Manufacturing method for multifunctional composite material bottle

A multi-layer composite material and composite material technology, applied in the field of manufacturing multifunctional composite material bottles, can solve the problems of high cost, complex molding process, and unfavorable mass production, and achieve low cost, simple preparation process, and reduced intermediate Effect of process cost and storage space for semi-finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

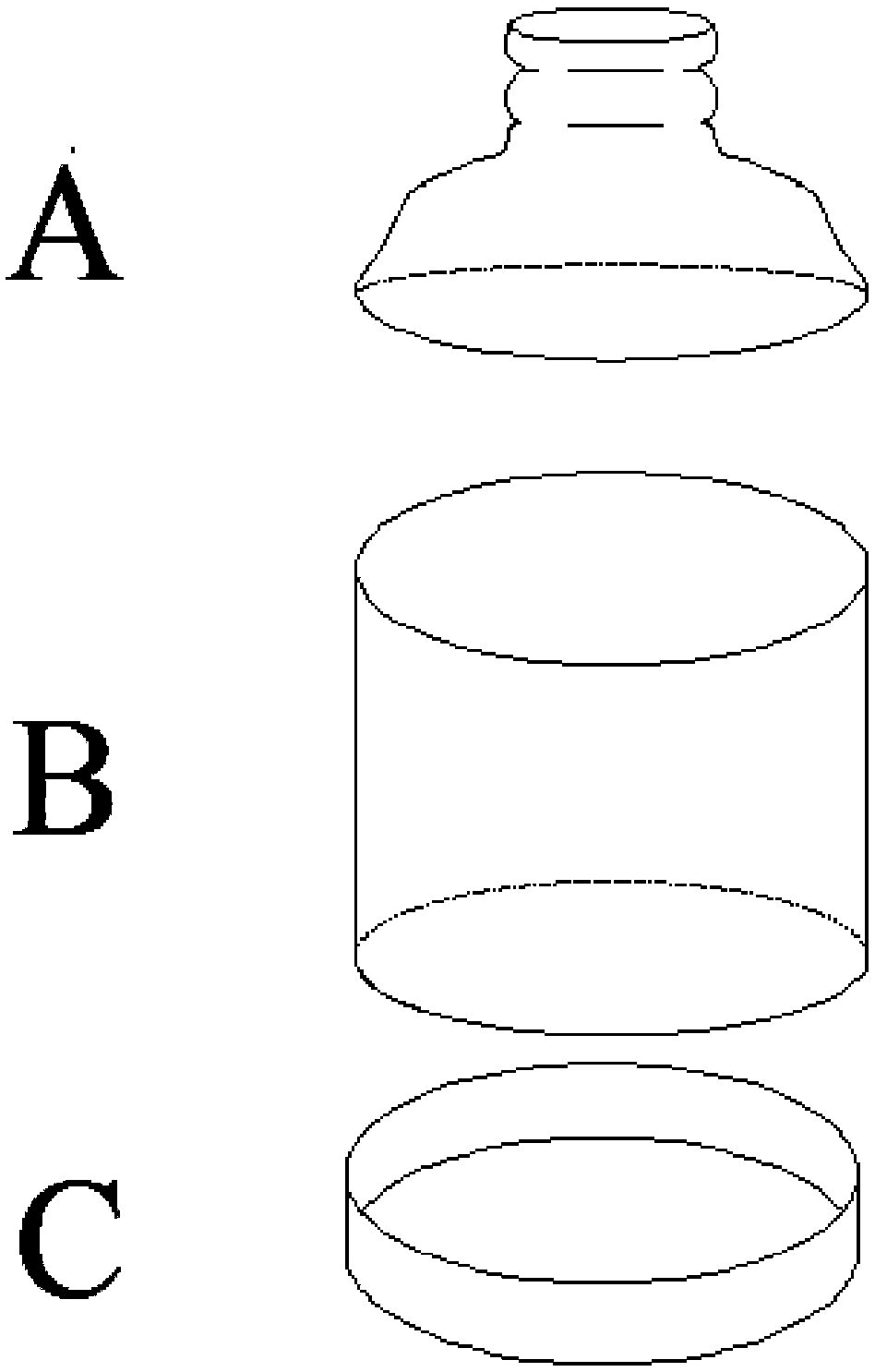

[0027] In the present invention, the multifunctional composite material bottle is divided into three parts: the bottle mouth and shoulder part A, the bottle body part B, and the bottle bottom C. Firstly, the three parts are processed and shaped separately, and then welded sequentially by welding to form an integral bottle. .

[0028] The bottle mouth and bottle shoulder part molding process of the multifunctional composite material bottle of the present invention is: form described bottle mouth and bottle shoulder part by multi-layer composite material sheet blister process or injection molding process; The use of the bottle The bottle mouth is designed in different shapes and sizes. The bottle mouth can be wide-mouthed, pointed, small-mouthed, etc.; different materials can be used according to different needs. The bottle mouth of the injection molding process can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com