Segmented chemical toughening process

A chemical tempering, segmented technology, applied in glass tempering, manufacturing tools, glass manufacturing equipment, etc., can solve the problems of inability to realize multiple chemical tempering parameters, unfavorable mass production of products, single chemical tempering parameters, etc., to achieve The effect of shortening the production cycle, good flatness and high surface stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

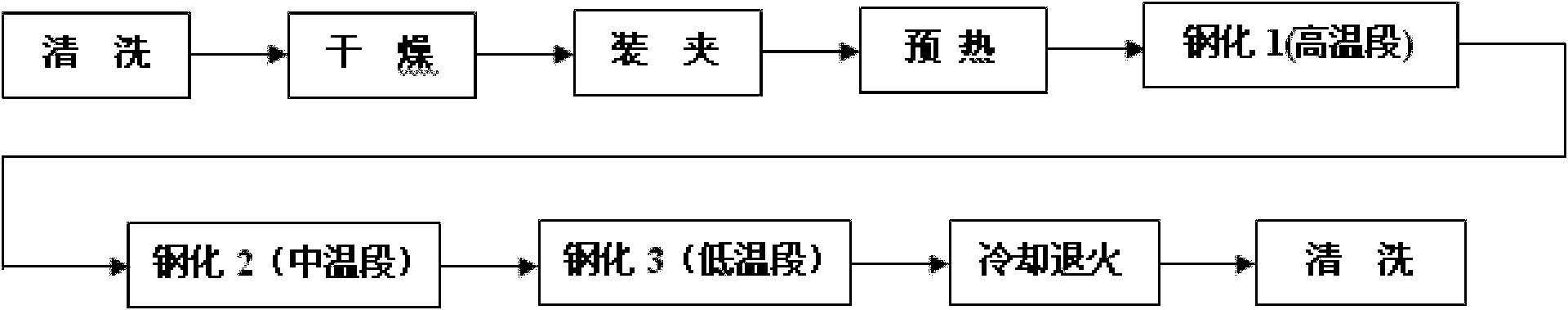

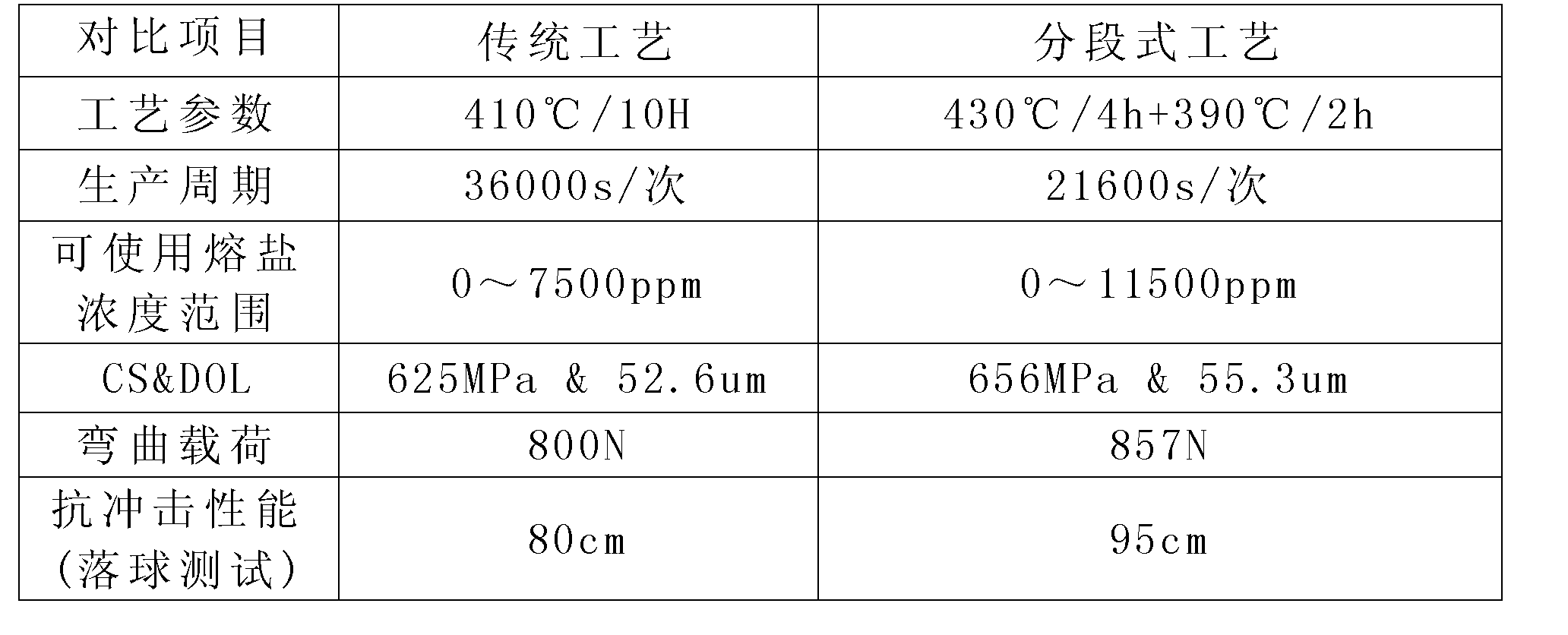

[0009] see figure 1 , Segmented chemical tempering process, including cleaning process, drying process, clamping process, preheating process, tempering process, cooling annealing process and cleaning process, the process parameters of the tempering process are: 430 ° C / 4h + 390 ° C / 2h. For example, a product requires that its surface tensile stress (CS) reach more than 600MPa after chemical tempering, and the tempering depth reach more than 50um. For this requirement, a comparison and verification of the segmented chemical tempering process and the traditional single-slot chemical tempering process is made. The comparison Data are as follows:

[0010]

Embodiment 2

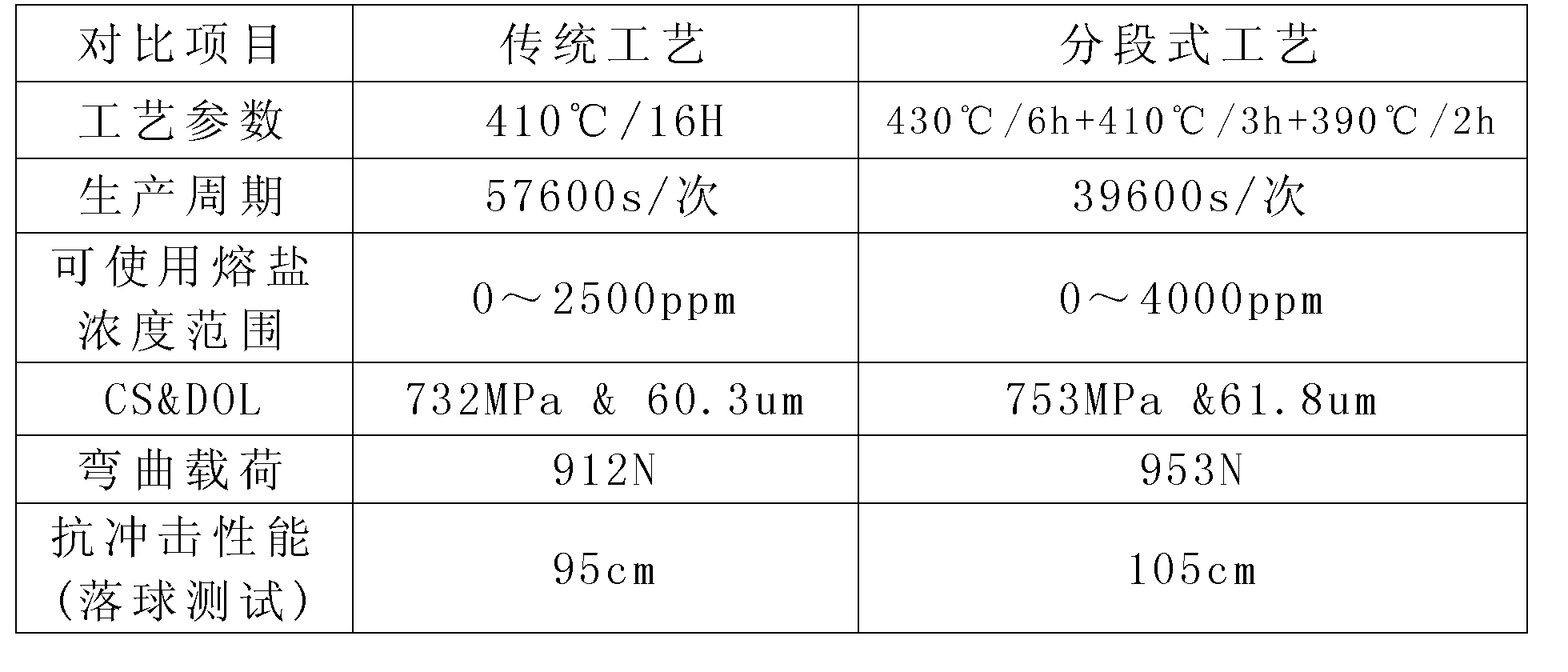

[0012] see figure 1 , segmented chemical tempering process, including cleaning process, drying process, clamping process, preheating process, tempering process, cooling annealing process and cleaning process, the process parameters of the tempering process are: 430℃ / 6h+410℃ / 3h+ 390°C / 2h. For example, a product requires that its surface tensile stress (CS) reach more than 700MPa after chemical tempering, and the tempering depth reach more than 60um. For this requirement, we have compared and verified the segmented chemical tempering process and the traditional single-slot chemical tempering process. The comparison data are as follows:

[0013]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com