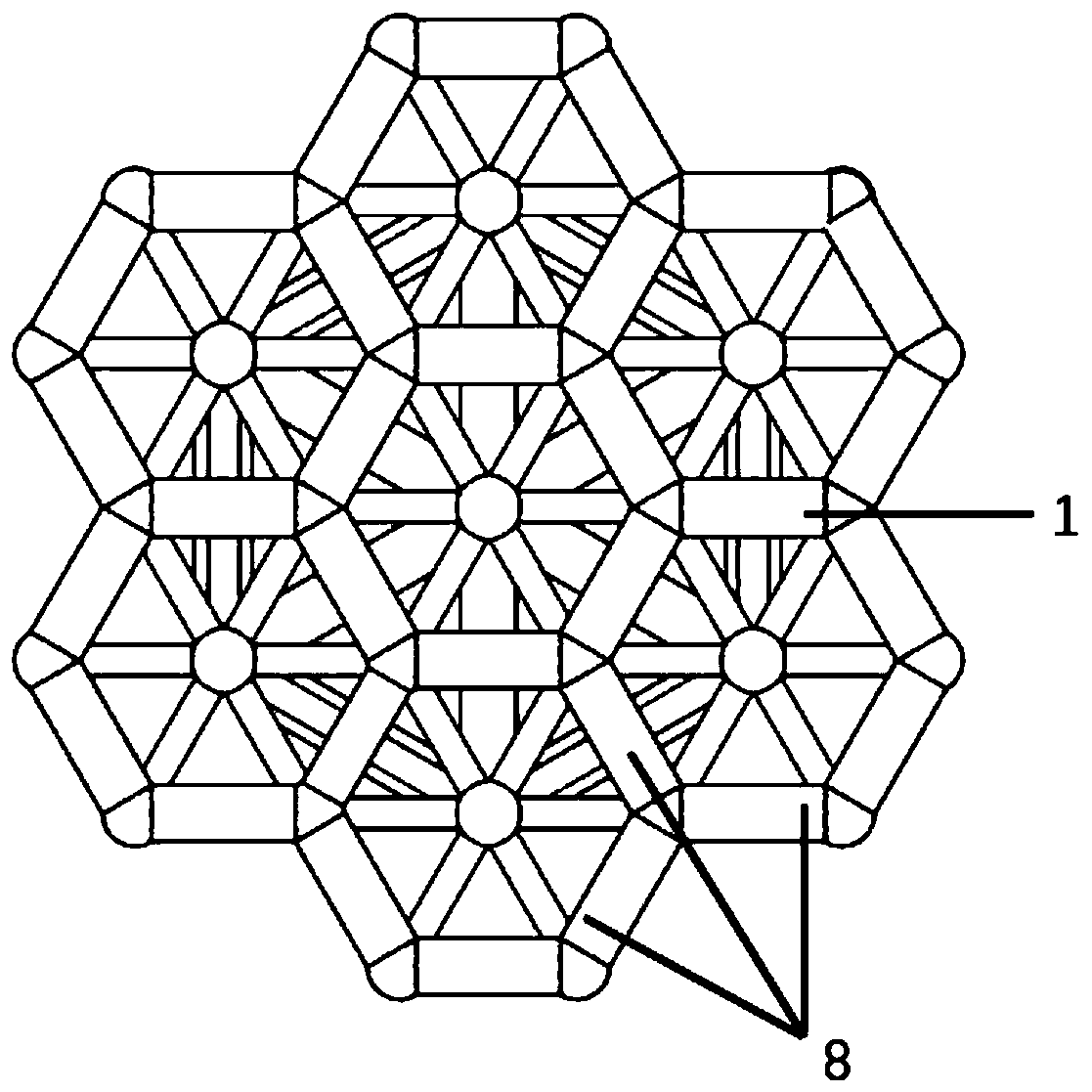

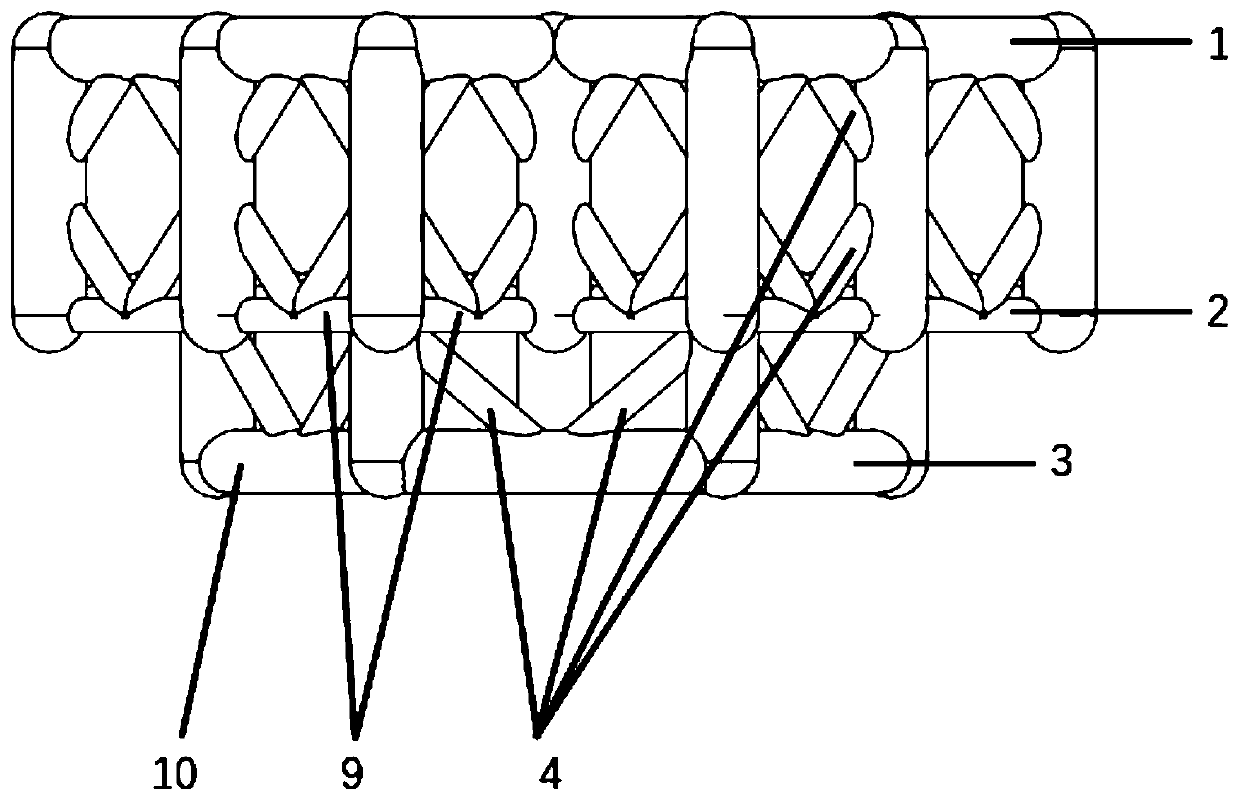

3D printed graded resilience structure and shoe sole using 3D printed graded resilience structure

The invention discloses a 3D printed graded resilience structure and a shoe sole using the 3D printed graded resilience structure. The 3D printed graded resilience structure comprises surface meshes,a plurality of 3D printed graded resilience crystal lattice units, loop edges, bottom meshes and inclined support rods, wherein each graded resilience crystal lattice unit consists of a cushioning component and a cushioning resilience part; each cushioning component forms a plane stress structure by n vertical rods, n inclined pull rods and 4n inclined support rods (n is greater than or equal to 3); and each cushioning resilience part is of a single elastic vertical post structure. Based on the foot sole pressure distribution, a 3D printed secondary rebounding structure is applied to the shoesole; through twice cushioning, impact energy generated through sports doing can be sufficiently absorbed; in addition, strong resilience force can be provided; sportsmen of different sports events and different sports features are supported to complete skills; the sportsmen are protected from sports injury; and in addition, the graded resilience structure also has the functions of comfortable andbreathable performance, customization, light weight and the like.

Owner:NANJING AMEBA ENG STRUCTURE OPTIMIZATION RES INST CO LTD

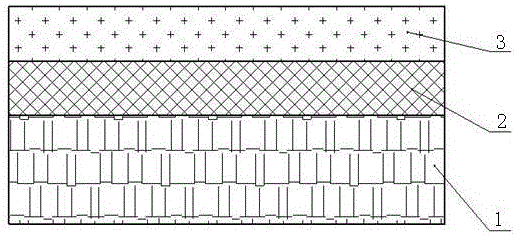

Waterproof fabric having waterproof, oilproof and antifouling functions

InactiveCN106273755AImprove waterproof performanceGood oil resistanceSynthetic resin layered productsClothingsPolyesterFiber

The invention relates to a waterproof fabric having waterproof, oilproof and antifouling functions which comprises a basic layer (1). An antibacterial layer (2) and a waterproof layer (3) are sequentially arranged on the surface of the basic layer (1). The antibacterial layer (2) is made of bamboo fibers. The waterproof layer (3) is a TPU coating. A lining fabric layer is arranged on the back side of thebasic layer and comprises three layers including the outer layer Teflon coating, an interlayer textile fabric and the inner layer Teflon coating, the textile fabric is a waterproof nylon fabric or a polyester fabric, and the thickness of the Teflon coating is 10-13 microns. The waterproof fabric is breathable, comfortable, waterproof and antibacterial and further has waterproof, oilproof and antifouling functions.

Owner:JIANGYIN DONGFA GARMENT MAKING

Waterproof fabric having superiormemorability

The invention relates to a waterproof fabric having superiormemorability. The waterproof fabric comprises a basic layer (1), wherein an anti-bacterial layer (2) and a waterproof layer (3) are sequentially arranged on the surface of the basic layer (1). The anti-bacterial layer (2) is made of bamboo fiber. The waterproof layer (3) is a TPU coating. A lining fabric layer is arranged on the back side of the inner layer and comprises two parallelly distributed mesh hole surface layers and an elastic material layer arranged between the two mesh hole surface layers, and each mesh hole surface layer is distributed with a plurality of through holes. The elastic material layer is composed of more than one of a plurality of groups of vertical linear filiformelastic materials, a plurality of groups of vertical X-shaped cross structures and a plurality of groups of vertical U-shaped elastic loops, wherein each annular elastic loop is formed by crimping a filiformelastic material. The waterproof fabricis breathable, comfortable, waterproof and anti-bacterial and has the superiormemorability.

Owner:JIANGYIN CHUNZHILAN SPECIAL YARN

Anti-bacterial warm-keeping comfortable air-permeable knitted fabric with high color fastness

InactiveCN106240012AThree-dimensionalAntibacterialSynthetic resin layered productsCellulosic plastic layered productsWeft yarnAluminium oxide

The invention relates to an anti-bacterial warm-keeping comfortable air-permeable knitted fabric with the high color fastness. The knitted fabric comprises a knitted fabric body, the upper surface of the knitted fabric body is sequentially provided with an anti-radiation layer, an anti-static layer and a waterproof layer, and the lower surface of the knitted fabric body is sequentially provided with an anti-bacterial layer, a flame-retardant layer, a waterproof layer and a closed-fit layer. The back face of the closed-fit layer is provided with a lining fabric layer, the lining fabric layer comprises a surface layer and a bottom layer which are each formed by warp yarn and weft yarn, the warp yarn of the surface layer is composed of nano-titanium dioxide catalytic anti-bacterial fibers and copper ammonia fibers, the weft yarn of the surface layer is composed of mulberry silk fibers and the copper ammonia fibers, the warp yarn of the bottom layer is composed of aluminum oxide chemical fibers and the mulberry silk fibers, and the weft yarn of the bottom layer is composed of silver fibers and cotton fibers. The knitted fabric has the stereoscopic sensation, has the functions of bacterium resistance, high color fastness, flame retardance, radiation resistance, water resistance, static resistance and the like and has the anti-bacterial, warm-keeping, comfortable and air-permeable effects.

Owner:JIANGYIN TOPWAY TEXTILE

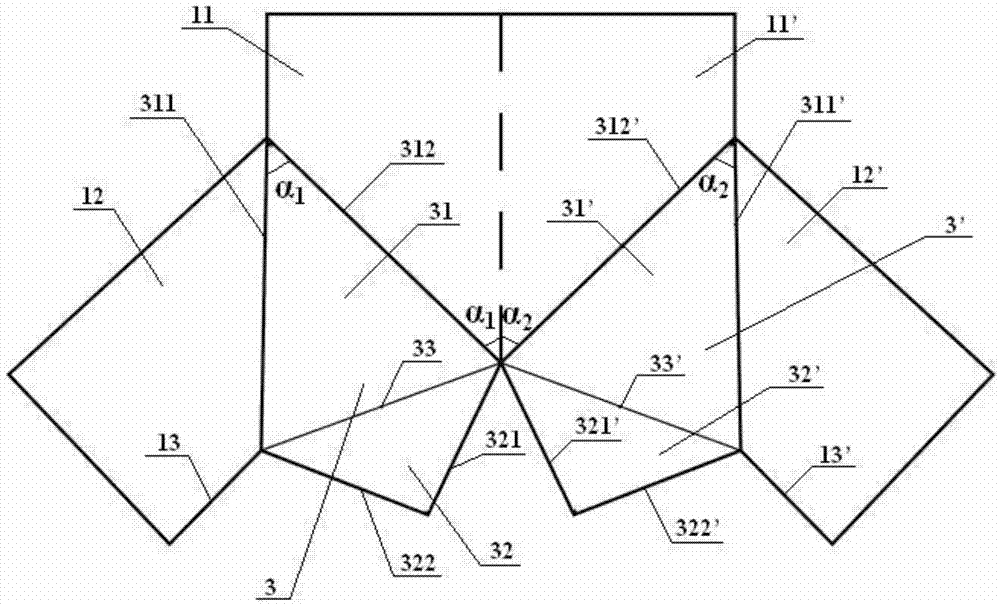

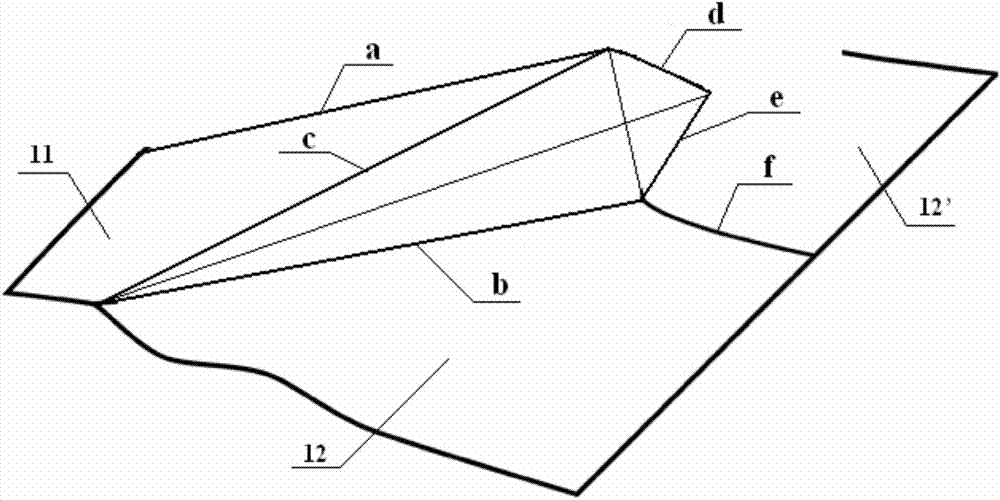

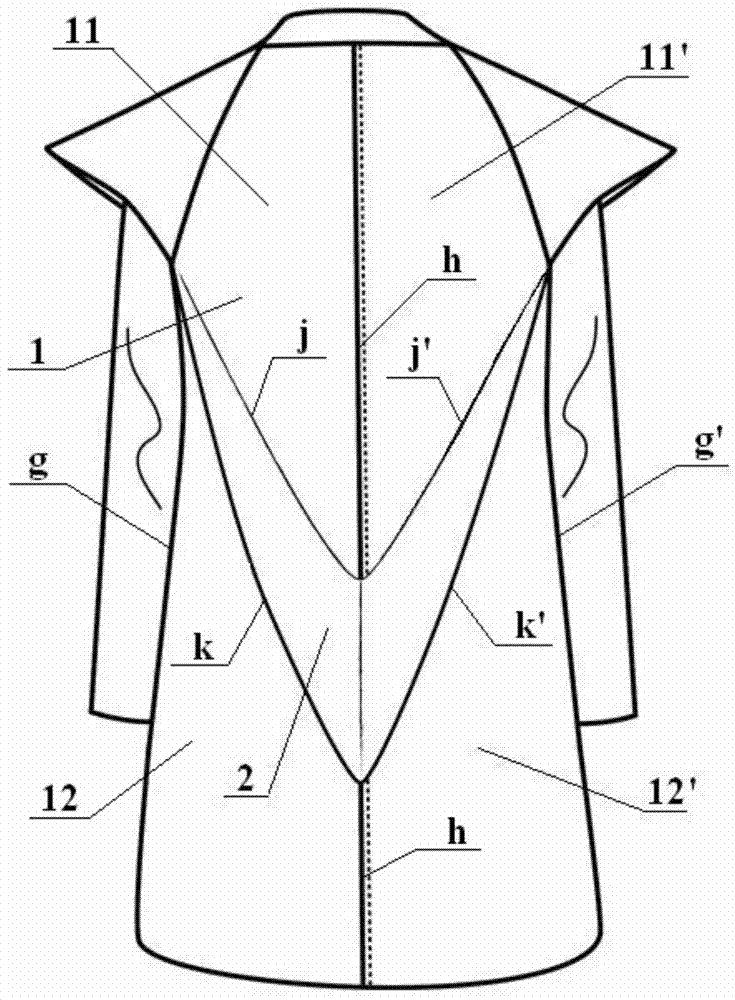

Three-dimensional jacket windbreaker and manufacture process thereof

ActiveCN104489959ASpeed up the slideReduce wind resistanceGarment special featuresOvergarmentsSplit linesVentilation mode

The invention discloses a three-dimensional jacket windbreaker and a manufacture process thereof. A triangular three-dimensional inserting piece is arranged on a front part or / and a rear part forming a jacket windbreaker body and consists of a left triangular planar inserting piece and a right triangular planar inserting piece, the left triangular planar inserting piece and the right triangular planar inserting piece are the same in shape, and each of the left triangular planar inserting piece and the right triangular planar inserting piece is formed by two different isosceles triangles sharing the same bottom edges, wherein two equal sides of the large isosceles triangles forming the left and right triangular planar inserting pieces are fixedly connected with cutting lines of the jacket windbreaker body in the position of the inserting pieces corresponding to the two equal sides, two equal sides of the small isosceles triangle forming the left triangular planar inserting piece are fixedly connected with two equal sides of the small isosceles triangle forming the right triangular planar inserting piece respectively, and the small isosceles triangles are axisymmetric, so that the triangular three-dimensional inserting piece is formed. According to the three-dimensional jacket windbreaker and the manufacture process thereof, the front part or / and the rear part which is / are originally planes forms / form a three-dimensional profile, so that wind resistance can be reduced, rainwater slipping is accelerated, a user can wear the three-dimensional jacket windbreaker comfortably in a ventilation mode, and obvious popularization and application values are achieved.

Owner:SHANGHAI UNIV OF ENG SCI

Air cushion

The invention discloses an air cushion, relates to the field of water bed equipment, and solves the technical problems of poor air permeability and discomfort of a water bed in the prior art; the aircushion comprises air bags and water bags, and the air bags and the water bags are formed by compounding, wherein each air bag is formed by connecting a plurality of mutually communicated air pipes, so that the pressure of gas in each air pipe is dispersed on the bag wall of each air pipe, the air cushion can bear larger pressure, and the air cushion is firmer and more reliable; in addition, the air bags and the water bags are arranged at intervals, the air bags are used for supporting a human body, the water bags are used for only performing energy exchange on air between the human body and the air cushion, and the air circularly flows below the skin of the human body by utilizing the air convection principle so as to perform heat and moisture exchange on the surface of the skin of the human body, so that the air cushion is better in air permeability and more comfortable for users.

Owner:苏州恒鼎科技咨询有限公司

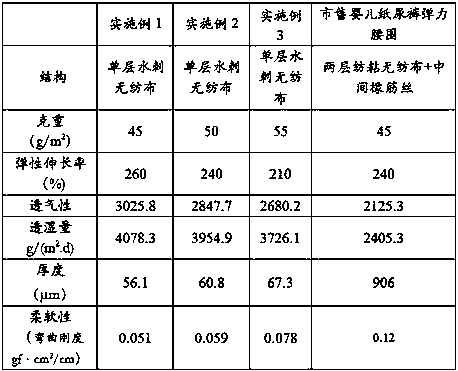

Paper diaper and preparation method thereof

ActiveCN108309571AReduce usageReduce investmentHeating/cooling textile fabricsAbsorbent padsPolyethylene terephthalate glycolCarding

The invention discloses a paper diaper and a preparation method thereof, and relates to the technical field of disposable sanitary products. PTT (polytrimethylene terephthalate) fibers and PTT / PET (polyethylene terephthalate) two-component fibers are selected, opening, carding and spunlace fixing processes are adjusted, special shrinkage and folding processes are selected, a prepared elastic non-woven fabric has excellent elasticity, further has good softness and breathability of a spunlace non-woven fabric and has better safety, and the elastic non-woven fabric is arranged at an elastic backposition of the paper diaper. Compared with a traditional paper diaper, the paper diaper has the advantages that a rubber band is omitted, and the prepared paper diaper applies more uniform elastic force to the body of an infant, so that the paper diaper has better conformity and helps good development of the hip of the infant to a certain degree.

Owner:JIAXING UNIV

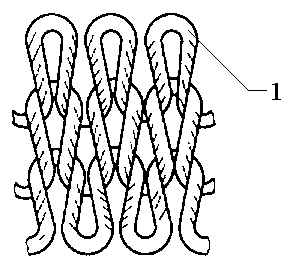

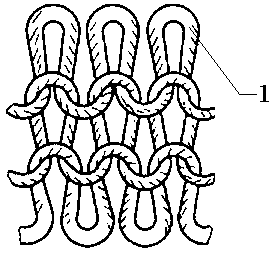

Hygroscopic material knitted by warps and wefts

The invention discloses a hygroscopic fabric knitted by warps and wefts, wherein the hygroscopic fabric is formed by knitting of the warps and the wefts. The warps are formed by knitting and blending of silk fibers and voile fibers, and the wefts are formed by knitting and blending of plumetis fibers and ramie fibers. The warps comprise, by weight, 15%-21% of the silk fibers and 79%-85% of the voile fibers, and the wefts comprise, by weight, 26%-32% of the plumetis fibers and 68%-74% of the ramie fibers. According to the hygroscopic fabric knitted by the warps and the wefts, the hygroscopic fabric is formed by knitting of the warps and the wefts and is compact in structure, the warps and the wefts are composed of the silk fibers, the voile fibers, the plumetis fibers and the ramie fibers, and the hygroscopic fabric formed by the warps and the wefts is soft in touch, comfortable and breathable to wear and good in hygroscopicity and does not stick on the body when a user sweats.

Owner:WUJIANG XUYANG TEXTILE

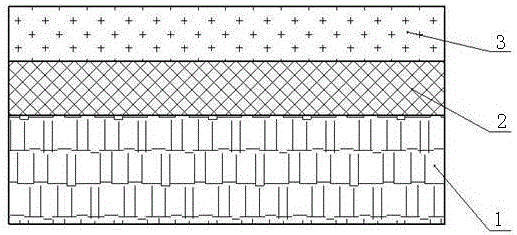

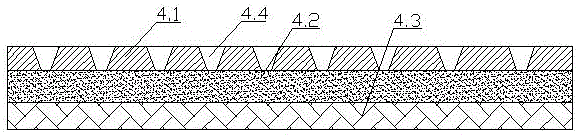

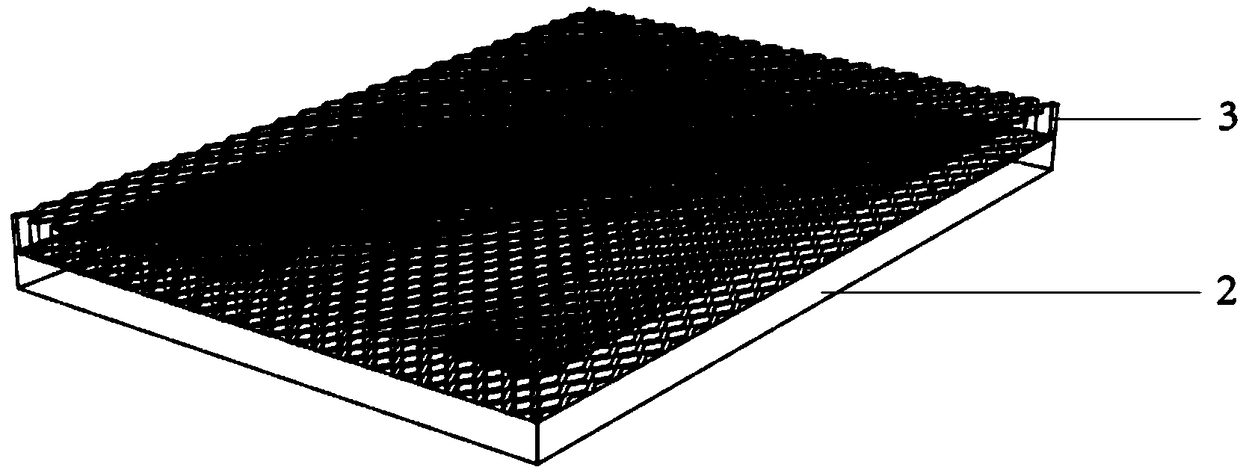

Preparation process of 3D overlapping curve memory cotton

The invention discloses a preparation process of 3D overlapping curve memory cotton. The 3D overlapping curve memory cotton is sequentially provided with a supporting layer, a comfortable layer and a3D breathable layer from bottom to top; the preparation process comprises the following steps that 1) a foaming mold is made according to the specific shape and size of a target product; 2) memory cotton slices are cut into 3D overlapping curve memory cotton slices through a machine to obtain the 3D breathable layer; 3) the comfortable layer is compounded on the 3D breathable layer through a bonding agent to form a first structure layer; 4) a mixed material of the supporting layer is prepared, and the first structural layer is put into the preheated foaming mold; and 5) the mixed material is injected into the foaming mold, and the 3D overlapping curve memory cotton can be obtained after the mixed material is cooled and formed. According to the process, the supporting layer takes a fast-resilience supporting cotton as a bottom-layer cotton core, deformation is not prone to occur, the supporting layer conforms to a human body curve, can relieve nerve compression, and is beneficial to blood circulation; the comfortable layer adopts a common slow-resilience memory cotton, and the comfortable and breathable performance is achieved; and a 3D overlapping curve memory cotton pillow core has the advantages that the supporting performance and the comfort are achieved, and the skin-friendly and breathable effects are both achieved.

Owner:苏州乐土家居生态科技有限公司

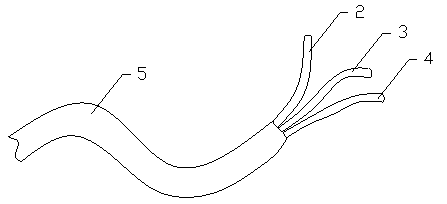

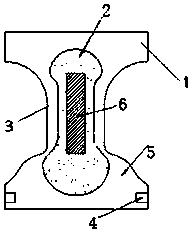

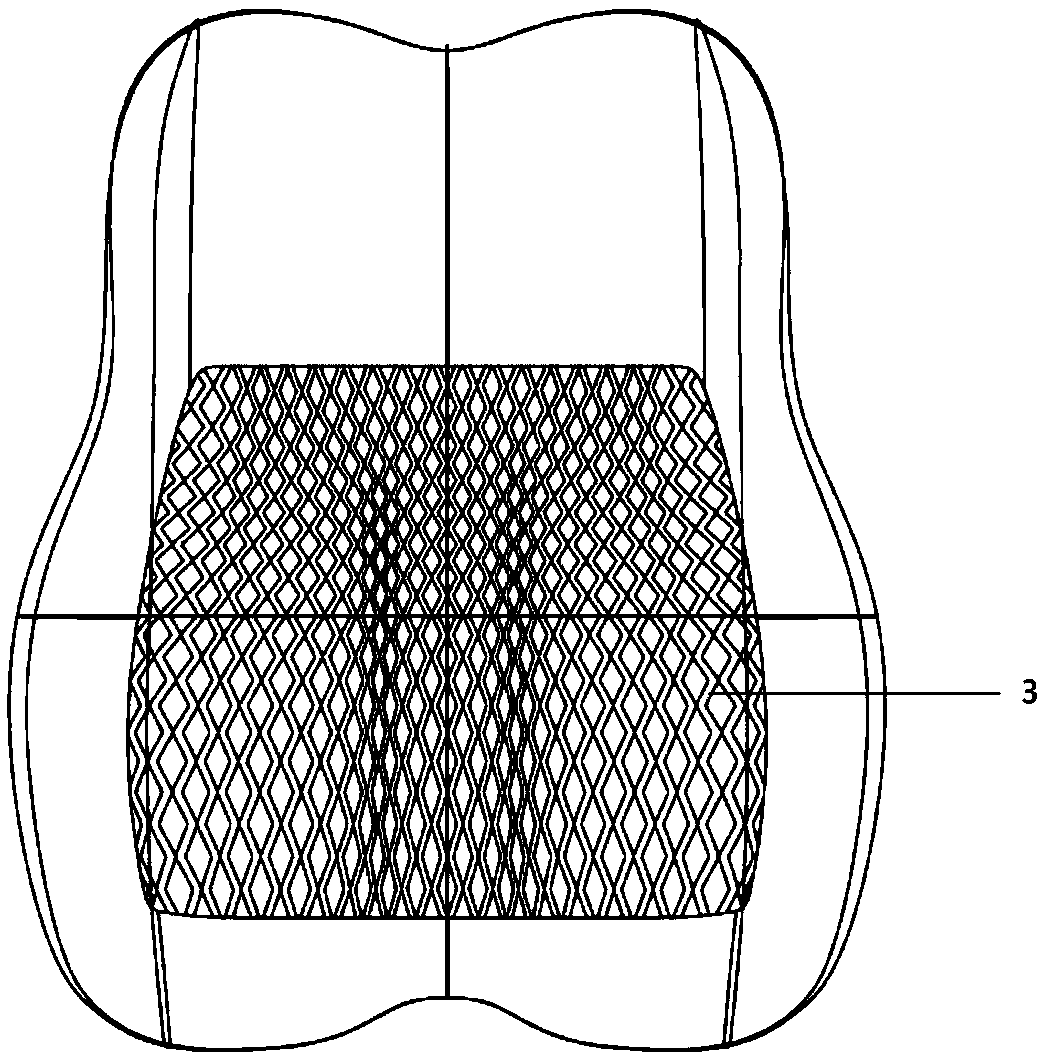

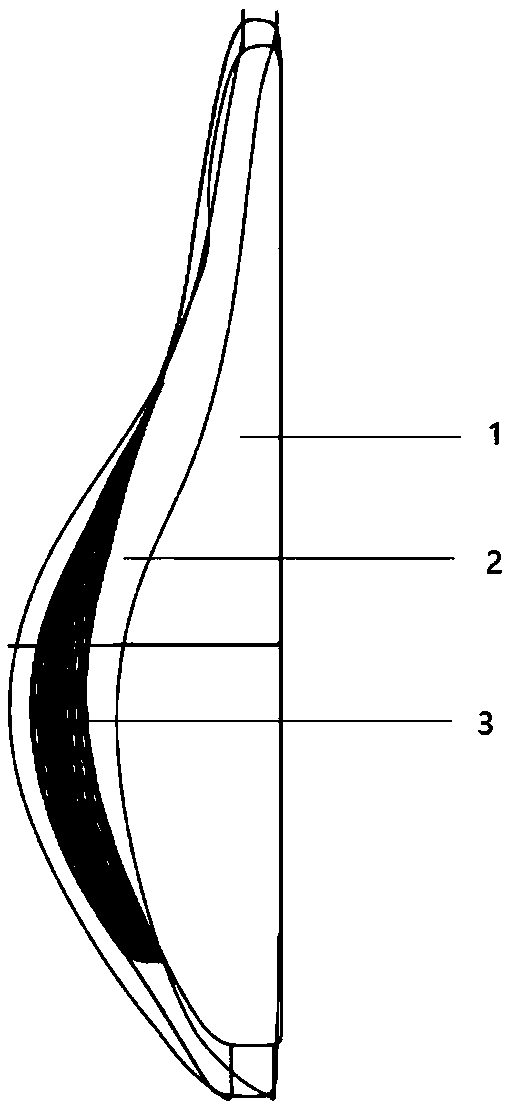

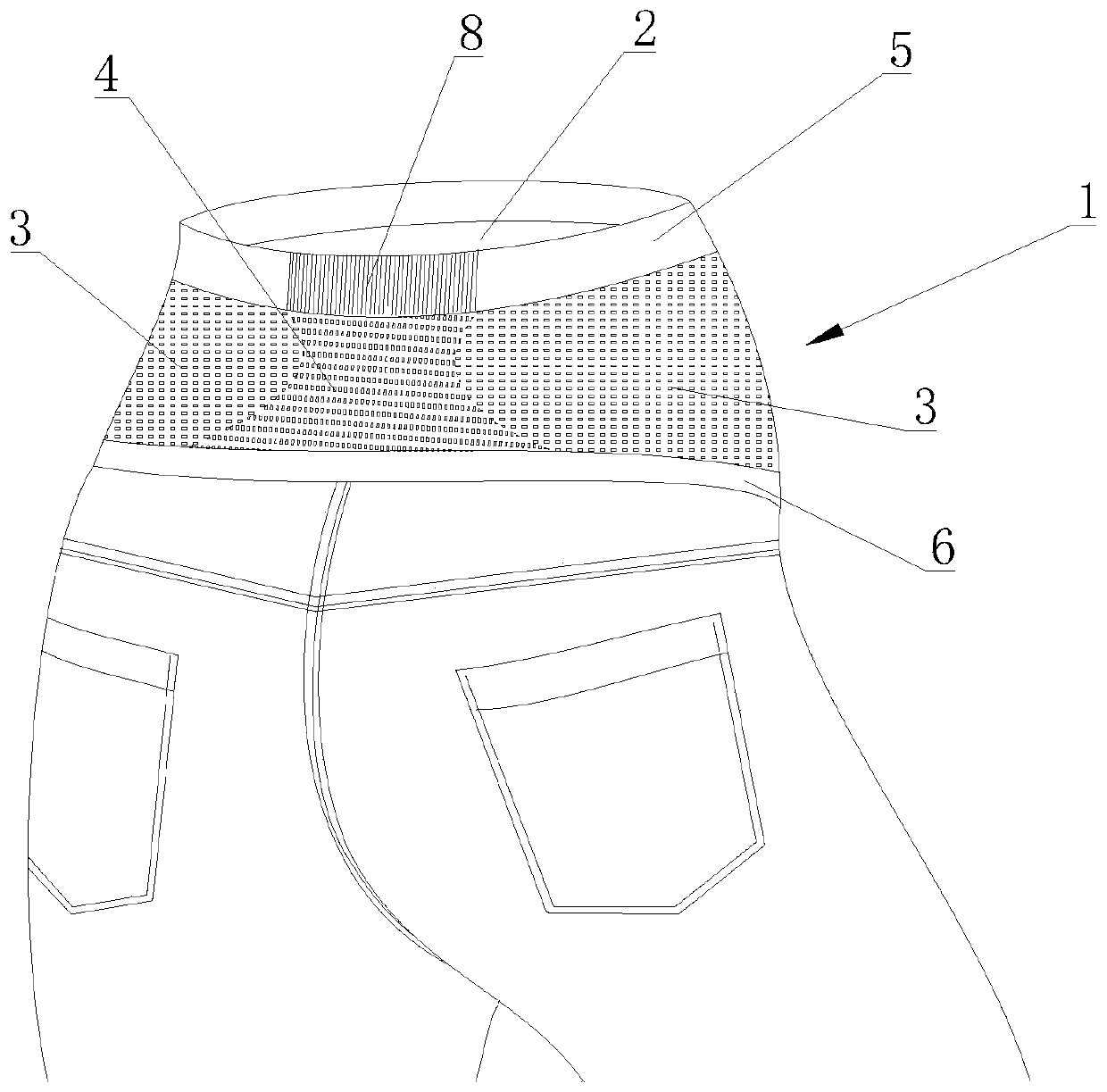

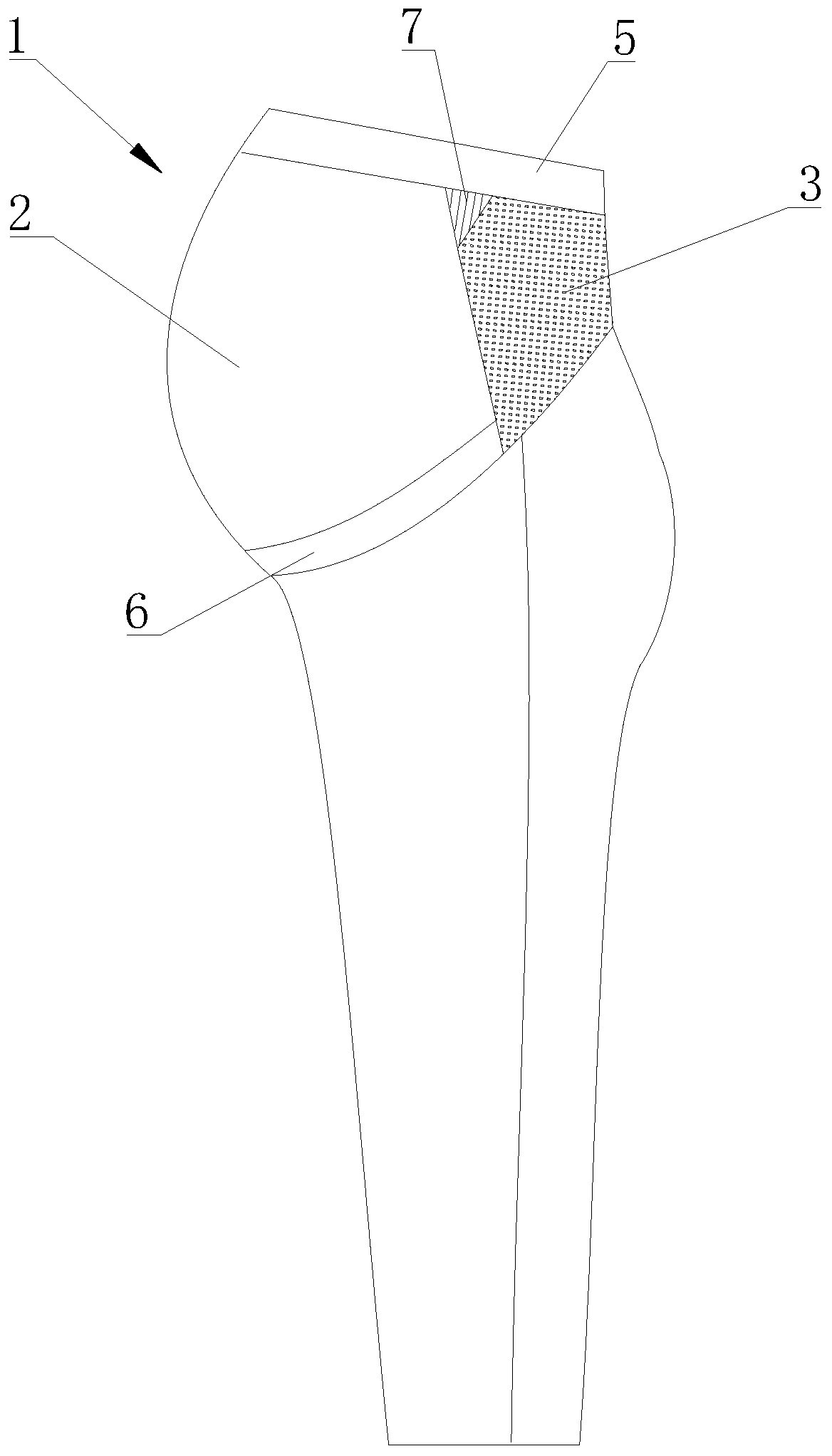

360-degree high-elasticity anti-sliding pregnant woman abdominal loincloth

The invention discloses a 360-degree high-elasticity anti-sliding pregnant woman abdominal loincloth which comprises an abdominal loincloth main body (1), wherein the abdominal loincloth main body (1)comprises a front abdominal piece (2); rear waist pieces (3) in symmetrical distribution are respectively arranged on both sides of the front abdominal piece (2); the two rear waist pieces (3) are connected through a middle waist piece (4); the front abdominal piece (2) is of a plain woven structure; the rear waist pieces (3) are of a hollow whorl interwoven structure; the middle waist piece (4)is of a whorl interwoven structure. The abdominal loincloth has the characteristics of being high in elasticity, capable of preventing sliding off, and good in flexibility, good in air permeability and high in comfortableness as well.

Owner:杭州有尚贸易有限公司

Waterproof fabric for improving guided optical activity

InactiveCN107685501AImprove waterproof performanceComfortable and breathableSynthetic resin layered productsFilament/thread formingFiberElectric power system

The invention relates to a waterproof fabric for improving guided optical activity. The fabric comprises a base layer (1), wherein the surface of the base layer (1) is successively provided with an antibacterial layer (2) and a waterproof layer (3). The antibacterial layer (2) is made from bamboo fiber. The waterproof layer (3) is a TPU (thermoplastic polyurethanes) coating. The reverse side of the base layer is provided with a lining fabric layer, and the lining fabric layer is a light-emitting fabric and comprises a light transmitting unit, at least a light-emitting unit which is combined with the light transmitting unit, and an electric power unit which is electrically connected with the light transmitting unit. The light transmitting unit comprises a plurality of pieces of complex fiber. The waterproof fabric is ventilated, comfortable, waterproof and antibacterial. The waterproof fabric improves the guided optical activity.

Owner:JIANGYIN QUANSHUN TEXTILE CO LTD

Preparation technique of imitated-silk fabric with health-care function

The invention discloses a preparation technique of imitated-silk fabric with a health-care function. The technique includes the following steps that first, 92.6% of modal and 7.4% of spandex are subjected to mixed weaving to form spandex single jersey, and the spandex single jersey is dyed in an environmentally-friendly mode and dried for usage; then, PARAFOME SHB (shea butter processing agent) of50 g / L is blended, and a sizing groove of 150 DEG C*20 y of a setting machine performs finished product setting to form the imitated-silk fabric with the health-care function. The imitated-silk fabric prepared through the preparation technique of the imitated-silk fabric with the health-care function has oxidation resistance, ageing resistance, and smooth hand feeling like silk.

Owner:浙江雅雪纺织科技有限公司

Composite luminous fabric

InactiveCN105266241AExcellent fluorescence performanceNot easy to wearLayered productsWoven fabricsPolyesterFiber

The invention discloses composite luminous fabric. The composite luminous fabric comprises a luminous layer located in the surface layer and a comfortable layer located in the inner layer. The luminous layer is formed by weaving of warps and wefts. The warps are formed by blended weaving of fluorescent fibers for rare earth and polyester fibers. The wefts are formed by blended weaving of poly-triphenylamine fluorescent fibers and polyvinyl alcohol fibers. The comfortable layer is blended weaving of voile fibers and modal fibers.The composite luminous fabric has following beneficial effects: due to the fact that fluorescence fibers and ordinary fabric fibers are blended to form a fluorescent fabric layer, fine fluorescent effect is obtained and composite luminous fabric is not easily to get abraded; therefore, the composite luminous fabric is long in service lifetime and does not affect breathability and comfortableness of fabric; and the inner layer is formed by weaving of comfort fabric so that the composite luminous fabric is comfortable to wear and is breathable.

Owner:张晖

Antistatic flame-retardant textile

InactiveCN101724965BImprove flame retardant performanceImprove spinnabilityWoven fabricsYarnYarnPolymer science

The invention provides antistatic flame-retardant textile which is weaved by antistatic flame-retardant yarn. The antistatic flame-retardant yarn is blended by modacrylic fiber with chloride and cotton fiber. The antistatic flame-retardant textile also can be weaved in such a way that conductive fiber is weaved in when the antistatic flame-retardant yarn is blended by modacrylic fiber with chloride and cotton fiber with conductive fiber. The antistatic flame-retardant textile further can be weaved by the antistatic flame-retardant yarn which is blended by modacrylic fiber with chloride, cotton fiber and conductive fiber. The invention has the advantages of low price, sot hand feel, good comfort, air permeability, permanent fire resistance, low content of formaldehyde, good strength and excellent antistatic performance.

Owner:汕头市奥山服饰有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com