3D printed graded resilience structure and shoe sole using 3D printed graded resilience structure

A 3D printing and elastic technology, applied in the field of sports shoes, can solve problems such as collapse, weakened cushioning effect, and weakened rebound performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

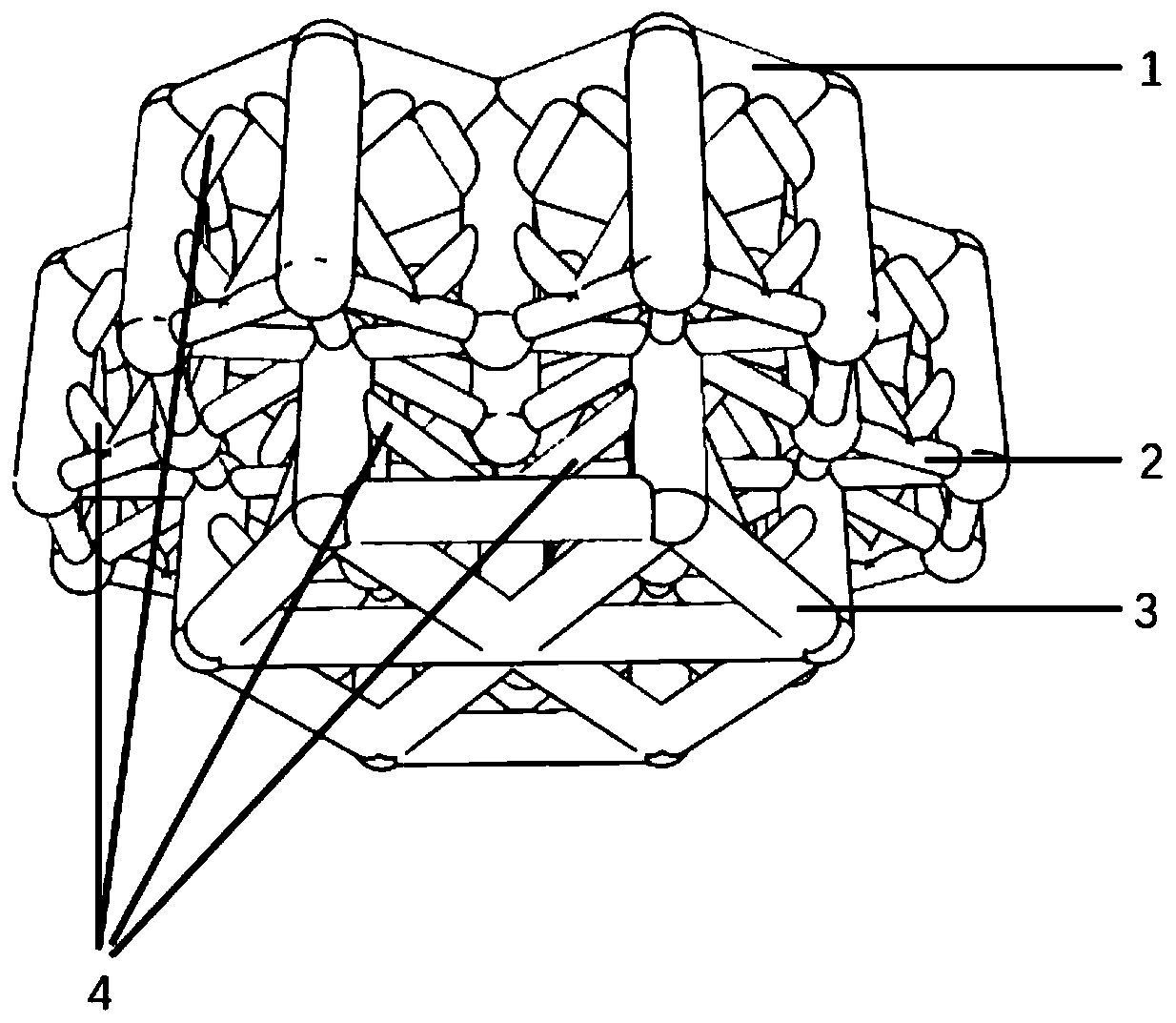

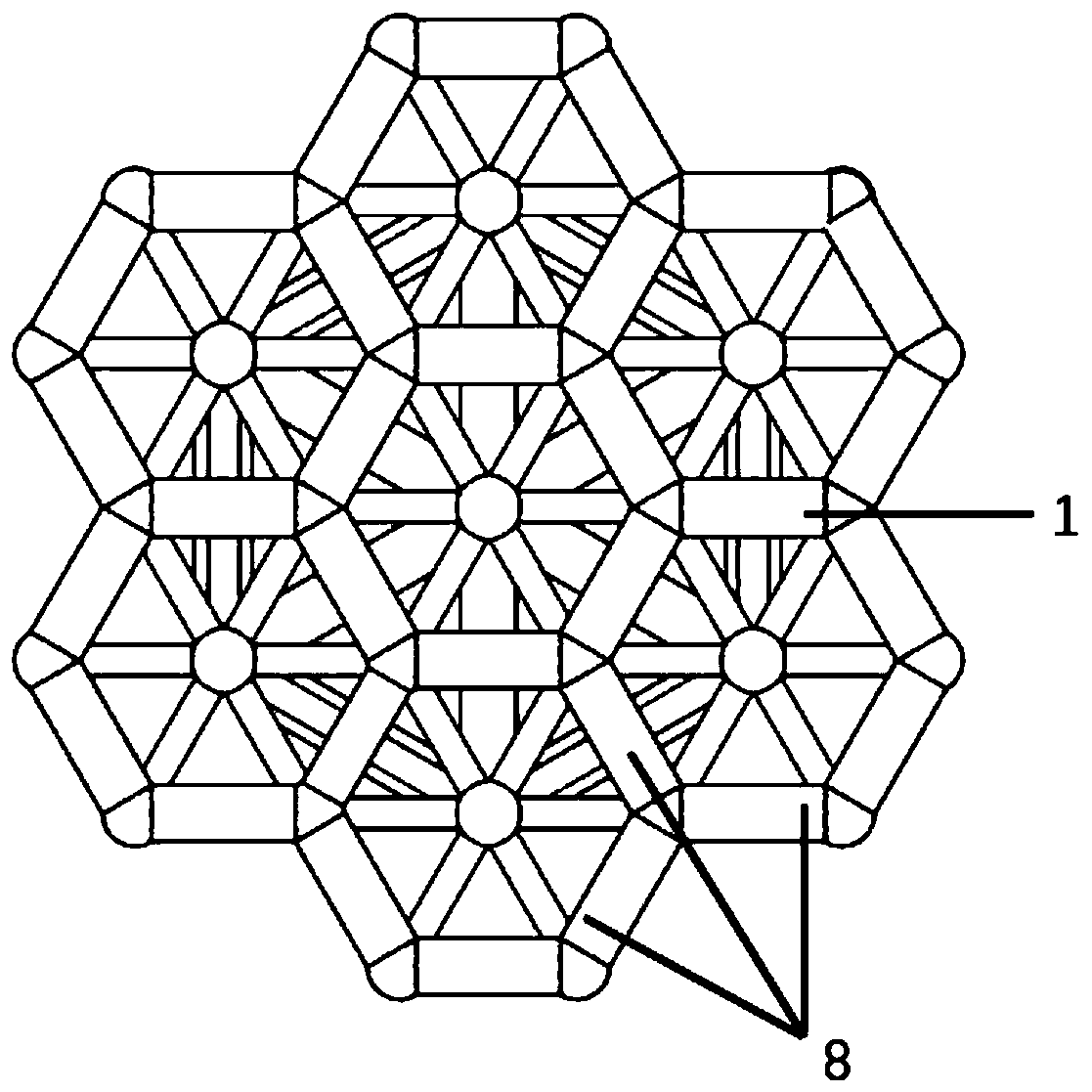

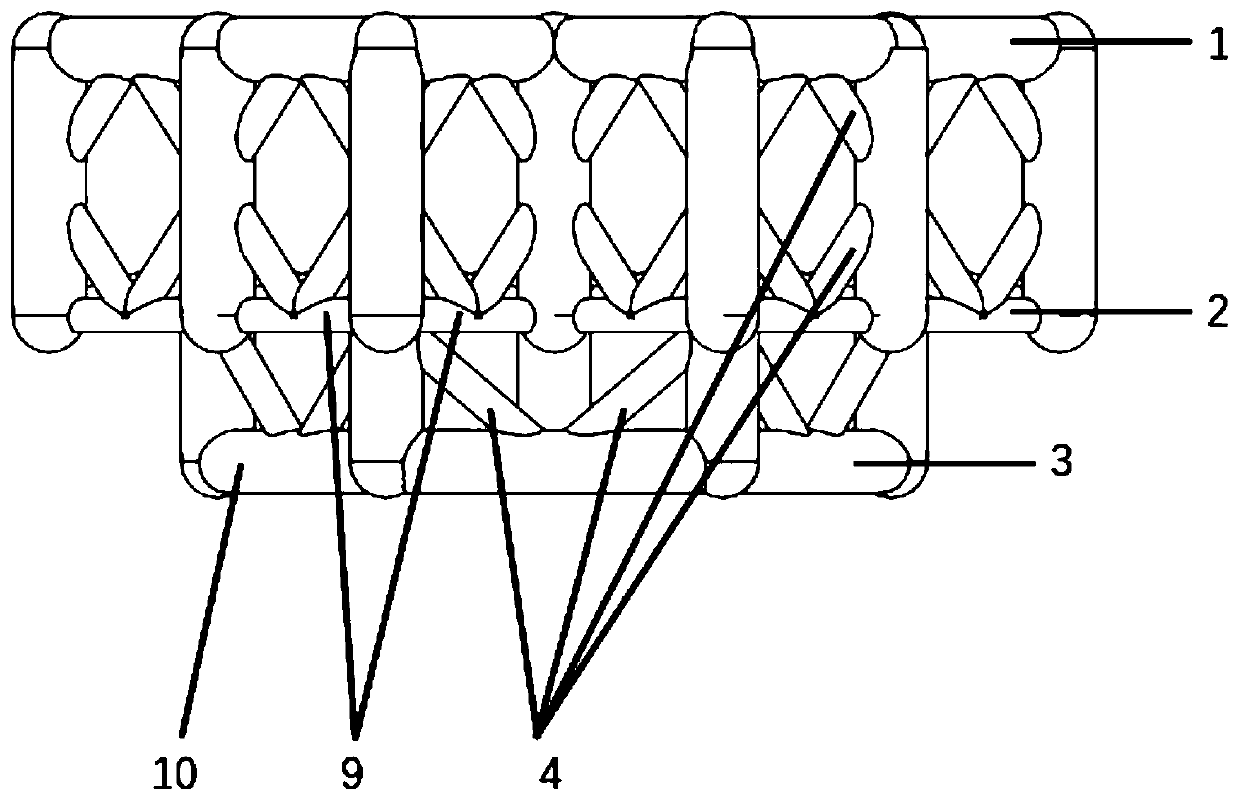

[0029] Such as Figure 1-4 As shown, a 3D printed hierarchical springback structure is composed of surface grid 1, multiple 3D printed hierarchical springback lattice units, ring edge 2, bottom grid 3, and diagonal struts 4, and the hierarchical springback The shape of the structure can be designed into three-dimensional shapes such as cylinders and cubes.

[0030] The hierarchical rebound lattice unit is composed of a cushioning component and a cushioning rebound part.

[0031] The cushioning component is composed of 3 vertical rods 5, 3 diagonal stay rods 6, and 12 diagonal strut rods 4 to form a plane force structure: the distribution points of the 3 vertical rods 5 are triangular, and the diameter of the vertical rods 5 ranges from 1.5 to 5 mm. The height ranges from 5 to 18mm, and the distance between the vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com