Metal ceramic combination sintering free low carbon sliding plate brick and preparation method thereof

A technology of cermets and sliding bricks, which is applied in the field of inorganic non-metallic refractory materials, can solve the problems of reduced corrosion resistance, chemical corrosion, and high energy consumption, and achieve good thermal shock resistance and oxidation resistance, high thermal strength, expansion uniform hole effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

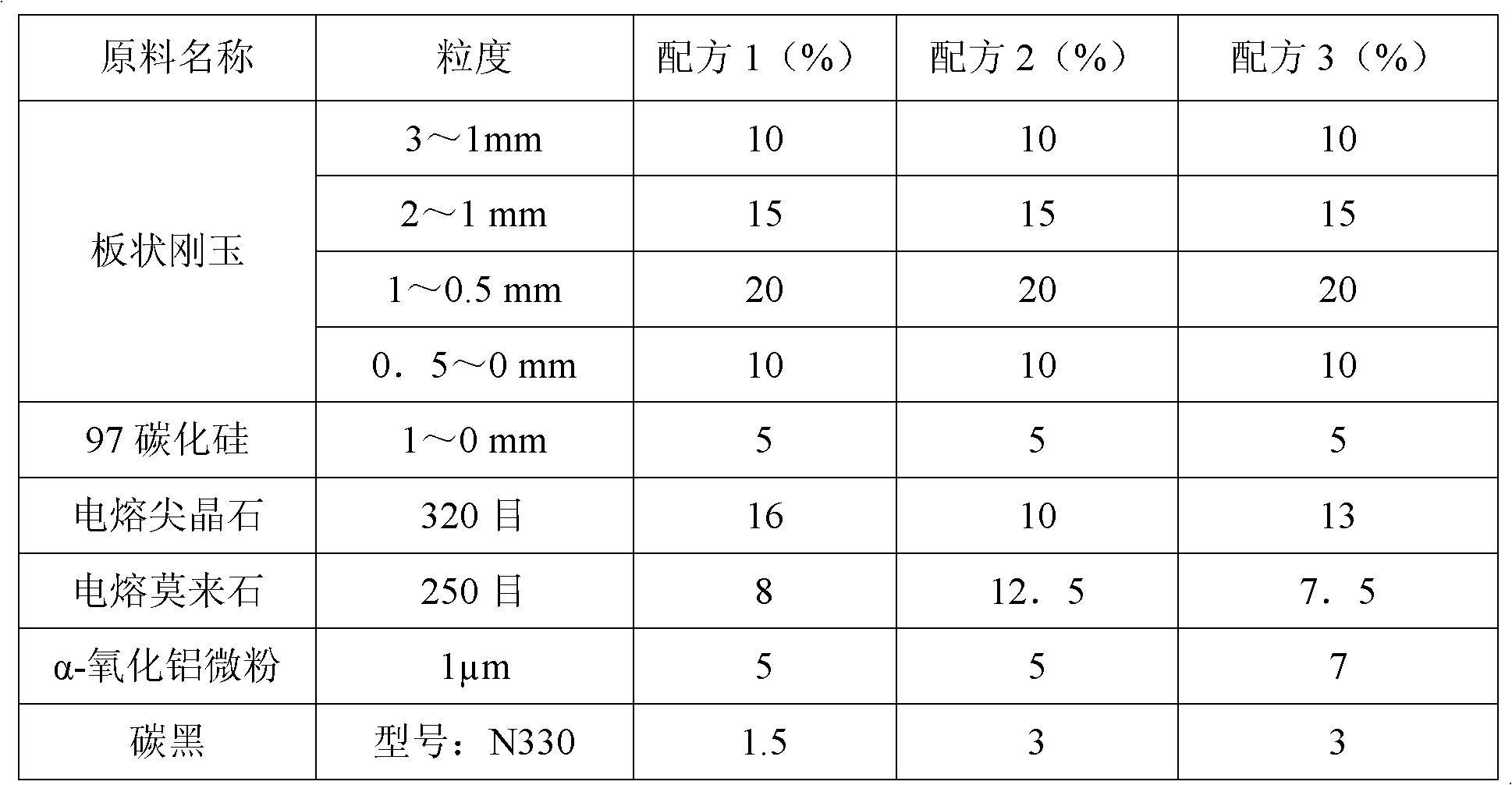

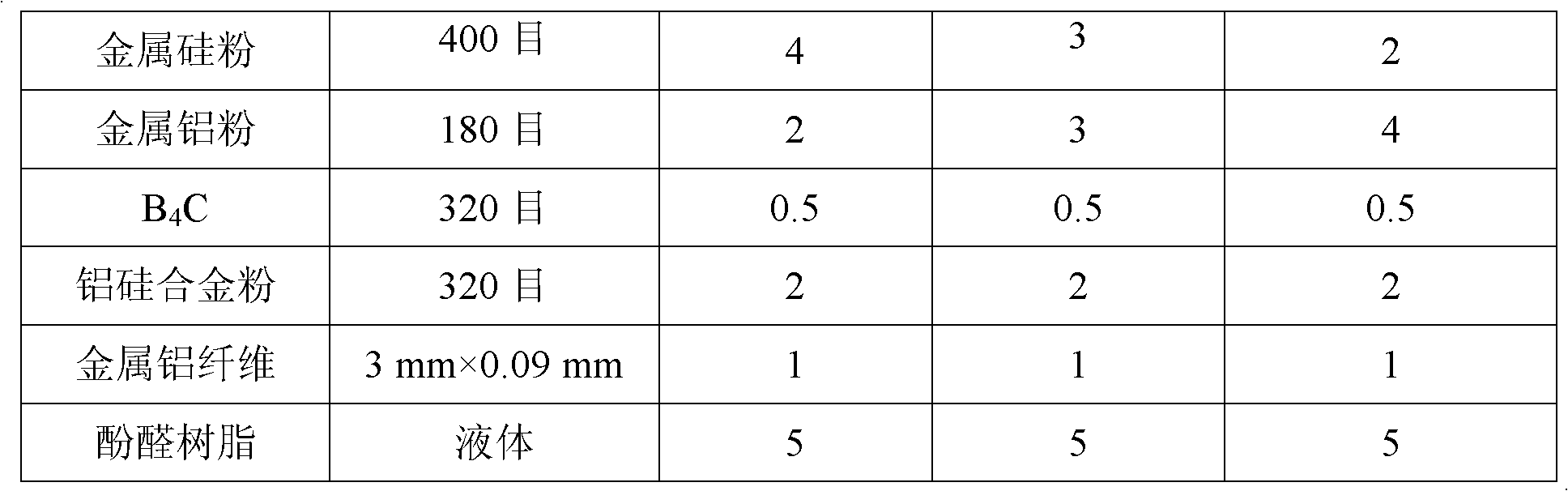

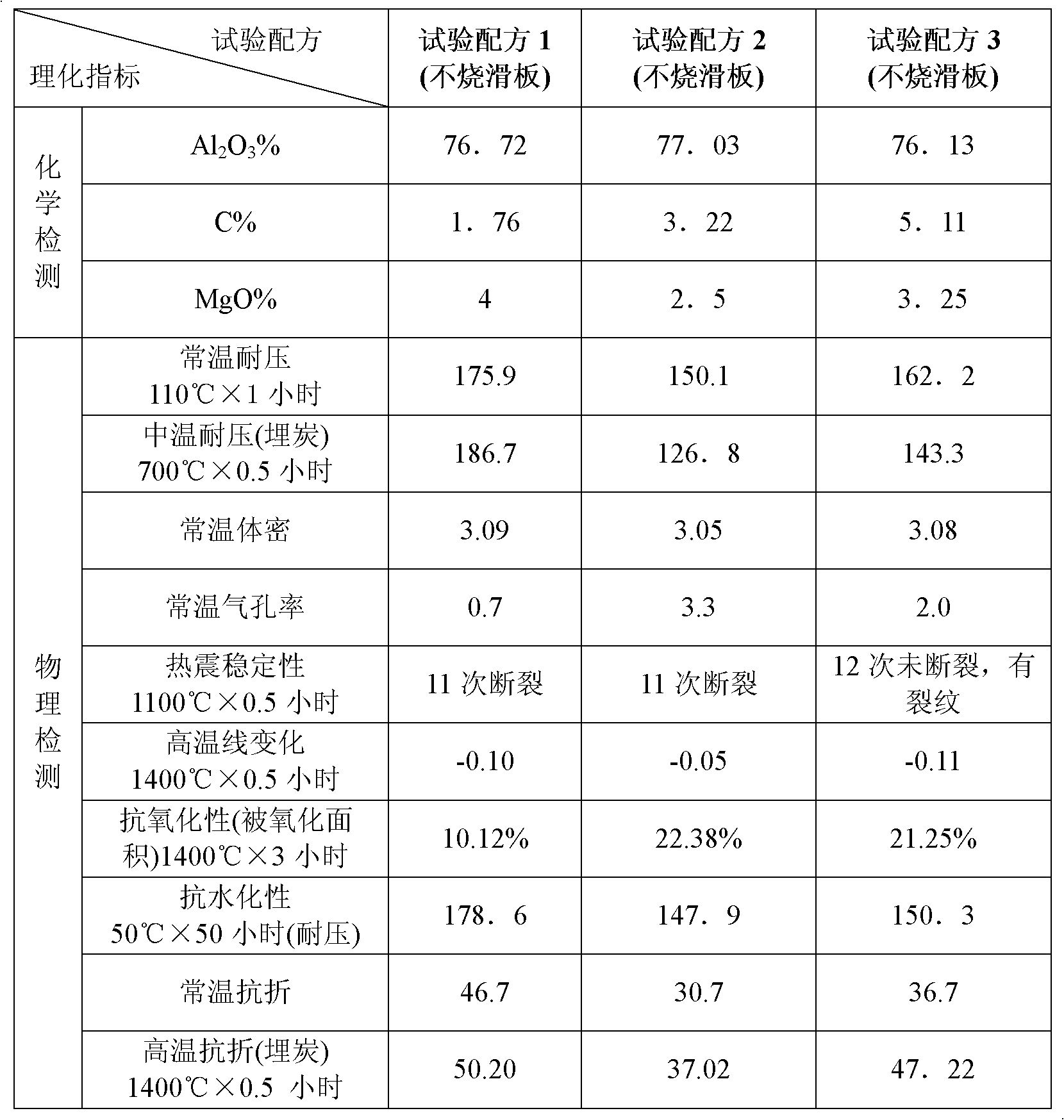

[0036] The basic production process of the invented product is: according to the formula in Table 1, sintering platy corundum (Al 2 o 3 Content ≥ 99.5%) after crushing and screening, carry out batching according to the formula in Table 1, add to wet mill or high-speed kneading machine and mix for 3 to 5 minutes, add liquid phenolic resin binder, and then add carbon black ( Model: N330), metal silicon powder (Si content ≥ 98%), silicon carbide, boron carbide, metal aluminum powder (Al content ≥ 99%), fused spinel (Al 2 o 3 content≥70%, MgO content≥25%), fused mullite (Al 2 o 3 Content≥75%, SiO 2 content ≤ 25%), aluminum-silicon alloy powder, metal aluminum fiber, α-alumina micropowder (alumina content ≥ 98%), mix for 10-30 minutes and discharge. Forming adopts a high-tonnage vacuum brick press of more than 630 tons. According to the shape and size of the brick, the material is accurately weighed. The weighed material is added to the mold and formed to the specified size. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com