Paper diaper and preparation method thereof

A diaper, PTT-PTT technology, applied in the field of disposable sanitary products, can solve the problems of poor air permeability and moisture permeability, stuffy wearing, poor comfort, etc., and achieve the effect of reducing equipment investment, reducing production processes, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

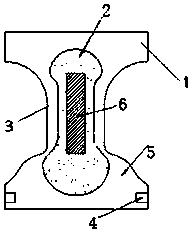

Image

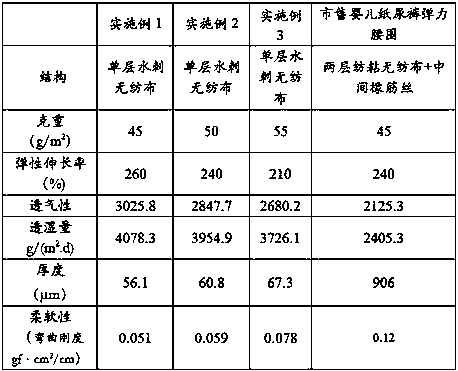

Examples

Embodiment 1

[0039] Step 101, mixing PTT fiber with PTT / PET bicomponent fiber to obtain PTT-PTT / PET mixed fiber, the ratio of PTT fiber and PTT / PET bicomponent fiber in the PTT-PTT / PET mixed fiber is 80- 95%: 5-20%, spray antistatic liquid to the PTT-PTT / PET mixed fiber, and leave the sprayed PTT-PTT / PET mixed fiber for 4-6h to make the PTT-PTT / PET The moisture regain of PET mixed fiber reaches 9.5-10.5%, wherein, the proportioning of each component in the described antistatic liquid is antistatic softening agent: water is 5-9%:91-95%, and described antistatic softening agent is Non-ionic.

[0040] Step 102, the PTT-PTT / PET mixed fiber after standing is subjected to rough opening, fine opening and carding into a web process to obtain a PTT-PTT / PET mixed fiber web, wherein the rough opening, fine opening The process parameters of the opening and carding process include: the line speed of the opening roller is 500-650m / min, 640-790 m / min, 850-900 m / min; the speed of the main cylinder is 620...

Embodiment 2

[0058] 201, prepare elastic non-woven fabric:

[0059] A. Selection of raw materials:

[0060] PTT fiber is selected, the fiber fineness is 1.5D, and the length is 38mm; the fiber structure is eccentric PTT / PET bicomponent fiber, the eccentric ratio is 6:4, the fiber fineness is 2D, and the length is 40mm.

[0061] B. Preprocessing:

[0062] PTT fibers are mixed with PTT / PET bicomponent fibers to obtain PTT-PTT / PET mixed fibers, and the ratio of PTT fibers to PTT / PET bicomponent fibers in the PTT-PTT / PET mixed fibers is 95%: 5% , spray antistatic liquid to the PTT-PTT / PET mixed fiber, and leave the sprayed PTT-PTT / PET mixed fiber for 4 hours, so that the moisture regain of the PTT-PTT / PET mixed fiber reaches 9.5% , wherein, the proportioning of each component in the antistatic liquid is antistatic softener: water is 5%:95%, and the antistatic softener is nonionic.

[0063] C. Preparation of non-woven base fabric:

[0064] (1) The PTT-PTT / PET mixed fiber after standing i...

Embodiment 3

[0077] 301, prepare elastic non-woven fabric:

[0078] A. Selection of raw materials:

[0079] PTT fiber is selected, the fiber fineness is 2D, and the length is 38mm; the fiber structure is eccentric PTT / PET bicomponent fiber, the eccentric ratio is 6:4, the fiber fineness is 2D, and the length is 40mm.

[0080] B. Preprocessing:

[0081] PTT fibers are mixed with PTT / PET bicomponent fibers to obtain PTT-PTT / PET mixed fibers, and the ratio of PTT fibers to PTT / PET bicomponent fibers in the PTT-PTT / PET mixed fibers is 85%: 15% , spray antistatic liquid to the PTT-PTT / PET mixed fiber, and leave the sprayed PTT-PTT / PET mixed fiber for 5 hours, so that the moisture regain of the PTT-PTT / PET mixed fiber reaches 10% , wherein, the proportioning of each component in the antistatic liquid is antistatic softener: water is 7%:93%, and the antistatic softener is nonionic.

[0082] C. Preparation of non-woven base fabric:

[0083] (1) The PTT-PTT / PET mixed fiber after standing is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com