Stainless steel surface treatment method, silica gel and stainless steel bonding technology and product

A surface treatment, stainless steel technology, used in special surfaces, pretreated surfaces, devices for coating liquids on surfaces, etc., can solve problems such as bonding difficulties, solve bonding difficulties, increase adhesion, and increase reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

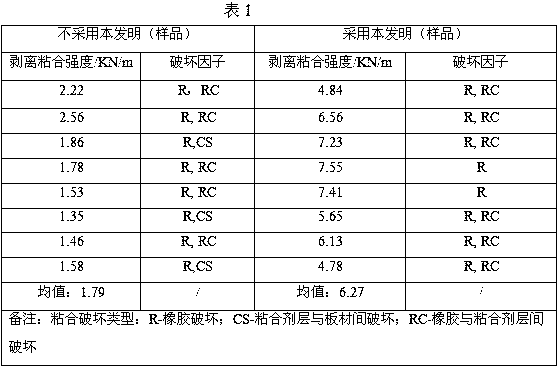

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below.

[0025] The stainless steel surface treatment method is characterized in that the steps are as follows:

[0026] 1) Degreasing: The degreasing agent KW-10B is mixed with water to form a degreasing liquid. The free base point of the degreasing liquid is 14~20. Heat the degreasing liquid to 60~80°C and keep it warm. Put the substrate into Put it in the degreasing solution at 60-80°C for 5-20 minutes, then take out the substrate and dry it at 80-110°C for 5-10 minutes to fully volatilize the residual liquid on the surface of the substrate;

[0027] 2) Sand blasting: Use a 10-30Kw shot blasting machine to load steel shots with a diameter of 0.6-1.0mm to shot blast the surface of the substrate for 10-30 minutes; or use a sand blasting machine to load 36 mesh white corundum pairs under an air pressure of 0.4-1.0Mpa The surface of the substrate is sandblasted for 10-30 minutes to make the surface sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com