Oil well pipe capable of expanding at large deformation and manufacturing method thereof

A manufacturing method and oil well pipe technology, applied in the field of alloy steel, can solve the problems of great difficulty, loss of expansion pipe drilling technology, cost saving, no mention of steel pipe expansion deformation uniform elongation, yield strength ratio, etc., to achieve impact performance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

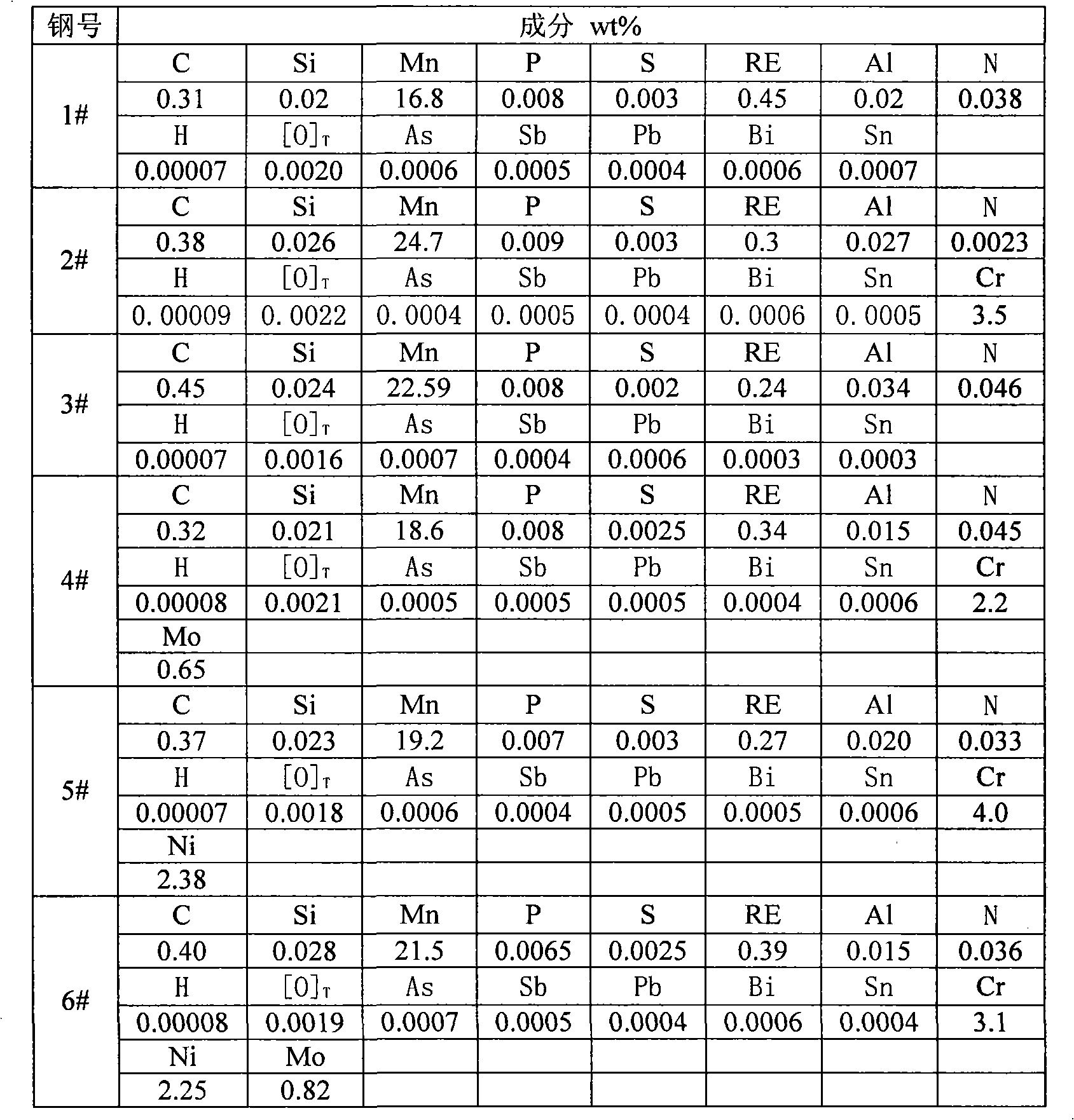

[0042] After "electric furnace smelting→ladle refining (electroslag remelting)→steel ingot casting→steel ingot finishing→forging round tube billet→rolling tube (tube billet heating+perforation+PQF continuous rolling+micro-stretching reduction)→cooling→straightening→ Flaw detection → heat treatment [solution treatment + water toughening treatment (+ aging)] or annealing treatment → spray mark → oiling → packaging and storage” steel pipe production process, in order to obtain the components in Table 2 φ133×15mm, φ177.8 ×9.19mm, φ139.7×7.72mm hot-rolled seamless steel pipe, its maximum outer diameter unevenness rate is 0.53%, and its maximum wall thickness unevenness rate is 2.99%.

[0043] Table 2 The chemical composition of the hot-rolled seamless steel pipe of the present invention

[0044]

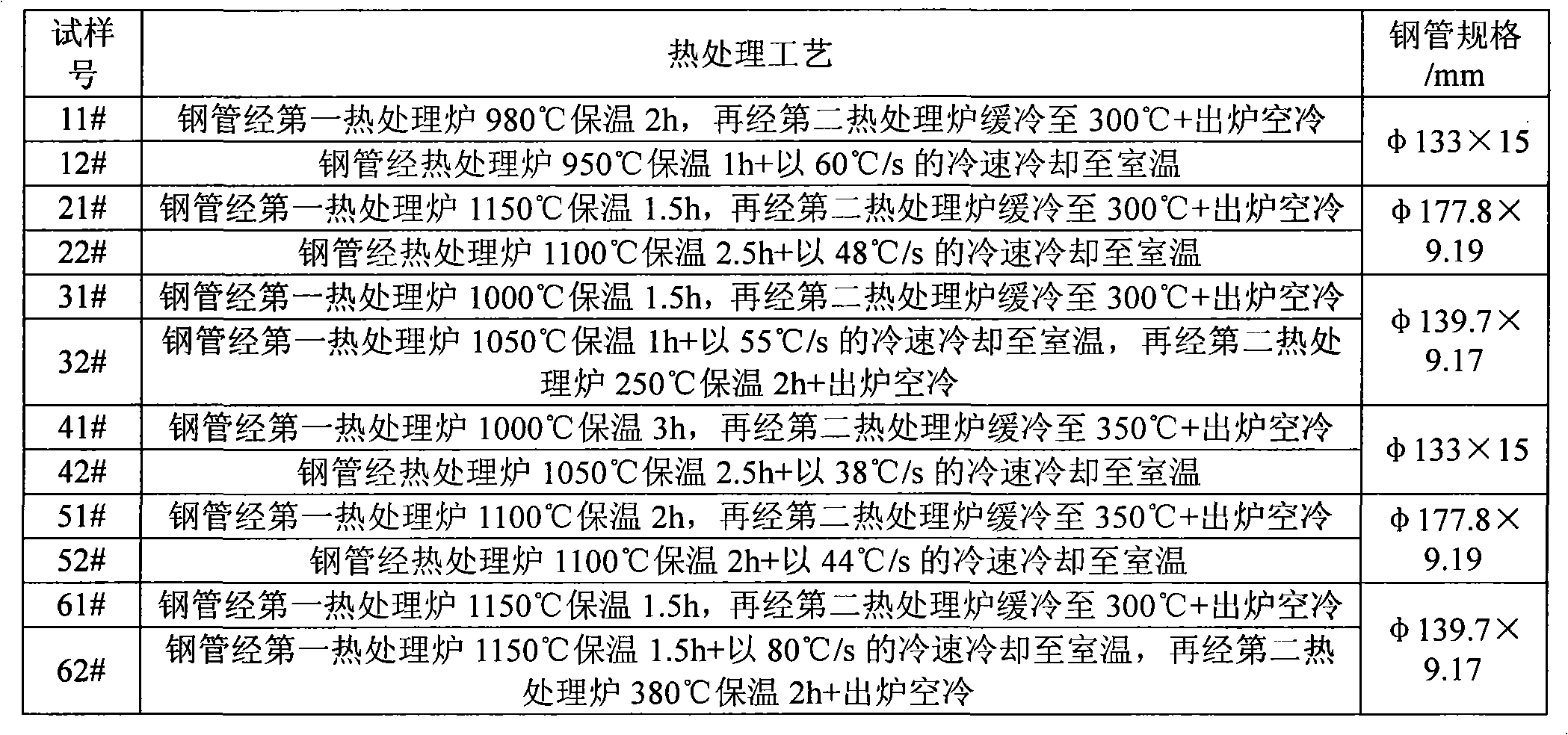

[0045] The heat treatment process implemented on the hot-rolled seamless steel pipe with the chemical composition in Table 2 is shown in Table 3, in which 11# and 12# have the same com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com