Method for preparing calcium ion selective molecular sieve and application of molecular sieve in descaling

A selective, calcium ion technology, applied in chemical instruments and methods, ion exchange water/sewage treatment, other chemical processes, etc., to achieve the effect of increasing ion exchange rate, efficient removal, and reducing diffusion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

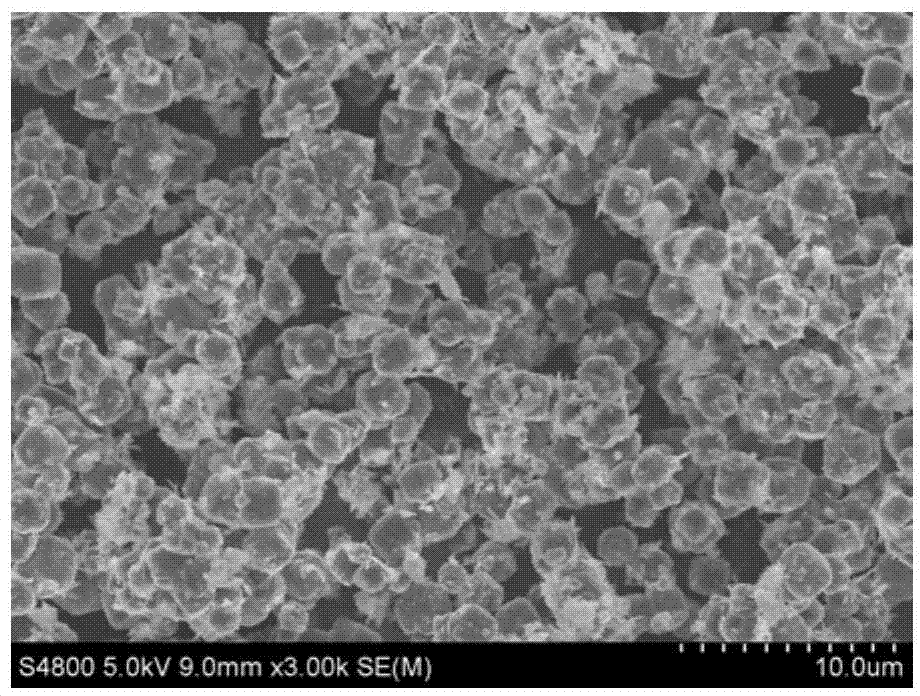

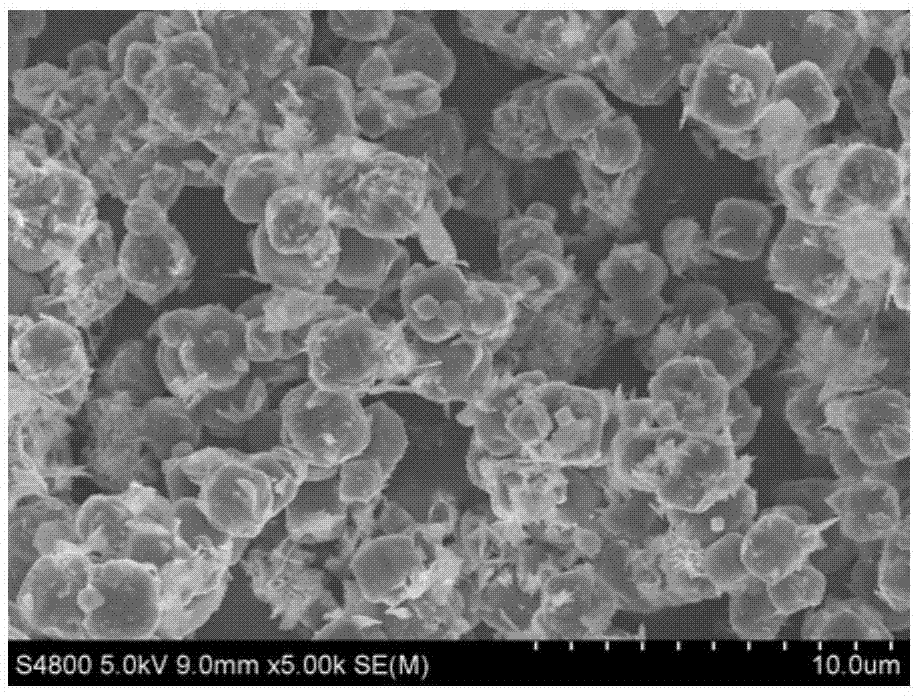

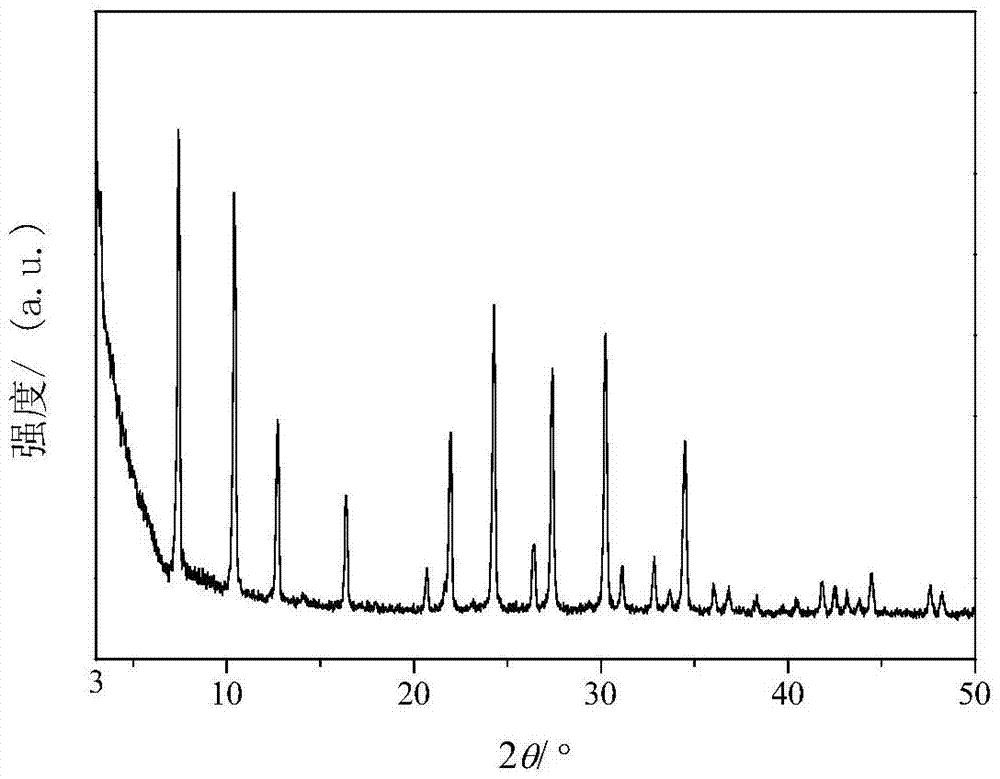

Image

Examples

Embodiment 1

[0028] (1) First, take 0.1 mol of NaOH in a beaker, add 99ml of deionized water and stir to dissolve, configure NaOH solution, divide into two parts of about 40ml and 59ml for use;

[0029](2) Take Na 2 SiO 3 9H 2 Add O0.05mol into a beaker containing 40ml NaOH solution, stir in a water bath at 50°C to form a sol; take NaAlO 2 Add 0.1mol to a beaker containing 59ml of NaOH solution, stir well with a glass rod to dissolve it;

[0030] (3) Take 0.02mol of cetyltrimethylammonium bromide (CTAB), add 30ml of sodium hydroxide solution with a concentration of 3.33mol / L, dissolve at 60°C, and stir for 1h;

[0031] (4) At room temperature, quickly add the above sodium silicate solution into the sodium aluminate solution, stir fully for 10 minutes, and form a milky white sol, and each component is composed of: 3Na 2 O: Al 2 o 3 :SiO2 2 :118.7H 2 O, then moved into a PTFE jar, sealed and placed in a water bath at 90°C for static crystallization for 1 hour;

[0032] (5) After tak...

Embodiment 2

[0037] (1) First, take 0.1 mol of NaOH in a beaker, add 100ml of deionized water and stir to dissolve, configure NaOH solution, divide into two parts of about 35ml and 65ml for use;

[0038] (2) Take 0.05mol SiO 2 Add water glass (modulus 2) into a beaker filled with 35ml NaOH solution, stir in a water bath at 50°C to form a sol; take NaAlO 2 Add 0.1mol to a beaker containing 65ml of NaOH solution, stir well with a glass rod to dissolve it;

[0039] (3) Take 0.025mol of cetyltrimethylammonium bromide (CTAB), add 36ml of sodium hydroxide solution with a concentration of 2.78mol / L, dissolve at 65°C, and stir for 2 hours;

[0040] (4) At room temperature, quickly add the above sodium silicate solution into the sodium aluminate solution, stir thoroughly for 5 minutes to form a milky white sol, and each component is composed of: 3Na 2 O: Al 2 o 3 :SiO2 2 :120H 2 O, then moved into a PTFE jar, sealed and placed in a water bath at 90°C for static crystallization for 1 hour;

...

Embodiment 3

[0046] (1) First, take 0.2 mol of NaOH in a beaker, add 100ml of deionized water and stir to dissolve it, configure it into a NaOH solution, divide it into two parts of about 35ml and 65ml for use;

[0047] (2) Take Na containing 0.05mol 2 SiO 3 9H 2 Add O into a beaker containing 35ml of NaOH solution, stir in a water bath at 40°C to form a sol; take Al(OH) 3 Add 0.1mol to a beaker containing 65ml of NaOH solution, stir well with a glass rod to dissolve it;

[0048] (3) Take 0.02mol of cetyltrimethylammonium bromide (CTAB), add 30ml of deionized water, dissolve at 60°C, and stir for 2h;

[0049] (4) At room temperature, quickly add the above sodium silicate solution into the sodium aluminate solution, stir fully for 10 minutes, and form a milky white sol, and each component is composed of: 3Na 2 O: Al 2 o 3 :SiO2 2 :124H 2 O, then moved into a PTFE jar, sealed and placed in a water bath at 60°C for static crystallization for 2 hours;

[0050] (5) After taking it out,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com