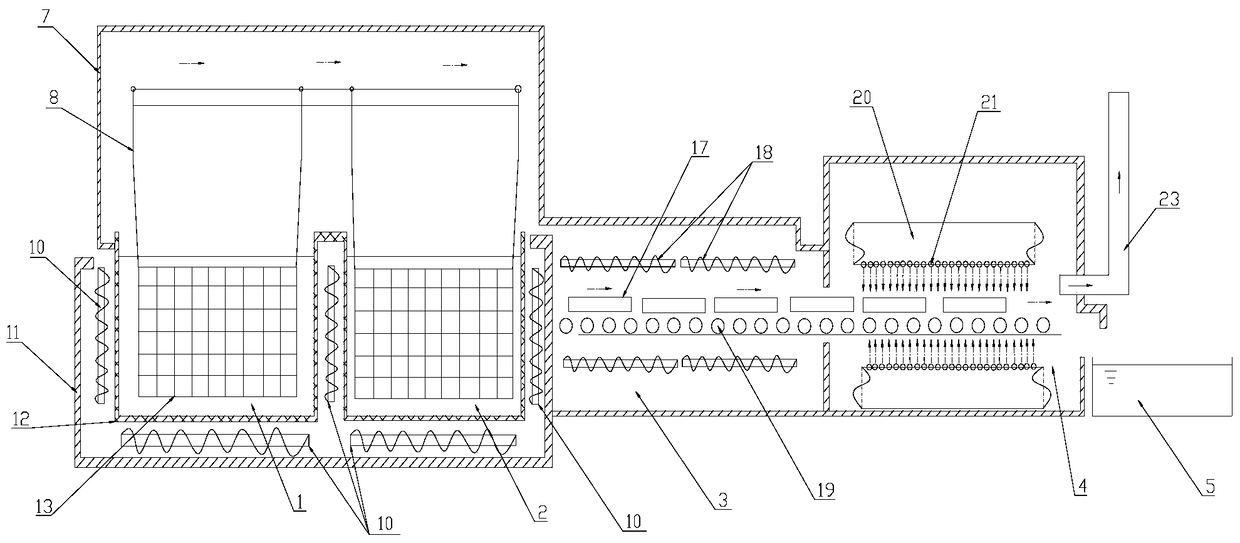

Tempering equipment and tempering method for display cover glass

A technology for cover glass and display screen, which is applied in the direction of glass tempering, glass manufacturing equipment, manufacturing tools, etc. To meet application requirements and other issues, to achieve the effect of high yield, improved physical properties, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

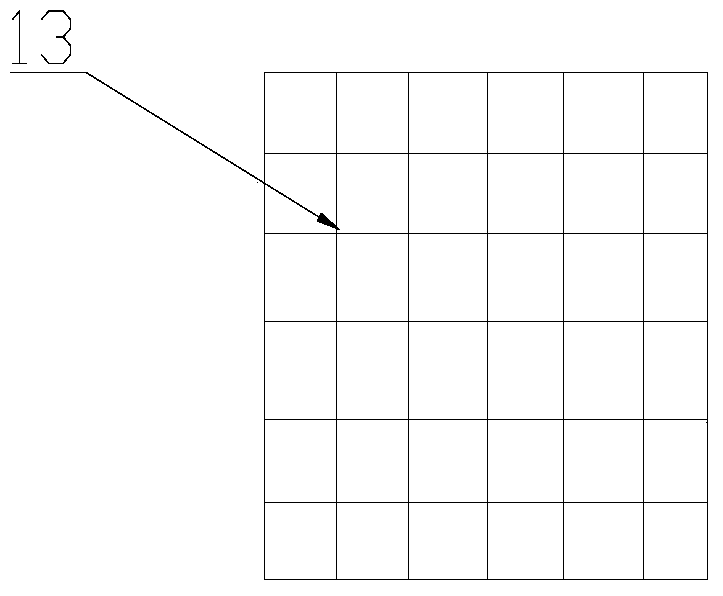

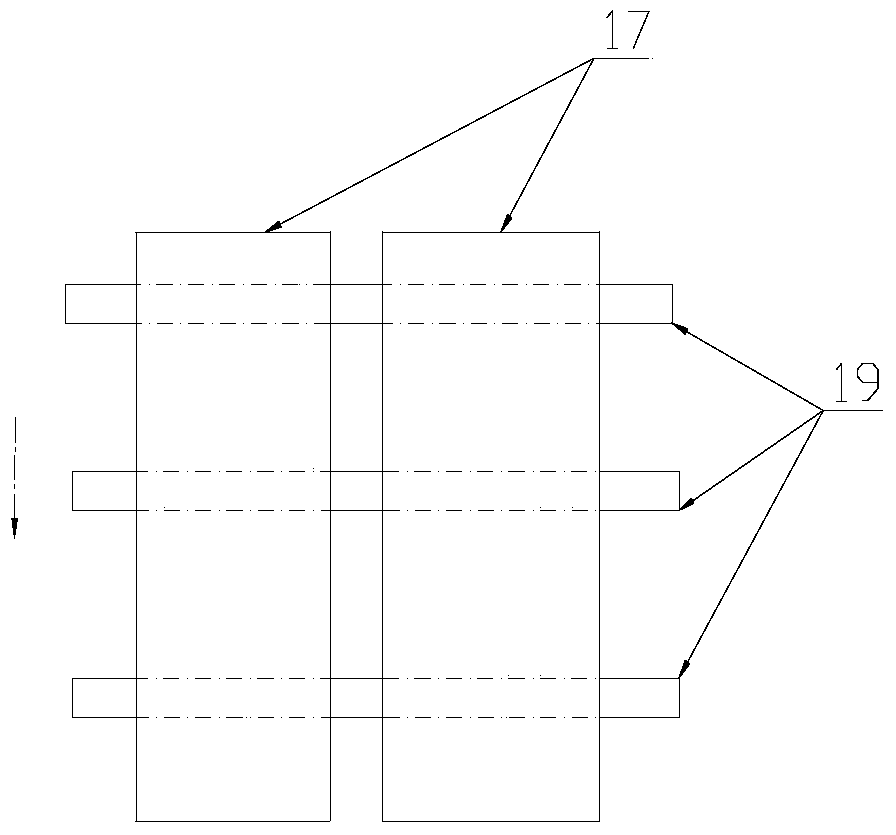

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1, the size is 130 * 65 * 0.7mm (length * wide * thick) the toughening of display screen cover glass

[0052] According to the tempering method of display screen cover glass of the present invention, ordinary glass (ordinary glass is selected from aluminosilicate flat glass produced by float process) of 130*65*0.7mm (length*width*thick) is tempered. Among them, the temperature of primary chemical tempering is 450°C, and the exchange time is 1.5h; the temperature of secondary chemical tempering is 600°C, and the exchange time is 11h; the temperature of primary physical tempering is 580°C, and the exchange time is 6s; The cooling air pressure is 650Pa and the flow rate is 100Nm 3 / h, the cooling air temperature is 15°C, and the cooling time is 10s.

Embodiment 2

[0053] Embodiment 2, the size is 120 * 50 * 0.7mm (length * width * thick) the toughening of display screen cover glass

[0054] According to the tempering method of display screen cover glass of the present invention, ordinary glass (ordinary glass is selected from aluminosilicate flat glass produced by float process) of 120*50*0.7mm (length*width*thick) is tempered. Among them, the temperature of primary chemical tempering is 400°C, and the exchange time is 3h; the temperature of secondary chemical tempering is 450°C, and the exchange time is 5h; the temperature of primary physical tempering is 750°C, and the exchange time is 2s; The cooling air pressure is 510Pa and the flow rate is 180Nm 3 / h, the cooling air temperature is 25°C, and the cooling time is 15s.

Embodiment 3

[0055] Embodiment 3, the size is 120 * 60 * 0.55mm (length * width * thick) the toughening of display screen cover glass

[0056] According to the tempering method of display screen cover glass of the present invention, ordinary glass (ordinary glass is selected from aluminosilicate flat glass produced by float process) of 120 × 60 × 0.55mm (length × width × thickness) is tempered. Among them, the temperature of primary chemical tempering is 380°C, and the exchange time is 2h; the temperature of secondary chemical tempering is 420°C, and the exchange time is 5h; the temperature of primary physical tempering is 600°C, and the exchange time is 4s; The cooling air pressure is 300Pa and the flow rate is 130Nm 3 / h, the cooling air temperature is 45°C, and the cooling time is 15s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com