Mask spinning cleaning machine and cleaning method of mask

A cleaning machine and photolithographic plate technology, applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as hidden quality problems, secondary pollution, long time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

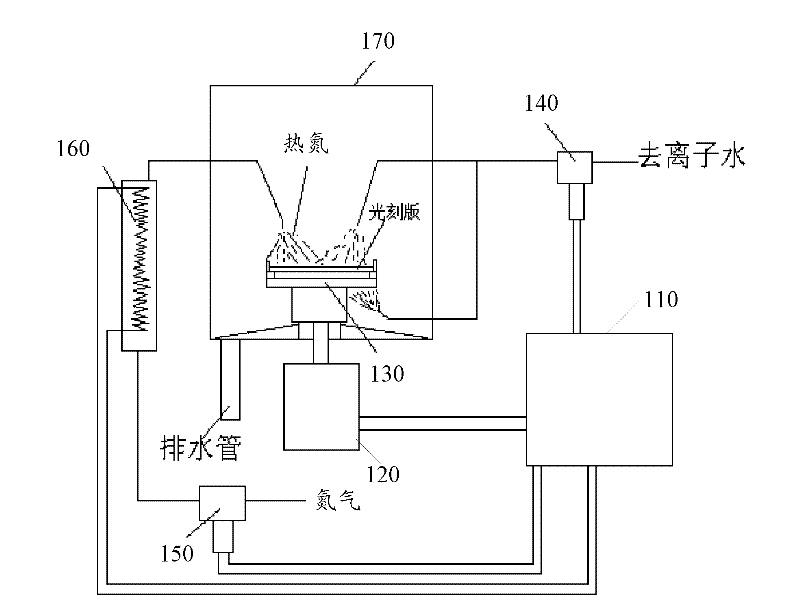

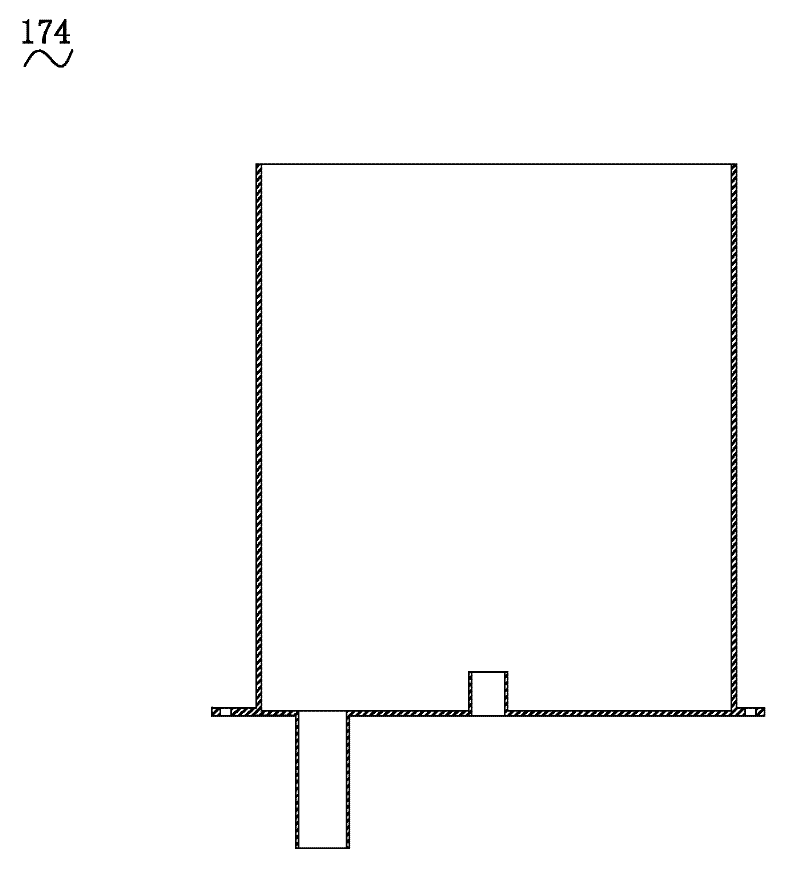

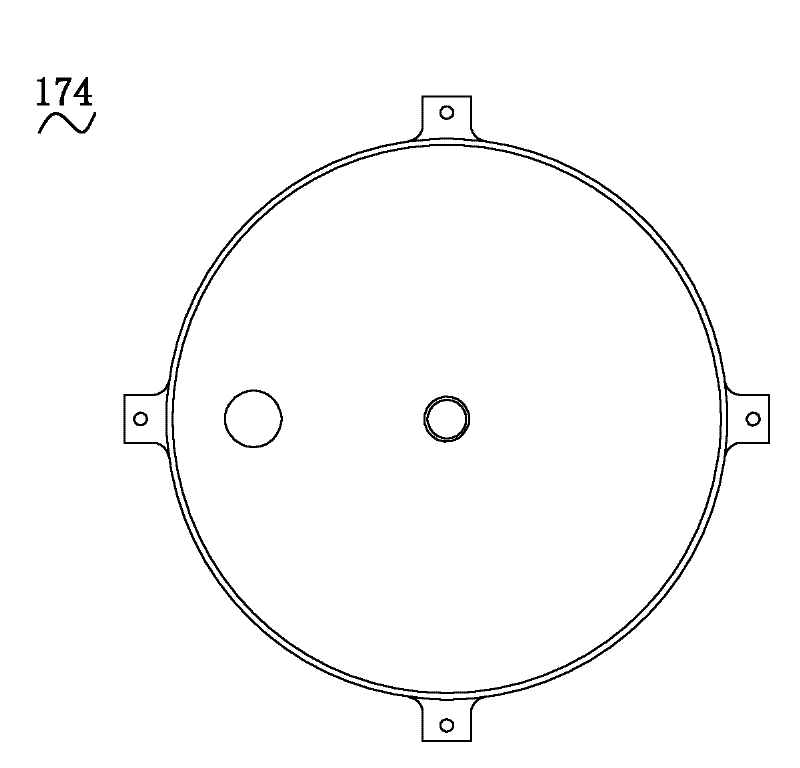

[0028] A plate-throwing cleaning machine, including a plate-throwing cleaning machine control circuit 110, a driving device 120, a photolithography plate clamping device 130, a water outlet valve 140, a water spray head (not marked), an air outlet valve 150, and an air spray head (not marked) , a heating device 160 and pipelines (not shown).

[0029] The driving device 120 is connected to the photolithographic plate clamping device 130 through a rotating shaft, and the control circuit 110 of the plate-spinning cleaning machine is electrically connected to the driving device 120, the water outlet valve 140, the air outlet valve 150 and the heating device 160, and is used to control the driving device 120 to drive the photolithography The plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com