Method for controlling roughness in ULSI multi-layer copper metallization chemico-mechanical polishing

A chemical-mechanical, control-method technology, applied in surface polishing machine tools, grinding/polishing equipment, polishing compositions containing abrasives, etc., can solve the problem of high surface roughness, achieve high concentration, good dispersion, low The effect of roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

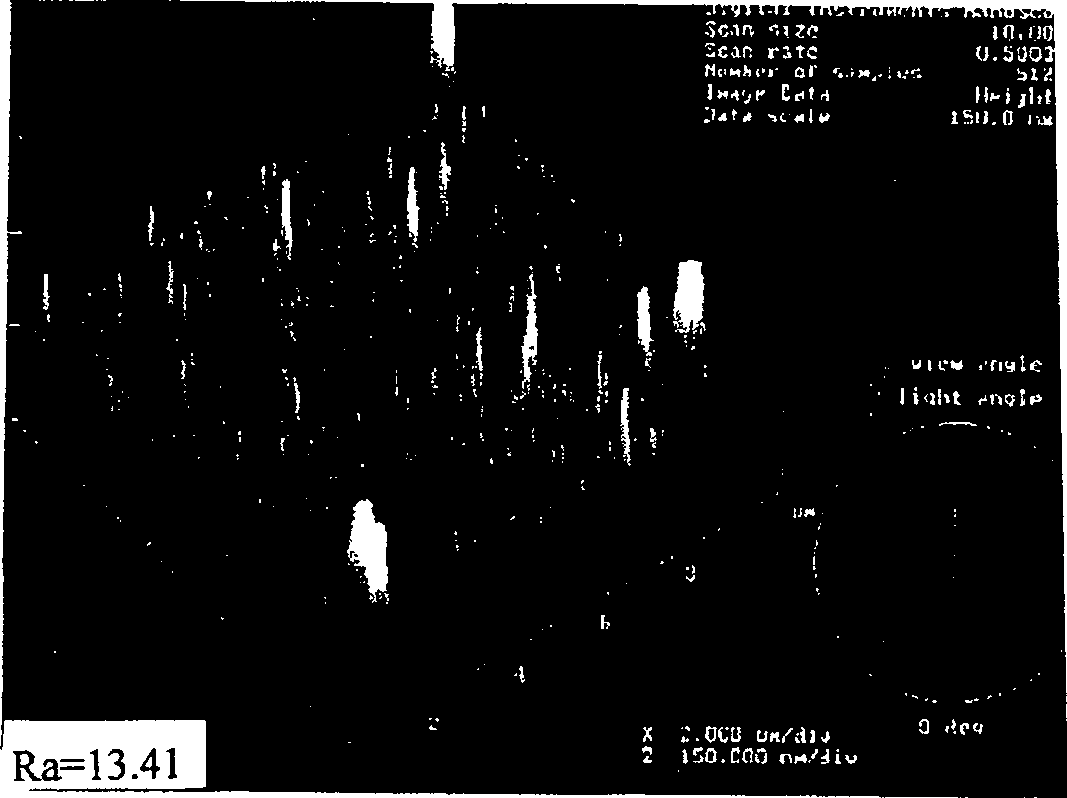

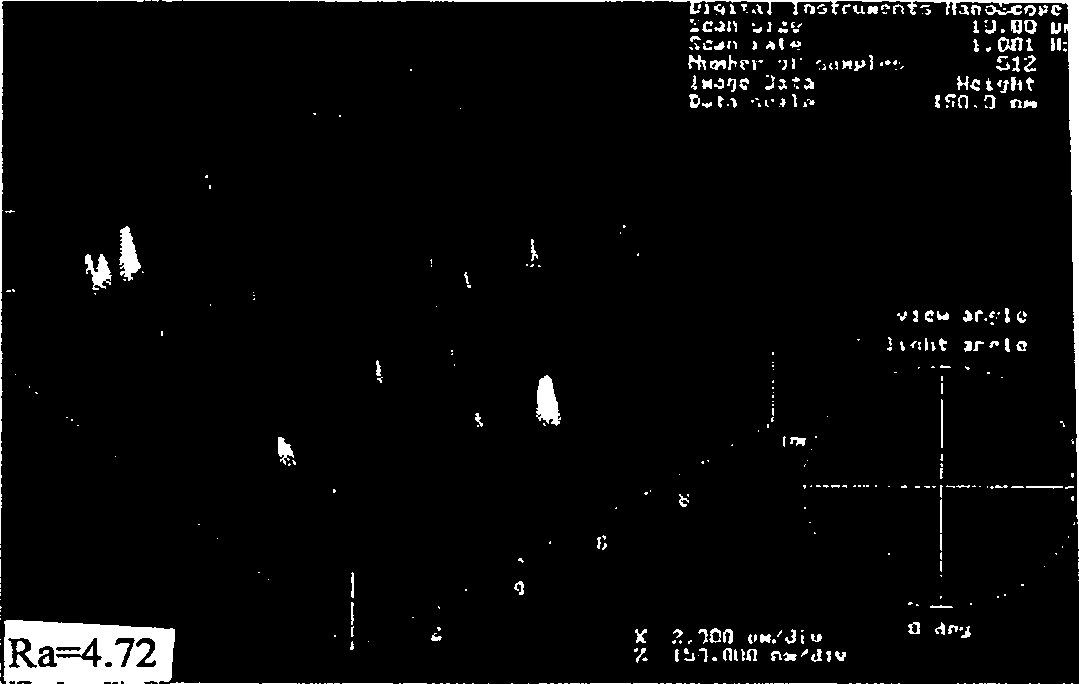

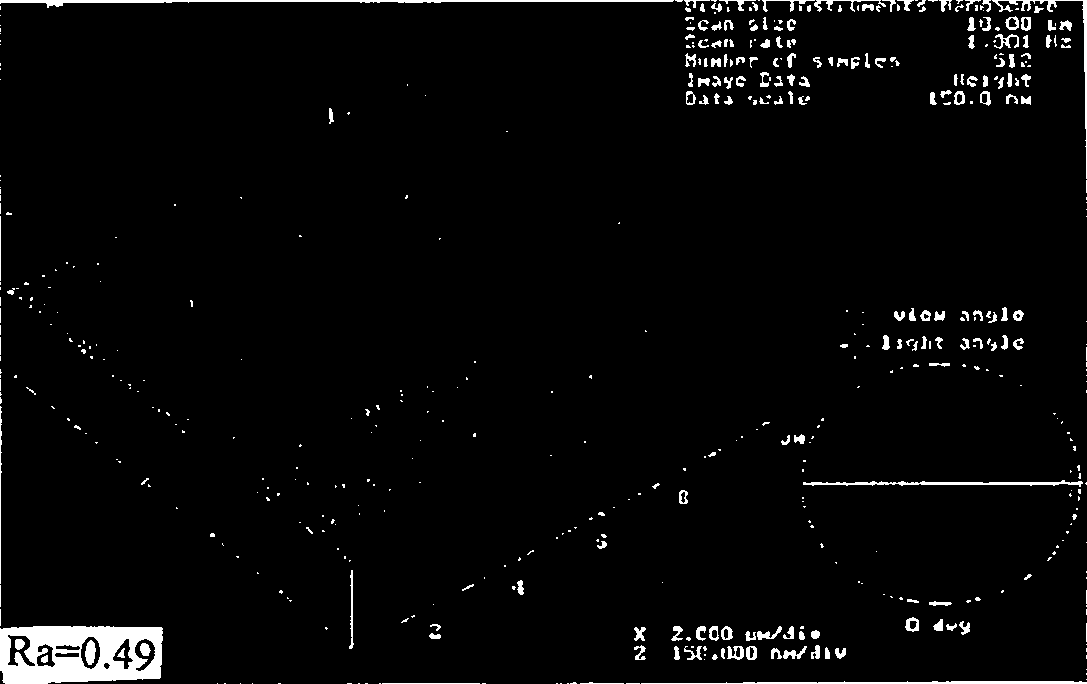

Embodiment 1

[0031] The preparation method of polishing liquid for reducing the surface roughness of ULSI multilayer copper wiring: choose nano-grade silica sol (15-20nm) as abrasive, the concentration is 40%, 30L is selected, and the ratio of deionized water is 1:1. While stirring, add the abrasive to the deionized water, add an appropriate amount of hydroxyethyl ethylene diamine to adjust the pH to 10, and then add 800ml of FA / O surfactant, 0π-7(C 10 H 21 -C 6 H 4 -O-(CH 2 CH 2 O) 7 -H), 0 π -10(C 10 H 21 -C 6 H 4 -O-(CH 2 CH 2 O) 10 -H), 0-20(C 12-18 H 25-37 -C 6 H 4 -O-CH 2 CH 2 O) 70 -H), JFC, fatty alcohol polyoxyethylene ether, polyoxyethylene alkyl amine, alkyl alcohol amide is added to the polishing liquid while stirring; the polishing conditions are: the external pressure is zero, the flow rate is 4L / min, rotating speed 60rpm / min, temperature 25℃, polishing time 4min. Figure 1-Figure 6 The surface topography of copper or tantalum during AFM detection before and after polishing are r...

Embodiment 2

[0033]The preparation method of polishing liquid for reducing the surface roughness of ULSI multilayer copper wiring: choose nano-scale silica sol (15-20nm) as abrasive, the concentration is 45%, 35L is selected, and the ratio of deionized water is 1:2. Add the abrasive to the deionized water while stirring, add an appropriate amount of dihydroxyethylethylenediamine to adjust the pH to 11, and then add 2000ml FA / OI type active agent to the polishing liquid while stirring; the polishing conditions are: the external pressure is zero , Flow rate 3L / min, speed 30rpm / min, temperature 20℃, polishing time 5min. Others are the same as in Example 1.

Embodiment 3

[0035] The preparation method of polishing liquid for reducing the surface roughness of ULSI multilayer copper wiring: choose nano-grade silica sol (15-20nm) as abrasive, concentration is 50%, choose 40L, and the ratio of deionized water is 1:3. Add the abrasive to the deionized water while stirring, add an appropriate amount of triethanolamine to adjust the pH to 12, and then add 2500ml FA / OI active agent to the polishing solution while stirring; the polishing conditions are: the external pressure is zero, and the flow rate is 5L / min , Rotating speed 120rpm / min, temperature 25℃, polishing time 3min. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com