Preparation method and 3D printing method of universal nano-electrode paste

A nano-electrode and 3D printing technology, applied in the field of electrochemical energy storage, can solve the problems of restricting the development of 3D printing technology and high requirements for rheological properties of 3D printing paste, and achieve the improvement of rheological properties and material dispersibility, and paste extrusion. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

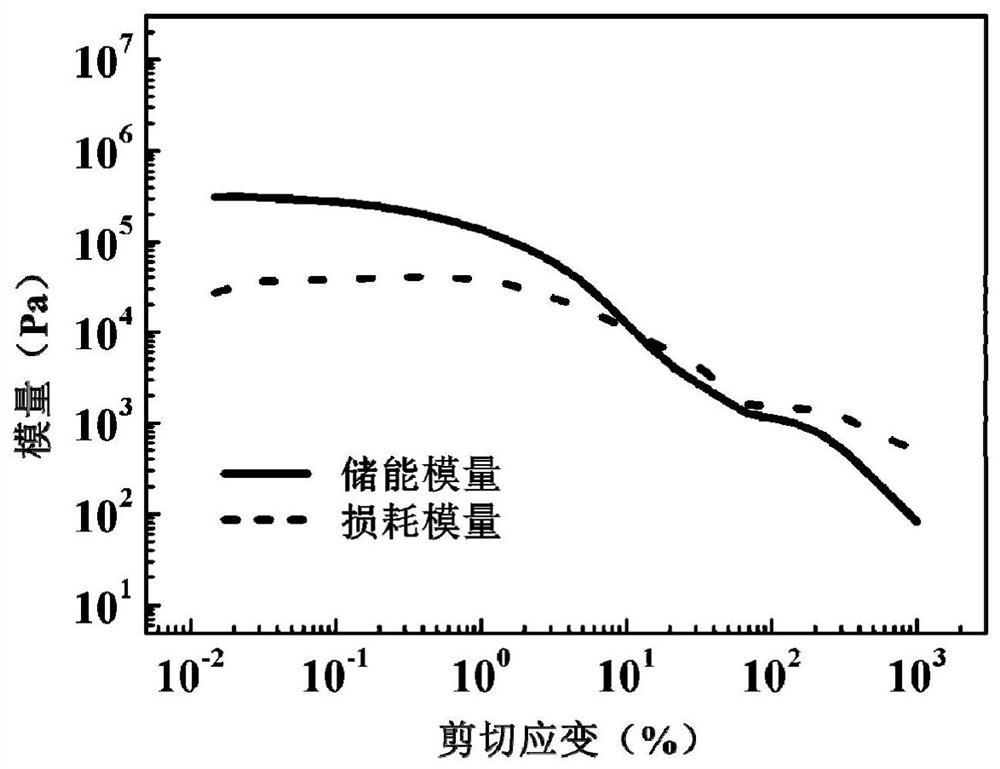

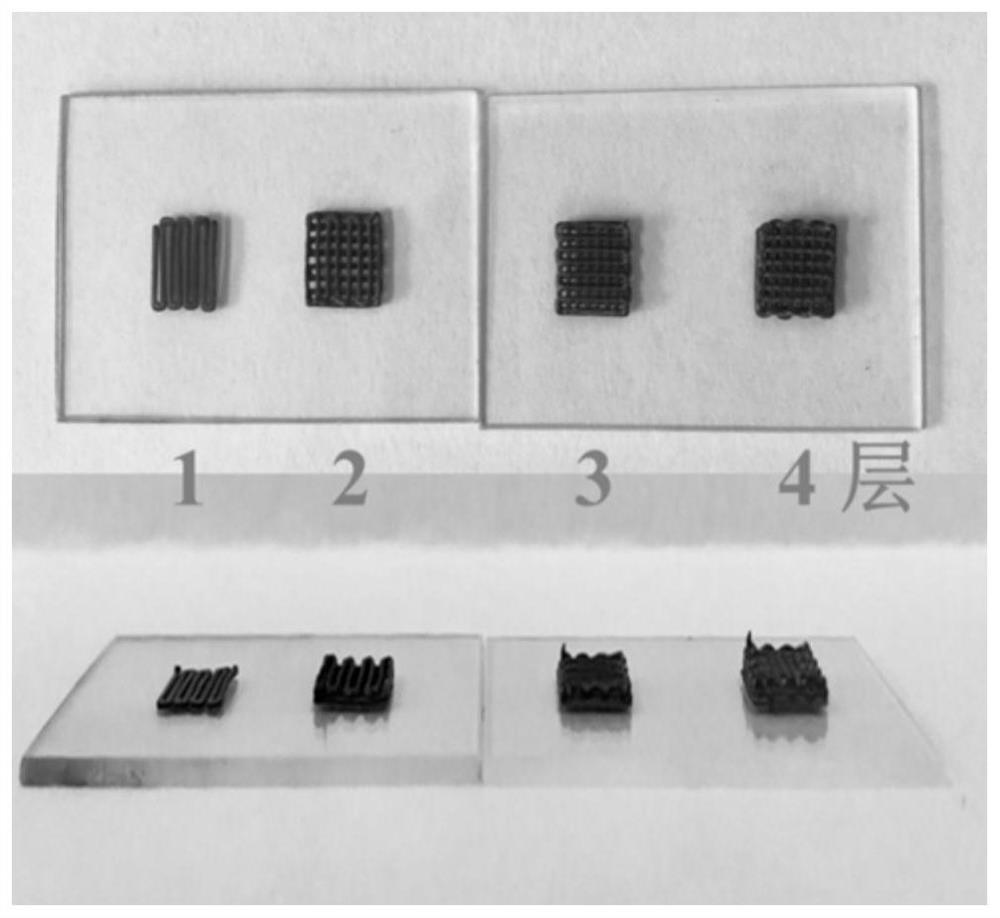

[0027] Weigh 700 mg of nano-lithium iron phosphate, 200 mg of graphene and 100 mg of polyvinylidene fluoride, mix them, add them into a mortar, grind for 10 minutes, add 3 mL of N-methylpyrrolidone, and continue grinding for 10 minutes to obtain the precursor of 3D printing nano-electrode slurry. grade samples, and then further make the final sample of pasty 3D printing battery electrode slurry by self-shear dispersion, the rheological properties of the prepared 3D printing battery electrode slurry are as follows: figure 1 shown.

Embodiment 2

[0029] Weigh 600mg of nano-lithium iron phosphate, 300mg of multi-walled carbon nanotubes and 100mg of polyvinylidene fluoride, mix them, add them into a mortar, grind for 10 minutes, add 2mL of N-methylpyrrolidone and continue grinding for 10 minutes to obtain 3D printing nano-electrode slurry The pre-stage samples were further made into paste-like 3D printing battery electrode paste final samples by self-shear dispersion.

Embodiment 3

[0031] Weigh 600mg of nano-lithium titanate, 300mg of conductive carbon black and 100mg of sodium carboxymethyl cellulose and mix them into a mortar. After grinding for 10 minutes, add 4mL of N pure water and continue grinding for 10 minutes to obtain the 3D printing nano-electrode slurry. Grade samples, and then further make the final sample of paste-like 3D printing battery electrode slurry by self-shear dispersion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com