Three-dimensional pressure sensor based on 3D printing template method and preparation method of pressure sensor

A three-dimensional pressure, 3D printing technology, applied in the direction of instruments, processing and manufacturing, force/torque/power measuring instruments, etc., can solve the problems of increased manufacturing costs, vulnerable contact surfaces, complex processes, etc., to achieve high precision and reliability The effects of stability, reducing structural constraints, and reducing the risk of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the drawings and embodiments of the specification.

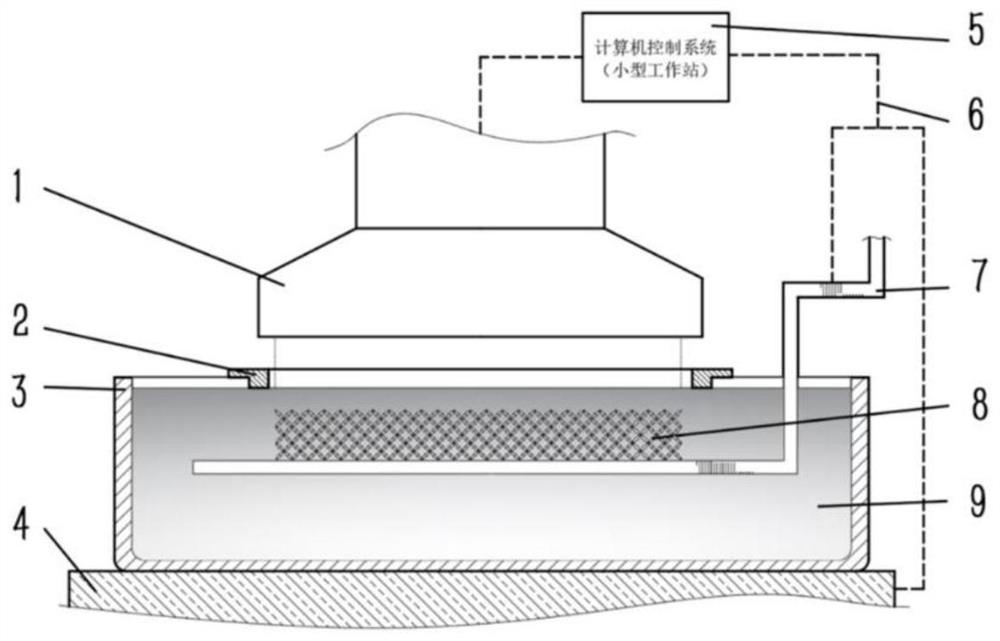

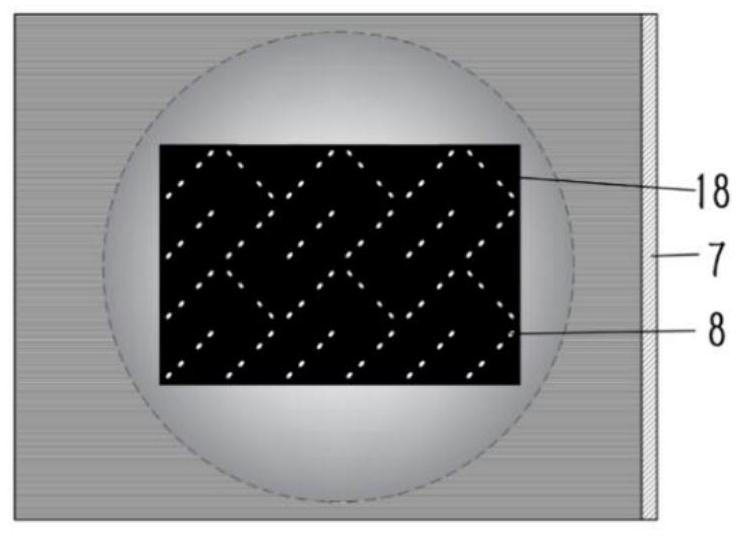

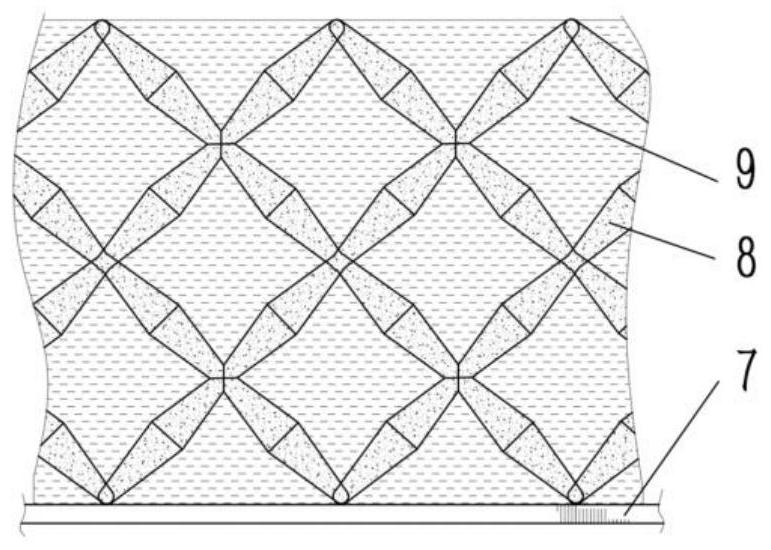

[0044] refer to Figure 9 , a three-dimensional pressure sensor based on the 3D printing template method, including a soluble truss 8. The soluble truss 8 uses a prototype made of a soluble photosensitive resin photocured additive as a template. The surface is wrapped with a metal film and a graphene elastic layer is grown. After melting, the Graphene / copper hollow composite struts 19 with a hollow structure; two pairs of hollow composite struts 19, that is, four outer surfaces with a smaller area, are provided with A flexible substrate 15 / multilayer triboelectric sensing layer, to triboelectric The signal is the sensing principle, at least two electrodes for independent signal transmission are arranged on each surface, and the two pairs of orthogonal direction sensing signals are independent of each other, and are used to output the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com