De-dusting device capable of rapidly cleaning fabric dust

A dust removal device, textile cloth technology, applied in the direction of cleaning methods and utensils, cleaning methods using tools, cleaning methods using gas flow, etc., can solve problems such as processing troubles, falling on the ground, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

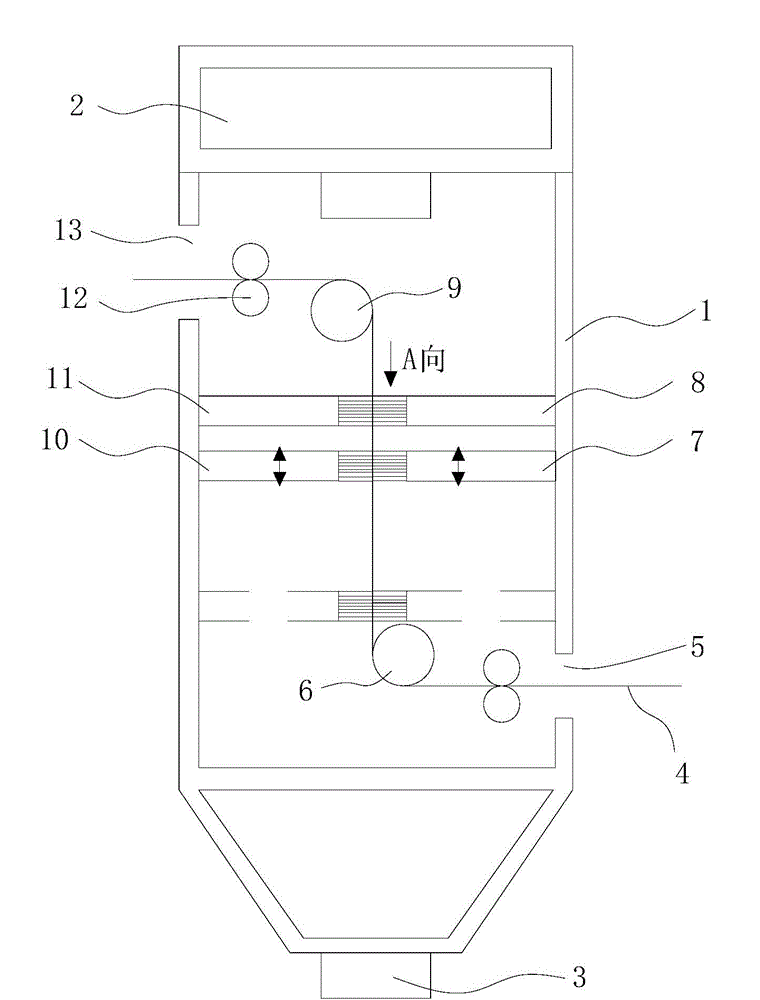

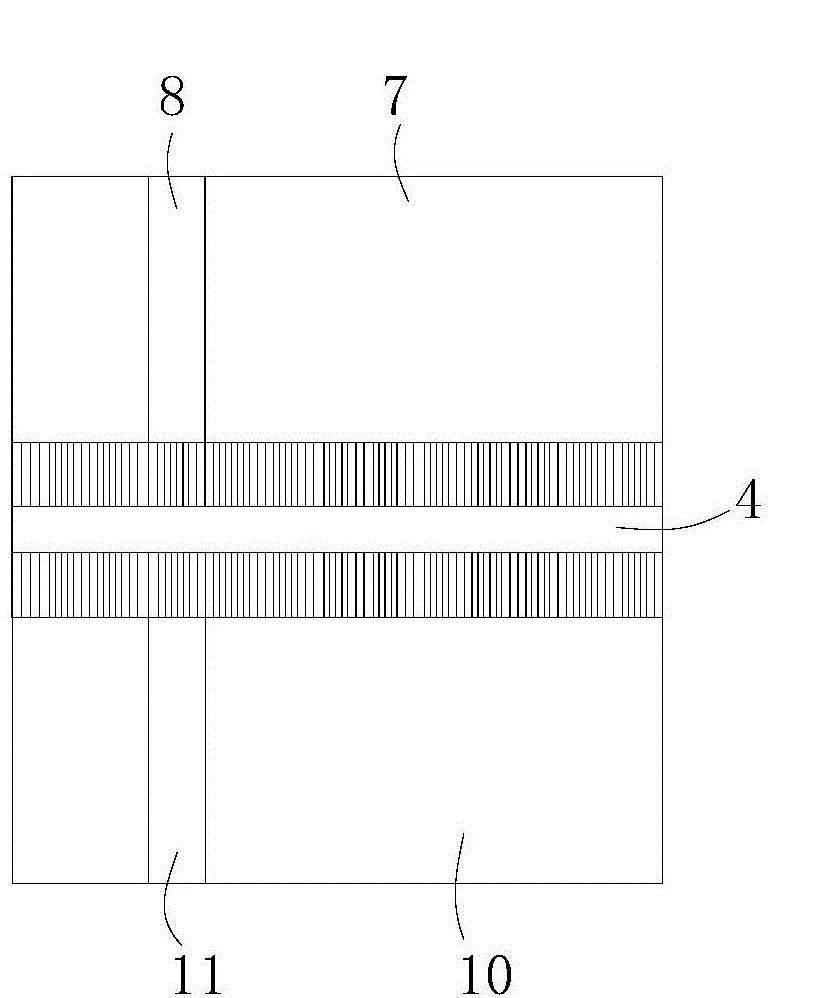

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0017] Such as figure 1 , figure 2 As shown, a dust removal device that can quickly clean the dust of textile cloth includes a box body 1, a blower 2 is arranged on the top of the box body 1, an exhaust fan 3 is arranged on the bottom of the box body 1, and a bottom of one side of the box body 1 is provided with Cloth inlet 5, the top of the other side of the box is provided with a cloth outlet 13, the inner middle of the box 1 is provided with a first transmission roller 6 and a second transmission roller 9 on the same vertical line, the first transmission The roller 6 is located at the same level as the cloth inlet 5, the second drive roller 9 is located at the same level as the cloth outlet 13, and the inner side of the side wall with the cloth inlet 5 of the box body 1 is provided with a width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com