Preparation method and application of aptamer electrochemical sensor

An aptamer and electrochemical technology, which is applied in the field of biosensors and electrochemical detection, can solve the problems of high maintenance costs, unsatisfactory rapid detection, expensive instruments and equipment, etc., achieve low cost, improve electrode surface state, and sample consumption little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

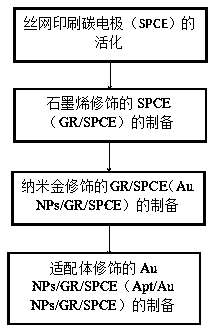

[0028] Based on SPCE, graphene and nano gold, the construction process of the aptamer electrochemical sensor for the detection of BPA is as follows: figure 1 Shown:

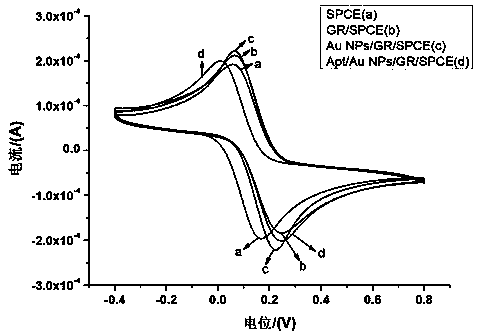

[0029](1) Activation of SPCE: Draw 80 µL of 0.1 mol / L sulfuric acid solution and drop it on the surface of the electrode, and activate it by cyclic voltammetry (CV). 20 laps. Finally, the cyclic voltammetry test was carried out in 10 mmol / L potassium ferricyanide solution, the scanning range was -0.4~0.8 V, and the scanning speed was 100 mV / s, and the peak potential difference of the obtained cyclic voltammetry curve was observed (200 mV about). Then rinse with absolute ethanol and ultrapure water in sequence, and finally blow dry with nitrogen to obtain the activated SPCE.

[0030] (2) Preparation of GR / SPCE: PEDOT:PSS was mixed with ultrapure water at a ratio of 1:1 as a graphene dispersant, and a dispersion liquid with a graphene concentration of 0.25 mg / mL was prepared. Pipette 5 µL of the above on the su...

Embodiment 2

[0034] Construction of an aptamer electrochemical sensor for the detection of BPA based on SPCE, graphene and gold nanoparticles:

[0035] (1) Activation of SPCE: 90 µL of 0.1 mol / L sulfuric acid solution was dropped on the surface of the electrode, activated by cyclic voltammetry (CV), the scanning range was -0.6~1.5 V, and the scanning speed was 100 mV / s. 30 laps. Finally, the cyclic voltammetry test was carried out in 10 mmol / L potassium ferricyanide solution, the scanning range was -0.4~0.8 V, and the scanning speed was 100 mV / s, and the peak potential difference of the obtained cyclic voltammetry curve was observed (200 mV about). Then rinse with absolute ethanol and ultrapure water in sequence, and finally blow dry with nitrogen to obtain the activated SPCE.

[0036] (2) Preparation of GR / SPCE: PEDOT:PSS was mixed with ultrapure water at a ratio of 1:1 as a graphene dispersant, and a dispersion liquid with a graphene concentration of 0.5 mg / mL was prepared. Pipette 8 ...

Embodiment 3

[0040] Construction of an aptamer electrochemical sensor for the detection of BPA based on SPCE, graphene and gold nanoparticles:

[0041] (1) Activation of SPCE: 85 µL of 0.1 mol / L sulfuric acid solution was dropped on the surface of the electrode, activated by cyclic voltammetry (CV), the scanning range was -0.6~1.5 V, and the scanning speed was 80 mV / s. 25 laps. Finally, the cyclic voltammetry test was carried out in 10 mmol / L potassium ferricyanide solution, the scanning range was -0.4~0.8 V, and the scanning speed was 100 mV / s, and the peak potential difference of the obtained cyclic voltammetry curve was observed (200 mV about). Then rinse with absolute ethanol and ultrapure water in sequence, and finally blow dry with nitrogen to obtain the activated SPCE.

[0042] (2) Preparation of GR / SPCE: PEDOT:PSS was mixed with ultrapure water at 1:1 as a graphene dispersant, and a dispersion liquid with a graphene concentration of 0.35 mg / mL was prepared. Pipette 7 µL of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com