Locking device

A technology of locking device and stop position, which is applied in the direction of mechanical control device, transmission device control, device for preventing/limiting/recovering the movement of parts of the control mechanism, etc. Parts fall off and other problems, to ensure the effect of setting the degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

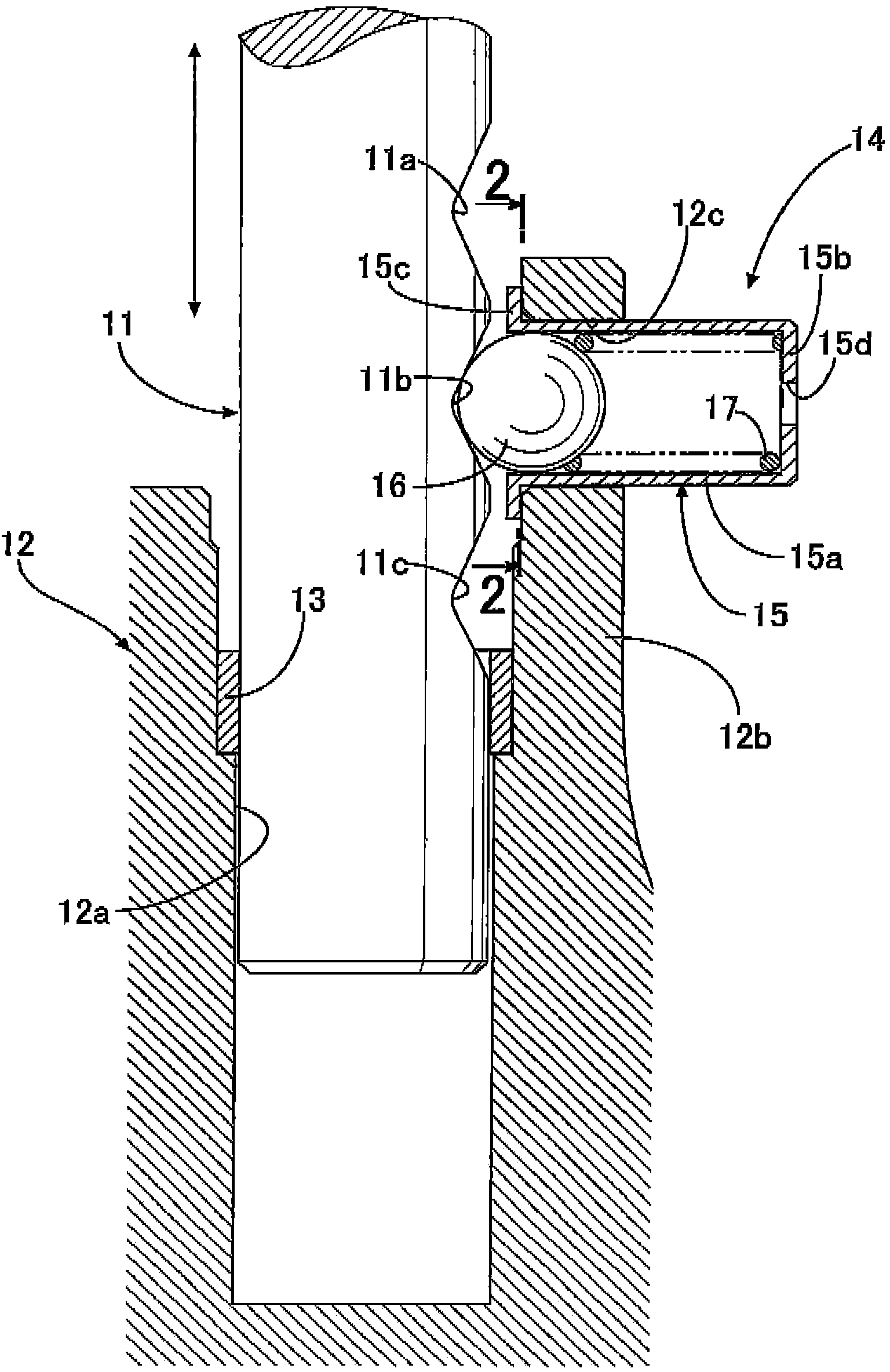

[0032] Below, based on Figure 1 ~ Figure 3 First and second embodiments of the present invention will be described.

[0033] Such as figure 1 As shown, the shift fork shaft 11 supporting the shift fork of the automobile transmission is slidably supported by the bush 13, and the bush 13 is formed by pressing into the case 12 of the transmission made of an aluminum material. The guide hole 12a of the shift fork shaft 11 is connected with the shift lever or actuator operated by the driver and moves in the axial direction. For example, three V-shaped grooves 11 a , 11 b , and 11 c are separately formed at predetermined intervals in the axial direction on the outer peripheral surface of the shift fork shaft 11 .

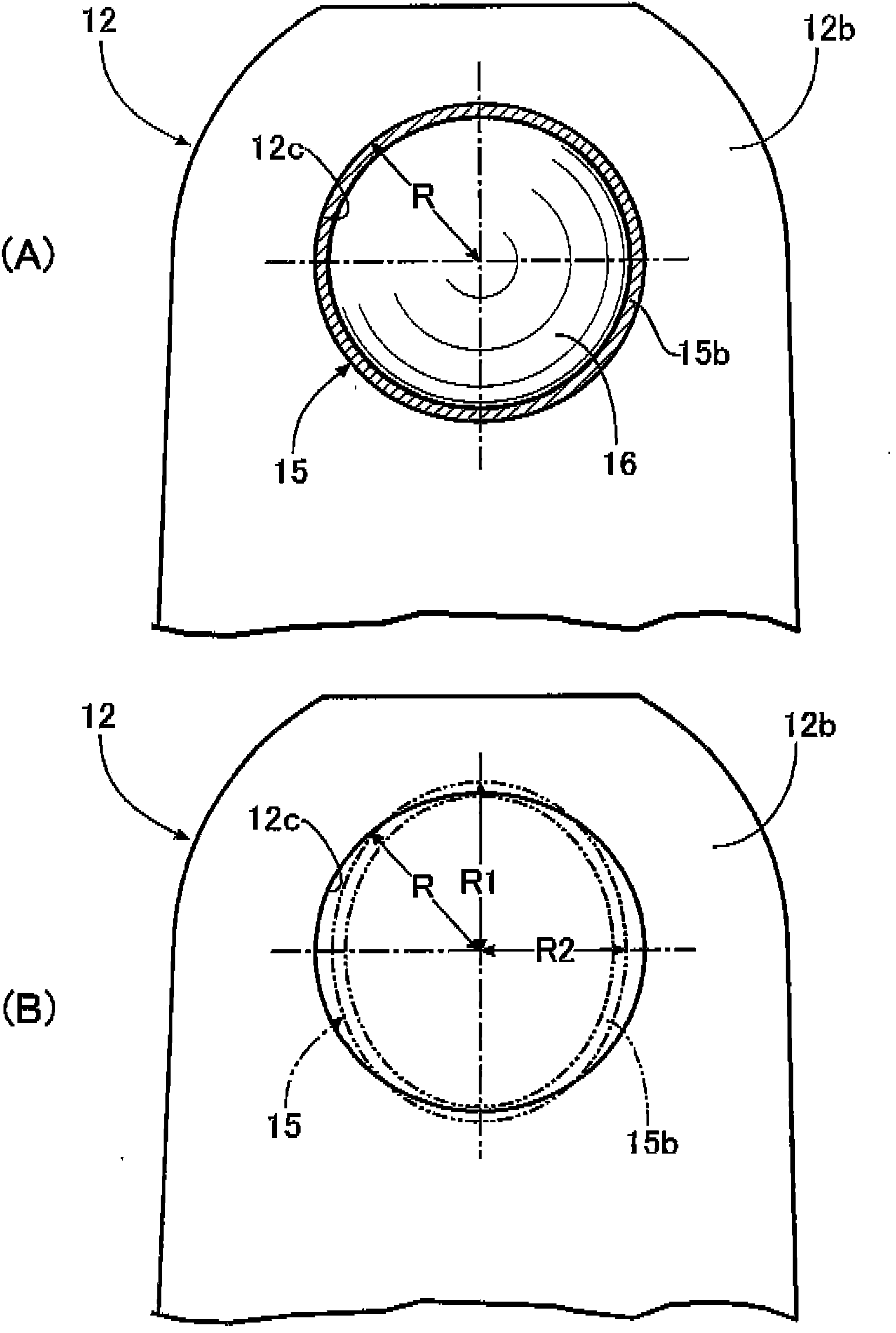

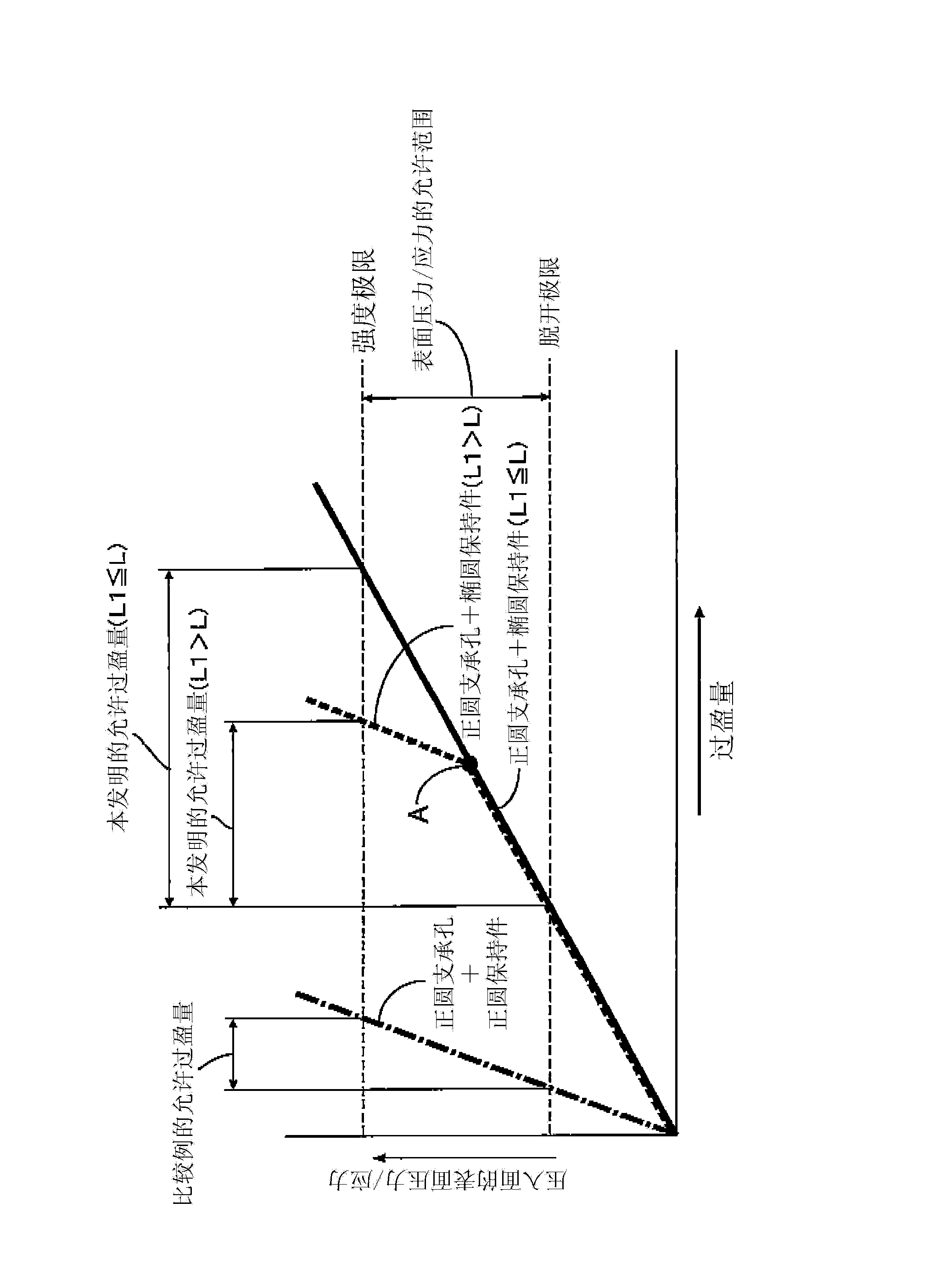

[0034] The locking device 14 for positioning the shift fork shaft 11 at three positions in the axial direction is constituted by three members of a retainer 15 , a ball 16 and a spring 17 . The holder 15 is a member obtained by drawing a plate material made of iron, a...

no. 3 Embodiment approach

[0056] Next, based on Figure 4 A third embodiment of the present invention will be described.

[0057] In the first and second embodiments, the cross-sectional shape of the inner peripheral surface of the support hole 12c of the housing 12 is a perfect circle, and the cross-sectional shape of the outer peripheral surface of the main body portion 15a of the holder 15 is an ellipse, but in the third embodiment In the form, the cross-sectional shape of the inner peripheral surface of the support hole 12c of the housing 12 is formed into an ellipse, and the cross-sectional shape of the outer peripheral surface of the main body portion 15a of the holder 15 is formed into a triangular shape (rice ball shape) with rounded corners. . And, when the cross-sectional shape of the inner peripheral surface of the support hole 12c and the cross-sectional shape of the outer peripheral surface of the holder 15 are overlapped in a state where their centers coincide, the cross-sectional shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com