Anti-impact tempered glass, preparation method of anti-impact tempered glass and display terminal

A kind of tempered glass, impact resistance technology, applied in the direction of instrument, electrical digital data processing, data processing input/output process, etc., can solve the problem of poor tempered glass resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

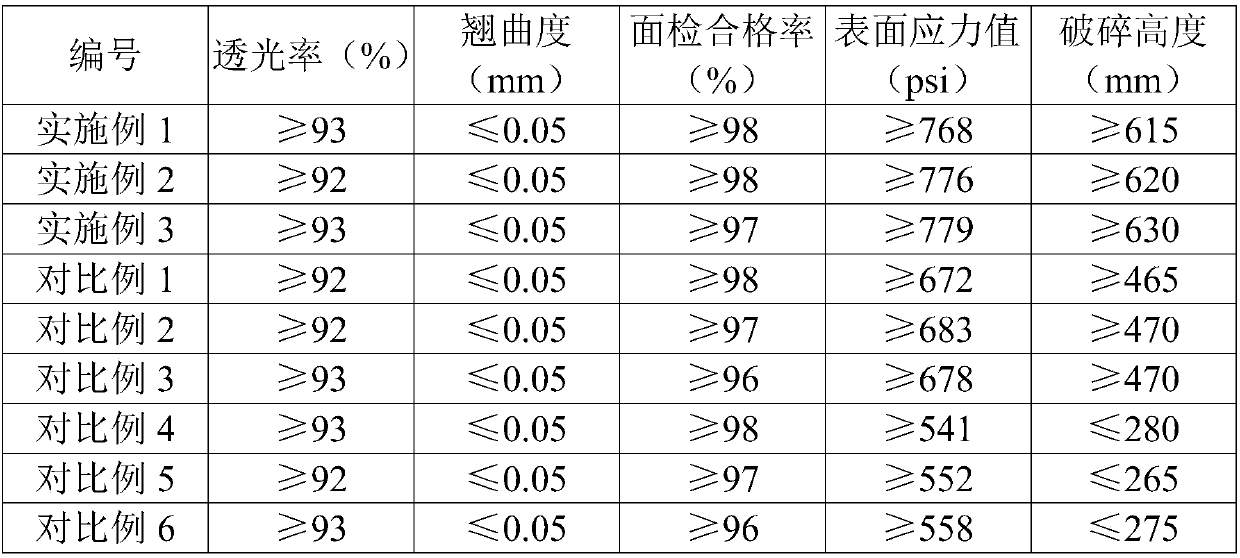

Examples

preparation example Construction

[0024] The first aspect of the present invention provides a method for preparing impact-resistant tempered glass, wherein the method includes: contacting the tempered glass with silicone oil, then cleaning the glass with the solution, and drying it.

[0025] In the present invention, silicone oil forms a silicon-oxygen film on the surface of tempered glass, which is similar to the Si-O tetrahedral skeleton structure in glass, and can fill the microcracks on the glass surface to heal the microcracks on the glass surface, eliminating Fractured layer on glass surface. Improve the impact strength of glass.

[0026] In the present invention, the contacting method may be but not limited to the dipping method.

[0027] In the present invention, the temperature of the silicone oil may be 150-300°C.

[0028] In the present invention, the tempered glass may be in contact with the silicone oil for 0.5-2 hours.

[0029] In the present invention, the tempered glass is tempered sodium al...

preparation example 1

[0040] 20 pieces of size 100mm (length) × 100mm (width) × 0.7mm (thickness), containing 61% by weight of SiO 2 , 13 wt% Al 2 o 3 , 14 wt% Na 2 O, 3% by weight of K 2O, 4 wt% CaO, 4 wt% MgO and 1 wt% ZrO 2 of sodium aluminosilicate glass into the premium grade KNO 3 , ion exchange was carried out at 440° C. for 6 hours, and then washed with deionized water and dried to obtain tempered glass A.

preparation example 2

[0042] 20 pieces of size 100mm (length) × 100mm (width) × 0.7mm (thickness), containing 58% by weight of SiO 2 , 9 wt% Al 2 o 3 , 17 wt% Na 2 O, 1.5% by weight of K 2 O, 3% by weight of CaO, 3% by weight of MgO, 0.5% by weight of ZrO 2 and 8% by weight of B 2 o 3 of sodium aluminosilicate glass into the premium grade KNO 3 , conduct ion exchange at 440°C for 6 hours, then wash with deionized water, and dry to obtain tempered glass B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com