Patents

Literature

34results about How to "Customizable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

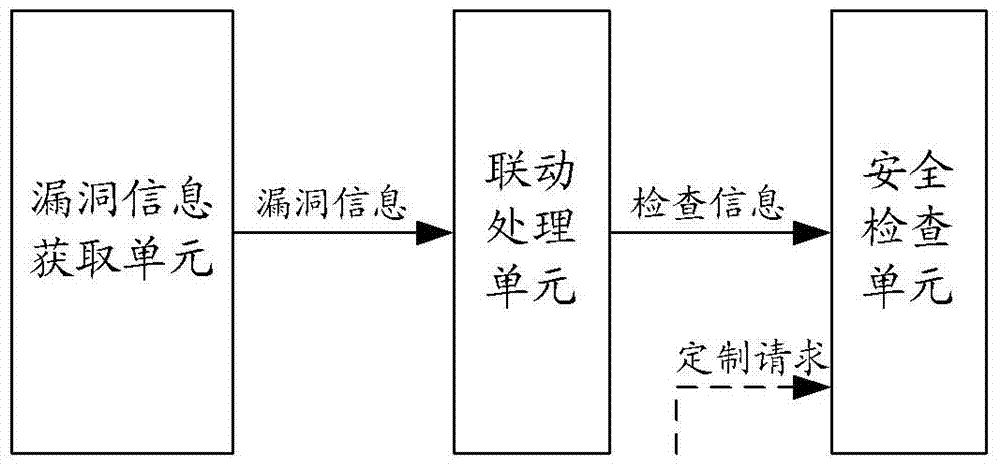

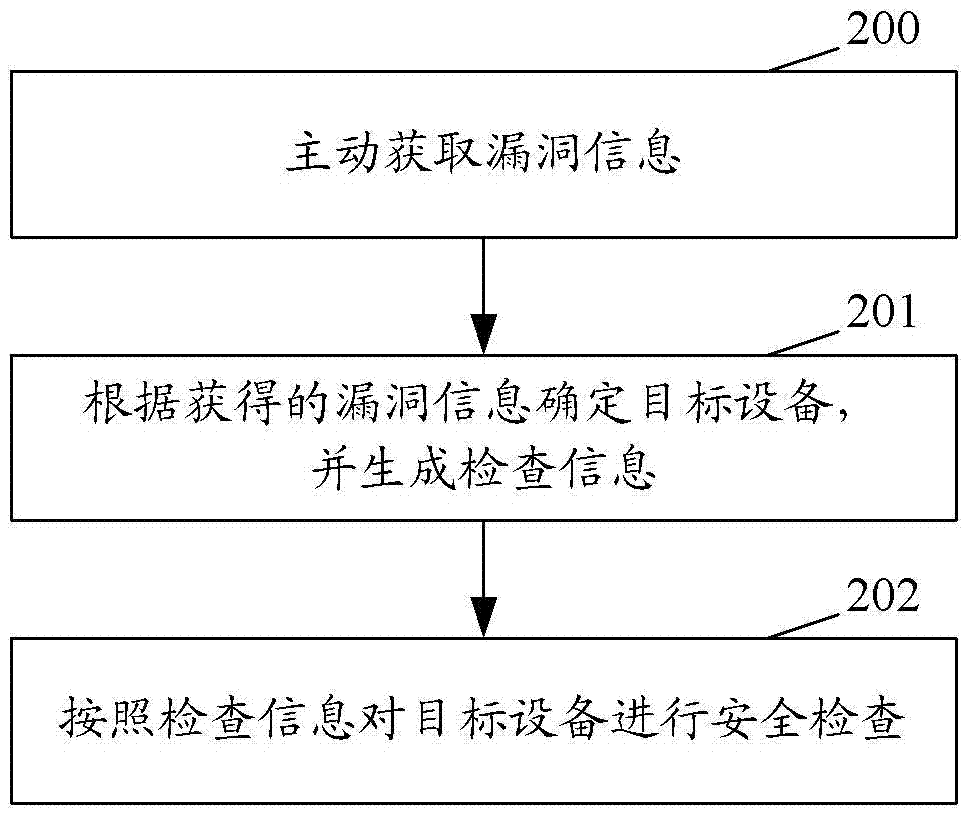

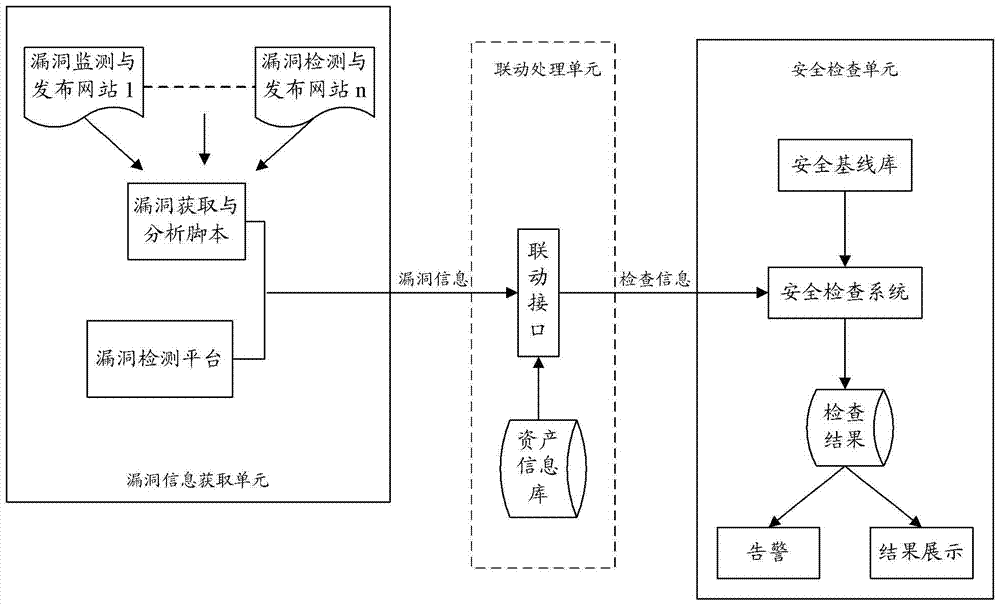

Security baseline system and method thereof for implementing security checks

ActiveCN104125197AMeet customizable needsMeet application needsTransmissionTime responseThe Internet

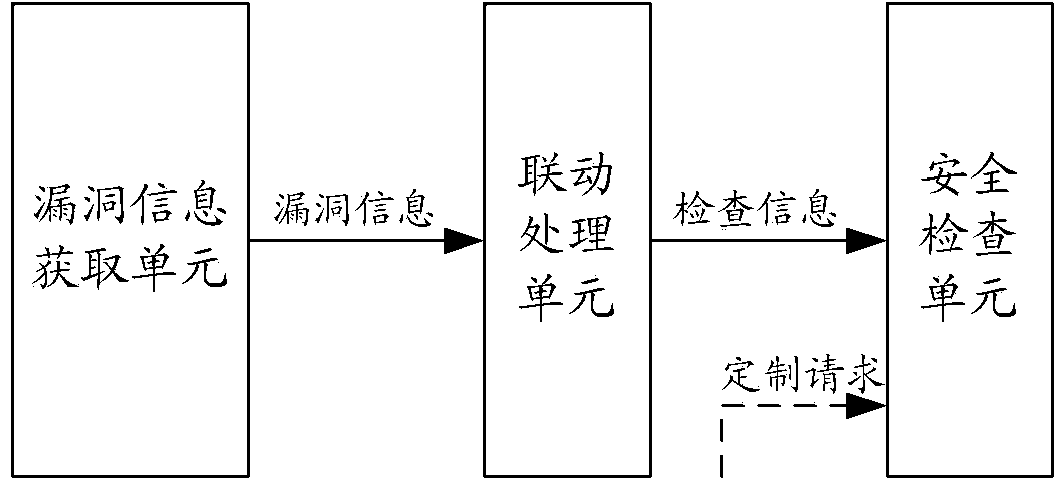

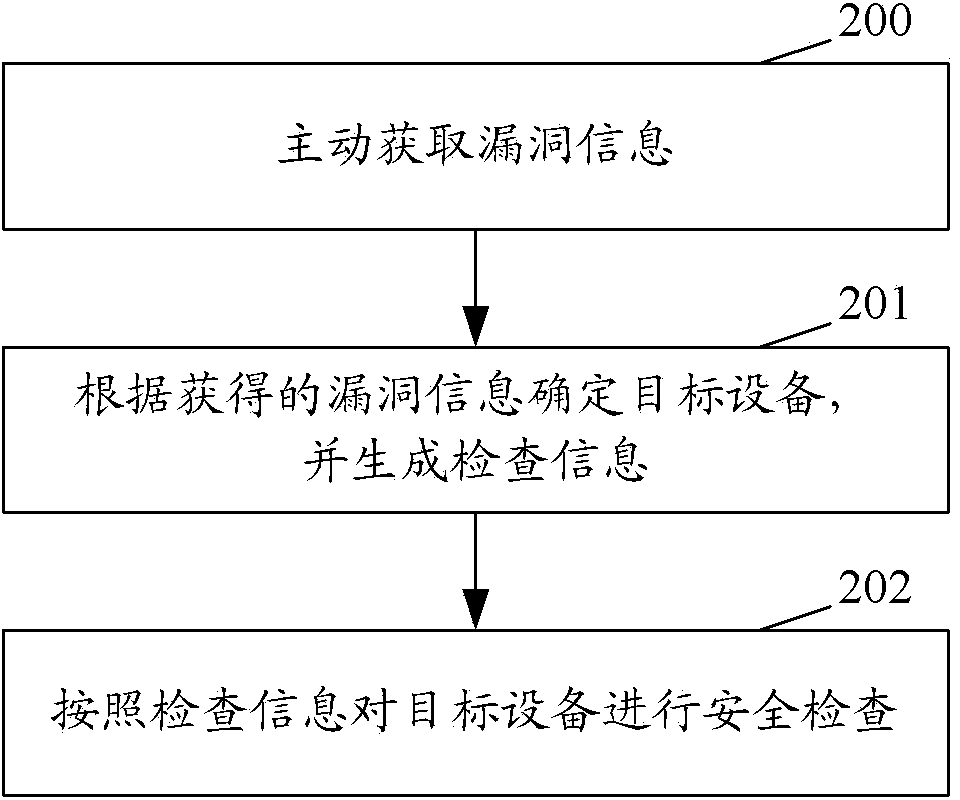

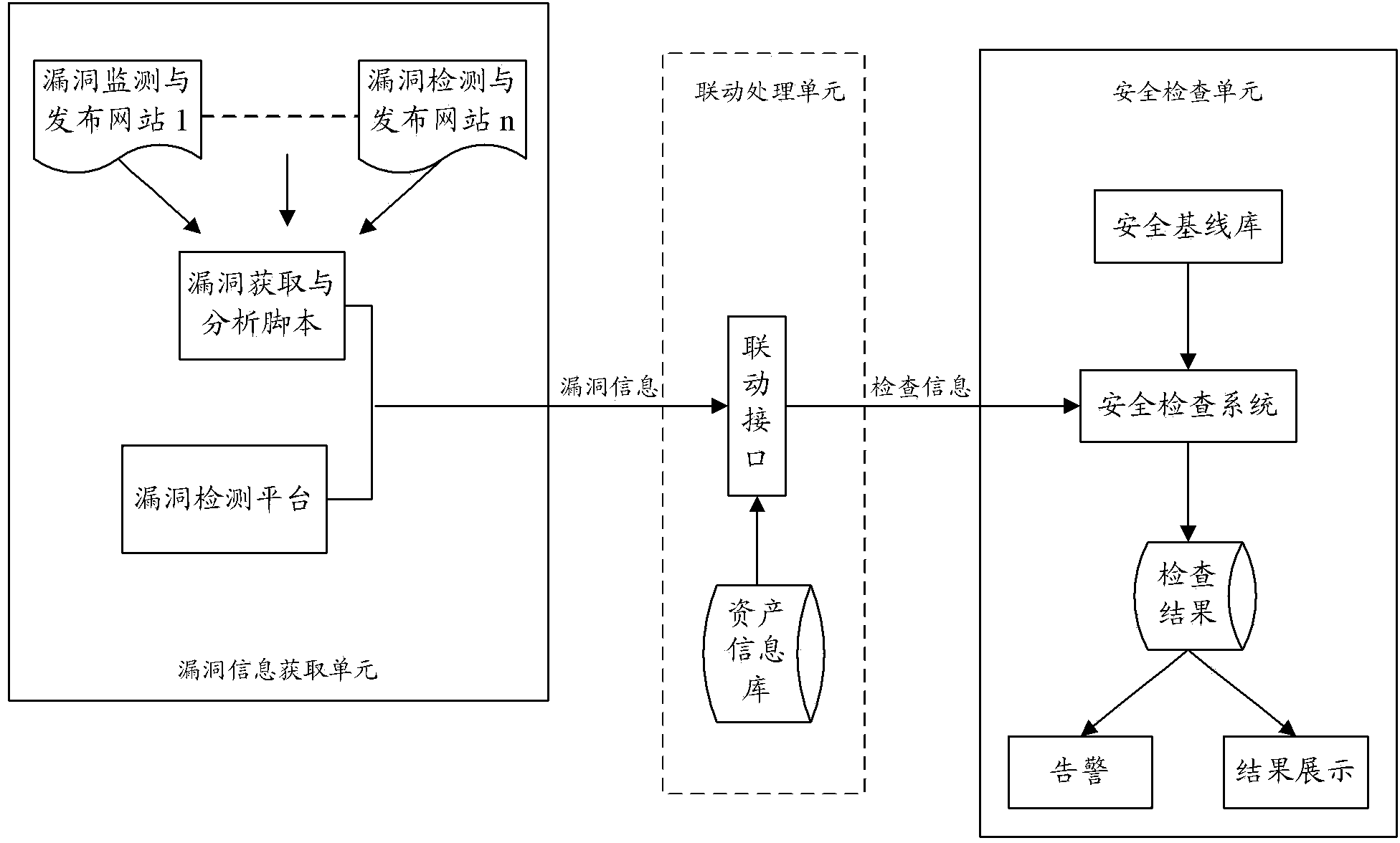

The application discloses a security baseline system and a method thereof for implementing security checks. Included are that a vulnerability information acquisition unit obtains vulnerability information actively; a linkage processing unit determines a target device based on the obtained vulnerability information, and generates checking information; and a security check unit conducts security checks for the target device based on the generated checking information. According to the application, through the active approach, the security baseline system and the method thereof for implementing the security checks obtain newly discovered vulnerability information positively in an active manner, adapt to the internet field full of such changes, and therefore achieve real-time response to newly discovered vulnerability. Further, by following the customized request of a user, the security baseline system and the method thereof for implementing the security checks establish a user security baseline library, allow the user to customize security rules to conduct security checks for the system, and thus meet the demand that the security checks can be customized.

Owner:ALIBABA GRP HLDG LTD

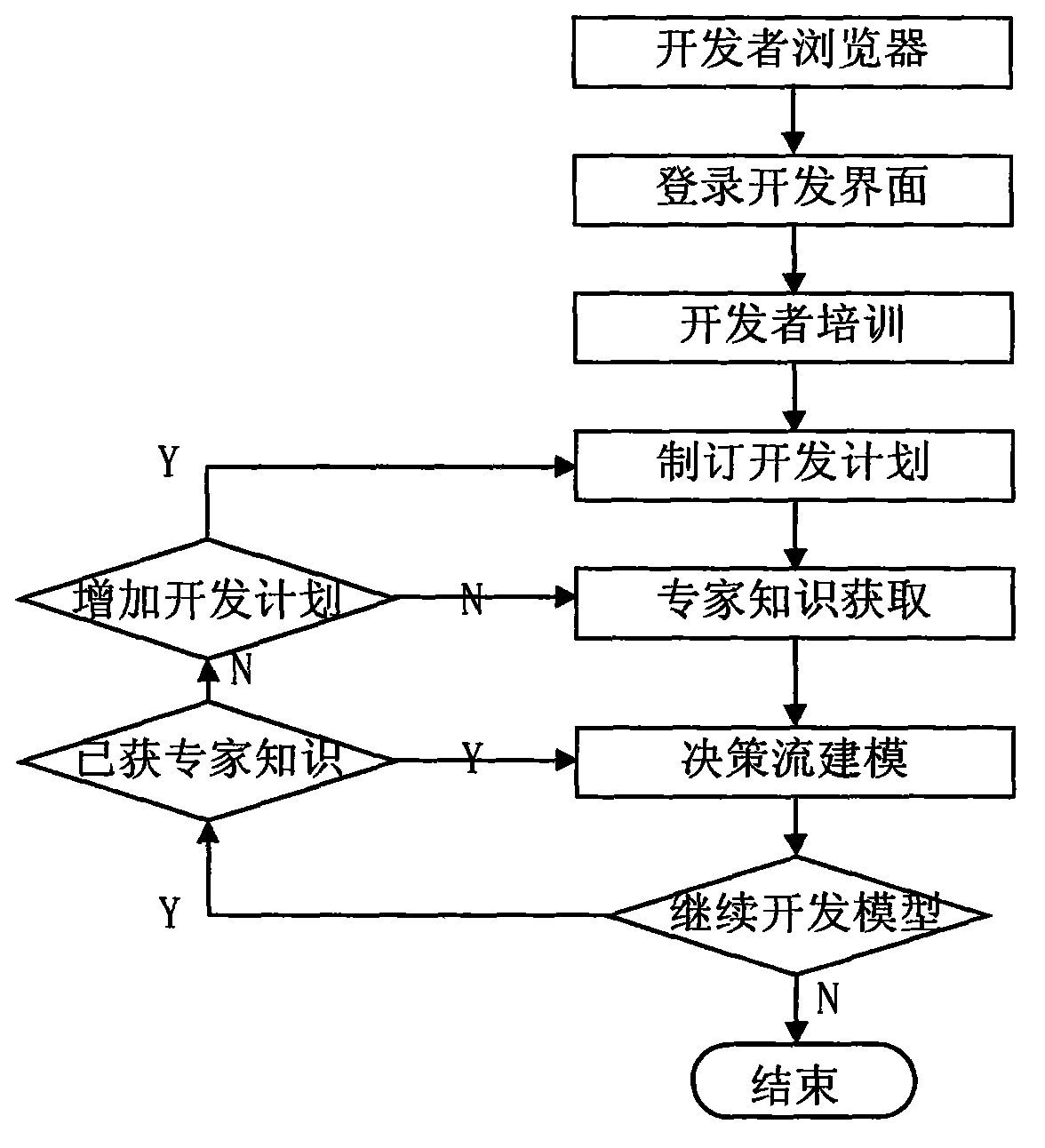

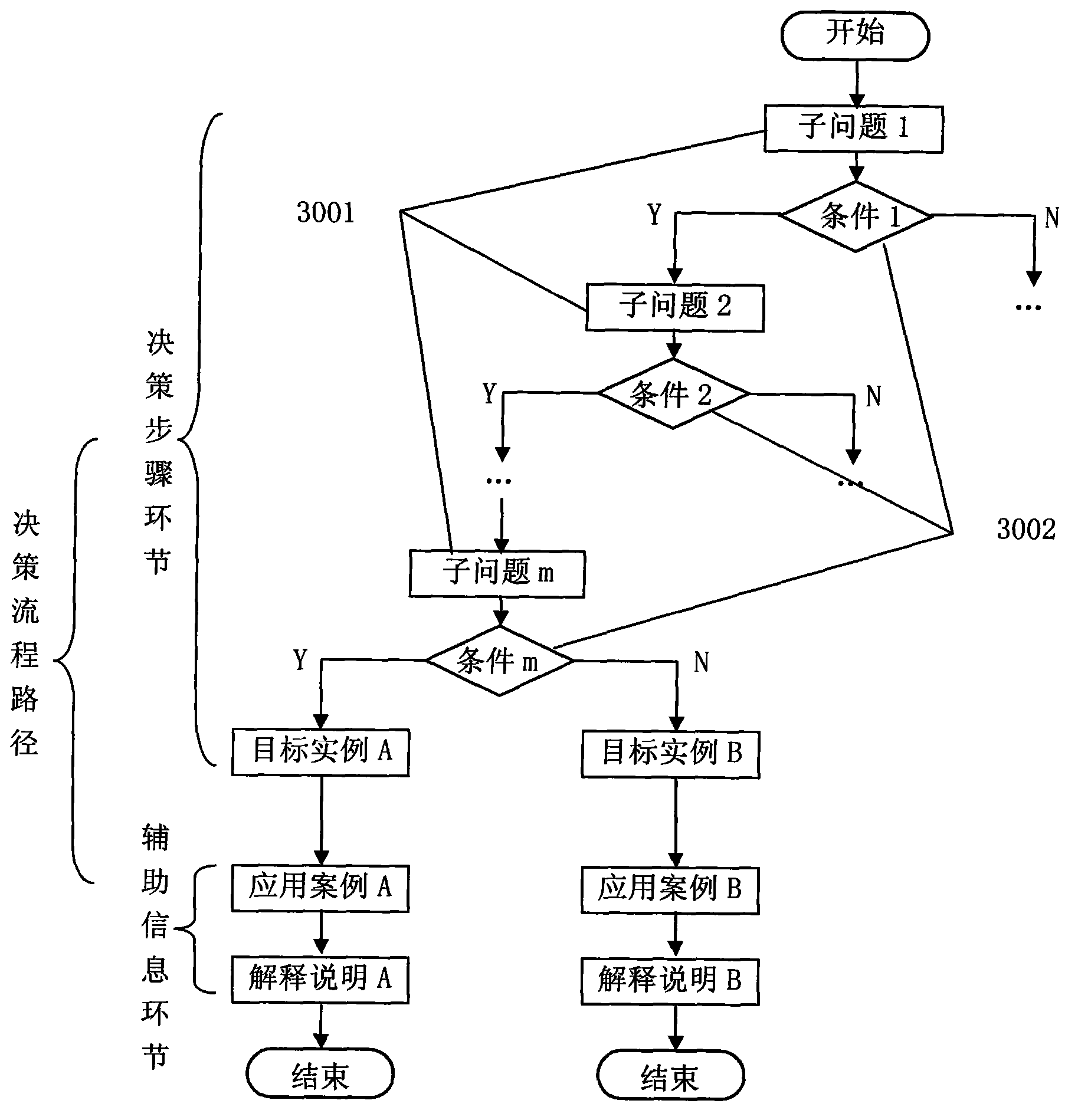

Intelligent decision-making and entity recommending union system based on internet and work flow

InactiveCN103019673ACustomizableStrong targetingSpecial data processing applicationsSpecific program execution arrangementsDecision makerService development

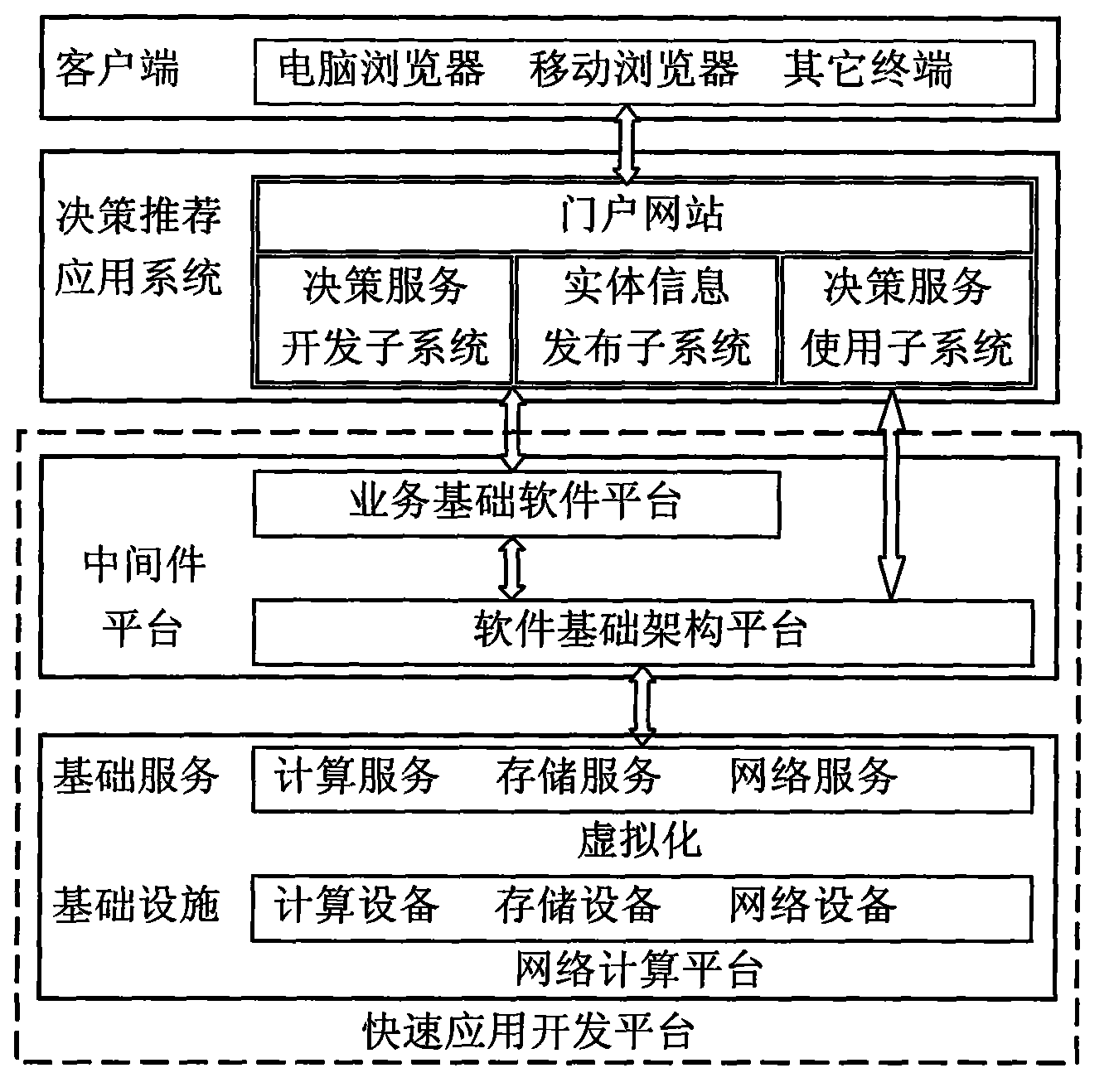

The invention provides an intelligent decision-making and entity recommending union system based on an internet and work flow. The union system consists of a rapid application and development platform, a client end and a decision-making and recommending application system, wherein the decision-making and recommending application system comprises a portal website, a decision-making service development sub-system, an entity information distribution sub-system and a decision-making service usage sub-system. According to the union system, a developer utilizes the decision-making service development sub-system to carry out the development of a decision-making service example, a promulgator carries out the distribution of entity information by the adoption of the entity information distribution sub-system, a decision maker implements auxiliary decision making by utilizing the decision-making service usage sub-system, and obtains the information of recommended specific entity while obtaining a decision-making result. According to the union system, model establishment based on decision-making flow of work flow and entity recommendation technology based on body matching are realized, the decision-making service development sub-system and the entity information distribution sub-system have the characteristics of a cloud platform i.e. service, and the decision-making service example for the use of the decision maker has the characteristics of cloud software i.e. service.

Owner:北京仟手莲科技有限公司 +1

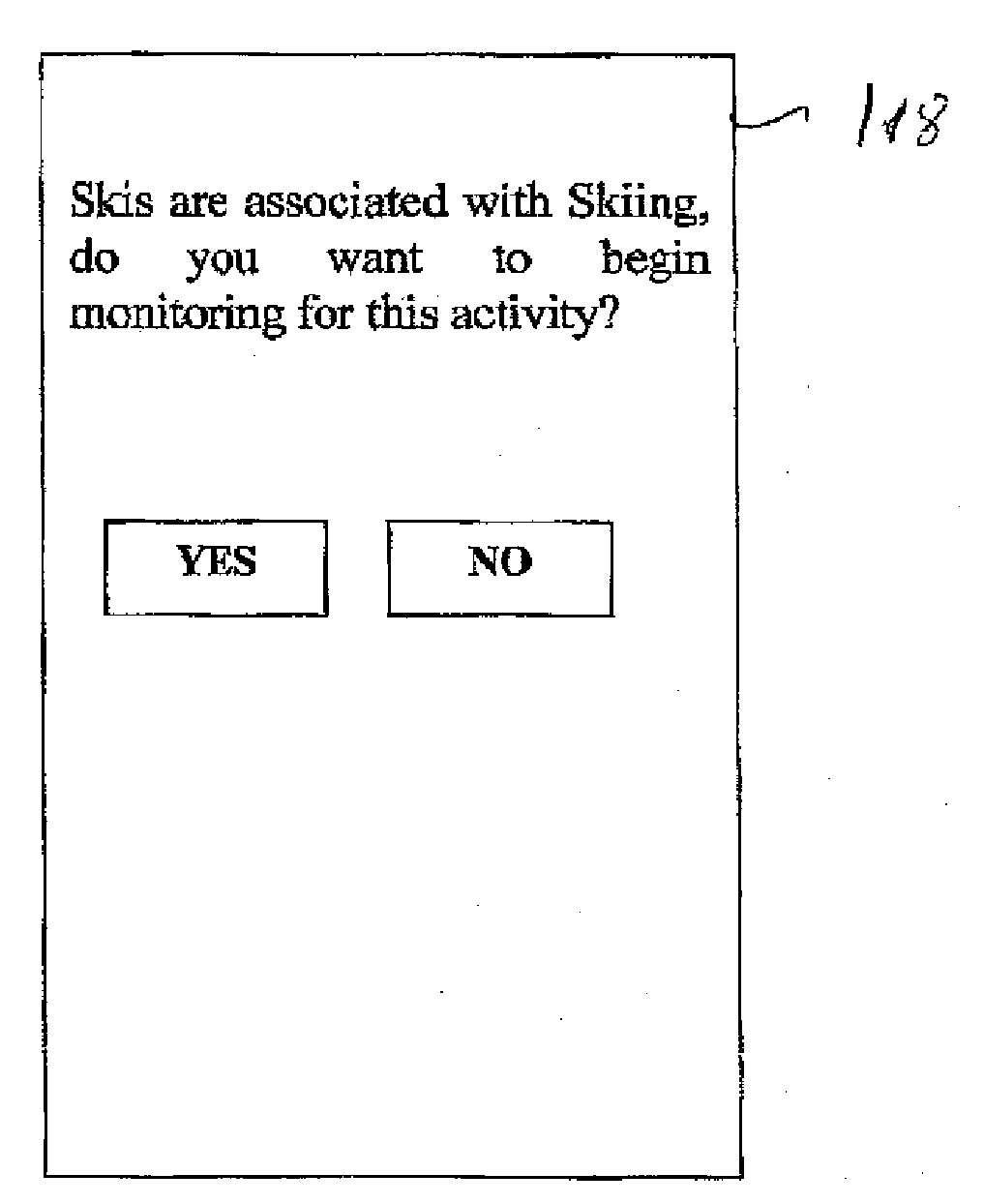

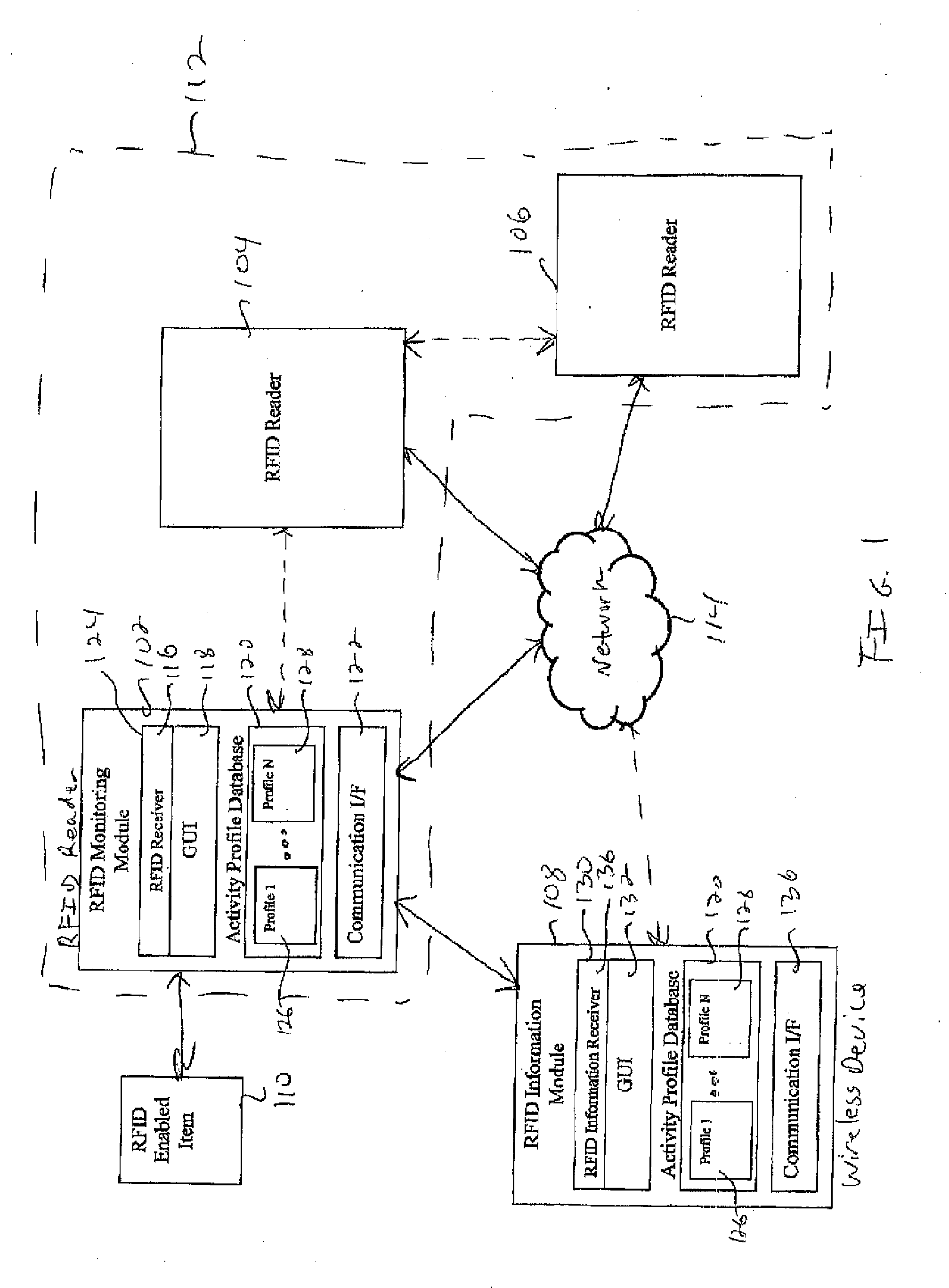

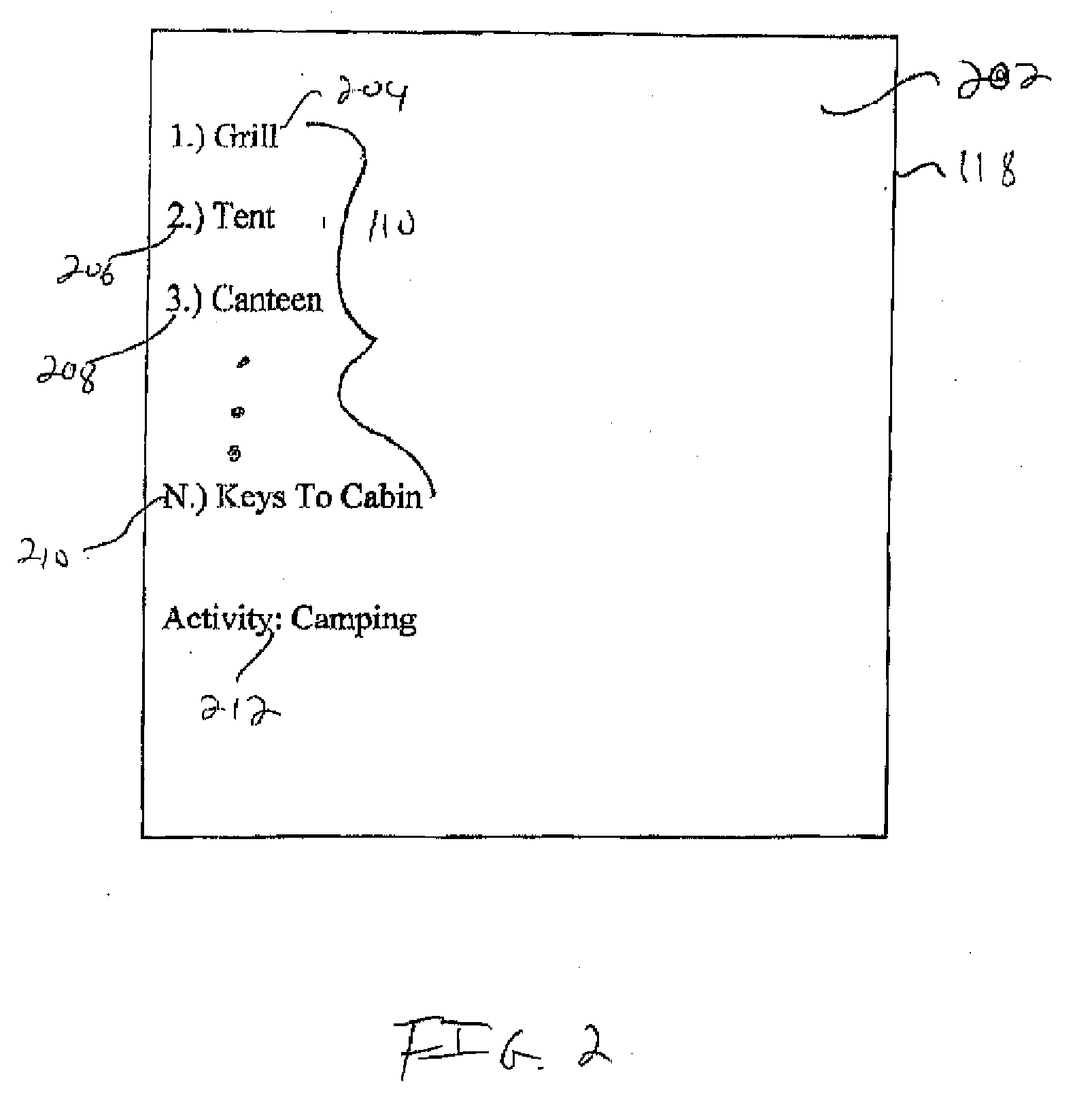

Monitoring for radio frequency enabled items based on activity profiles

ActiveUS20080157966A1CustomizableCustomizable monitoringProgramme controlElectric signal transmission systemsRadio frequencyRadio-frequency identification

A method, wireless communication device, and radio frequency ID reader are provided for monitoring radio-frequency identification enabled items. The method includes receiving a set of radio frequency IDs (1104) representing a set of radio frequency ID enabled items (110) to be monitored. An identifier representing a user activity and its relationship with at least one radio frequency ID in the set of radio frequency IDs and at least one radio frequency ID reader is received (1106). The method also includes determining if at least one condition associated with the user activity has occurred indicating that the user activity is occurring (1108). The set of radio frequency IDs representing a set of radio frequency ID enabled items (110) to be monitored by the at least one radio frequency ID reader are monitored (1110) in response to the determining that the at least one condition is occurring.

Owner:GOOGLE TECH HLDG LLC

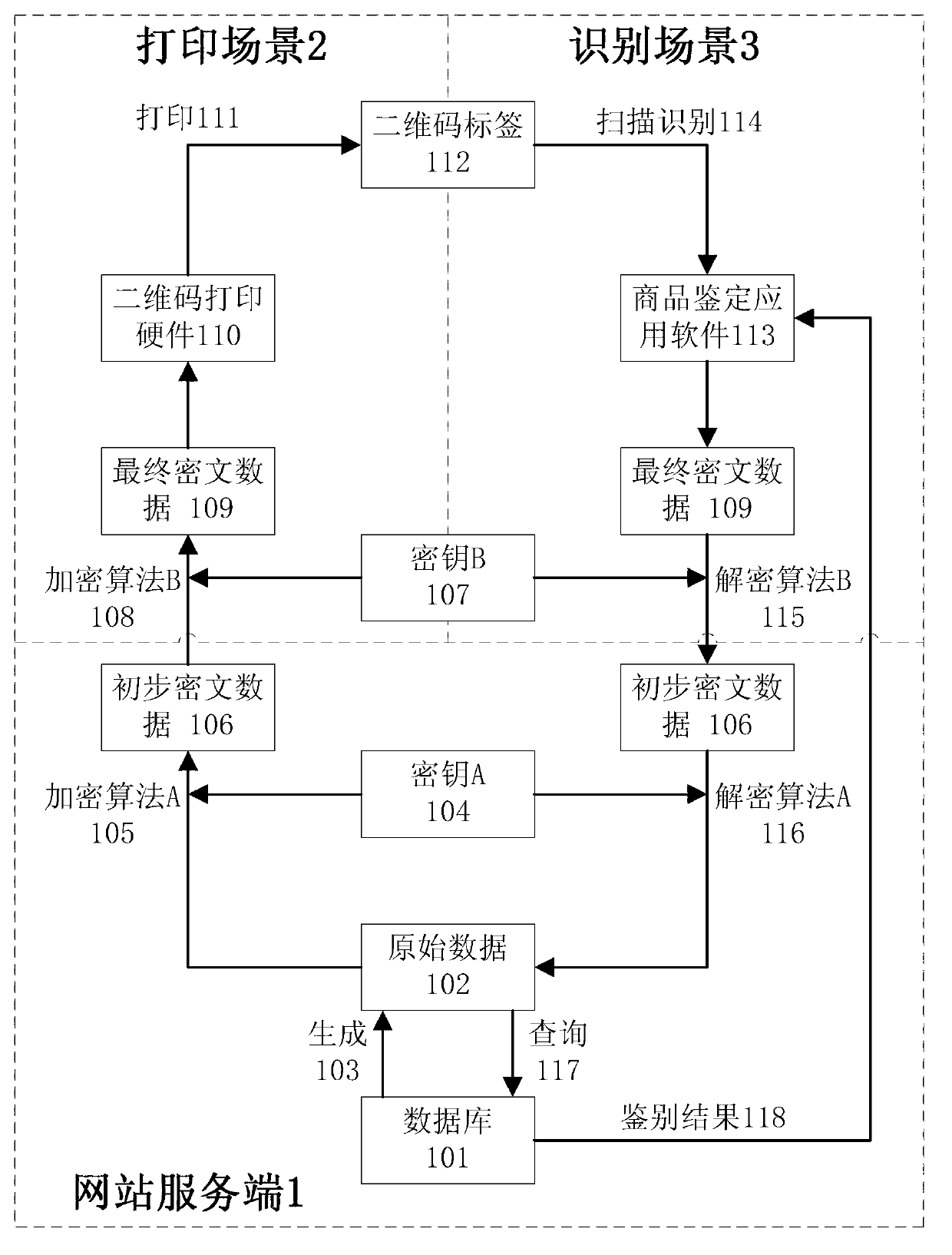

Two-dimensional code network anti-fake method with secondary encryption characteristics

The invention discloses a two-dimensional code network anti-fake method with secondary encryption characteristics. A website server, a printing scene and an identification scene are used in the two-dimensional code network anti-fake method. The website server is connected with the printing scene and the identification scene through internet or a wireless network, the website server is connected with the printing scene through the internet or the wireless network to form a printing stage, and the website server and the identification scene are connected through the internet or the wireless network to form an identification and authentication stage. The two-dimensional code network anti-fake method has customization and high security, commodity identification application software in the identification scene is a decipherment algorithm B and a secret key B embedded in particular commodities, and the customized commodity identification software has good security, effective prevents the decipherment algorithm and the secret key from being diffused and cracked, and has a good user interactive interface.

Owner:浙江乾冠信息安全研究院有限公司

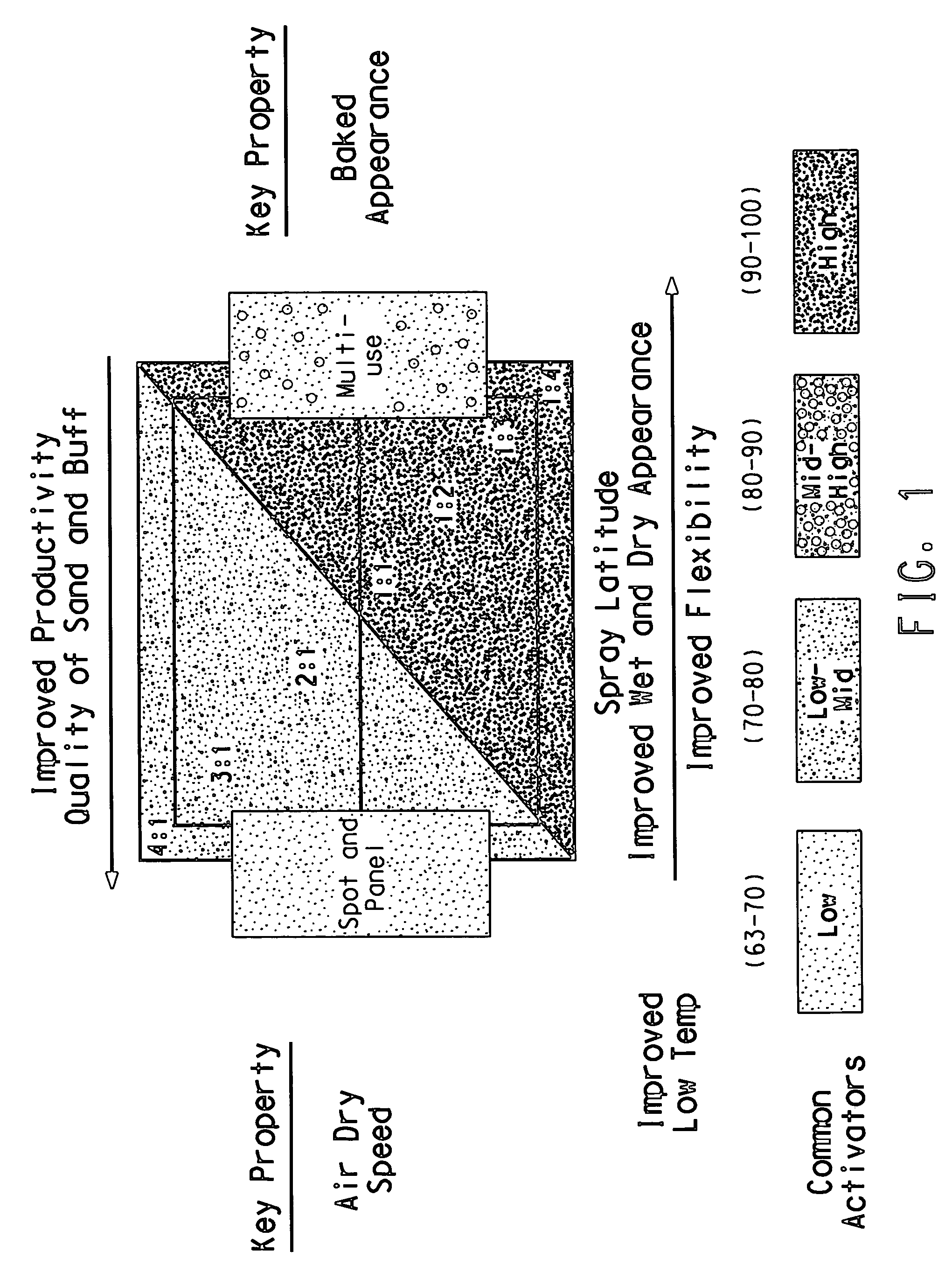

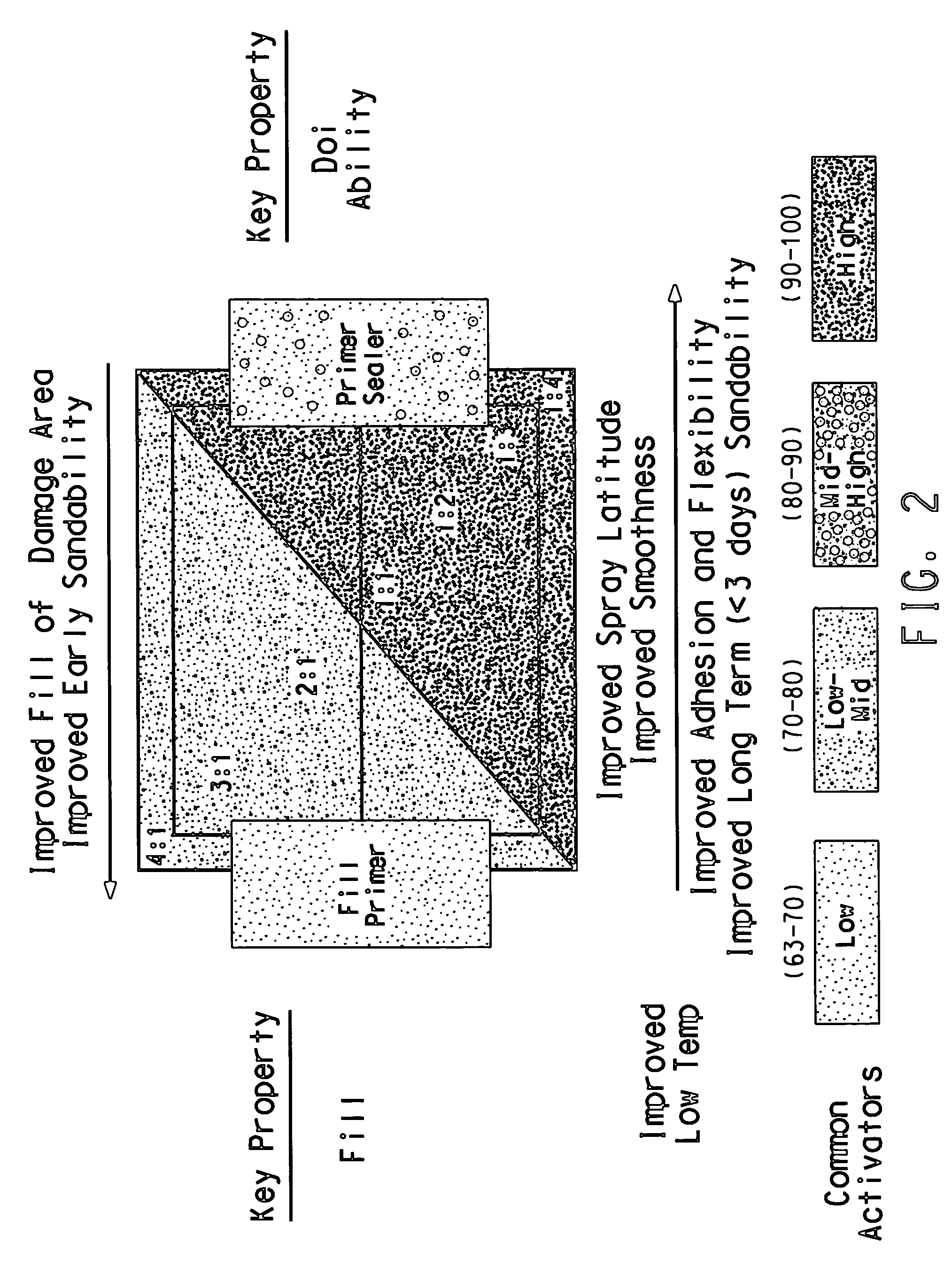

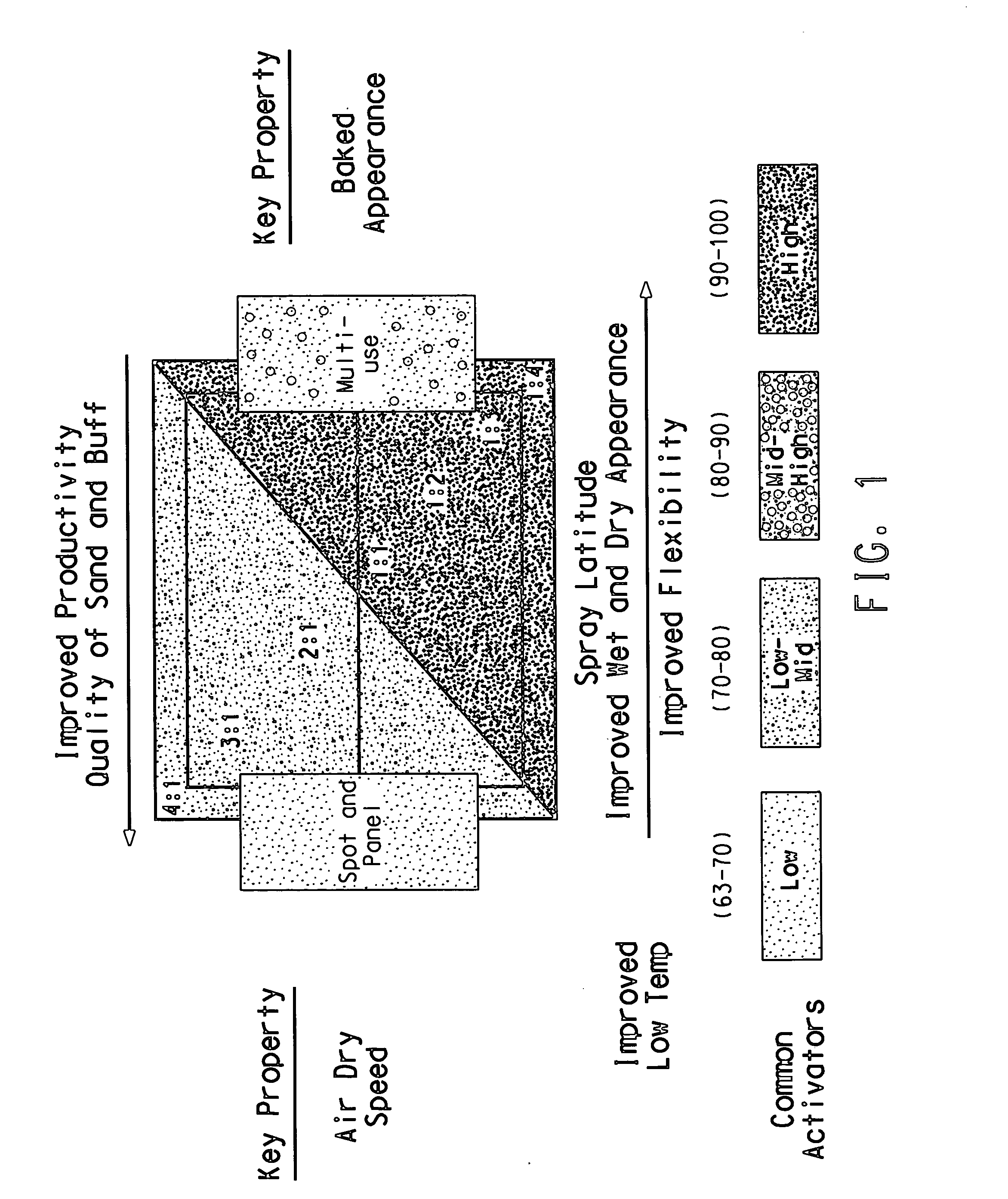

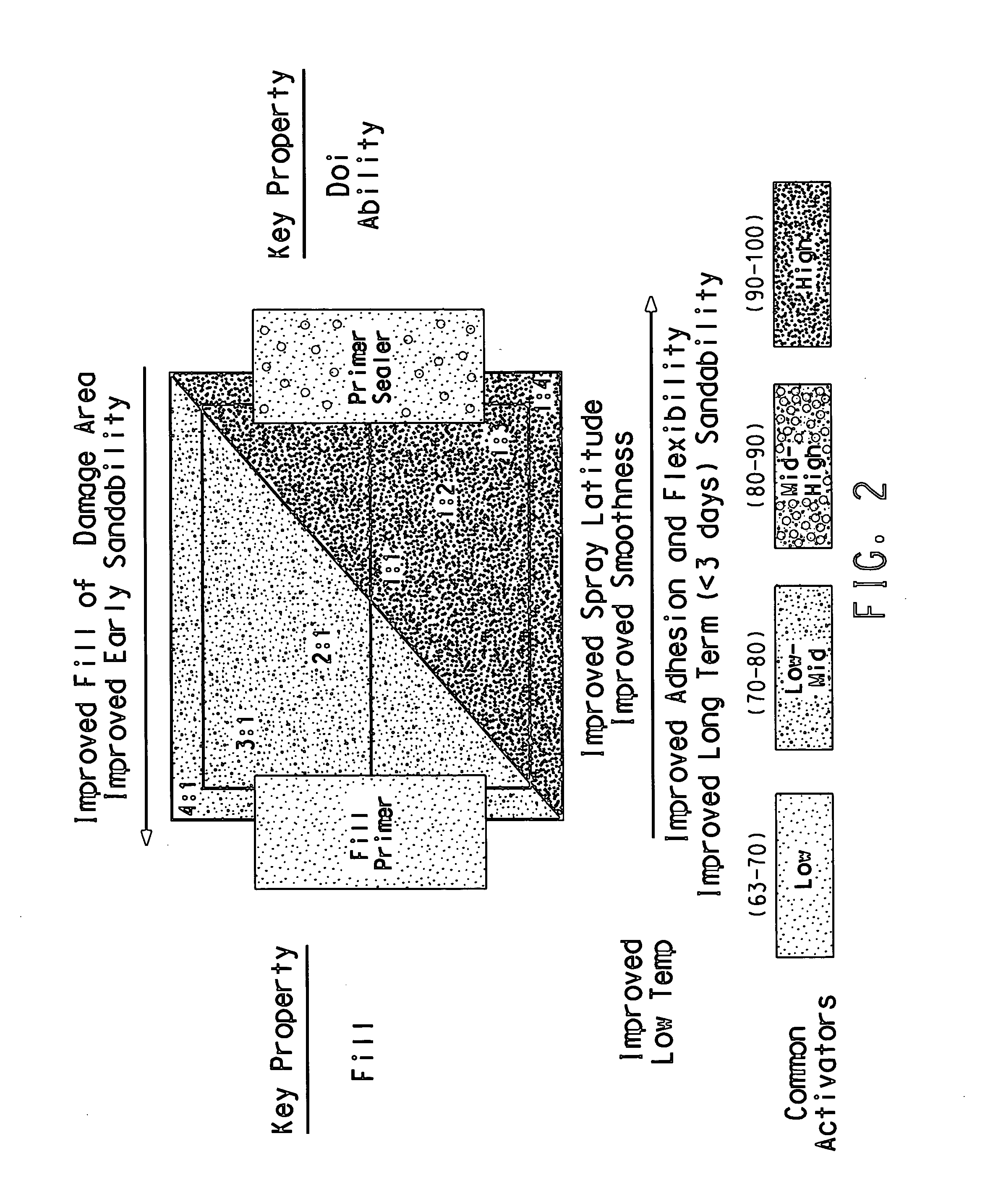

Process for producing coating compositions with customizable properties

ActiveUS7652099B2Achieve correctionProper propertiesPolyurea/polyurethane coatingsLiquid spraying apparatusCoatingProperty a

A process for making coating compositions with adjustable properties by blending two or more coating compositions of distinctly different attributes to achieve custom properties. The coating compositions formed herein are particularly useful in automotive refinish applications where customized properties are desired depending on the needs of the job.

Owner:AXALTA COATING SYST IP CO LLC

Universal 3D printing nano electrode slurry and preparation method thereof

ActiveCN110752354AExtrude evenlyEvenly dispersedCell electrodesSecondary cellsNanotechnologyElectrically conductive

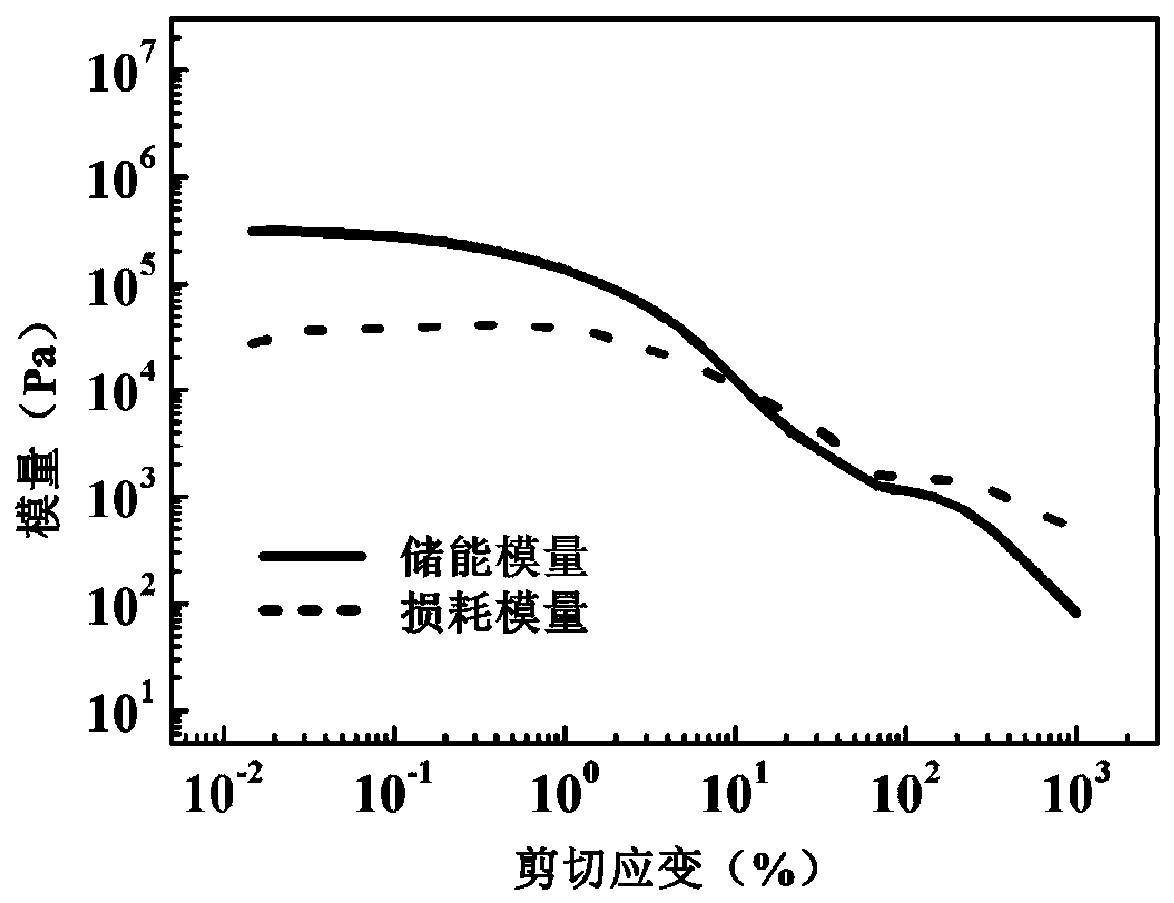

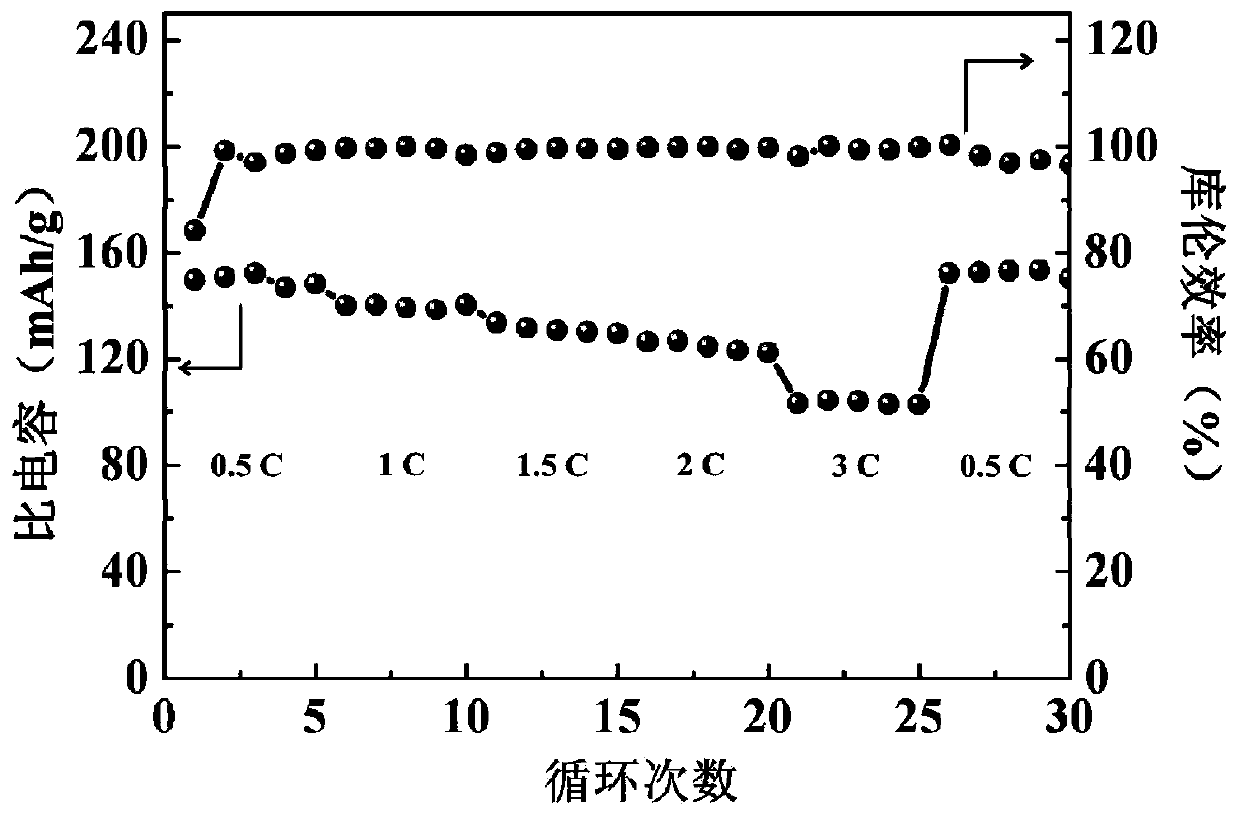

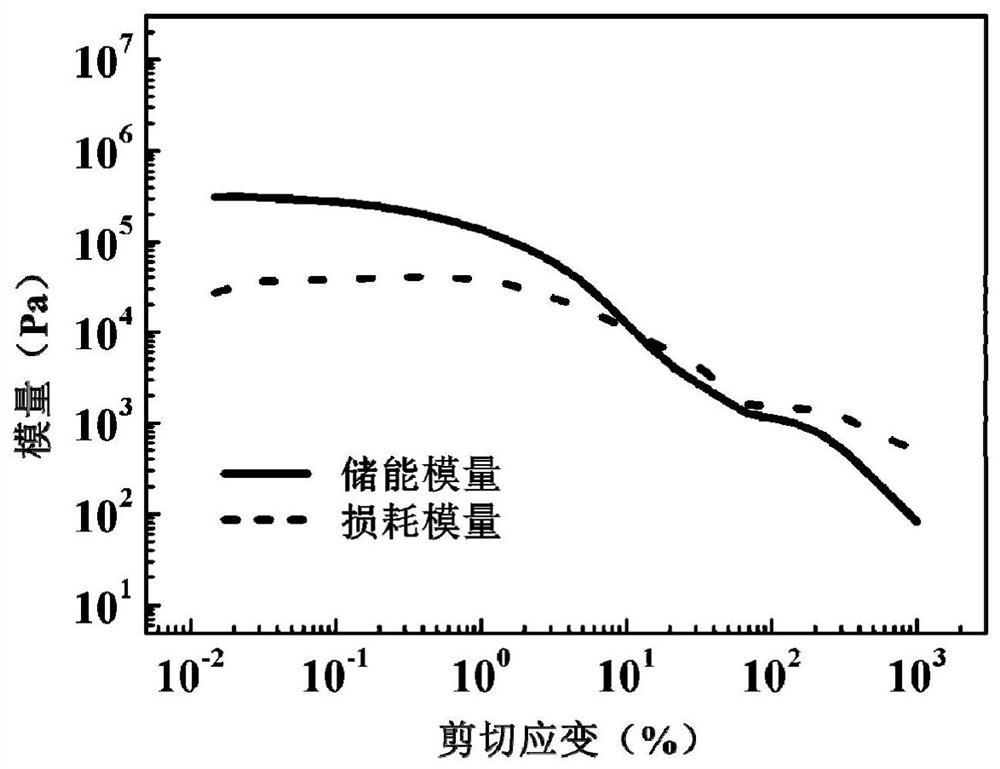

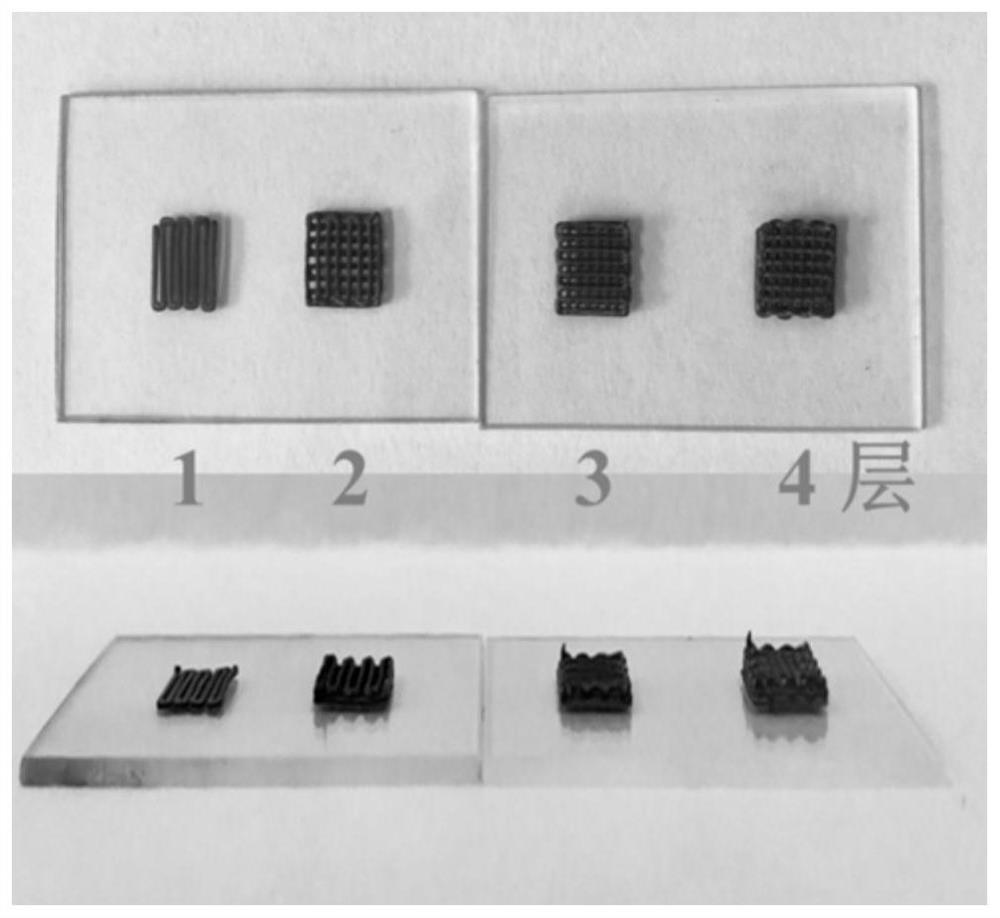

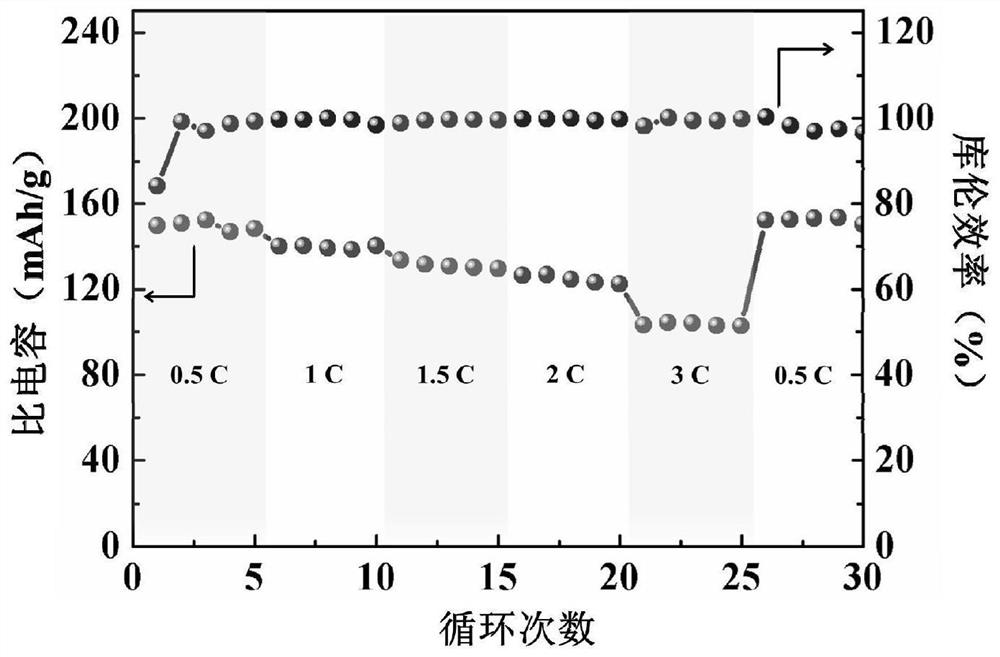

The invention discloses universal 3D printing nano electrode slurry. The universal 3D printing nano electrode slurry is prepared from the following components: a nano electrode active material, a conductive agent, a binding agent and a dispersant, wherein the weight ratio of the nano electrode active material to the conductive agent to the binding agent is (5 to 7) to (2 to 4) to 1; the ratio of the volume of the dispersant to the total weight of the nano electrode active material, the conductive agent and the binding agent is (2 to 5 mL) to 1 g. The invention further provides a preparation method of the universal 3D printing nano electrode slurry. The universal 3D printing nano electrode slurry disclosed by the invention has the beneficial effects that the rheological property and the material dispersity of the 3D printing nano electrode slurry are improved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

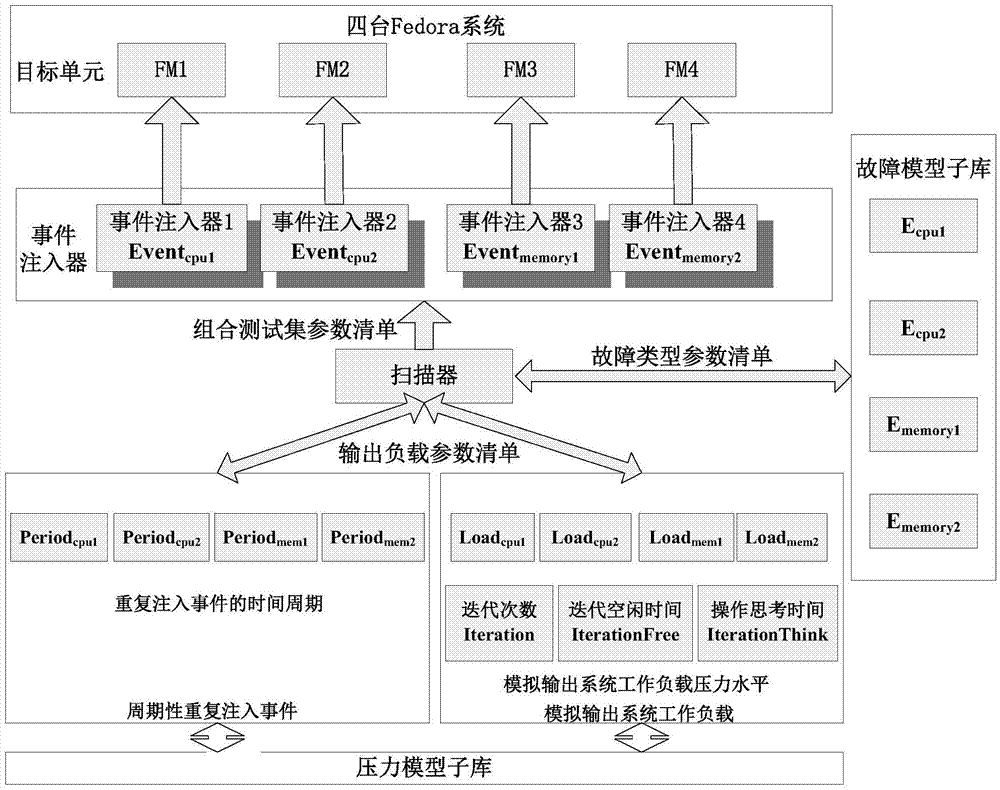

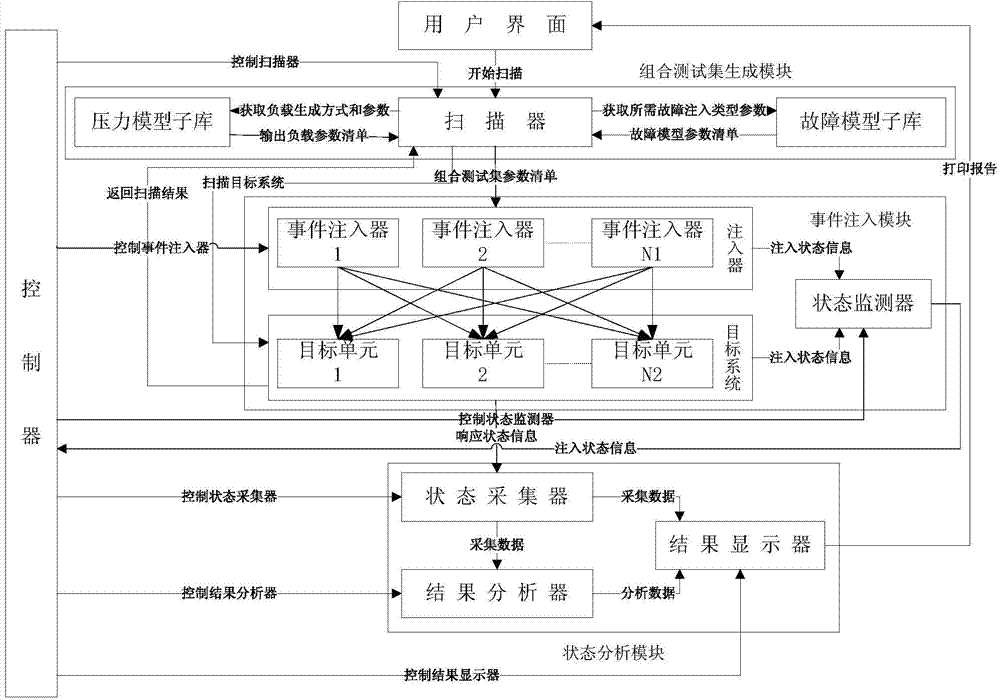

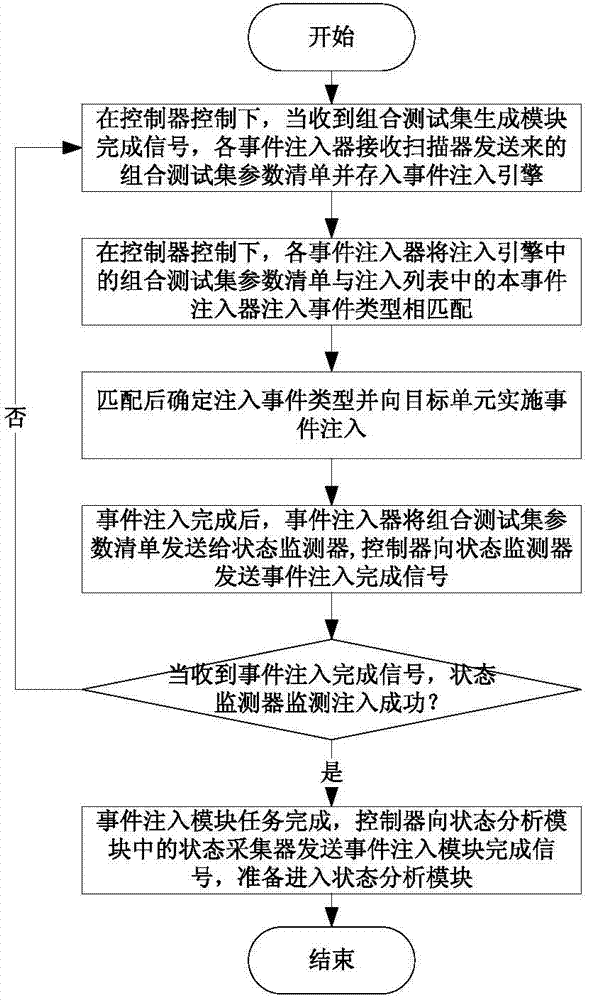

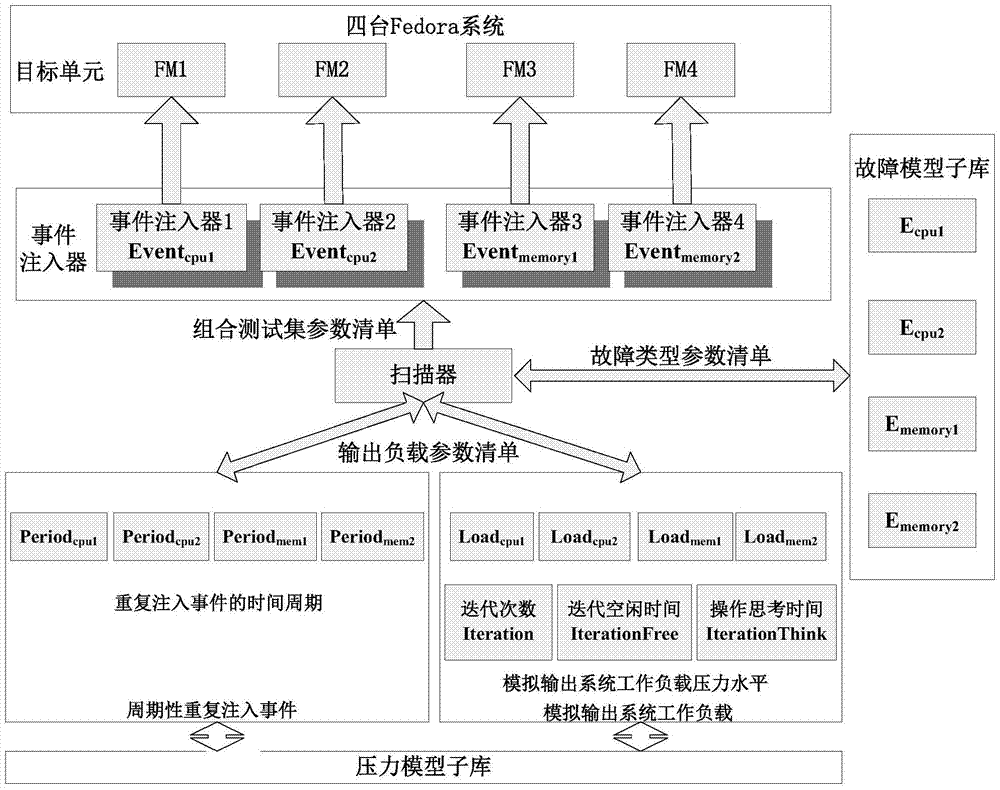

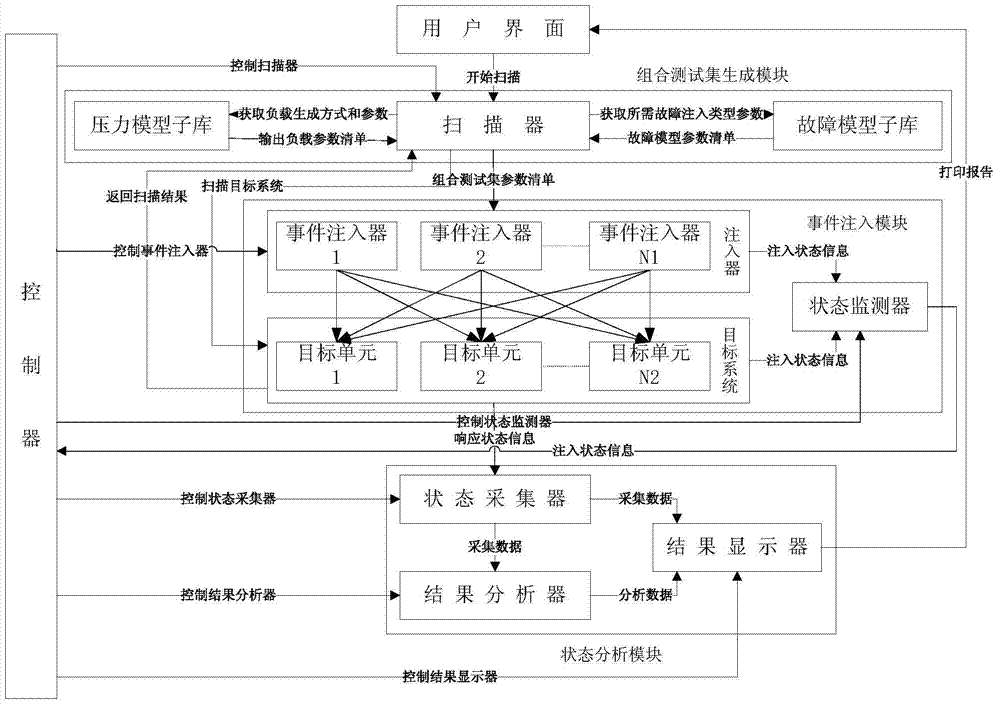

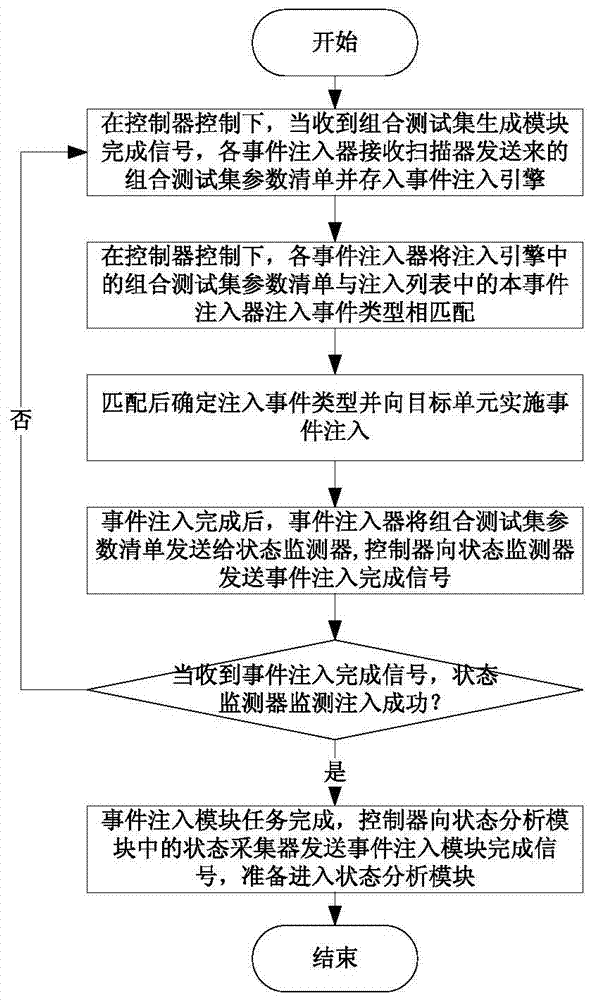

Distributed event injection device based on combined test set

ActiveCN103944778AEfficient Event InjectionWide range of applicationsFault responseData switching networksCombined testResource consumption

The invention relates to a distributed event injection device based on a combined test set for computer tolerant systems. The distributed event injection device comprises a controller, a combined test set generation module, an event injection module and a status analysis module. According to the distributed event injection device, in the event injection technology, the distributed design structure generally adopted for existing computer systems is fully considered, the problems of enabling different types of faults and different magnitudes of loads to be suitable for being injected into different target units are fully considered, the distributed event injection method based on the combined test set is introduced, and more flexible and more efficient event injection is achieved. Thus, the distributed event injection device has the advantages of being wide in application range, low in resource consumption, flexible in event injection method, high in pertinence, capable of being customized, and the like. The distributed event injection device can be widely applied to distributed tolerant systems especially usability evaluation on special tolerant systems.

Owner:HARBIN ENG UNIV

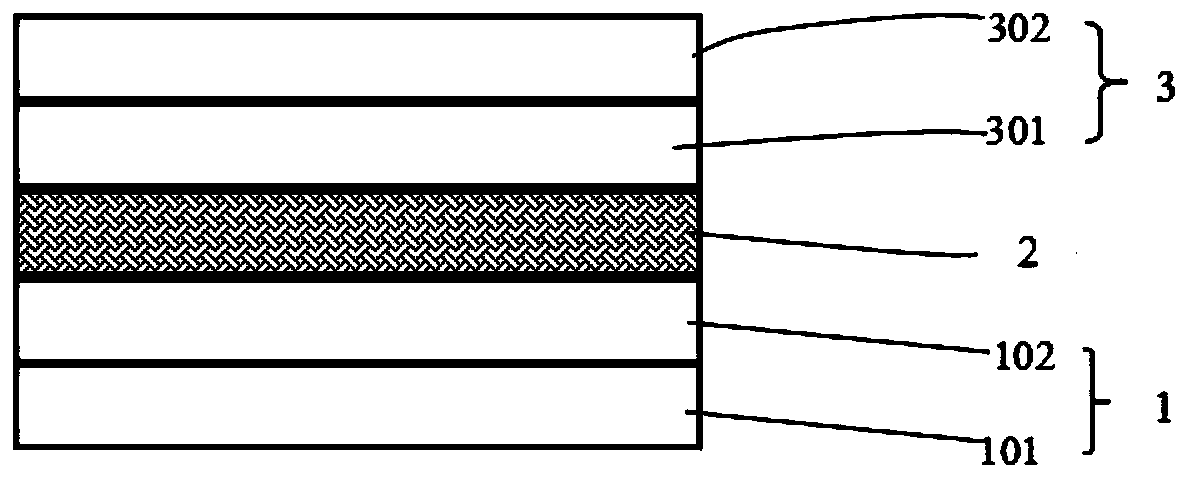

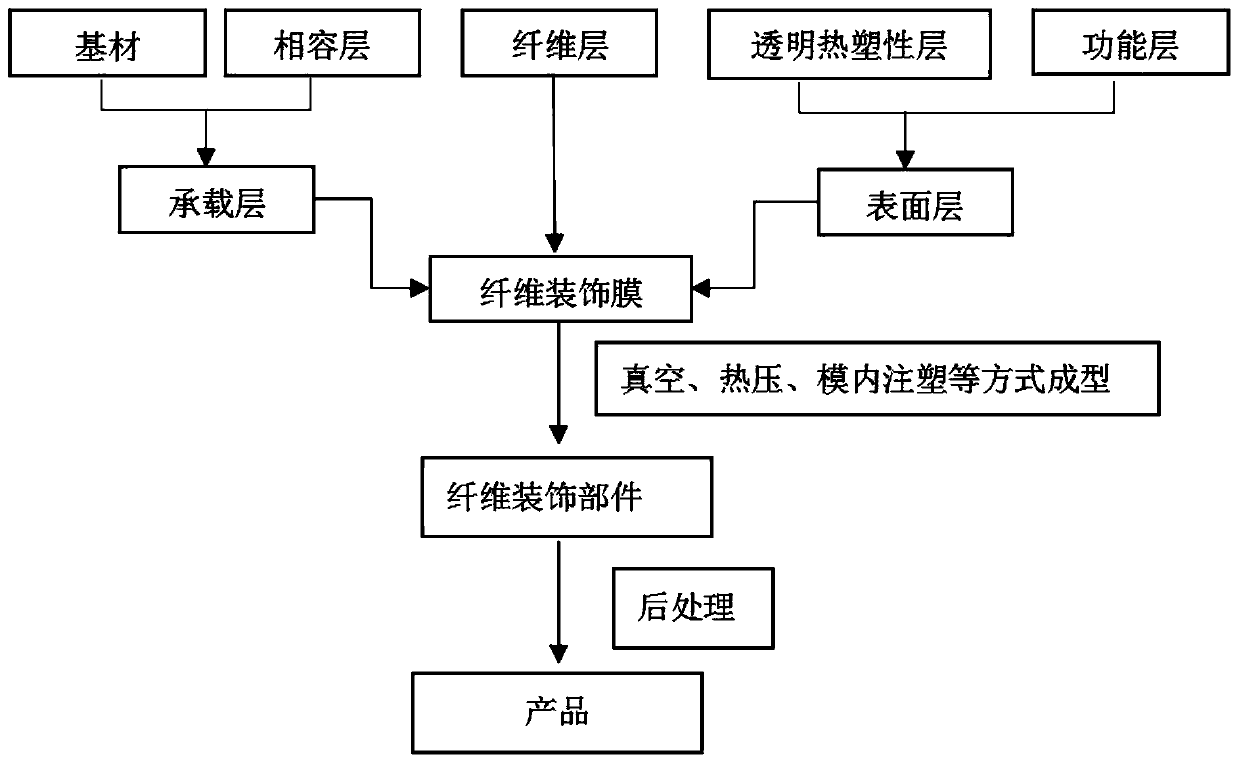

Fiber decorative film and preparation method and product thereof

PendingCN109878186AVOC-freeGood mechanical propertiesLayered productsFlat articlesFiberPolymer science

The invention belongs to the technical field of decorative materials, and particularly relates to a fiber decorative film and a preparation method and product thereof. The fiber decorative film is free of VOC, excellent in mechanical property, high in specific strength and specific rigidity, low in weight and good in surface quality; the fiber decorative film has good thermoplasticity, the productwith the complex geometrical shape can be prepared, no new mold needs to be developed, forming is easy and convenient, the speed is high, and the high yield and the short processing period can be achieved; the product prepared from the fiber decorative film is diversified in texture, has design flexibility and customization, has a beautiful appearance effect and is a feast for the eyes; and the product prepared from the fiber decorative film can be recycled, and thus waste and environment pollution are reduced to the utmost extent.

Owner:SHENZHEN MOMA CLEVER CHEM TECH CO LTD

Process for producing coating compositions with customizable properties

A process for making coating compositions with adjustable properties by blending two or more coating compositions of distinctly different attributes to achieve custom properties. The coating compositions formed herein are particularly useful in automotive refinish applications where customized properties are desired depending on the needs of the job.

Owner:AXALTA COATING SYST IP CO LLC

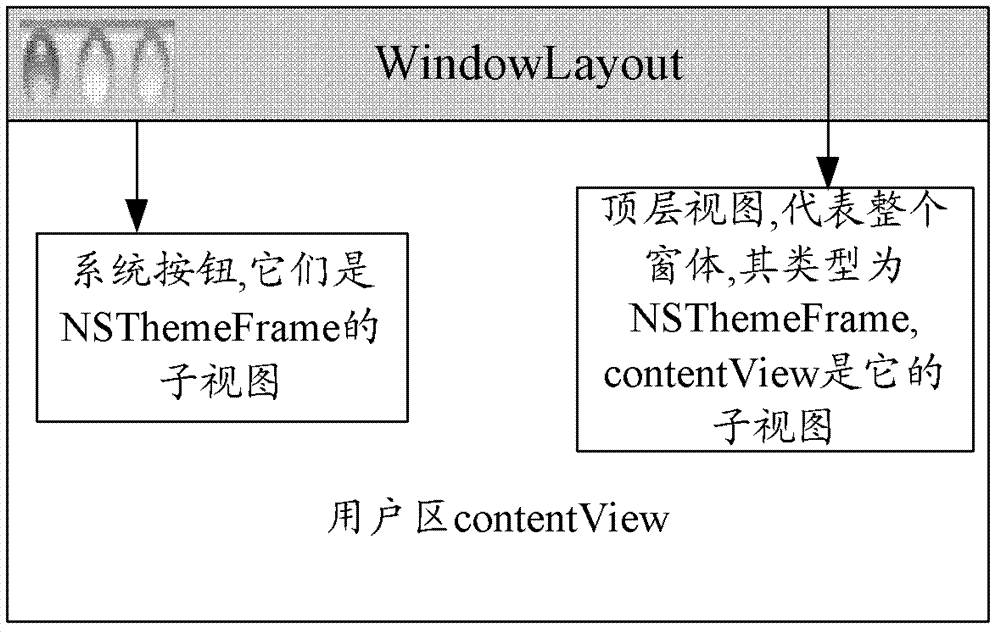

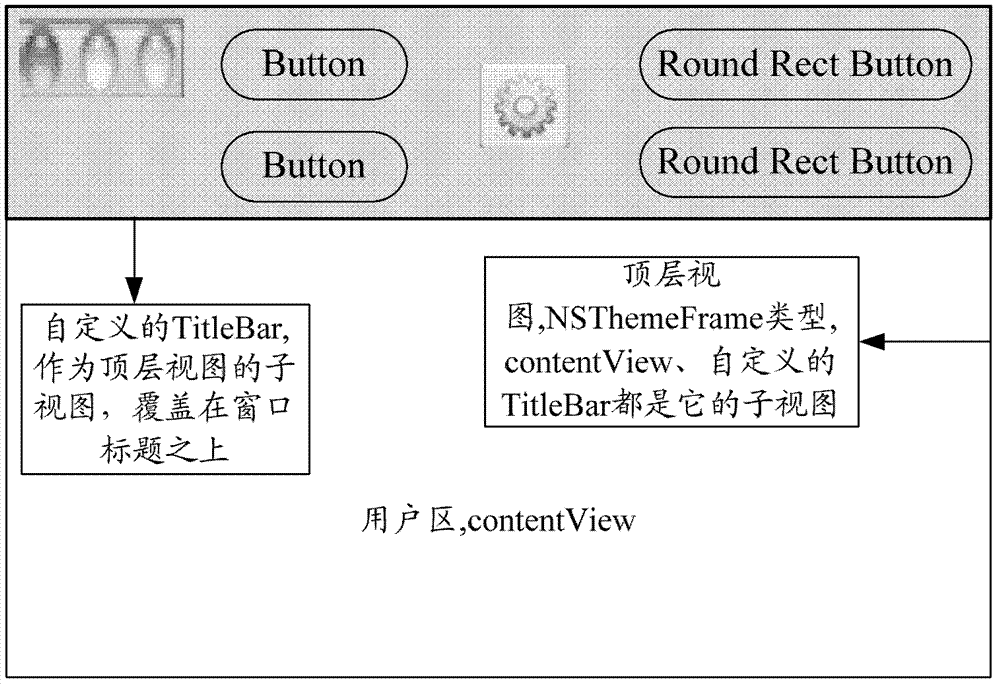

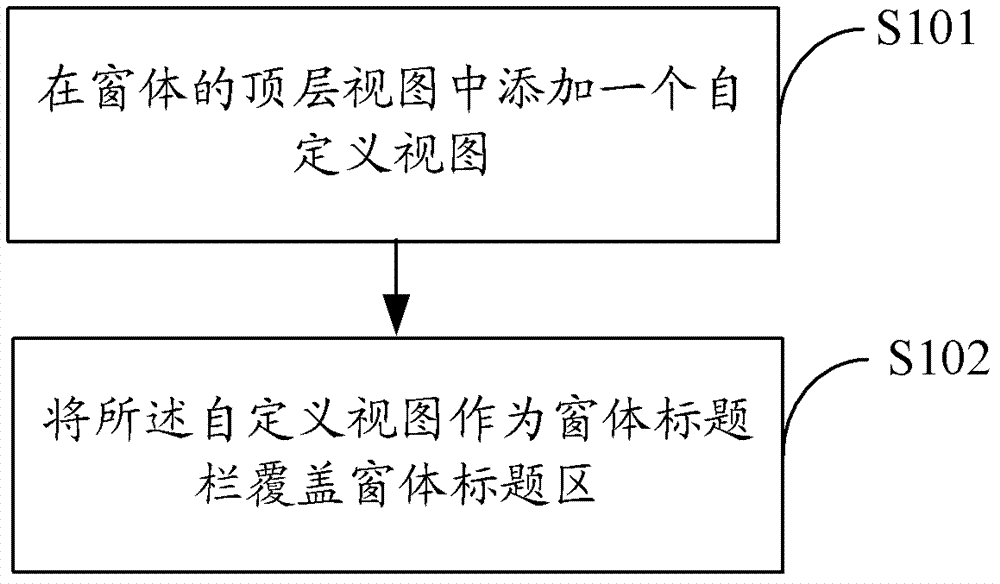

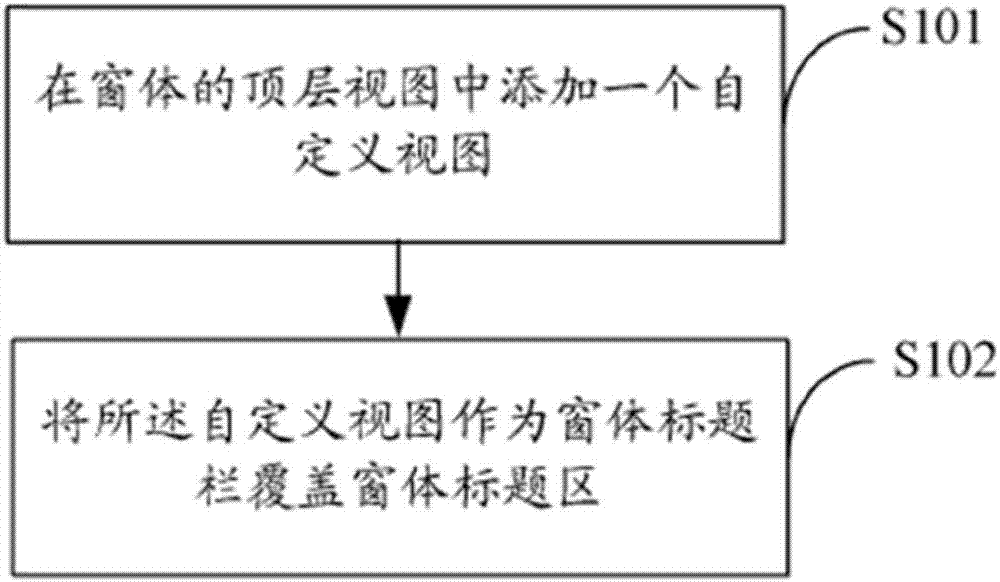

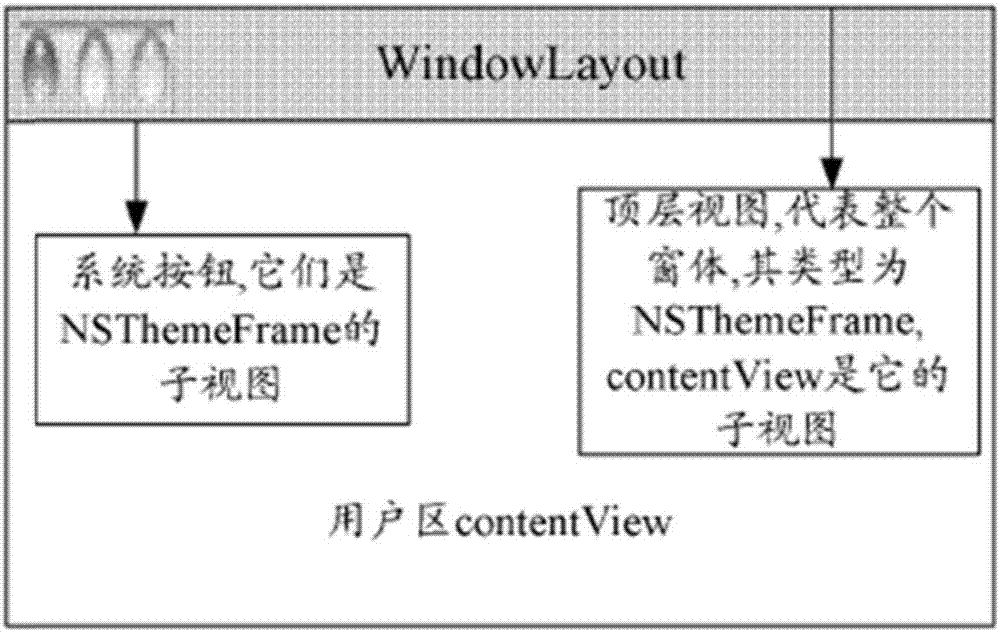

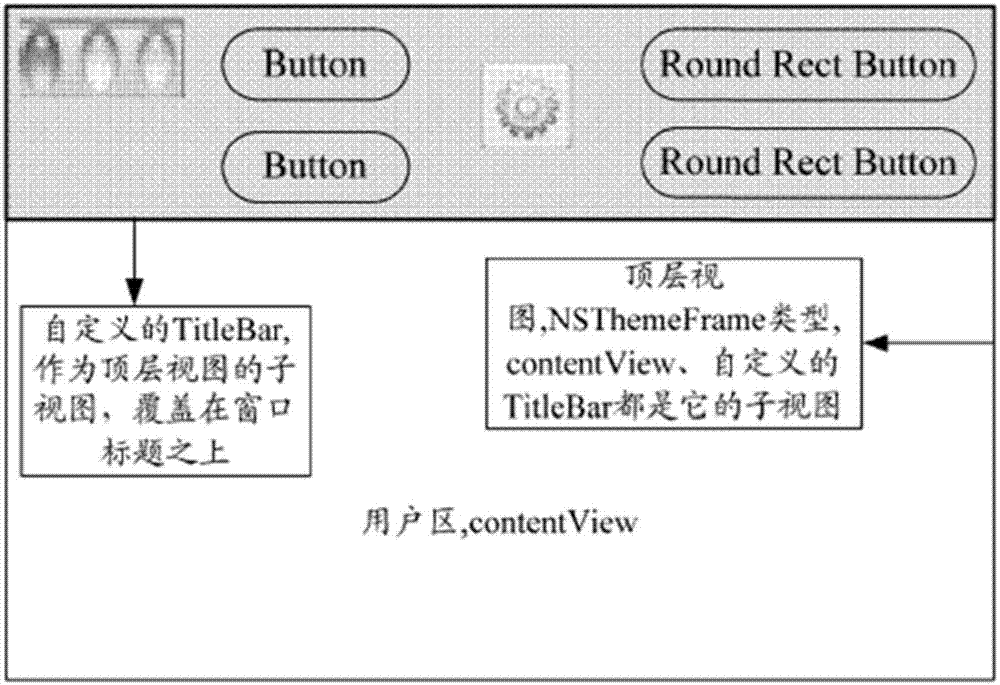

Window title bar creating method and device

ActiveCN103246505ACustomizableHave operational characteristicsSpecific program execution arrangementsThe InternetDatabase

The invention is applicable to the technical field of IOS (internet work operating system) and provides window title bar creating method and device. The method includes: adding a user-defined view in a top view of a window, and utilizing the user-defined view as a window title bar to cover a window title band. The window title bar creating method and device can meet the requirements of user definition of the window title bar in MAC (macintosh) operating system and display of window titles in Dock and Expose.

Owner:TENCENT TECH (SHENZHEN) CO LTD

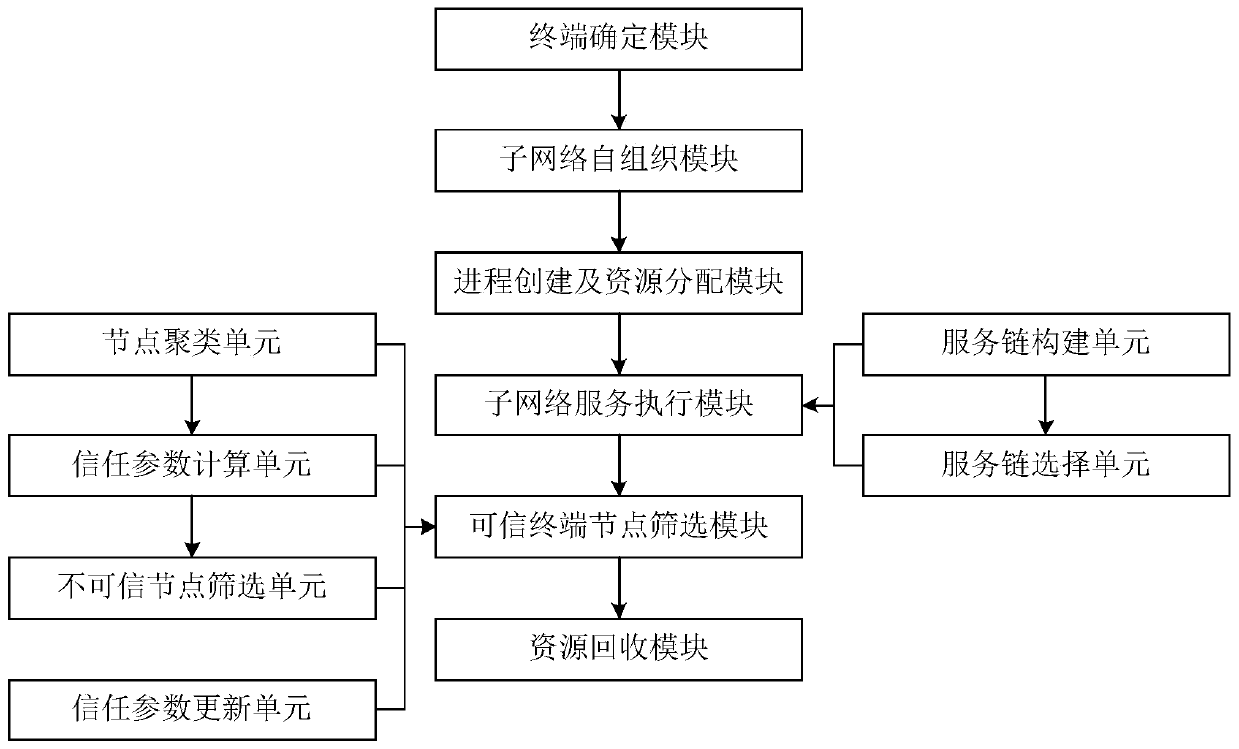

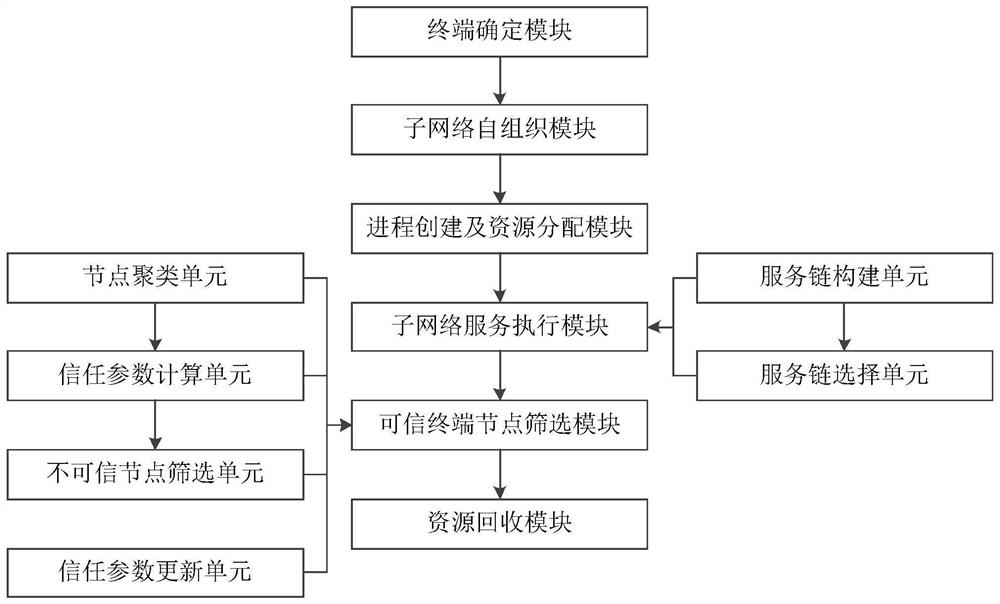

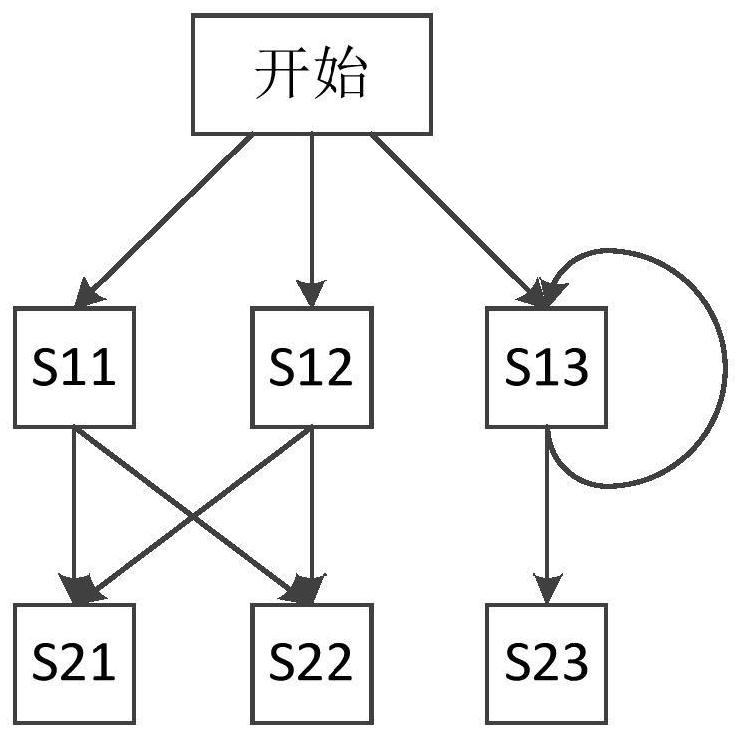

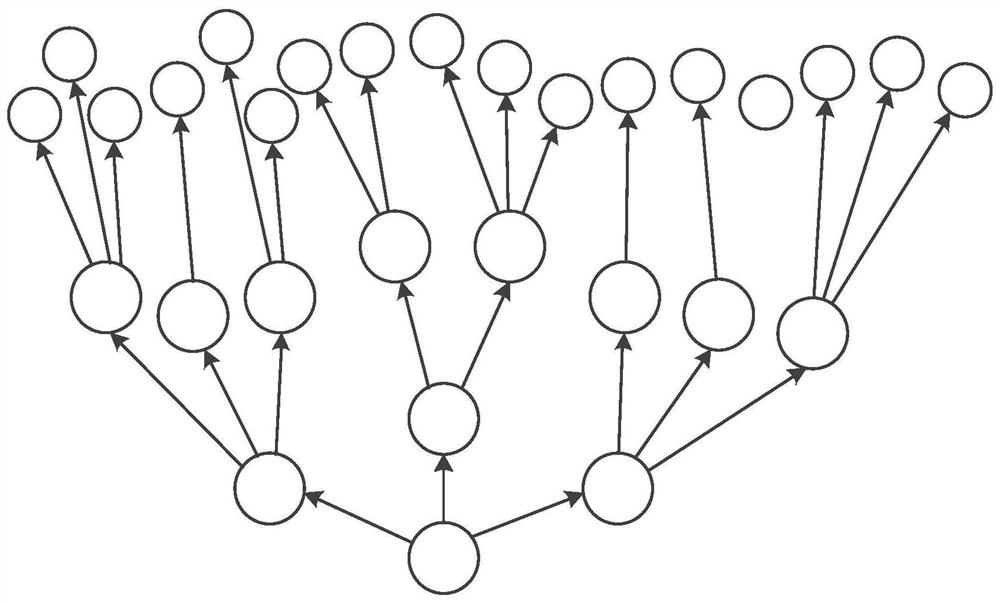

Function aggregation self-organizing system and method of intelligent internet of things

ActiveCN111556090AVersatileGeneralization of network structureData switching networksResource assignmentThe Internet

The invention discloses a function aggregation self-organizing system of an intelligent internet of things. A terminal determination module is used for determining an Internet of Things terminal associated with a task according to a current to-be-executed task; a sub-network self-organizing module is used for self-organizing the determined Internet of Things terminal on a network architecture, andobtaining one or more sub-networks of the Internet of Things; a process creation and resource allocation module is used for establishing processes for the sub-networks according to corresponding function tasks of the sub-networks, allocating corresponding computing resources to the processes and independently managing and storing the sub-networks; and a resource recovery module is used for endingthe processes of the corresponding sub-networks and releasing the computing resources of the corresponding sub-networks when the function tasks are completed. According to the system, the network structure of the Internet of Things service is generalized, the functions are diversified, the customizability is achieved, the timeliness of responding to key data is improved, and the adaptability to actual demands and actual scenes is enhanced.

Owner:重庆特斯联智慧科技股份有限公司

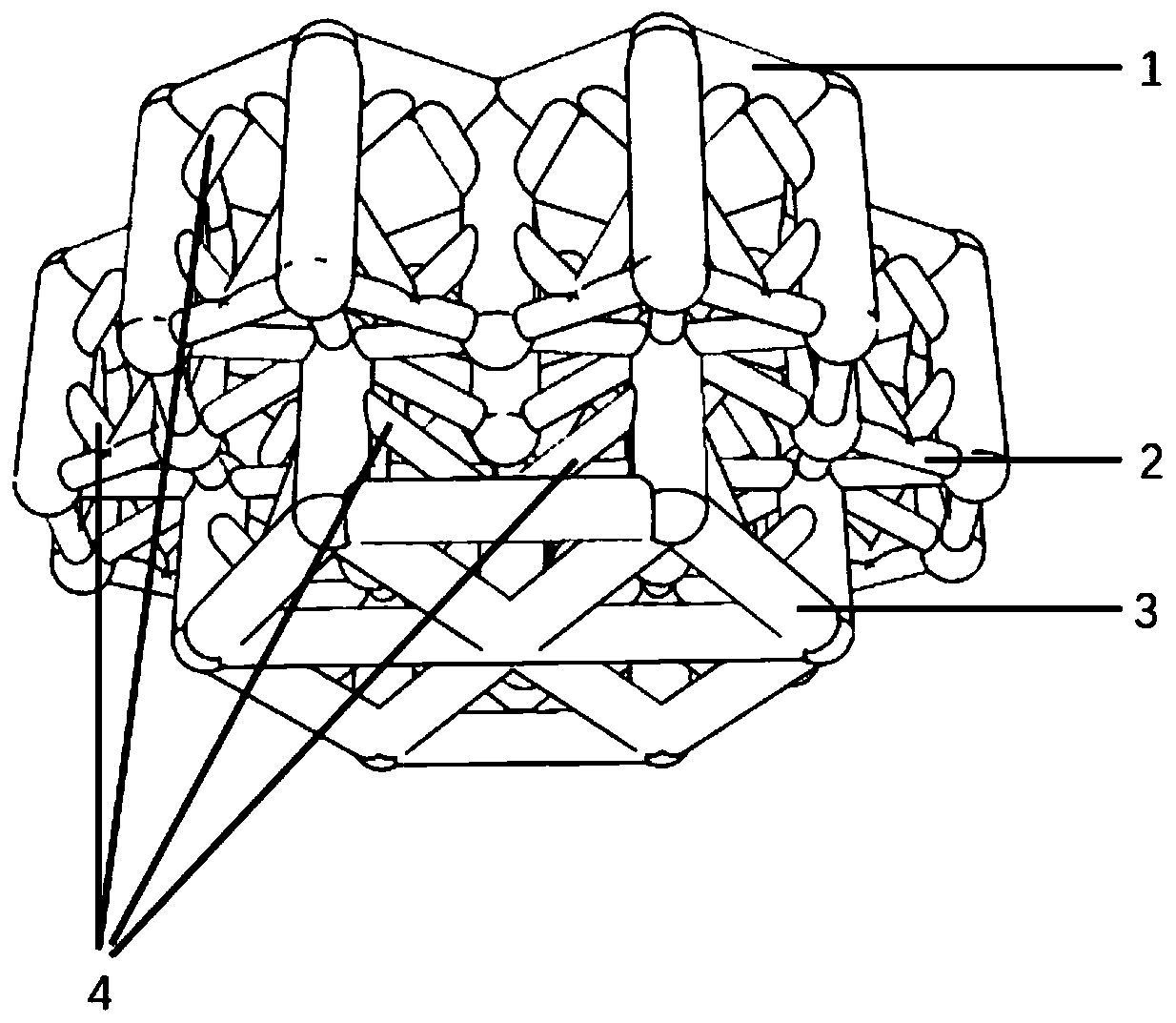

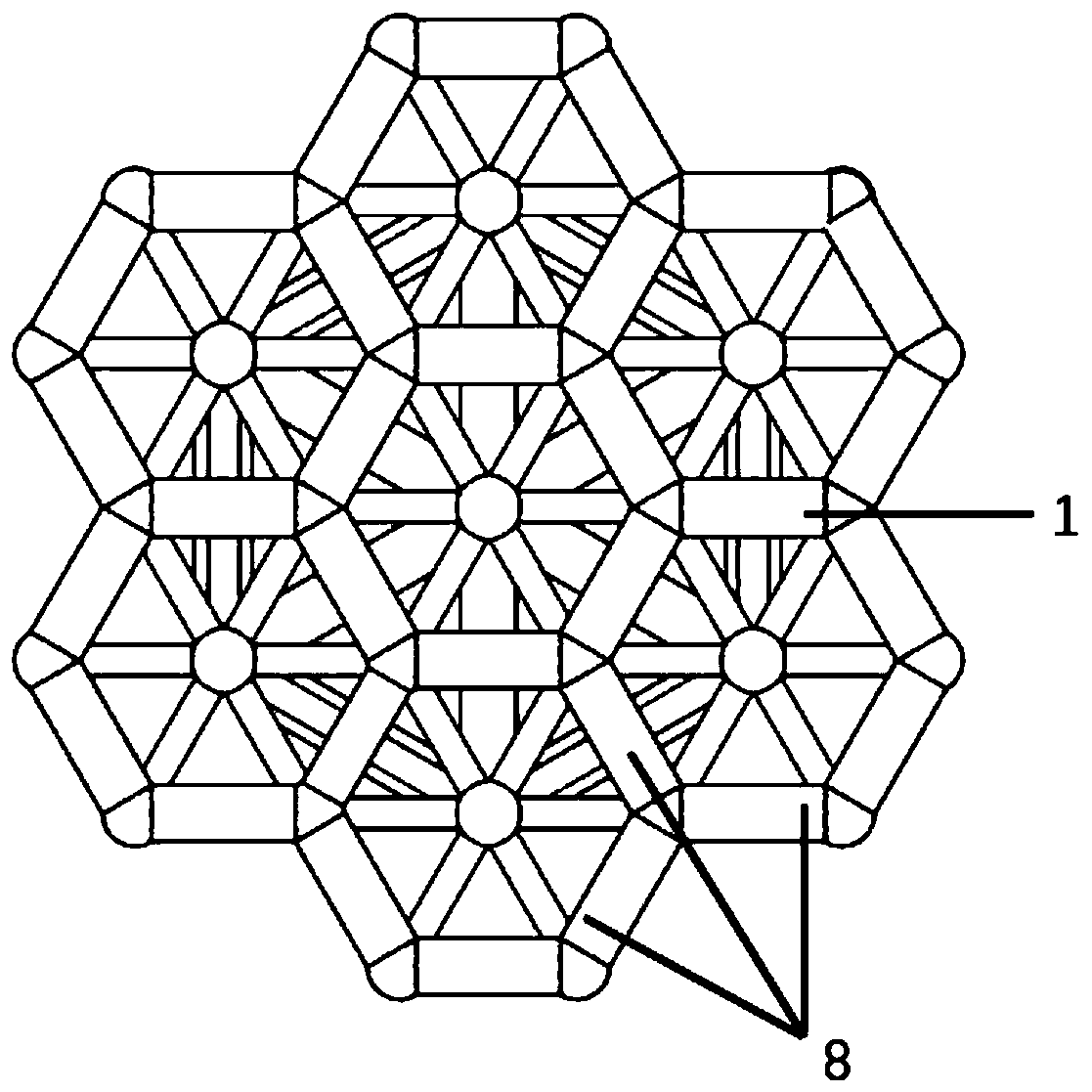

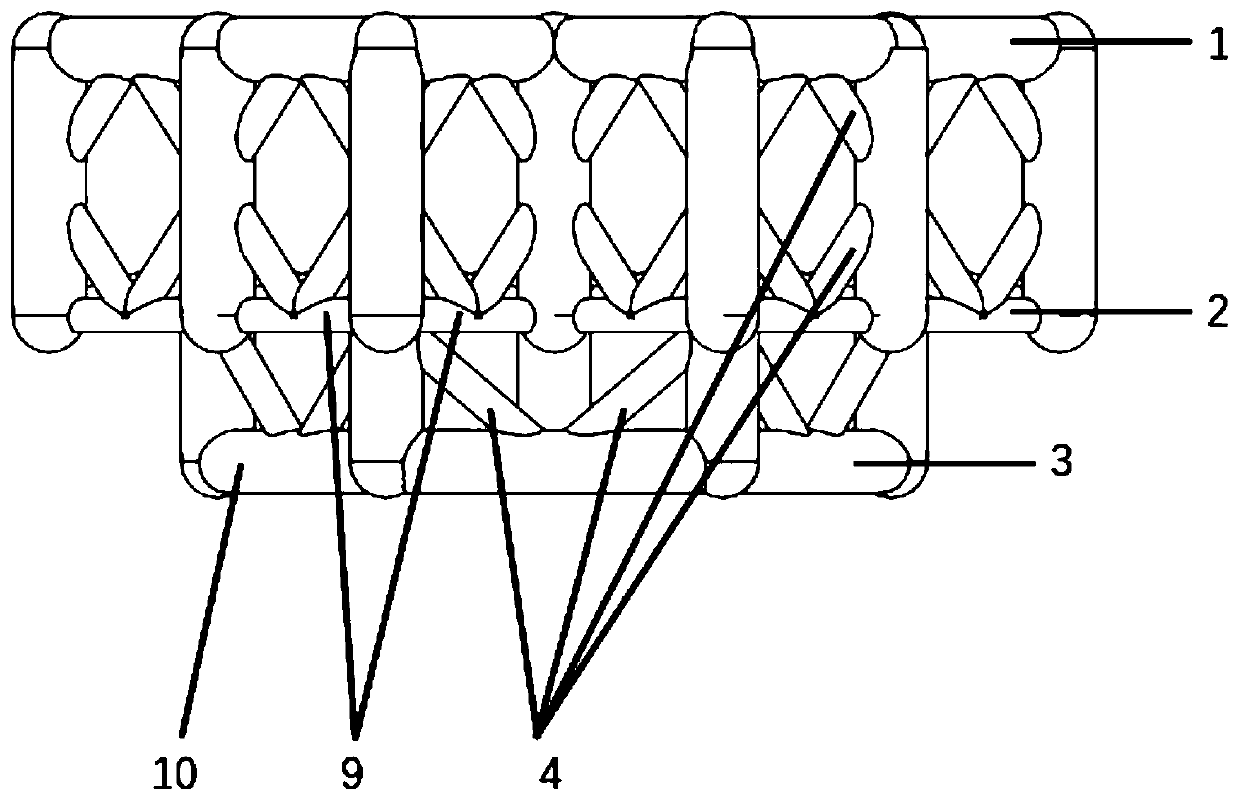

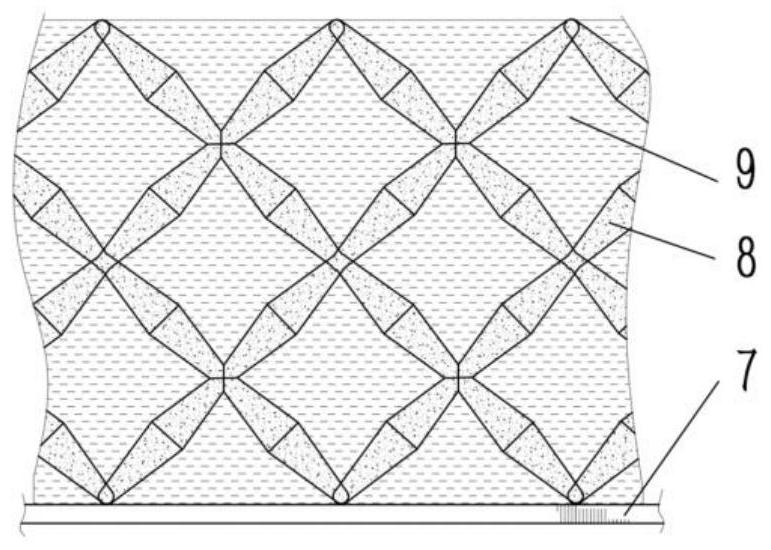

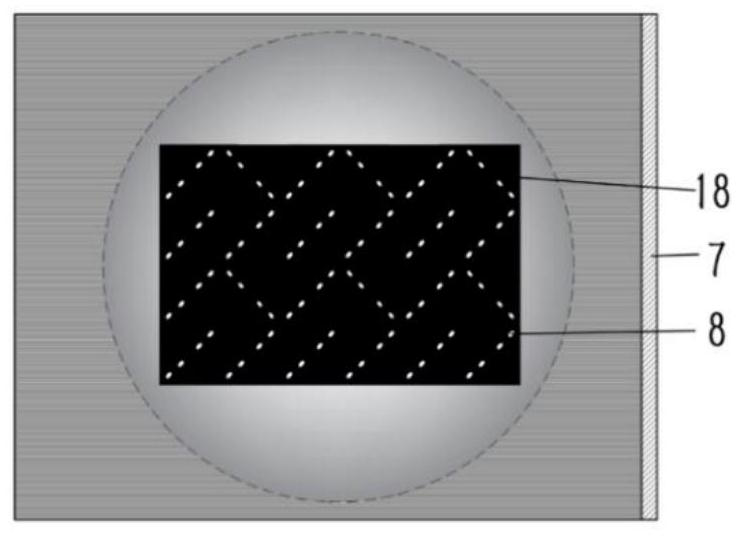

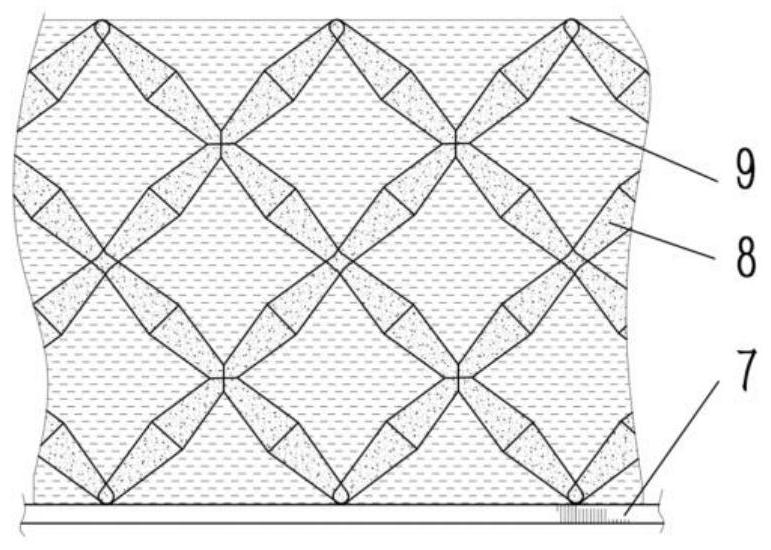

3D printed graded resilience structure and shoe sole using 3D printed graded resilience structure

The invention discloses a 3D printed graded resilience structure and a shoe sole using the 3D printed graded resilience structure. The 3D printed graded resilience structure comprises surface meshes,a plurality of 3D printed graded resilience crystal lattice units, loop edges, bottom meshes and inclined support rods, wherein each graded resilience crystal lattice unit consists of a cushioning component and a cushioning resilience part; each cushioning component forms a plane stress structure by n vertical rods, n inclined pull rods and 4n inclined support rods (n is greater than or equal to 3); and each cushioning resilience part is of a single elastic vertical post structure. Based on the foot sole pressure distribution, a 3D printed secondary rebounding structure is applied to the shoesole; through twice cushioning, impact energy generated through sports doing can be sufficiently absorbed; in addition, strong resilience force can be provided; sportsmen of different sports events and different sports features are supported to complete skills; the sportsmen are protected from sports injury; and in addition, the graded resilience structure also has the functions of comfortable andbreathable performance, customization, light weight and the like.

Owner:NANJING AMEBA ENG STRUCTURE OPTIMIZATION RES INST CO LTD

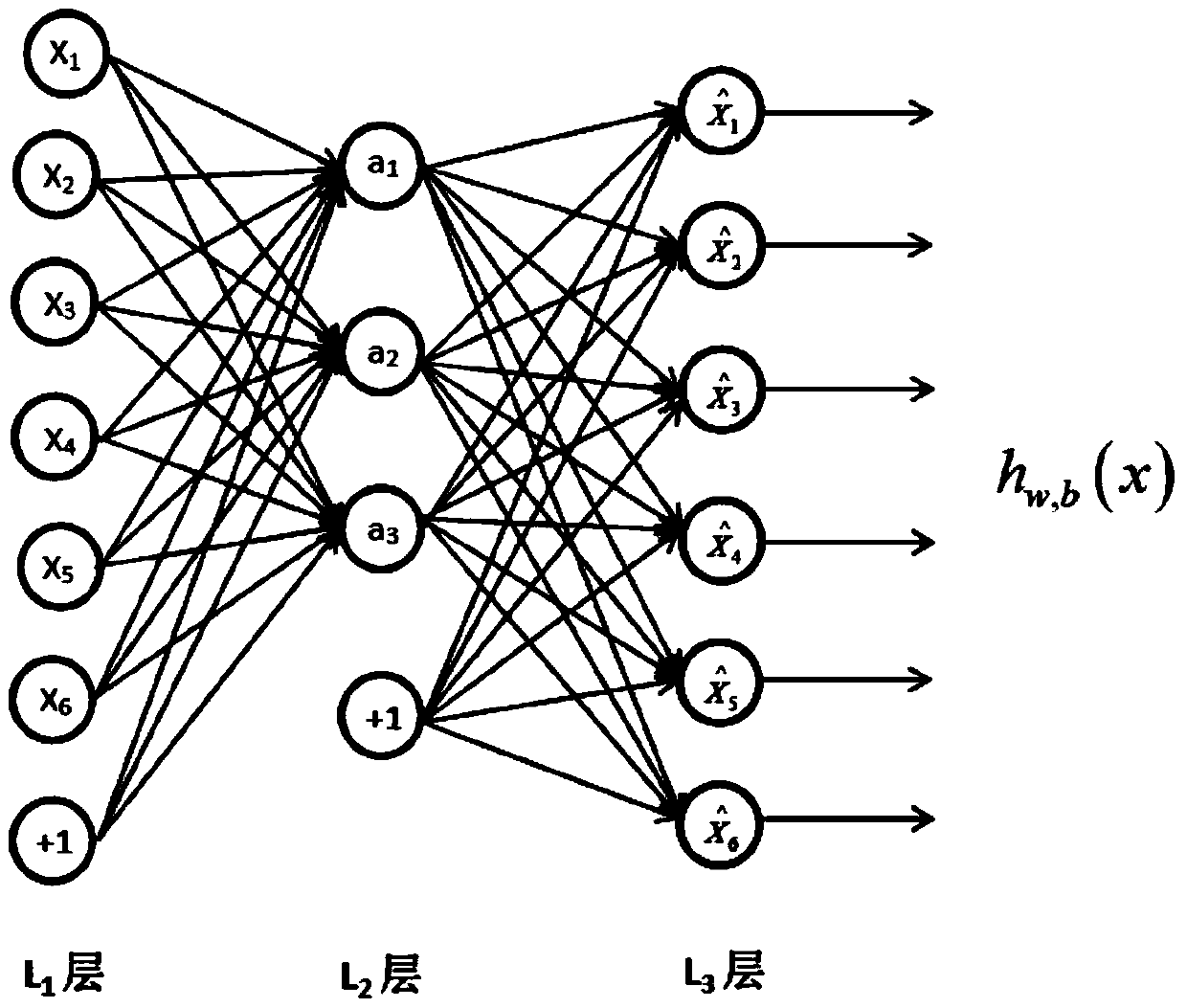

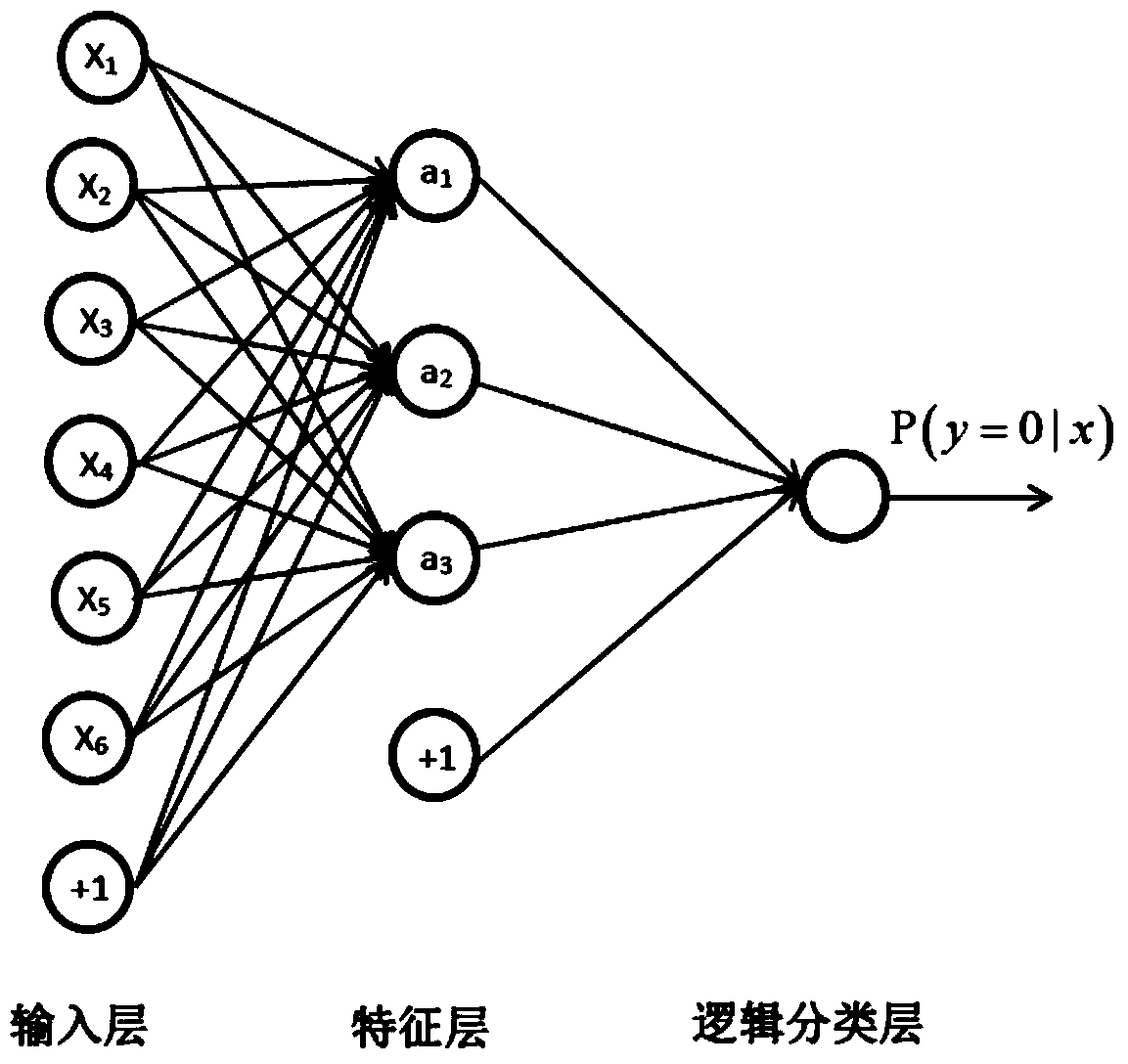

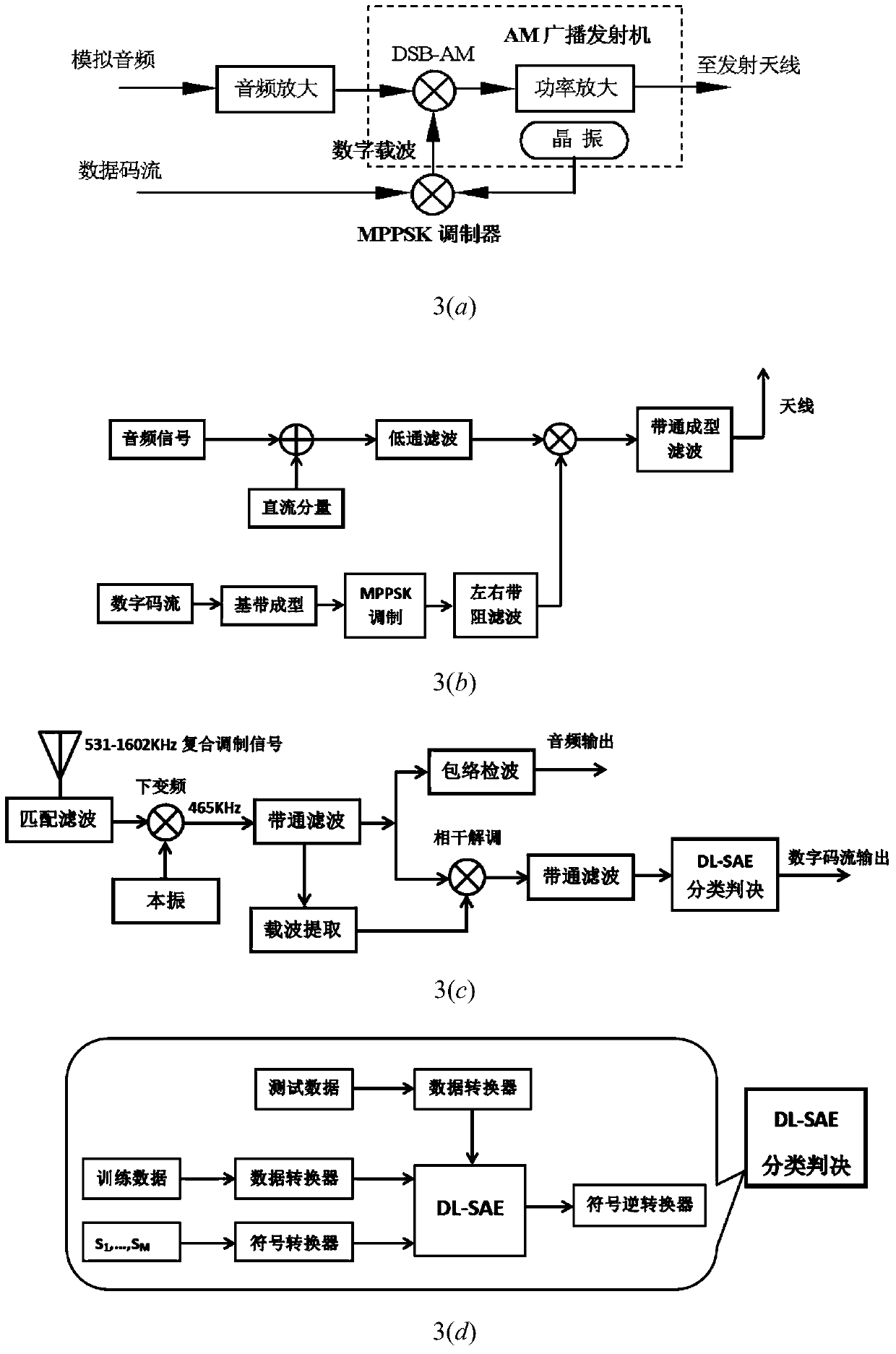

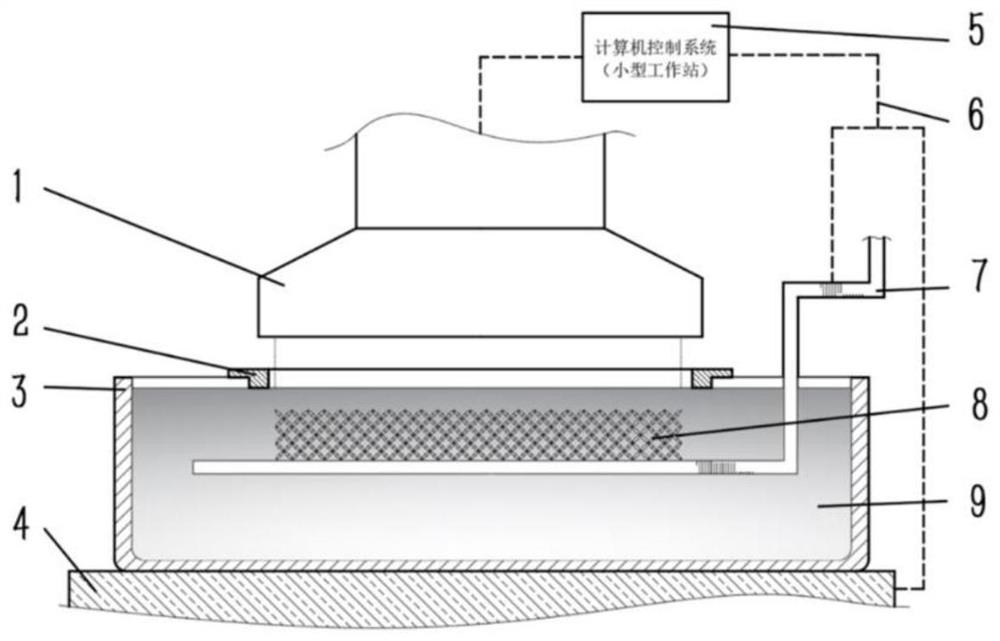

Polarity-interleaved binary offset pulse keying modulation and demodulation method

InactiveCN112804010AImprove spectral efficiencyImprove Spectrum PerformanceTransmissionBandpass filteringCarrier signal

The invention discloses a polarity-staggered binary offset pulse keying modulation and demodulation method, which comprises the following steps of: on the basis of a binary offset pulse keying modulation mode, performing pulse modulation of which the positive and negative polarities are staggered with those of a symbol '1' on a symbol '0' in an initial information modulation interval of each symbol period, so that all discrete line spectrums including carrier frequency can be greatly reduced or even completely eliminated, and the constellation point distance between symbols is greatly enlarged; and after a series of processing such as impact filtering-multiplication of coherent carrier-low-pass filtering or band-pass filtering is carried out on received signals, further performing final classification judgment on the received signals by using a deep learning (DL) algorithm based on a sparse auto-encoding (SAE) neural network, so that the received signal-to-noise ratio and the energy utilization rate are remarkably improved, and the noise suppression and anti-interference performance of the system is greatly enhanced.

Owner:苏州东奇信息科技股份有限公司

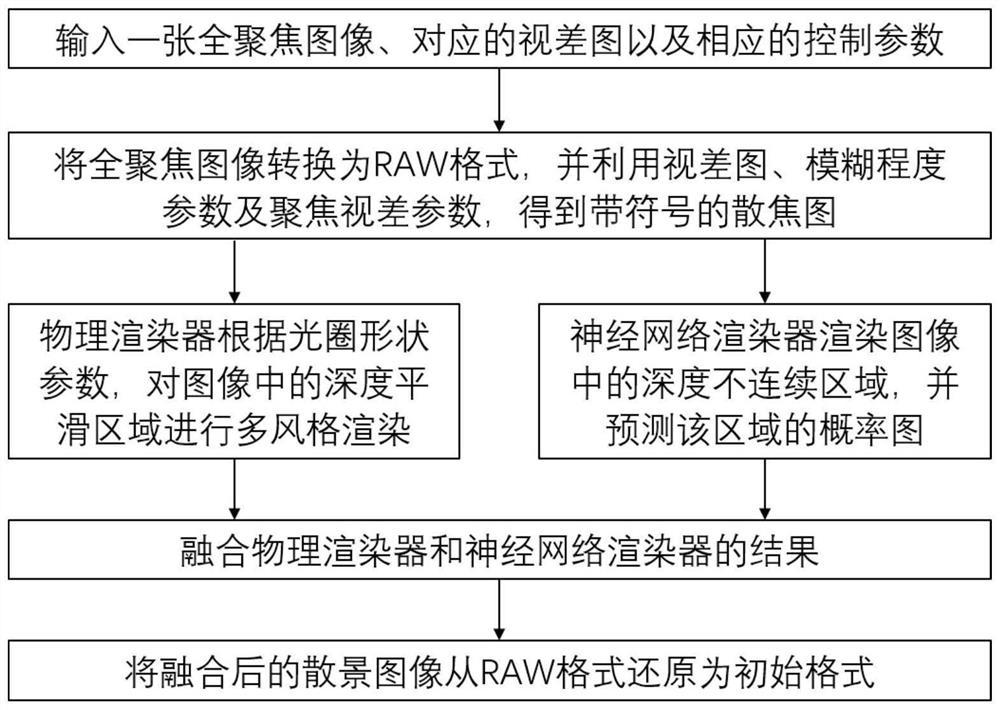

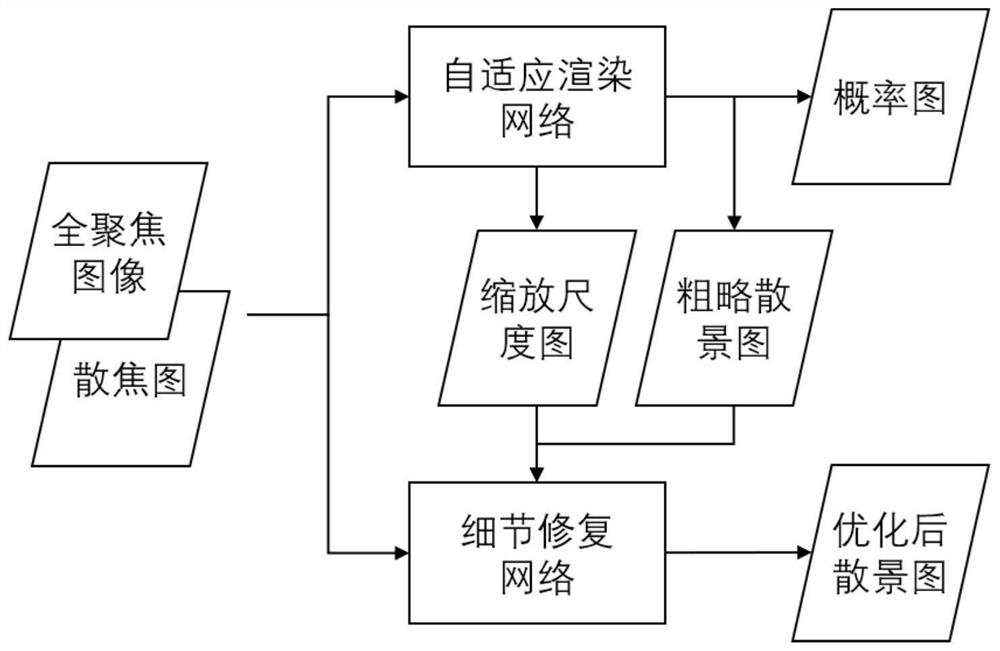

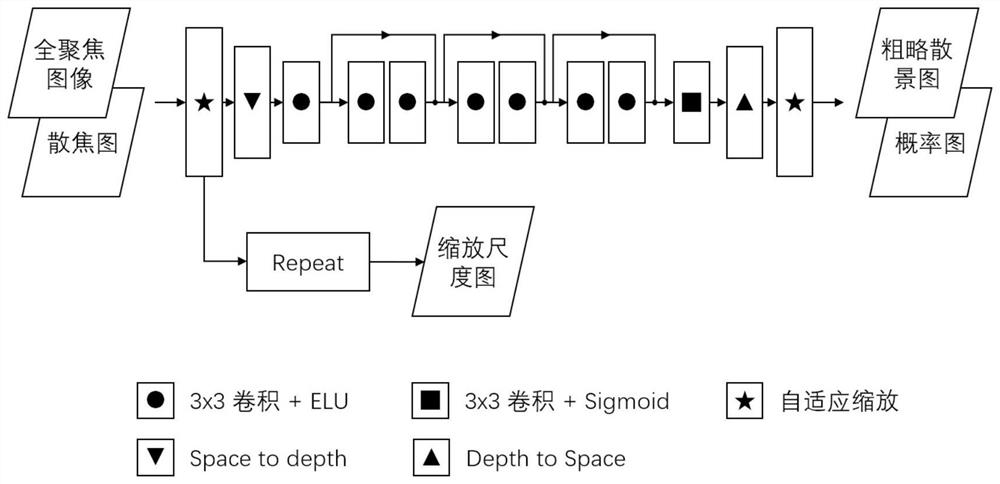

Double-flow bokeh rendering method and system based on physical optical model and neural network

PendingCN113763524AWith authenticityCustomizableCharacter and pattern recognitionNeural architecturesParallaxPhysical optics

The invention discloses a double-flow bokeh rendering method and system based on a physical optical model and a neural network, and belongs to the technical field of computer vision. The method comprises the following steps: converting a full-focus image into an RAW format, and obtaining a defocus image with a symbol through a disparity map, a fuzzy degree parameter and a focusing disparity parameter; enabling a physical renderer to perform multi-style rendering on the depth smooth area in the image according to the aperture shape parameters; enabling a neural network renderer to render a depth discontinuous region in the image, and predicting a probability graph of the region; fusing the results of the physical renderer and the neural network renderer; and restoring the fused bokeh image from the RAW format to the initial format. The method and the system not only can render a bokeh effect close to that of a single lens reflex camera, but also can freely adjust the focusing plane, the fuzzy degree and the rendering style, and are high in authenticity and high in customizability.

Owner:HUAZHONG UNIV OF SCI & TECH

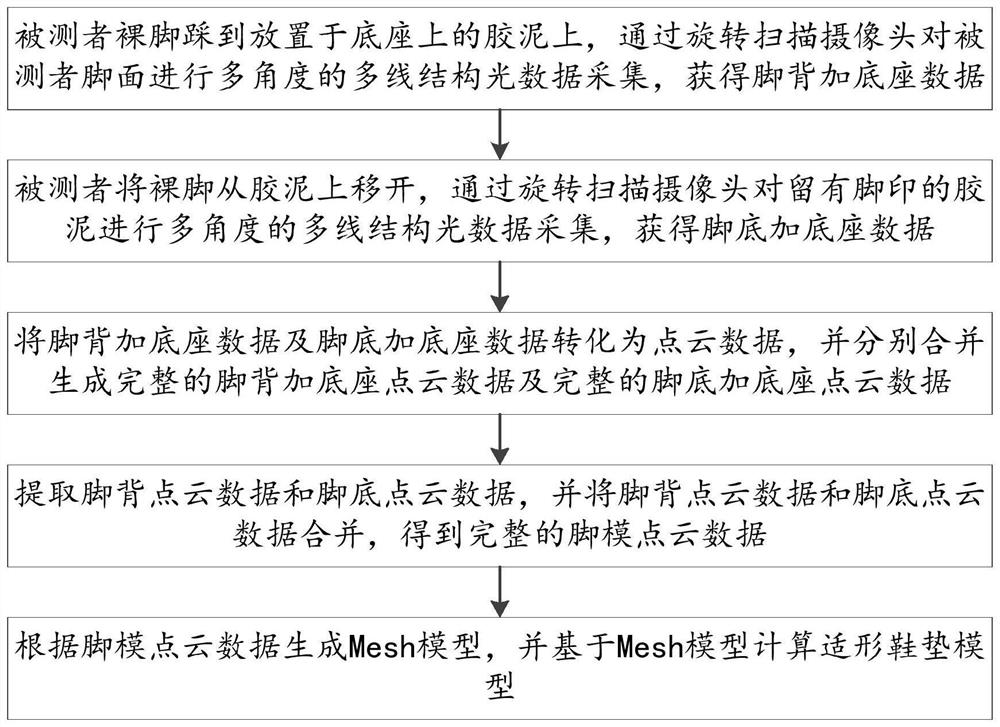

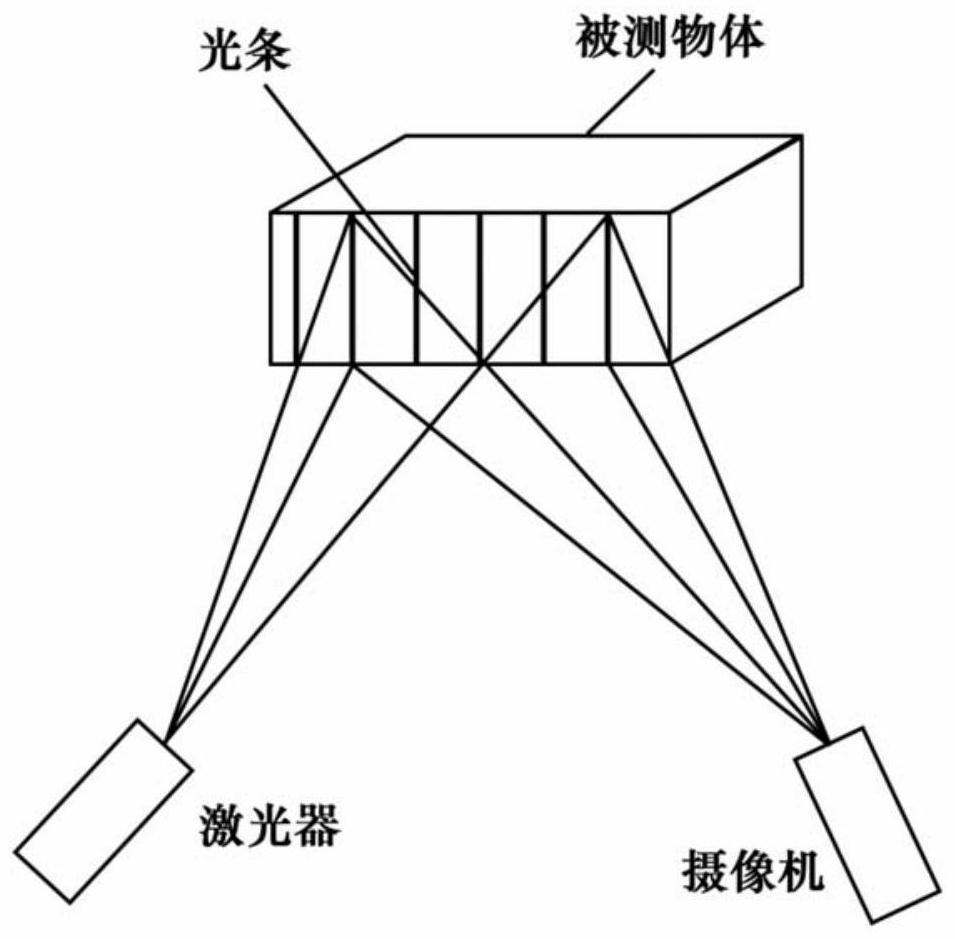

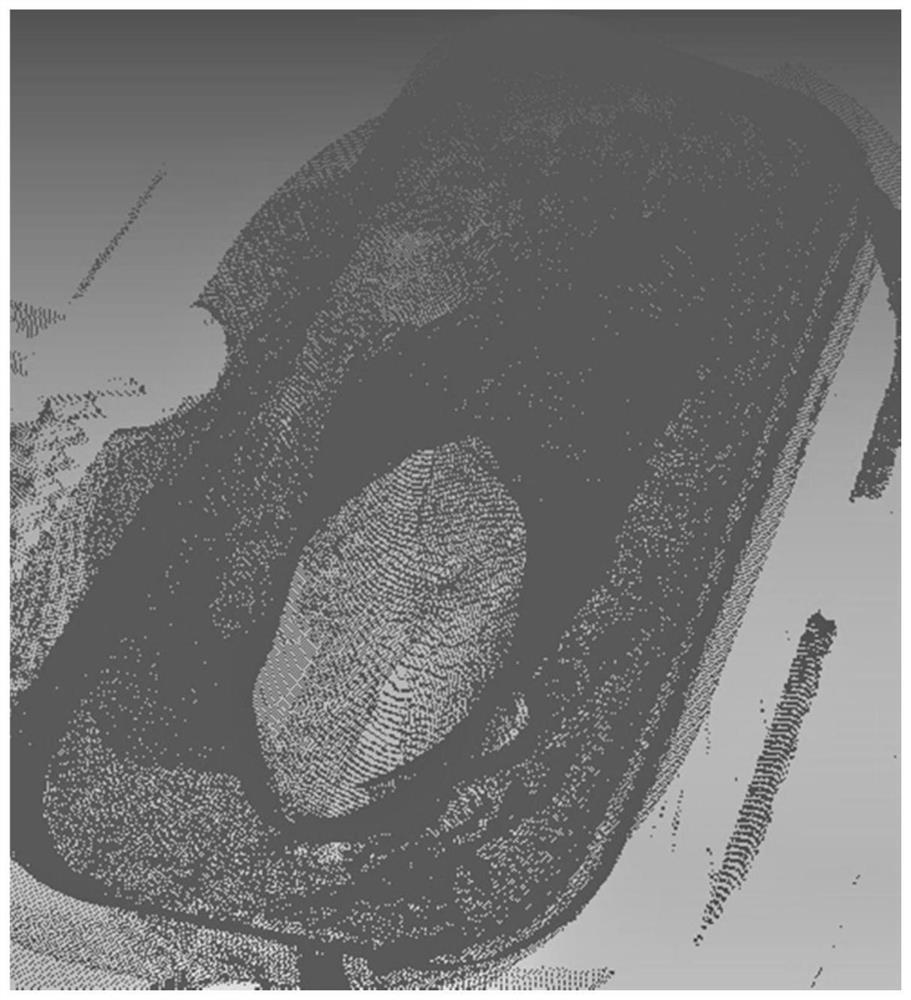

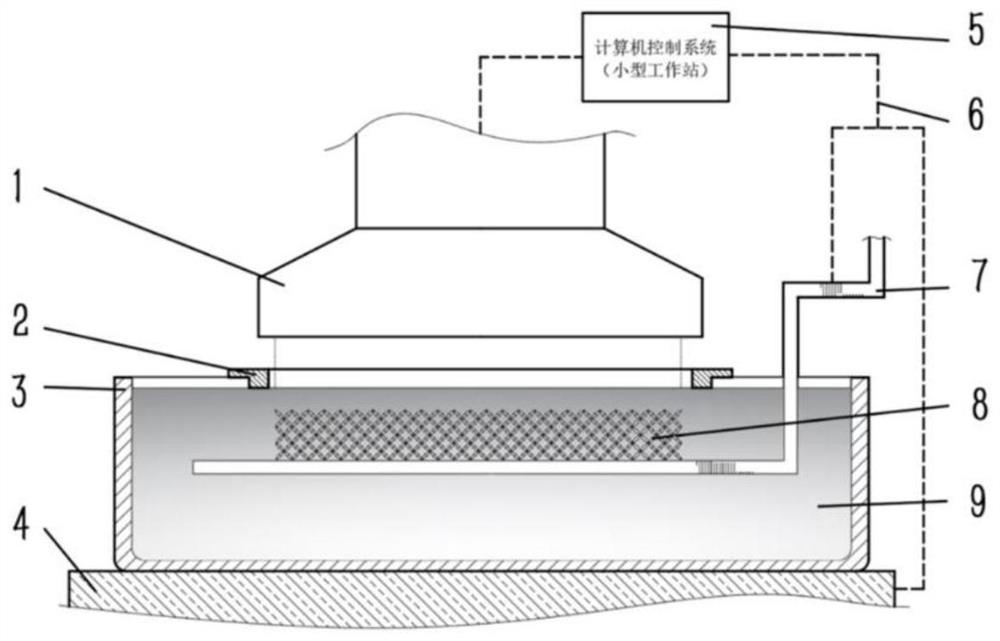

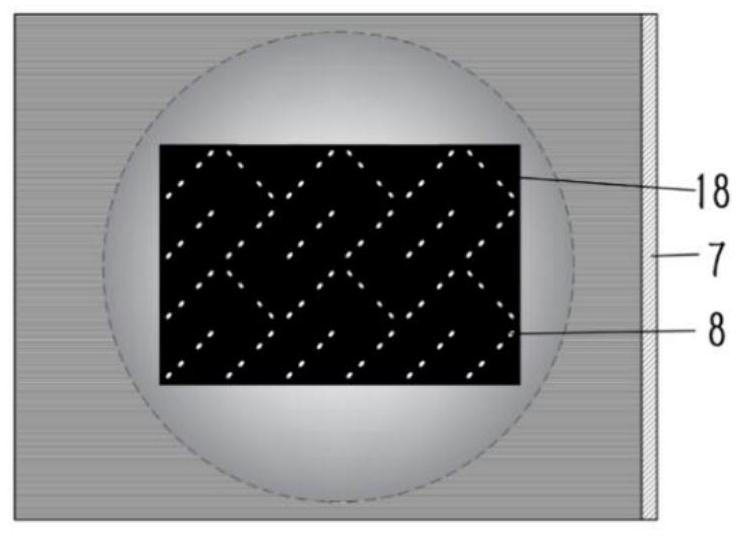

Conformal insole generation method based on rotary 3D foot shape scanner

ActiveCN114451636ASolve acquisition problemsMeeting the needs of special populationsImage enhancementFoot measurement devicesPoint cloudComputer graphics (images)

The invention provides a conformal insole generation method based on a rotary 3D foot type scanner, and relates to the technical field of conformal insole generation, and the method comprises the steps: a tested person steps on plaster with a naked foot, a rotary scanning camera carries out multi-angle multi-line structured light data collection on the instep of the tested person, and instep and base data is obtained; moving the bare foot from the plaster by the testee, and performing multi-angle multi-line structured light data acquisition on the plaster by a rotary scanning camera to obtain sole and base data; converting the instep and base data and the sole and base data into point cloud data, and respectively merging the point cloud data to generate complete instep and base point cloud data and complete sole and base point cloud data; extracting instep point cloud data and sole point cloud data, and merging to obtain complete foot model point cloud data; and generating a Mesh model according to the foot model point cloud data, and calculating a conformal insole model based on the Mesh model. According to the invention, the complete data of the foot shape of the tested person is collected, and the conformal insole is calculated and generated according to the foot shape data.

Owner:HEBEI UNIVERSITY OF ECONOMICS AND BUSINESS

Three-dimensional pressure sensor based on 3D printing template method and preparation method of pressure sensor

ActiveCN112848269ACustomizableFlexibleAdditive manufacturing apparatusApparatus for force/torque/work measurementSignal onGraphite

The invention relates to a three-dimensional pressure sensor based on a 3D printing template method and a preparation method of the pressure sensor. The pressure sensor comprises a flexible truss in a customizable shape, wherein the truss takes a prototype made from a soluble photosensitive resin photocured additive as a template, and a graphene / copper composite supporting rod of a hollow structure is obtained; two pairs of flexible substrates / multi-layer triboelectric composite materials are symmetrically arranged on a small-area outer surface of the composite supporting rod, and two pairs of sensing signals in the orthogonal direction are mutually independent and are used for outputting pressure components in an X direction and a Y direction; and a composite piezoresistive structure A is arranged on a large-area outer surface, senses signals in a piezoresistive mode and is used for monitoring a Z-direction pressure signal, capable of changing along with the shape, of the structure; The preparation method of the anisotropic pressure sensor based on the 3D printing template method is used for preparing the pressure sensor. The sensor is simple in manufacturing process, can be freely customized and rapidly manufactured, is low in cost, high in efficiency and sensitive in work, and can sense and recognize a three-dimensional pressure signal on the basis of coating perception.

Owner:XI AN JIAOTONG UNIV

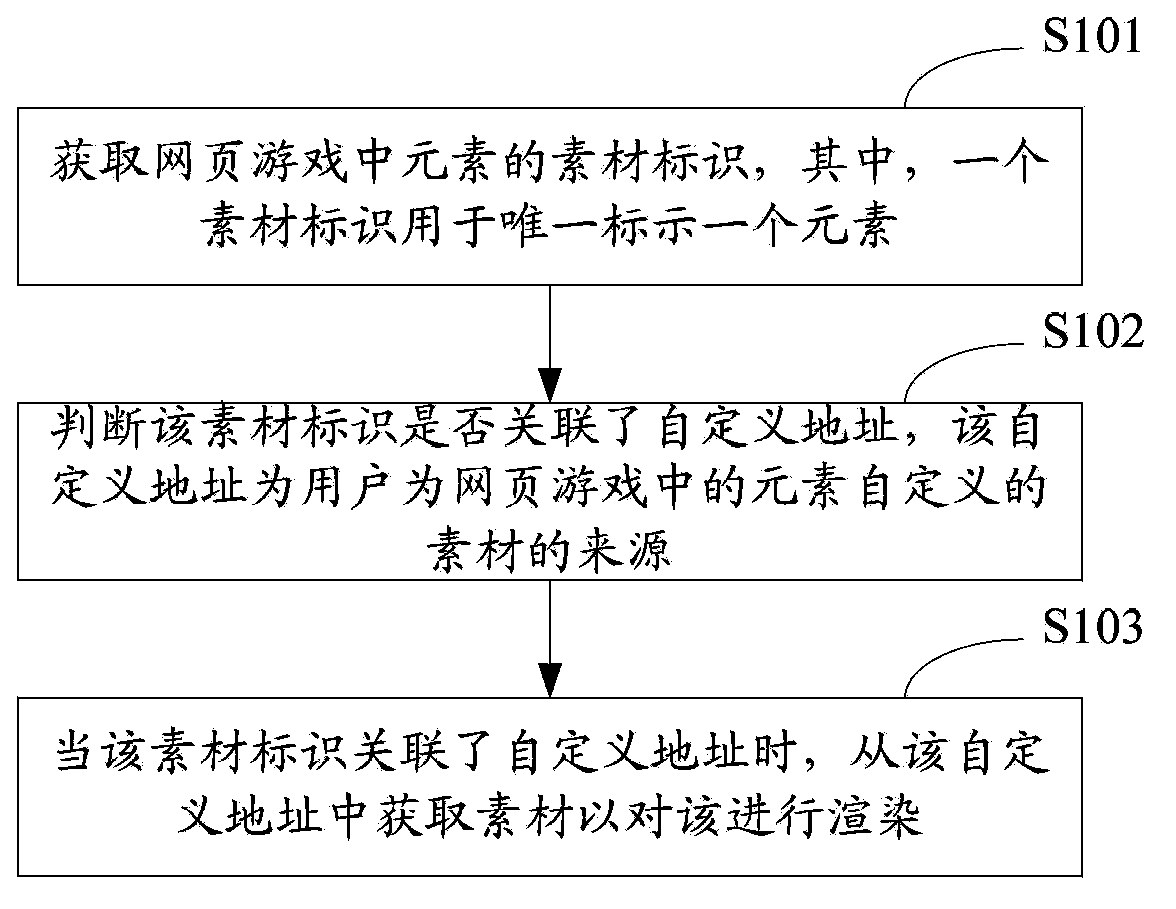

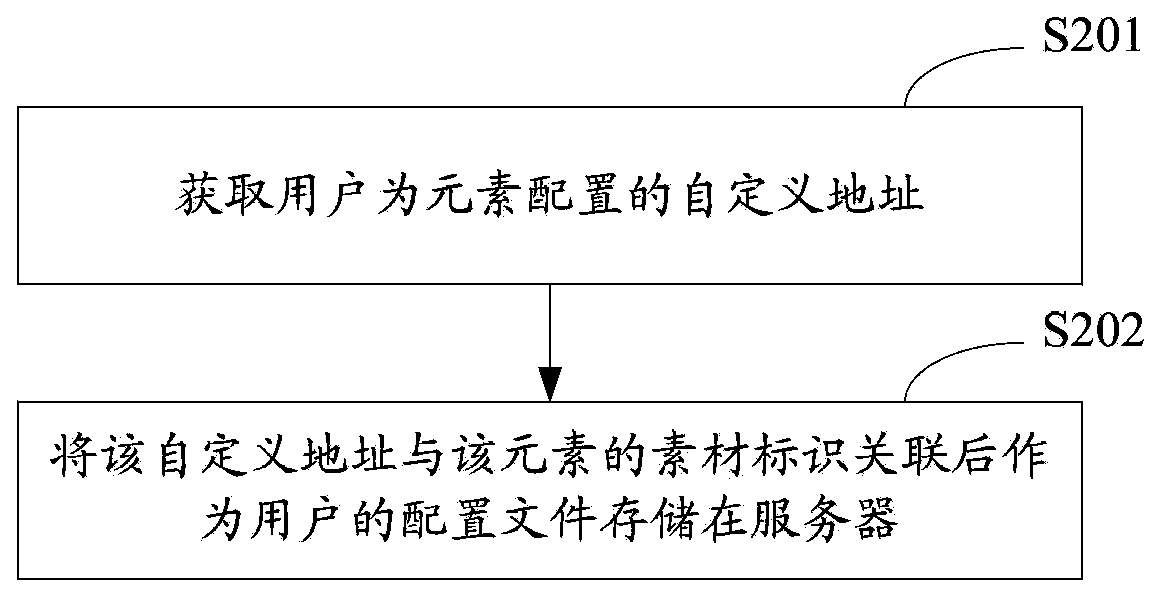

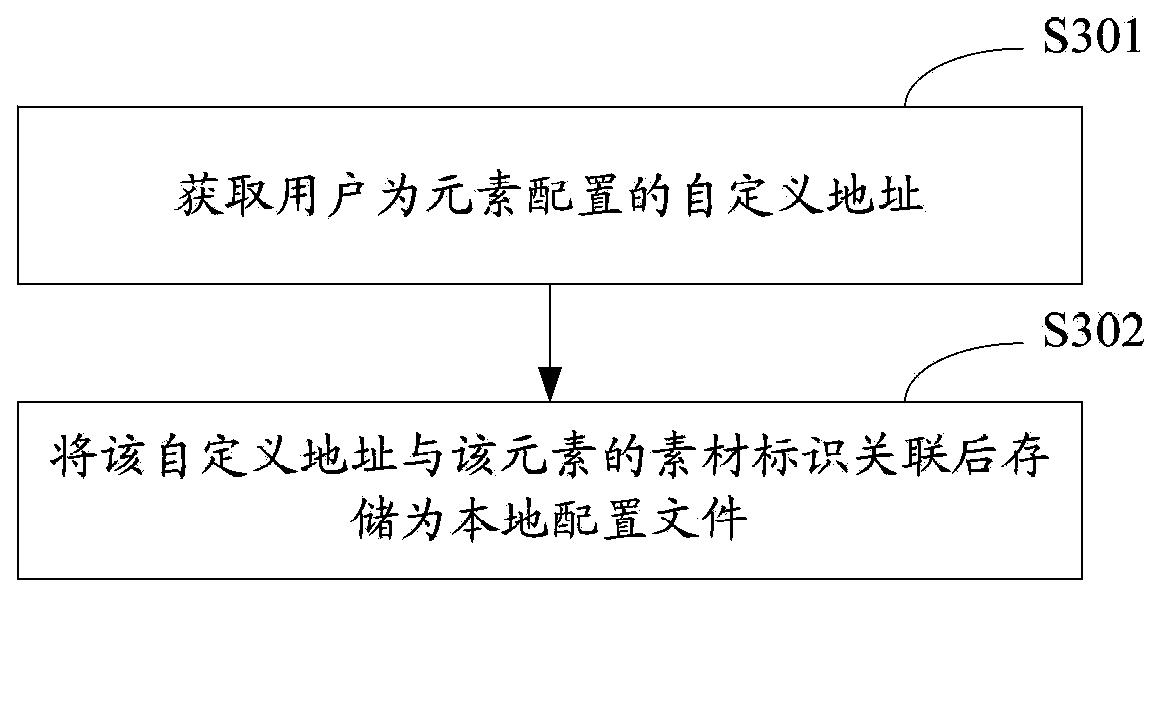

Webgame material rendering method and device

InactiveCN103778121ACustomizableIncrease engagementWebsite content managementVisual/graphical programmingMaterial IdentifierUser participation

The invention is applicable to the technical field of webpages and provides a webgame material rendering method and device. The method includes acquiring a material identifier of an element in a webgame and used for uniquely identifying the element; judging whether the material identifier is correlated with a user-defined address which is a material source of the element and defined by a user; acquiring a material from the user-defined address to render the element when the material identifier is correlated with the user-defined address. By means of the method and device, the webgame has user customizability, and the webgame user participation degree is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

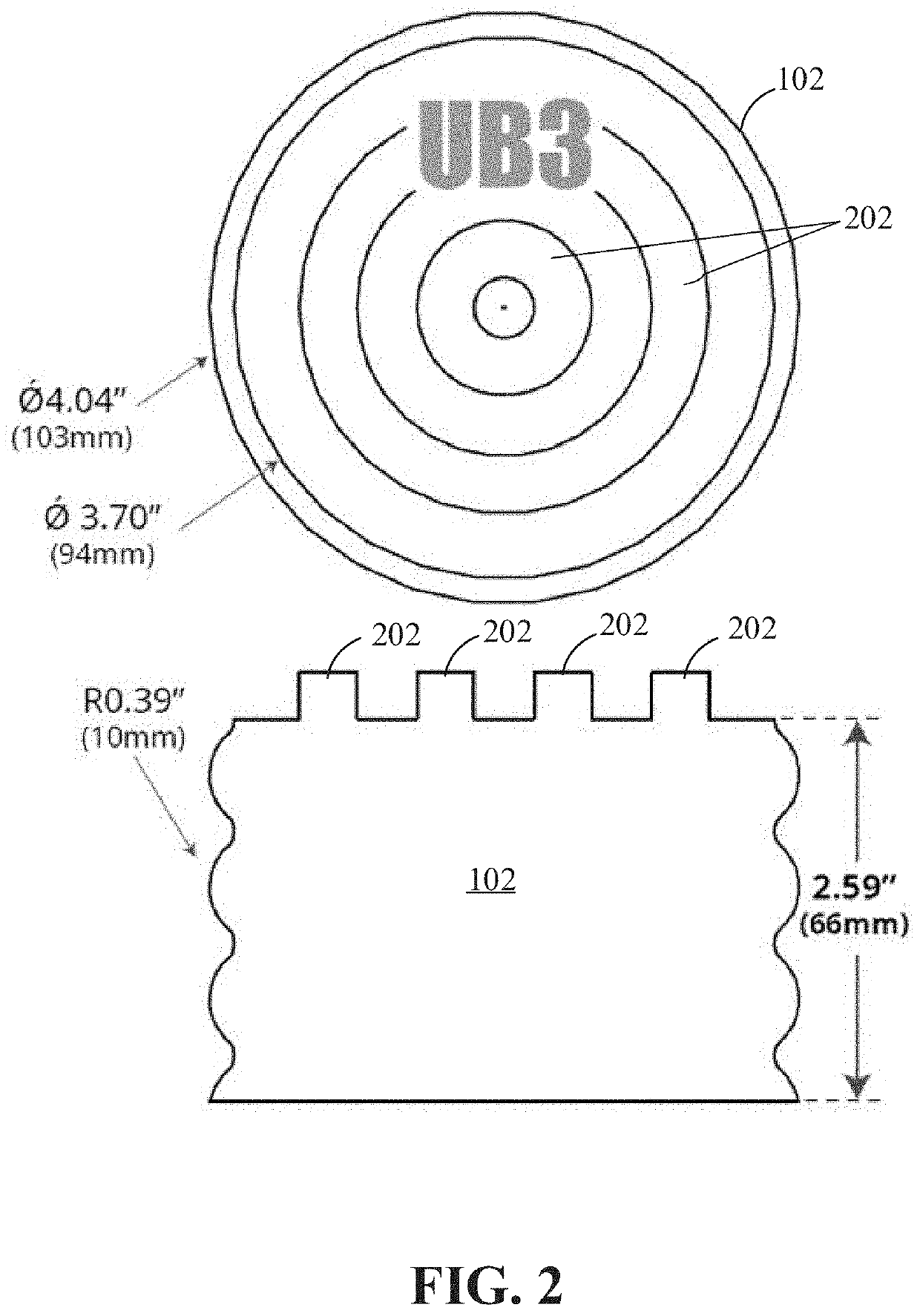

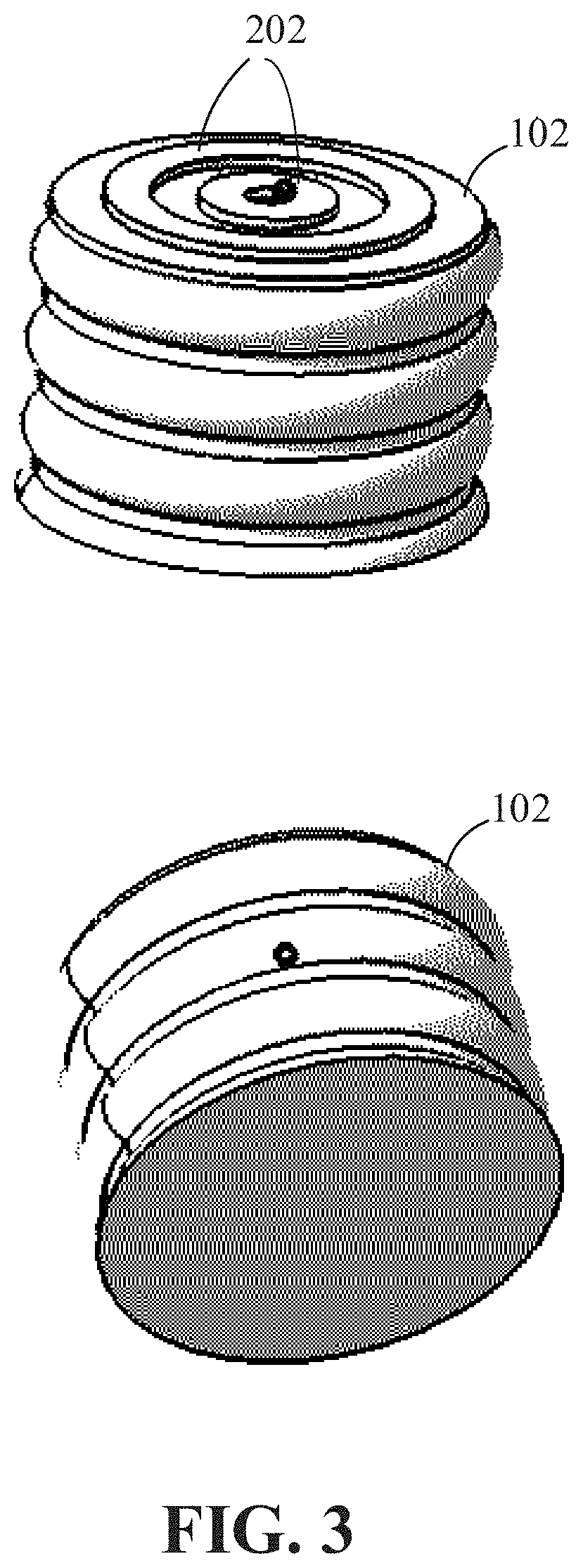

Modular bump buffer for vehicle

PendingUS20220339986A1Improve driving stabilityIncrease load capacityMultiple spring combinationsSprings/dampers design characteristicsControl theoryMechanical engineering

A modular suspension buffer for vehicle has customizable hardness and height to provide various combinations of initial contact softness and non-linearly increasing resistance during compression so as to improve driving stability, loading capacity, off road performance, and / or ride comfort while extending the operational lifespan of the vehicle suspension system.

Owner:ELITE BUFFER LLC

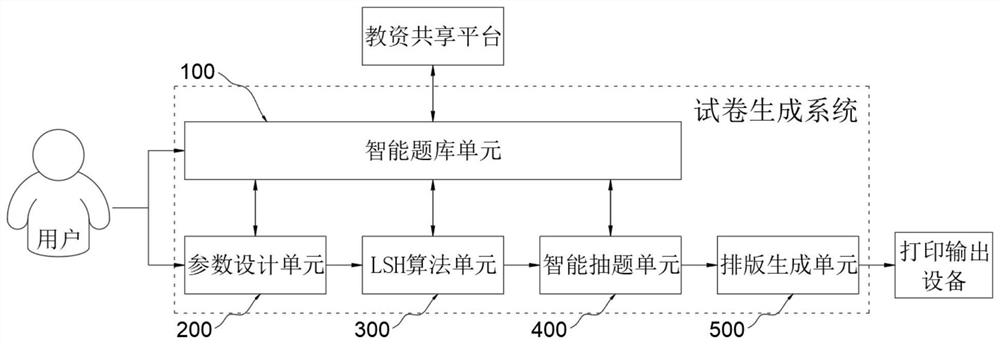

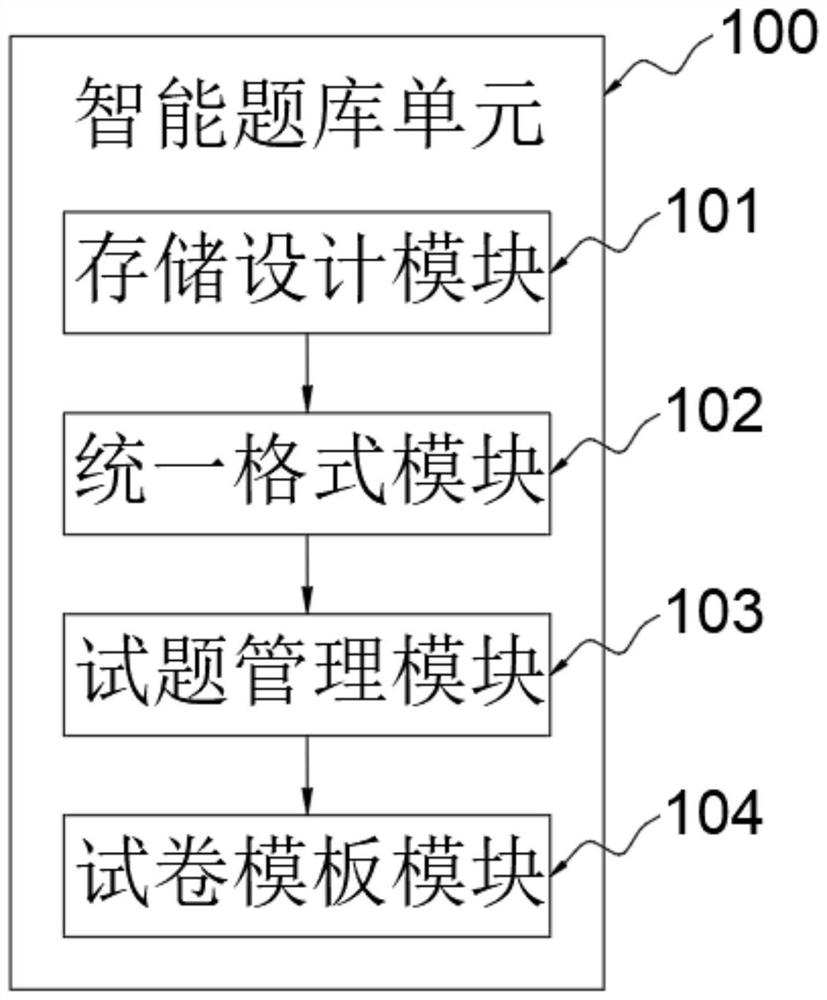

Test paper generation system capable of avoiding test question similarity

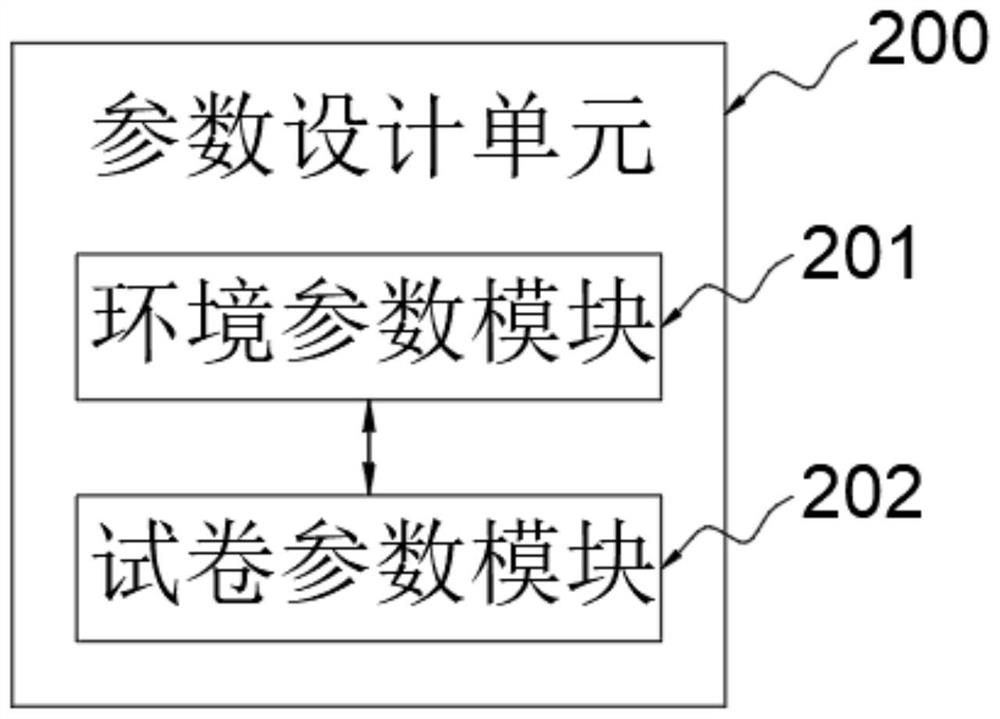

PendingCN114418014ASave time for paper assemblyImprove convenienceCharacter and pattern recognitionNatural language data processingTest questionParameter design

The invention relates to the technical field of computers, in particular to a test paper generation system capable of avoiding test question similarity. Comprising an intelligent question bank unit, a parameter design unit, an LSH algorithm unit, an intelligent question extraction unit and a typesetting generation unit. Wherein the intelligent question bank unit is used for differentially storing test question contents; the parameter design unit is used for designing environment parameters and test paper parameters; the LSH algorithm unit is used for quickly identifying similar test questions; the intelligent question extraction unit is used for automatically extracting test questions and answers; the typesetting generation unit is used for automatically typesetting and generating test paper. According to the design of the invention, teachers can complete test paper composition in a short time according to requirements, the test paper composition time is saved, and the method has the advantages of high flexibility, customizability, what you see is what you get, high matching with teachers and the like; the test paper can be generated only by office, the test paper can be conveniently formed at any place, and the use convenience is enhanced; according to the generated test paper, the repetition rate of similar test questions can be effectively reduced, and the test paper composition complexity is reduced.

Owner:CHUXIONG NORMAL UNIV

A Distributed Event Injection Device Based on Combined Test Set

ActiveCN103944778BInject flexibleEfficient injectionFault responseData switching networksComputer system designUsability

The invention relates to a distributed event injection device based on a combined test set for a computer fault-tolerant system. The invention includes a controller, a combined test set generation module, an event injection module and a state analysis module. In the event injection technology, the present invention fully considers the distributed design structure commonly used in today's computer systems, fully considers the problem that different target units are suitable for injecting different types of faults and different levels of load, and introduces a distributed event injection method based on combined test sets , to achieve more flexible and efficient event injection. Therefore, the present invention has the advantages of wide application range, less resource consumption, flexible event injection mode, strong pertinence, and customizability. It can be widely used in distributed fault-tolerant systems, especially in availability evaluation of dedicated fault-tolerant systems.

Owner:HARBIN ENG UNIV

A method and device for creating a title bar of a form

ActiveCN103246505BCustomizableHave operational characteristicsSpecific program execution arrangementsTitle bar

The present invention is applicable to the technical field of IOS operating system, and provides a method and device for creating a window title bar. The method includes: adding a custom view to the top-level view of the form; using the custom view as a window The body title bar covers the form title area. The invention can simultaneously satisfy the customization of the form title bar under the MAC and the display of the form title in the Dock and Exposé.

Owner:TENCENT TECH (SHENZHEN) CO LTD

A security baseline system and its method for realizing security inspection

ActiveCN104125197BMeet customizable needsMeet application needsTransmissionTime responseInternet network

This application discloses a security baseline system and a method for implementing security checks, including a vulnerability information acquisition unit actively acquiring vulnerability information; a linkage processing unit determining the target device according to the obtained vulnerability information, and generating check information; the security check is the unit according to the generated Check information to perform a security check on the target device. This application actively acquires newly discovered vulnerability information through active means, adapts to the network with rich changes in the Internet field, and thus achieves real-time response to newly discovered vulnerabilities. Furthermore, this application establishes a user security baseline library according to user customization requests, allowing users to call their own customized security rules to perform security checks on the system, thereby meeting the customizable requirements of security checks.

Owner:ALIBABA GRP HLDG LTD

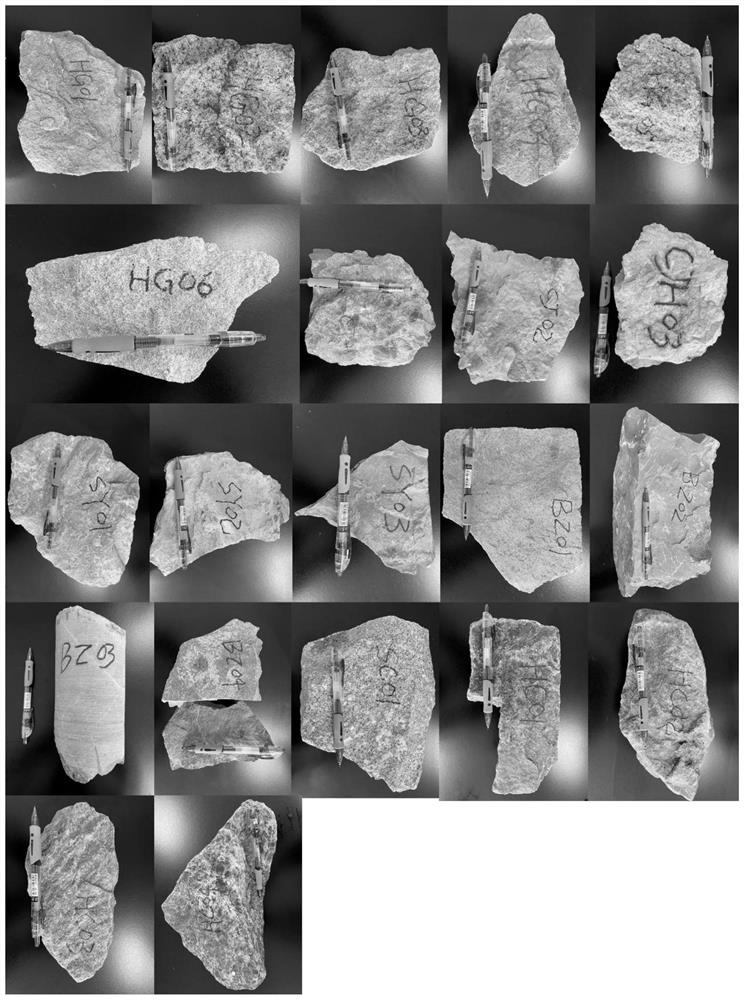

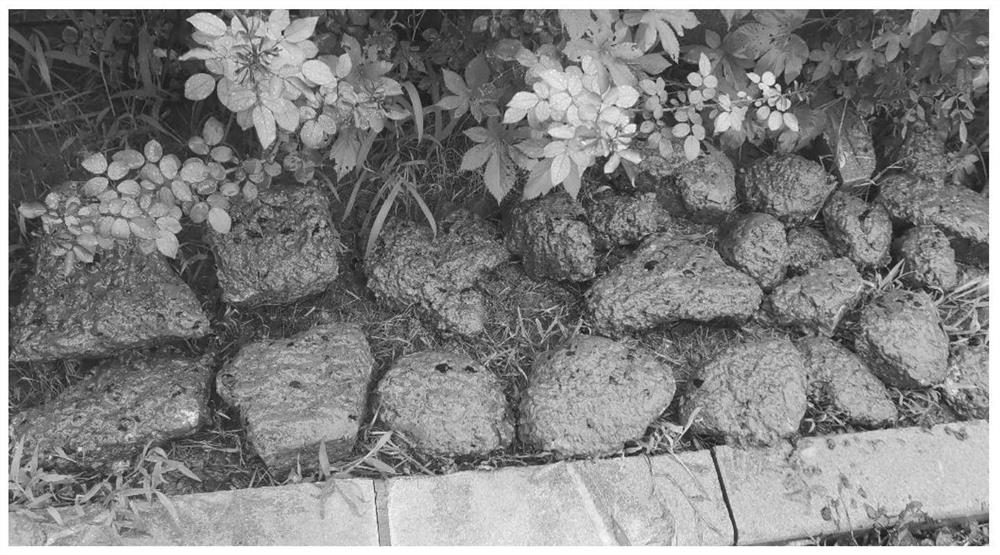

Rock aging repairing agent for fresh rock wound surface of high and steep slope as well as preparation method and application

The invention belongs to the field of ecological restoration and water and soil conservation, and discloses a rock aging repairing agent for a fresh rock wound surface of a high and steep slope as well as a preparation method and application. The preparation method comprises the following steps: material preparation: raw materials comprise main components and additives, and the mass of the additives is 5-10% of that of the main components; the main components comprise fruits and organic planting soil; the additives comprise vegetable gum, natural mineral powder, organic acid and a water-retaining agent; fruit fermentation; preparation of the organic planting soil: anaerobic water-logged compost is conducted in water according to the mass ratio of common soil or immature soil to animal waste or food waste to straw being 4:5:1; drying is performed to enable the moisture in the organic planting soil to be less than 10%; preparation of the main components: a fermentation product obtained by fruit fermentation is uniformly mixed with the organic planting soil for later use; preparation of the additives: the vegetable gum, the natural mineral powder, the organic acid and the water-retaining agent are uniformly mixed in a mass ratio of (30-35):(10-35):(5-15):(25-45); and the additive is obtained. The prepared rock aging repairing agent is low in cost and high in adsorption capacity.

Owner:NAT RESERACH CENT OF GEOANALYSIS

Preparation method and 3D printing method of universal nano-electrode paste

ActiveCN110752354BImproved rheological propertiesGood dispersionCell electrodesSecondary cellsElectrical batteryBattery cell

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

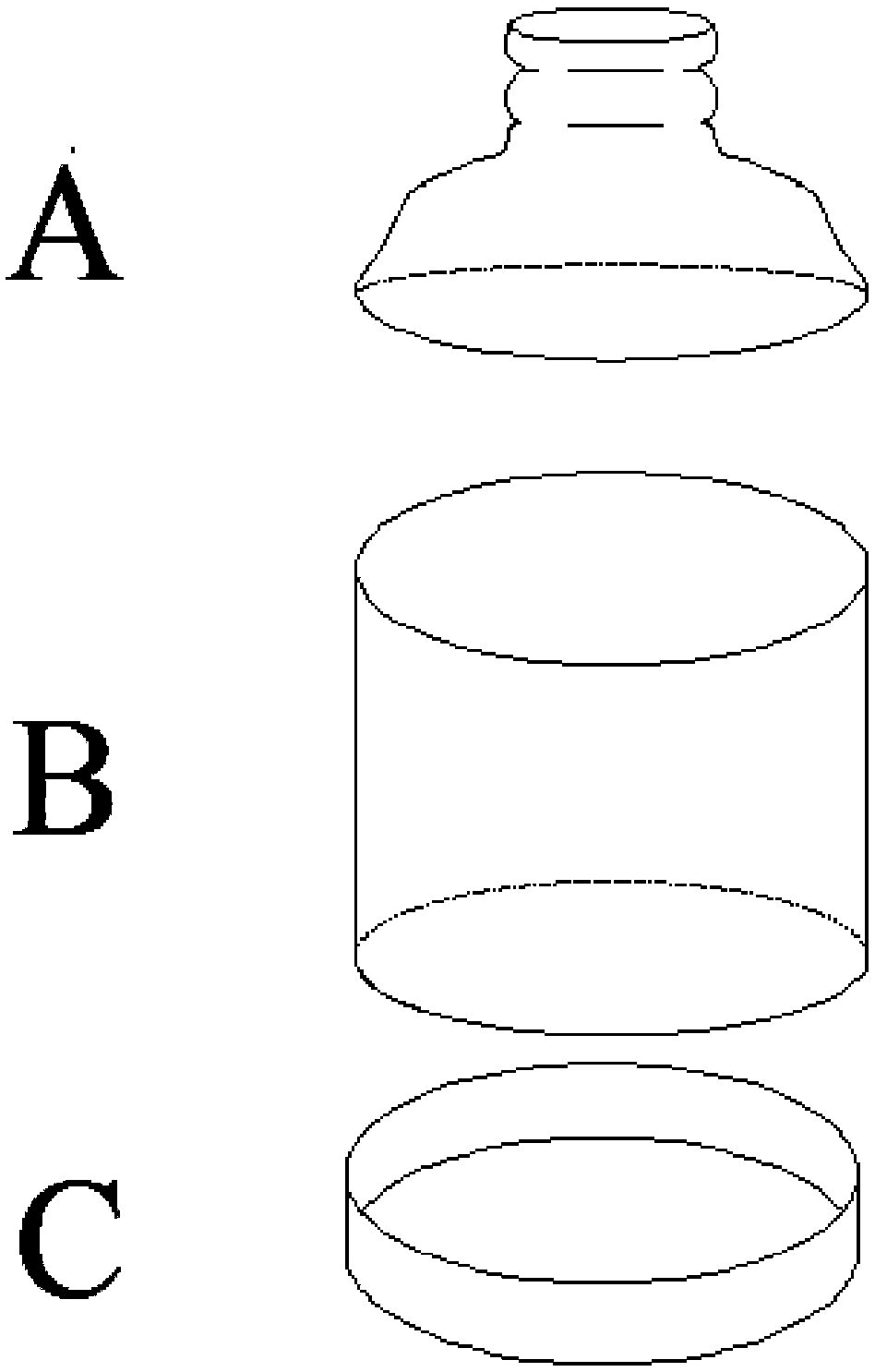

Manufacturing method for multifunctional composite material bottle

InactiveCN108215207ASimple processing technologyIncrease productivityHollow articlesHigh volume manufacturingBottle

The invention relates to a manufacturing method for a multifunctional composite material bottle. The method comprises the steps that a bottle mouth and bottle shoulder part, a bottle body part and a bottle bottom part are formed separately, the bottle body part is formed by winding a sheet material, and all the parts are connected into a whole through a welding technology. According to the method,due to the fact that the multiple parts are combined, different functional composite materials can be selected according to needs for the materials of all the parts so as to be combined and formed, and therefore compared with an existing traditional bottle making process product, the processing technology is simpler, a blow-injection mode does not need to be manufacture, the manufacturing cost can be greatly lowered, the manufacturing time can be greatly shortened, and rapid and mass production can be facilitated; in addition, combined addition of the functions except common requirements canbe realized, such as excellent printing of a bottle body, hot filling, high barrier property, high transparency and other special requirements; and meanwhile, the product has the characteristics of being low in production cost, environmental-friendly in production process, free of emission of highly toxic waste gas, light and capable of saving the transportation cost in every links such as production and use.

Owner:TRAGOT GUANGZHOU PACKAGING

Function aggregation self-organization system and method of intelligent internet of things

ActiveCN111556090BVersatileGeneralization of network structureData switching networksThe InternetNetwork structure

This application discloses a function aggregation self-organization system of the intelligent Internet of Things, wherein the terminal determination module is used to determine the Internet of Things terminal associated with the task according to the current task to be executed, and the sub-network self-organization module is used to determine the determined The Internet of Things terminal self-organizes on the network architecture to obtain one or more sub-networks of the Internet of Things. The process creation and resource allocation module is used to establish processes for the sub-networks according to the corresponding functional tasks of the sub-networks, and allocate corresponding computing resources for the processes. The sub-networks are managed and stored separately, and the resource recycling module is used to end the process of the corresponding sub-network and release the computing resources of the corresponding sub-network when the functional tasks are completed. The system makes the network structure of the Internet of Things service generalized, with diversified functions and customizability, improves the timeliness of response to key data, and enhances the adaptability to actual needs and actual scenarios.

Owner:重庆特斯联智慧科技股份有限公司

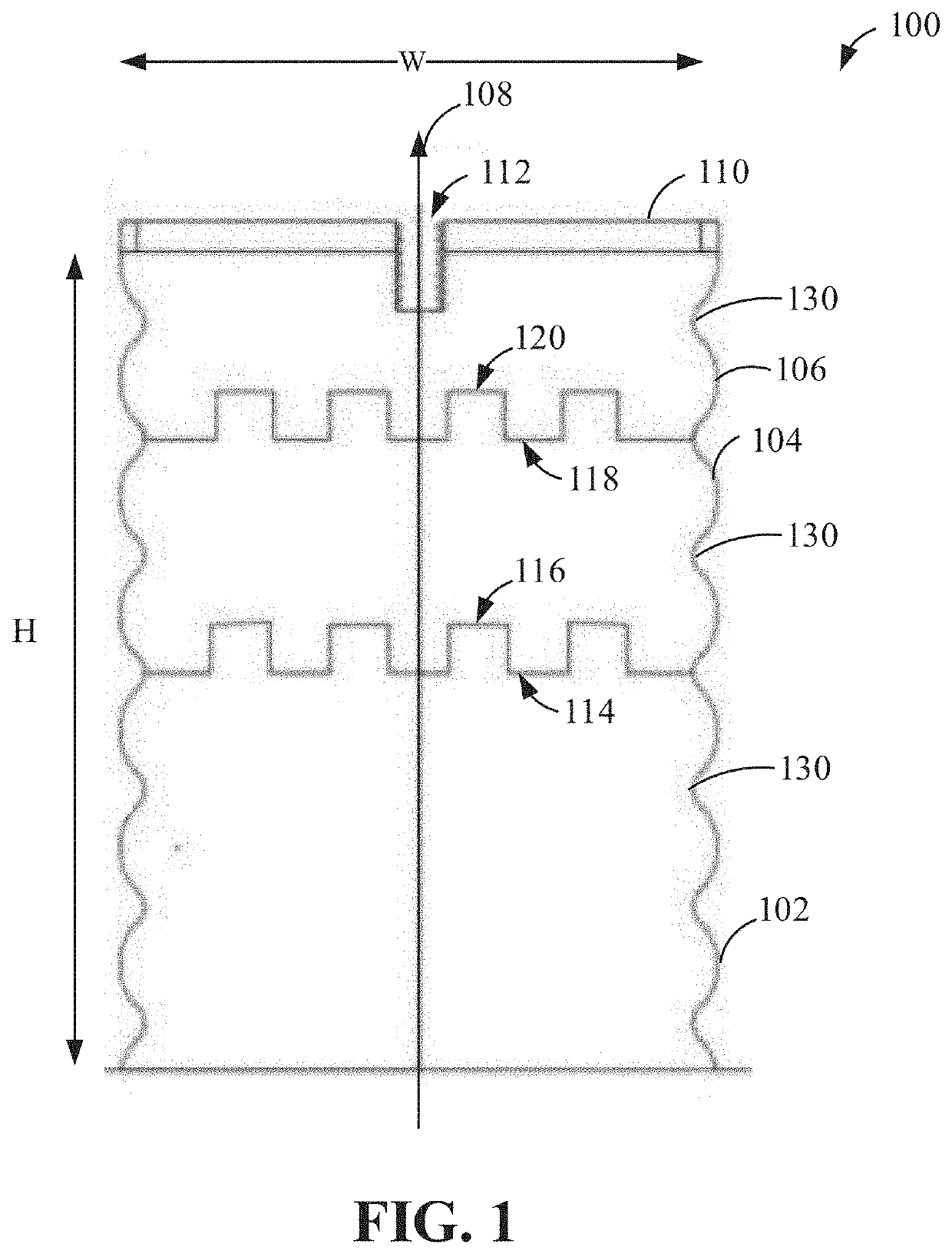

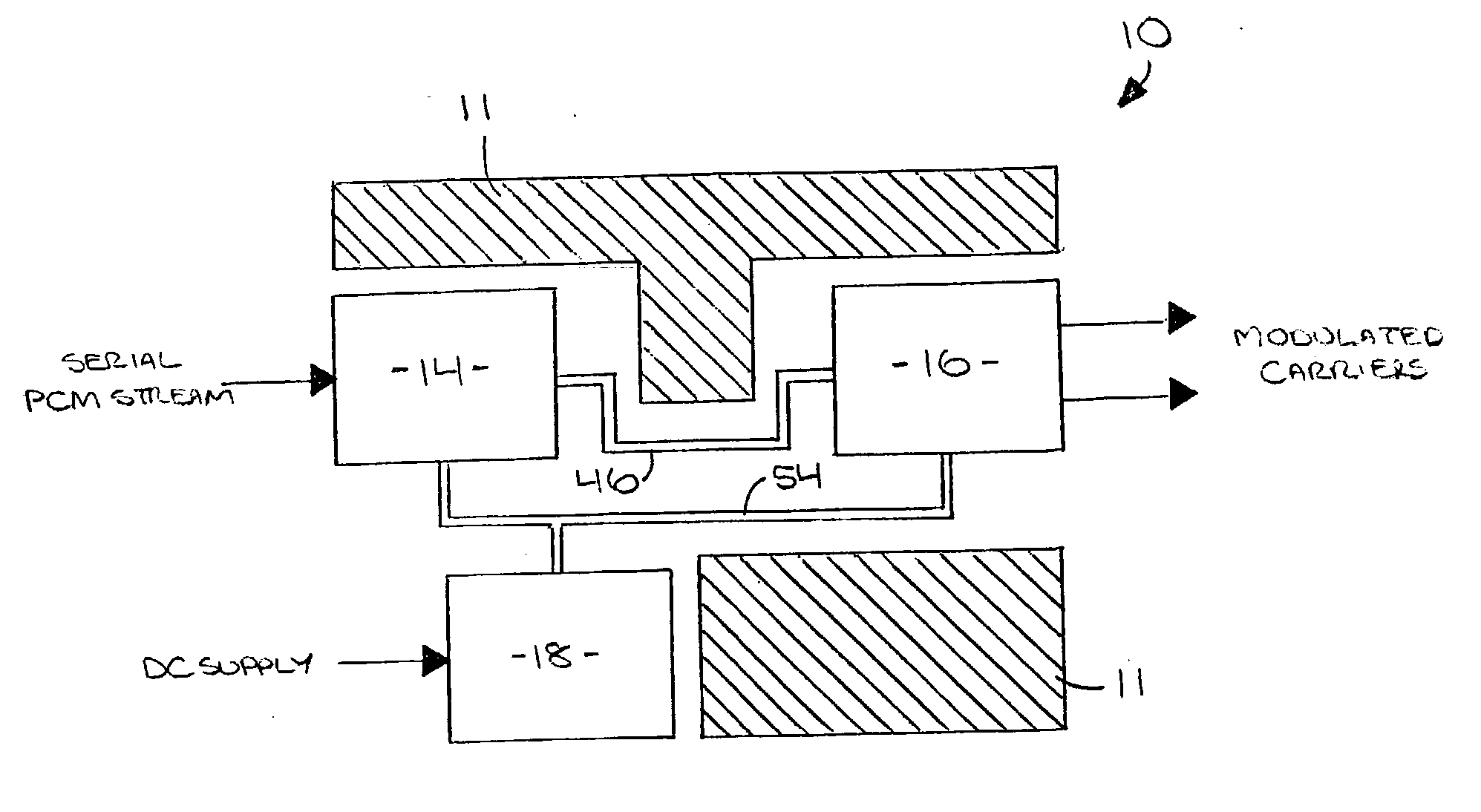

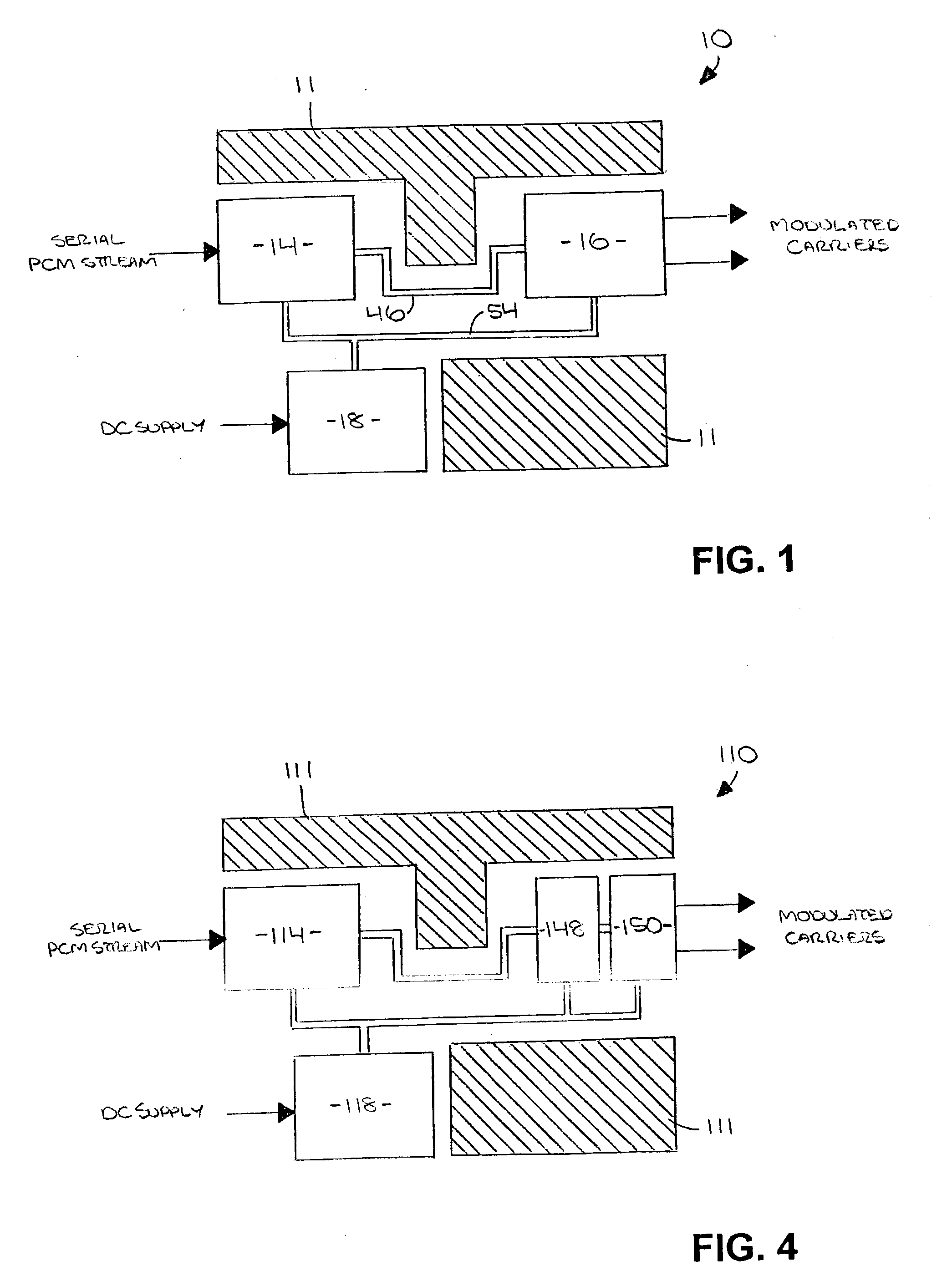

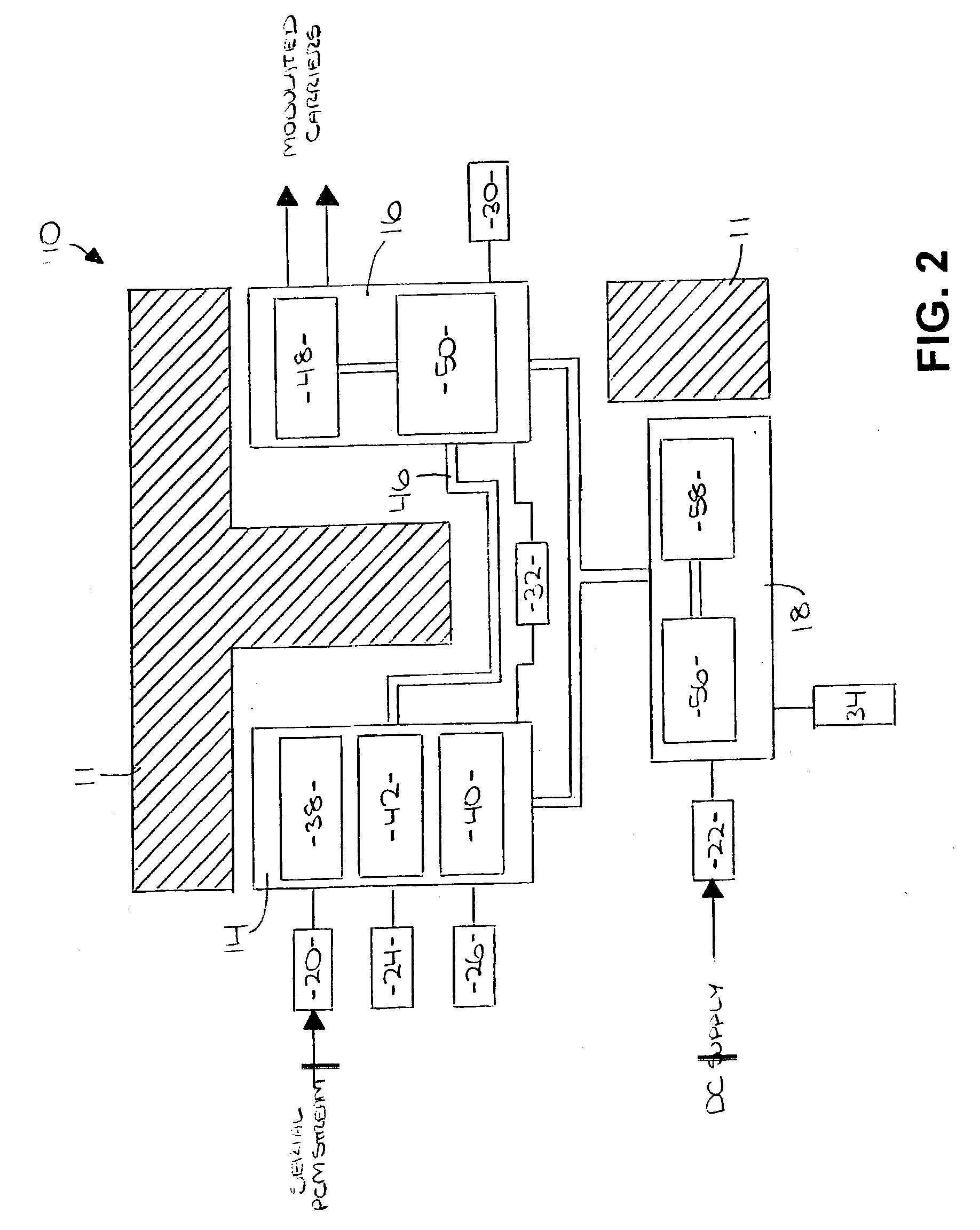

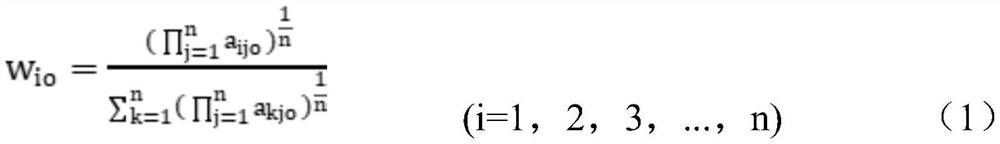

Distributed data transmitter

InactiveUS20040070466A1Easy interchangeEasy to removeAngle modulationFrequency-modulated carrier systemsAudio power amplifierFlight vehicle

A distributed data transmitter (DTXR) which is an adaptive data communication microwave transmitter having a distributable architecture of modular components, and which incorporates both digital and microwave technology to provide substantial improvements in physical and operational flexibility. The DTXR has application in, for example, remote data acquisition involving the transmission of telemetry data across a wireless link, wherein the DTXR is integrated into and utilizes available space within a system (e.g., a flight vehicle). In a preferred embodiment, the DTXR broadly comprises a plurality of input interfaces; a data modulator; a power amplifier; and a power converter, all of which are modularly separate and distinct so as to be substantially independently physically distributable and positionable throughout the system wherever sufficient space is available.

Owner:HONEYWELL FED MFG & TECHNOLOGI

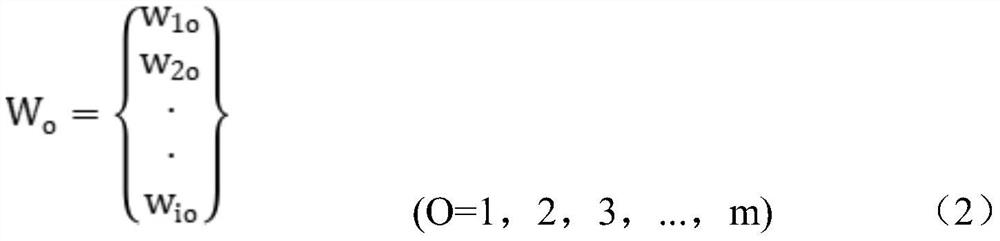

Method for evaluating water quality of home-entry domestic water

PendingCN114113518AImprove the problem of logic judgment error prone to indicator importanceIncrease the negative impactGeneral water supply conservationCharacter and pattern recognitionWater useEvaluation result

The invention discloses a home-entry domestic water quality evaluation method. The method comprises the following steps: step 1, presetting water quality indexes for water quality evaluation; 2, performing data optimization according to a preset water quality index; and step 3, giving a water quality evaluation result, and finally obtaining an evaluation matrix by constructing a data matrix and a scoring matrix so as to obtain the water quality evaluation result. Step 4, constructing a neural network model, constructing the neural network model according to the obtained water quality evaluation result, and iterating the water quality evaluation result, so that the problem that the traditional evaluation basis is single is solved, and meanwhile, the problem that the index importance logic judgment is easy to cause due to subjective evaluation criteria formulated by traditional experts is solved; therefore, the method is more customizable, comprehensive and reasonable.

Owner:HANGZHOU DIANZI UNIV

An Anti-aliasing Modem for Hybrid AM Broadcasting System

ActiveCN106027438BLower noise figureHigh sensitivityModulated-carrier systemsModem deviceCarrier signal

The invention discloses an anti-aliasing modulation demodulator for an analog-digital hybrid amplitude modulation broadcasting system. According to the demodulator, aiming at a MPPSK (M-ary Position Phase Shift Keying) digital modulation signal separated from a MPPSK / DSB-AM (M-ary Position Phase Shift Keying / carrier-reserved Double Side Band-Amplitude Modulation) hybrid modulation system received signal, DL (Deep Learning) training is carried out by utilizing an SAE (Sparse Autoencoder) neural network, so that the trained DL-SAE neural network can carry out classification on an MPPSK received signal sample which generates interference between strong codes due to bandwidth limitation of a sending end, and thus, compared with demodulation bit error rates of a conventional amplitude integral judgment demodulator and matched filtering judgment demodulator, a demodulation bit error rate of the anti-aliasing modulation demodulator is reduced by at least one magnitude order, and simultaneous and hybrid transmission of an analog audio and high-speed data in a 9kHz amplitude modulation broadcasting channel is ensured.

Owner:SOUTHEAST UNIV

A three-dimensional pressure sensor based on 3D printing template method and its preparation method

ActiveCN112848269BCustomizableFlexibleAdditive manufacturing apparatusApparatus for force/torque/work measurementEngineeringGraphite

A three-dimensional pressure sensor based on a 3D printing template method and its preparation method. The pressure sensor includes a flexible truss with a customizable shape. The truss is templated by a prototype made of a soluble photosensitive resin photocured additive to obtain a graphene / copper composite with a hollow structure. Struts; two pairs of flexible substrates / multilayer triboelectric composite materials are symmetrically arranged on the outer surface of the composite strut with a small area, and the sensing signals of the two pairs of orthogonal directions are independent of each other, and are used to output the magnitude of the pressure components in the X and Y directions; the area The larger outer surface is a composite piezoresistive structure A, which senses signals in a piezoresistive manner and is used to monitor the Z-direction pressure signal that the structure can change with shape; the preparation method of anisotropic pressure sensor based on the 3D printing template method is used to prepare The above-mentioned pressure sensor; the sensor provided by the present invention has a simple manufacturing process, can be freely customized and quickly manufactured, has low cost, high efficiency, and sensitive work, and can realize the sensing and identification of three-dimensional pressure signals on the basis of wrapping perception.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com