Preparation process of 3D overlapping curve memory cotton

A preparation process and technology of memory foam, which is applied in the field of 3D mesh memory foam preparation technology, can solve the problems of memory foam density, hand feeling, single softness and hardness, oppression of human nerves and blood vessels, and failure to meet the curve of the human body, so as to relieve blood circulation , good toughness, the effect of improving stability and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

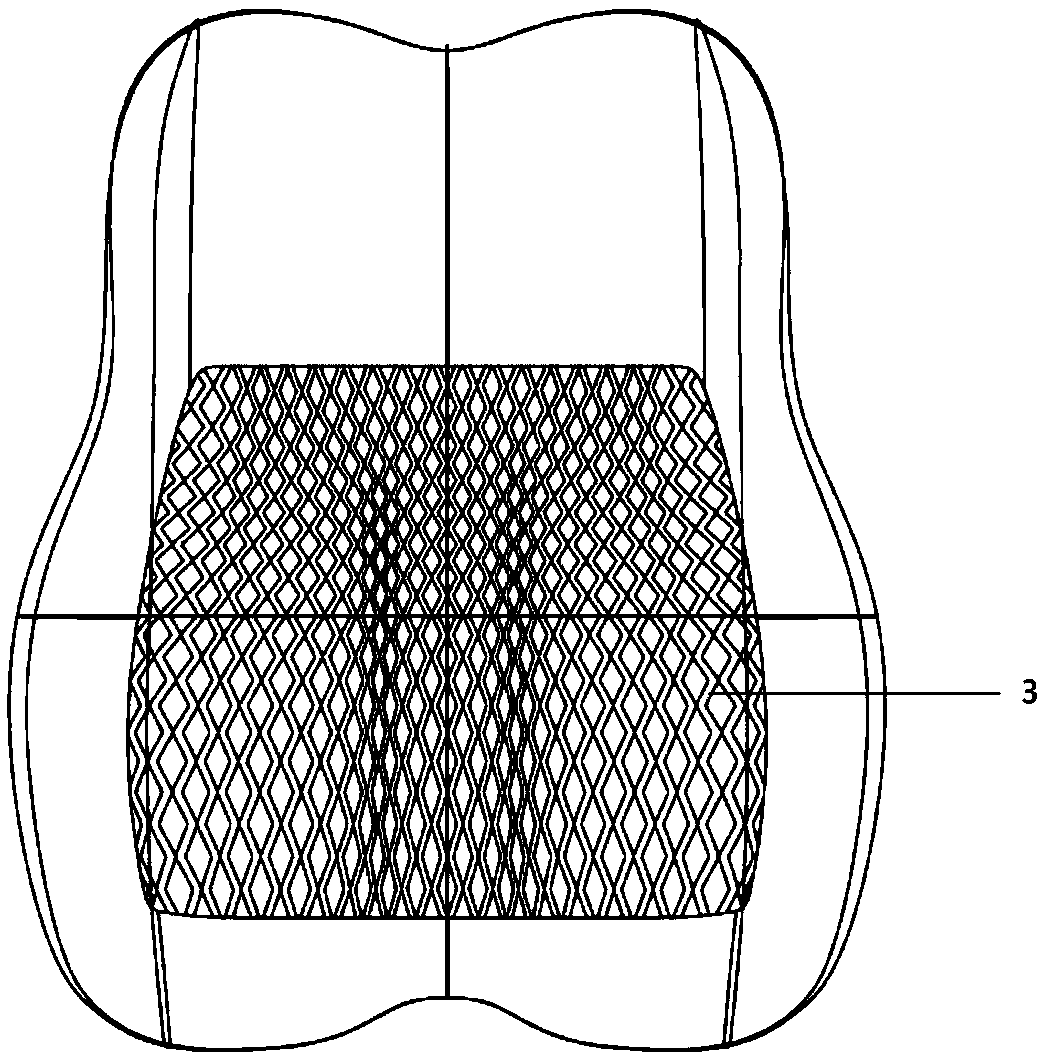

[0055] Example 4: Using the 3D mesh memory foam preparation process to prepare the cotton core of the vehicle waist pillow

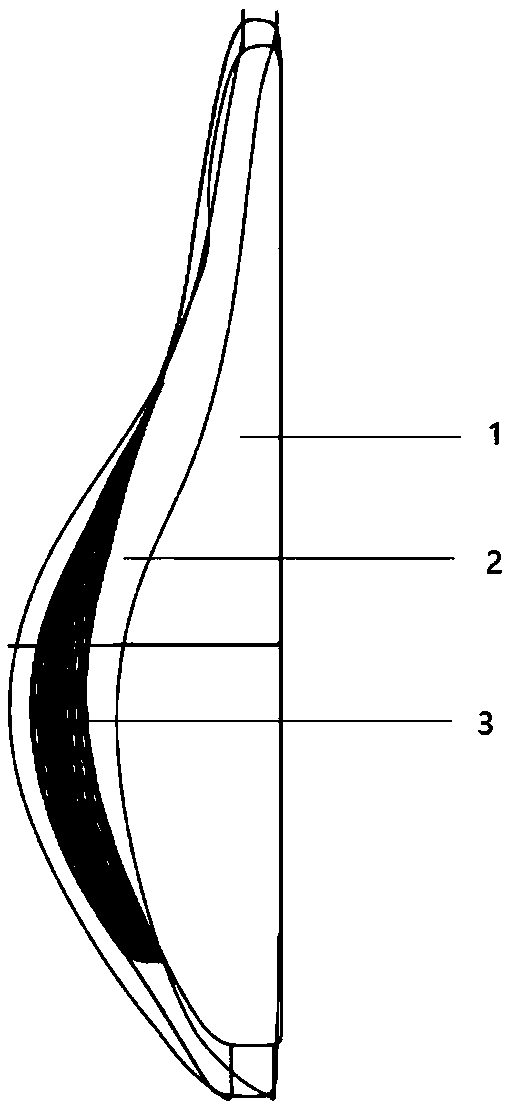

[0056] The vehicle-mounted lumbar pillow is provided with a support layer 1, a comfort layer 2 and a 3D breathable layer 3, and the preparation process includes the following steps:

[0057] 1) Make a foaming mold according to the specific shape and size of the vehicle-mounted lumbar pillow;

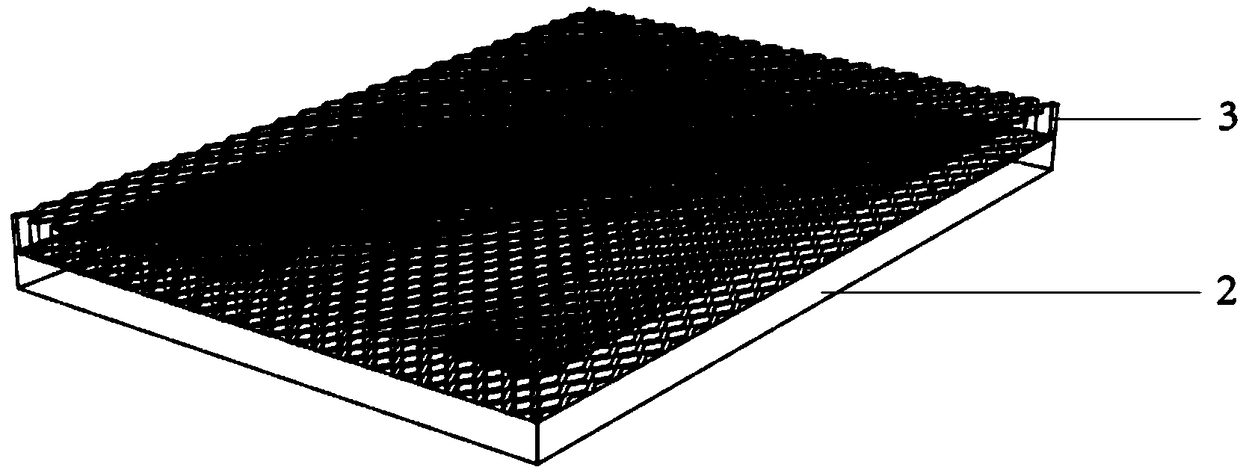

[0058] 2) The memory foam sheet is cut into a 3D reticulated memory foam sheet by a machine to obtain a 3D breathable layer;

[0059] 3) Combining the comfort layer on the 3D breathable layer with an adhesive to form the first structural layer;

[0060] 4) preparing the mixture of the supporting layer, and putting the first structural layer into the preheated foaming mold;

[0061] 5) Pour the mixture into the foaming mold, open the mold after cooling and molding, and obtain the cotton core of the car lumbar pillow and neck pillow.

[0062] The cotton core of th...

Embodiment 5

[0063] Example 5: Neck Pillow Cotton Core Prepared by 3D Mesh Memory Foam Preparation Process

[0064] The neck pillow cotton core is provided with a support layer 1, a comfort layer 2 and a 3D breathable layer 3, and the preparation process includes the following steps:

[0065] 1) Make a foaming mold according to the specific shape and size of the vehicle-mounted lumbar pillow;

[0066] 2) The memory foam sheet is cut into a 3D reticulated memory foam sheet by a machine to obtain a 3D breathable layer;

[0067] 3) Combining the comfort layer on the 3D breathable layer with an adhesive to form the first structural layer;

[0068] 4) preparing the mixture of the supporting layer, and putting the first structural layer into the preheated foaming mold;

[0069] 5) The mixture is poured into the foaming mold, and the mold is opened after cooling and molding to obtain a vehicle-mounted lumbar pillow.

[0070] The neck pillow cotton core prepared by the 3D mesh memory foam prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com