Desulfurized lead-containing wastewater recycling processing method

A treatment method and waste water recycling technology, applied in the field of lead ore smelting, can solve problems such as hazardous waste and secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

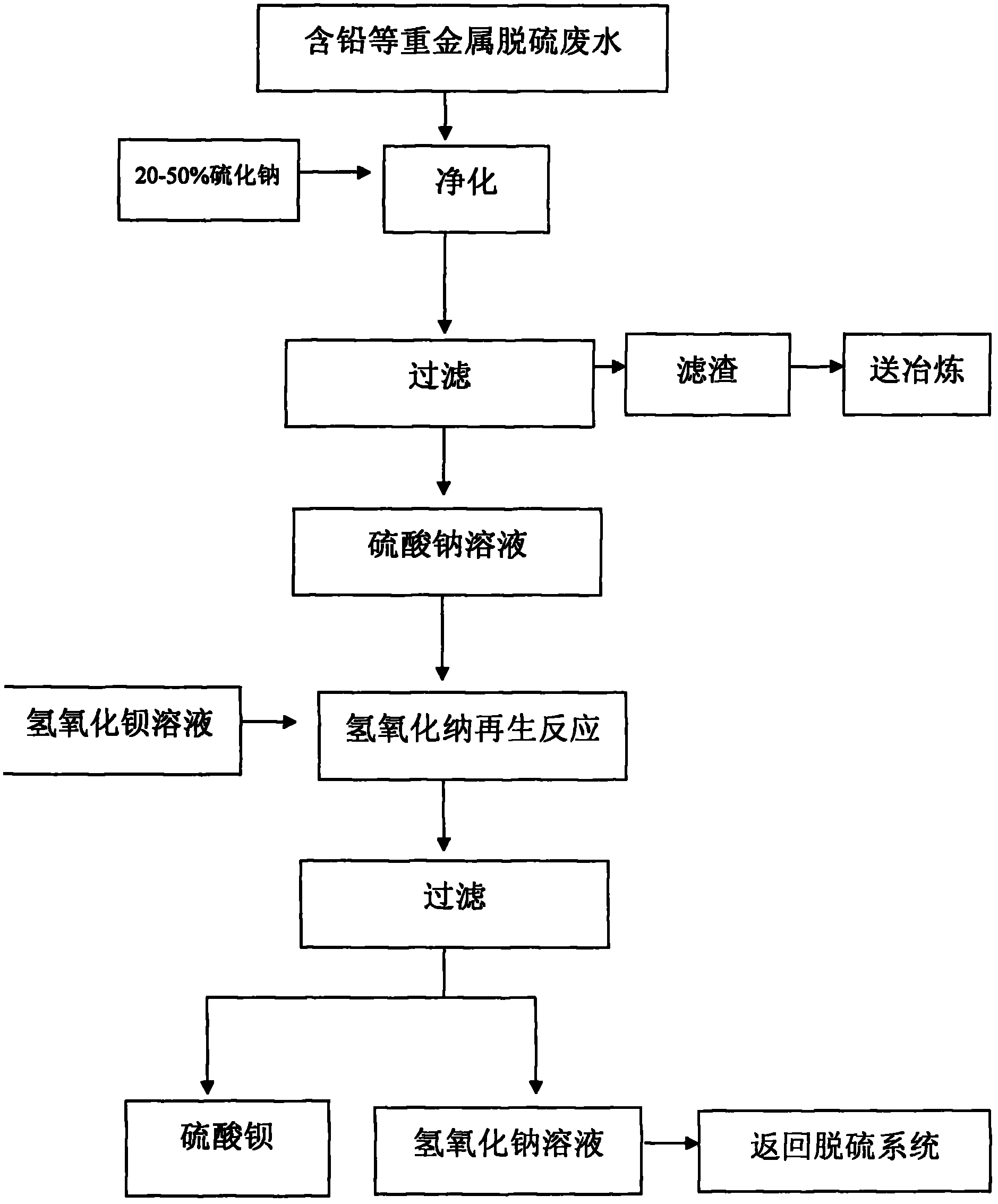

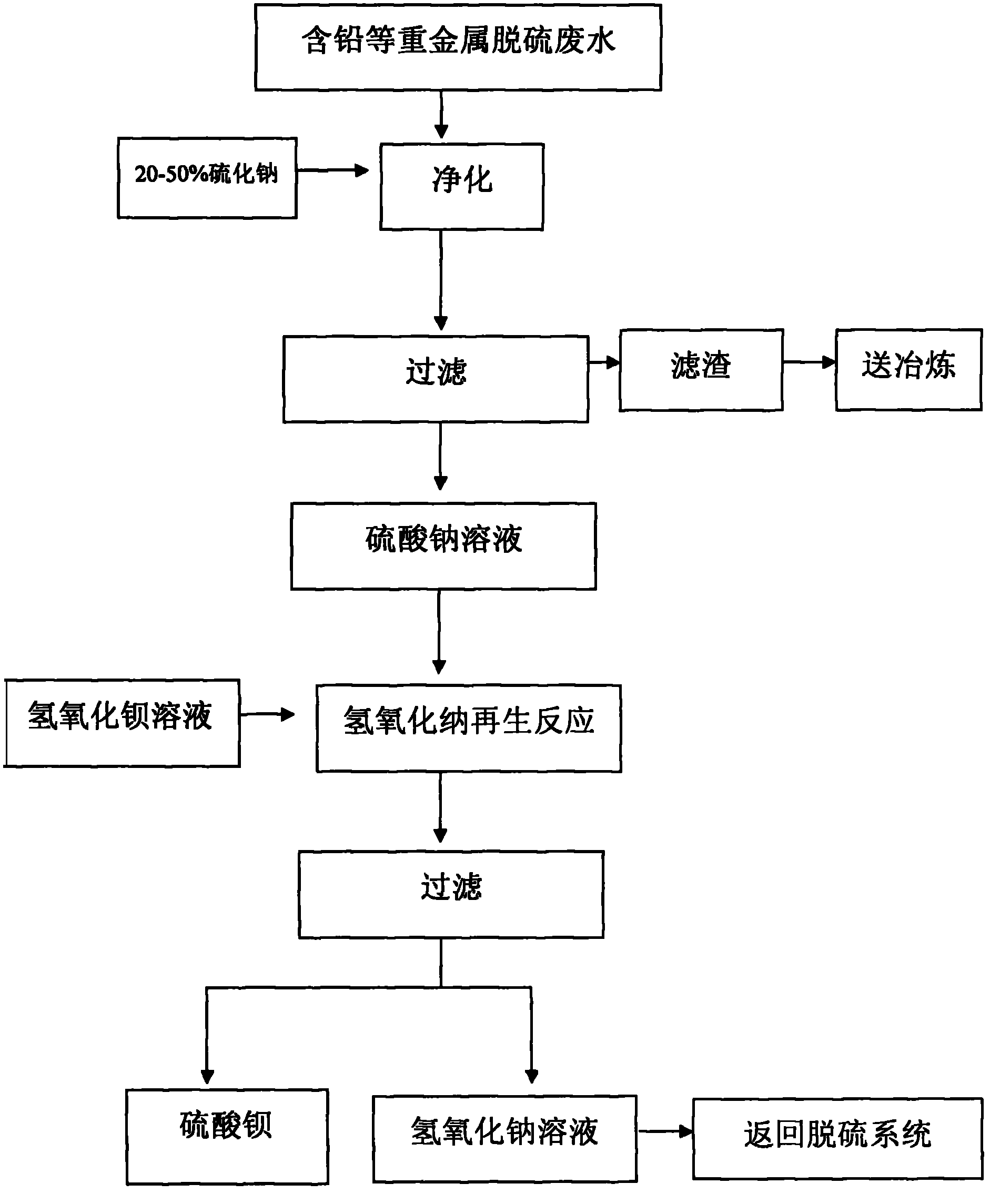

[0009] Such as figure 1 Shown, a kind of desulfurization lead-containing waste water recycling processing method, described processing method is,

[0010] First, according to the heavy metal content in the waste water, at room temperature, add a solution containing 20%--50% sodium sulfide by the weight required for the theoretical reaction to purify, stir and wait for a full reaction, then take a quantitative solution and add sodium sulfide solution dropwise to check until there is no Precipitation means that the reaction is complete, and then filter the fully reacted sodium sulfide solution, and the filtered residue is sent to the smelting process for re-smelting, and then the filtered sodium sulfide solution is slowly added to a theoretical amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com