Method for controlling roughness in ULSI multi-layer copper metallization chemico-mechanical polishing

A chemical-mechanical and control method technology, applied in surface polishing machine tools, grinding/polishing equipment, polishing compositions containing abrasives, etc., can solve the problem of high surface roughness, achieve high concentration, improve and reduce roughness, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

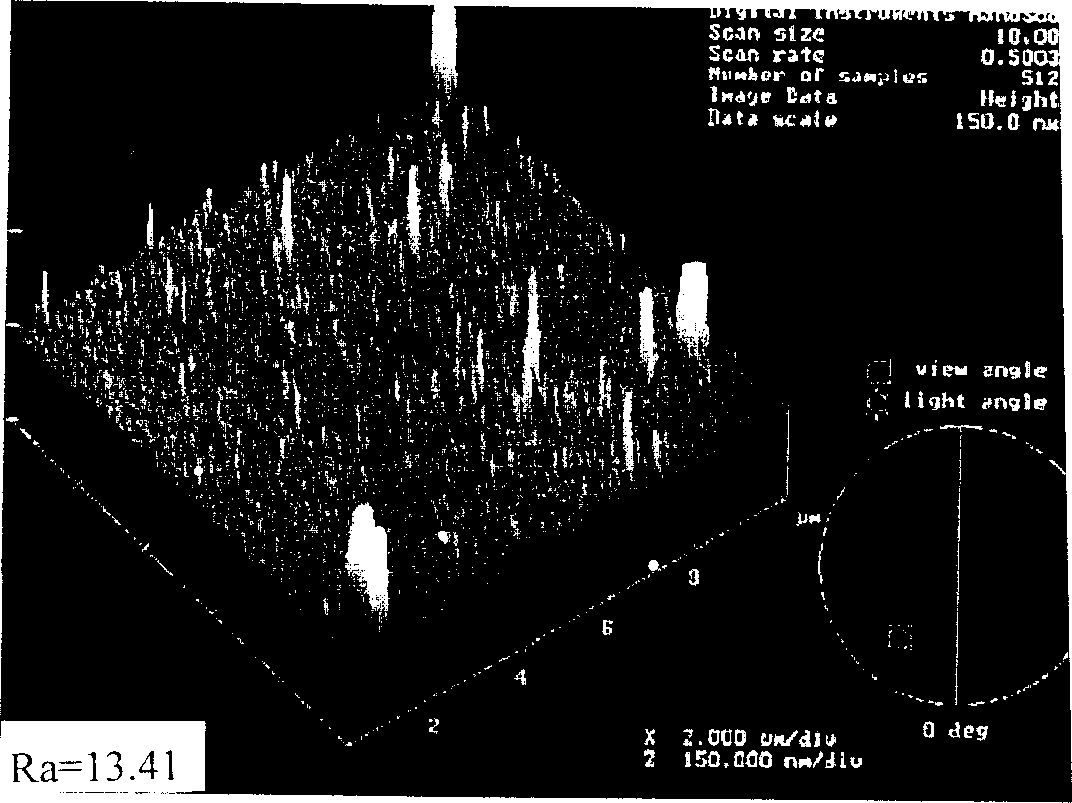

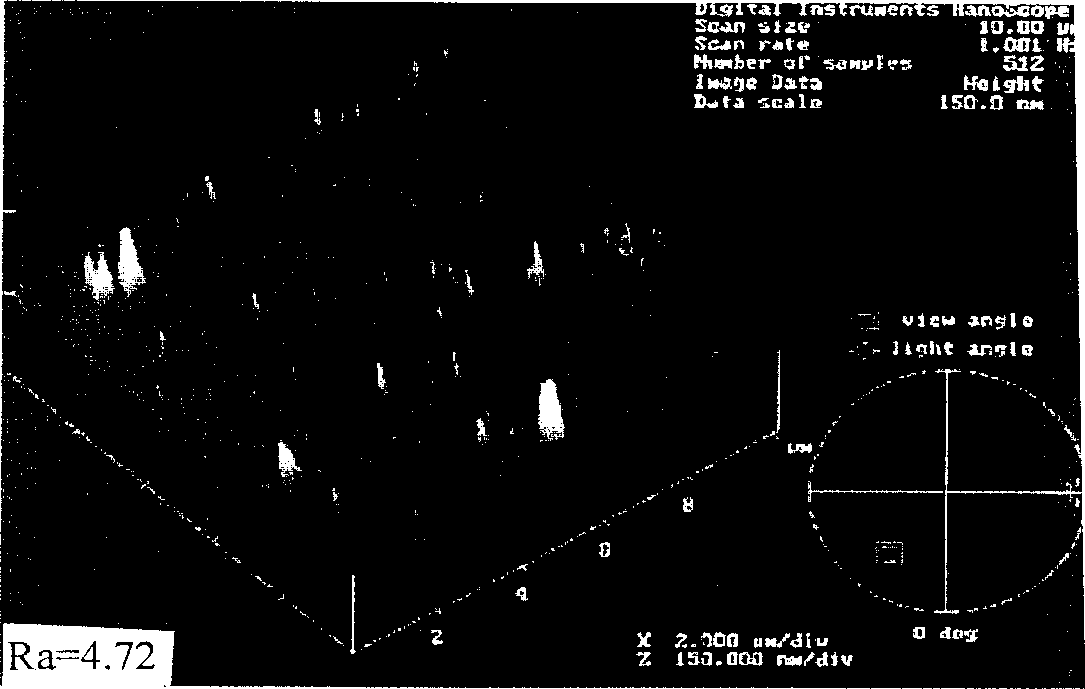

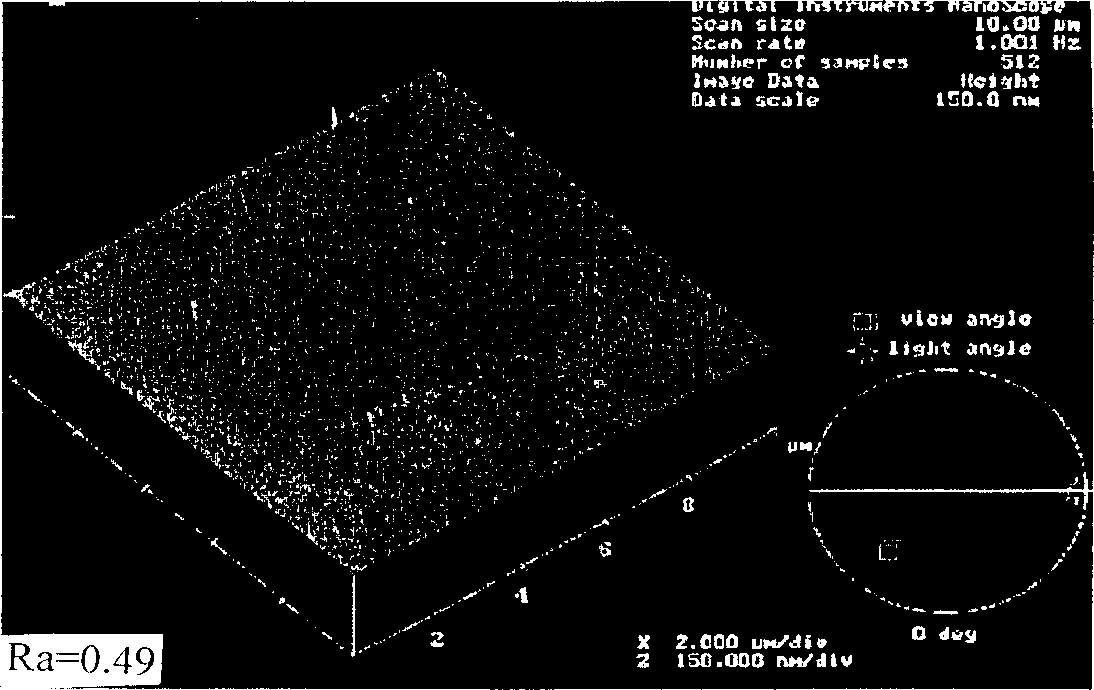

Embodiment 1

[0030] The preparation method of the polishing liquid that is used to reduce the surface roughness of ULSI multilayer copper wiring: select nano-scale silica sol (15-20nm) to make abrasive material for use, concentration is 40%, choose 30L, wherein and deionized water ratio is 1: 1, Add abrasives to deionized water while stirring, add an appropriate amount of hydroxyethylethylenediamine to adjust the pH value to 10, then add 800ml FA / O surfactant, O II -7((C 10 h 21 -C 6 h 4 -O-CH 2 CH 2 O) 7 -H), O II -10((C 10 h 21 -C 6 h 4 -O-CH 2 CH 2 O) 10 -H), O-20(C 12-18 h 25-37 -C 6 h 4 -O-CH 2 CH 2 O) 70 -H), JFC, fatty alcohol polyoxyethylene ether, polyoxyethylene alkylamine, alkanolamide one of the activators are added to the polishing solution while stirring; the polishing conditions are: the applied pressure is zero, and the flow rate is 4L / min, rotating speed 60rpm / min, temperature 25°C, polishing time 4min. Figure 1-Figure 6 The surface topography diagr...

Embodiment 2

[0032] The preparation method of the polishing liquid that is used to reduce the surface roughness of ULSI multilayer copper wiring: select nano-scale silica sol (15-20nm) to make abrasive material, concentration is 45%, choose 35L, be 1: 2 with deionized water ratio, edge Add the abrasive to the deionized water while stirring, add an appropriate amount of dihydroxyethylethylenediamine to adjust the pH value to 11, and then add 2000mlFA / O type I active agent to the polishing liquid while stirring; the polishing conditions are: the applied pressure is zero , the flow rate is 3L / min, the rotation speed is 30rpm / min, the temperature is 20°C, and the polishing time is 5min. other same

[0033] Example 1.

Embodiment 3

[0035] The preparation method of the polishing liquid that is used to reduce the surface roughness of ULSI multilayer copper wiring: select nano-scale silica sol (15-20nm) to make abrasive material, concentration is 50%, choose 40L, be 1: 3 with deionized water ratio, edge Add the abrasive to the deionized water while stirring, add an appropriate amount of triethanolamine to adjust the pH value to 12, and then add 2500mlFA / O type I active agent to the polishing liquid while stirring; the polishing conditions are: the applied pressure is zero, and the flow rate is 5L / min , rotating speed 120rpm / min, temperature 25°C, polishing time 3min. Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com