Preparation method for chronic springback resin material used for shoe sole

A resin material, a technology of chronic rebound, applied in the field of resin products, can solve the problems of use and poor compression performance, and achieve the effects of reducing discomfort or pain, good anti-slip effect, and preventing falls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

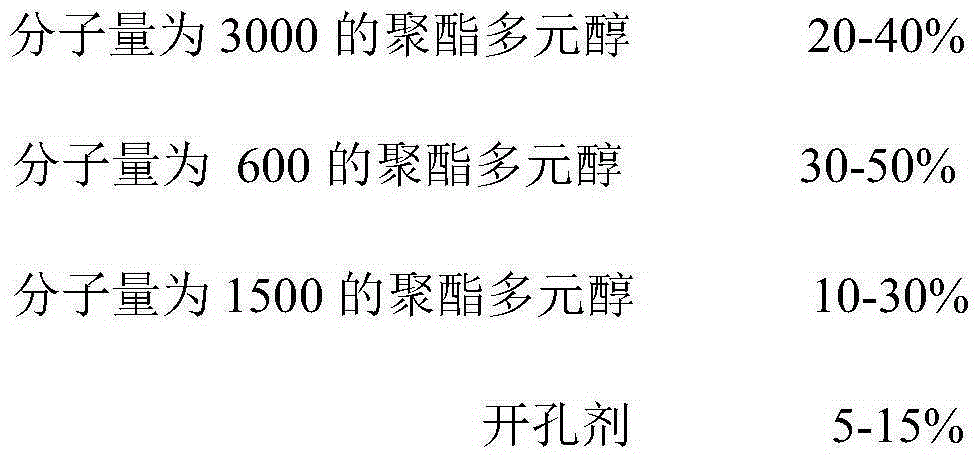

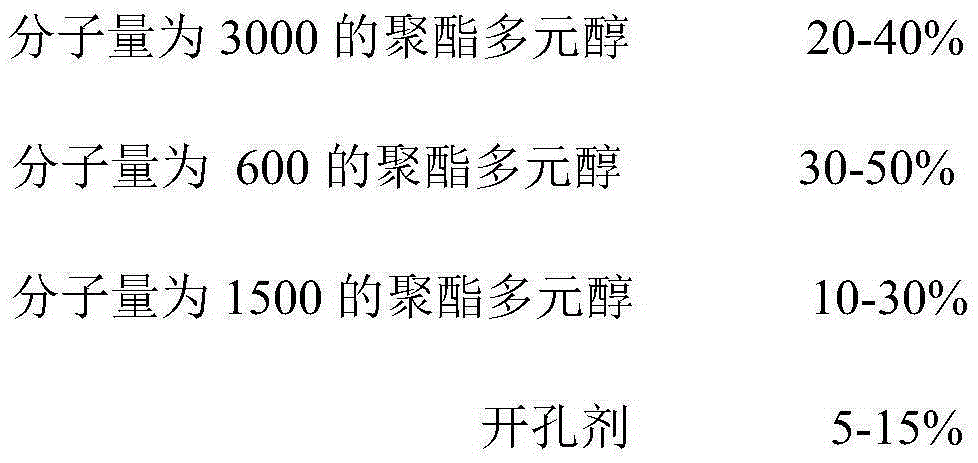

[0040] The composition and weight ratio of A raw material are as follows:

[0041]

[0042] The production method of A raw material is as follows:

[0043] First, heat the reaction tank to 80°C and keep it for 1 hour to dry it;

[0044] Next, add polyester polyols of different molecular weights and cell openers in the raw material A above into the reaction tank according to the ratio, and stir evenly for 90 minutes. The temperature of the reaction tank is controlled between 80°C and 100°C;

[0045] Finally, after cooling the reaction tank to 50°C, put material B into the material tank and seal the material.

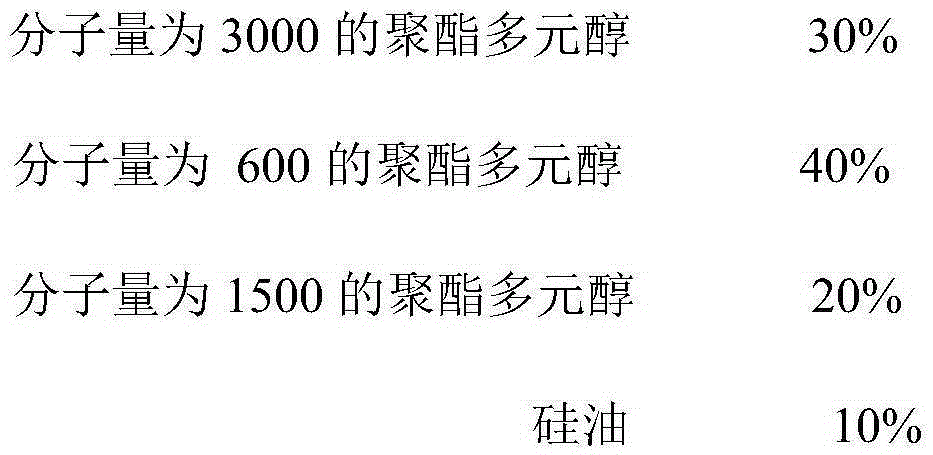

[0046] The composition and weight proportion of described B raw material are as follows:

[0048] Isocyanate 70%;

[0049] The molecular weight of described polyester polyol is 3000, and B raw material composition preparation method is as follows:

[0050] First, heat the reaction tank to 80°C and keep it for 1 hour to dry it;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com