Chemical tempering method for glass

A chemical tempering and glass technology, applied in the field of glass preparation, can solve problems such as time-consuming and chemical solution replacement, and achieve the effects of improving efficiency, increasing strength and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

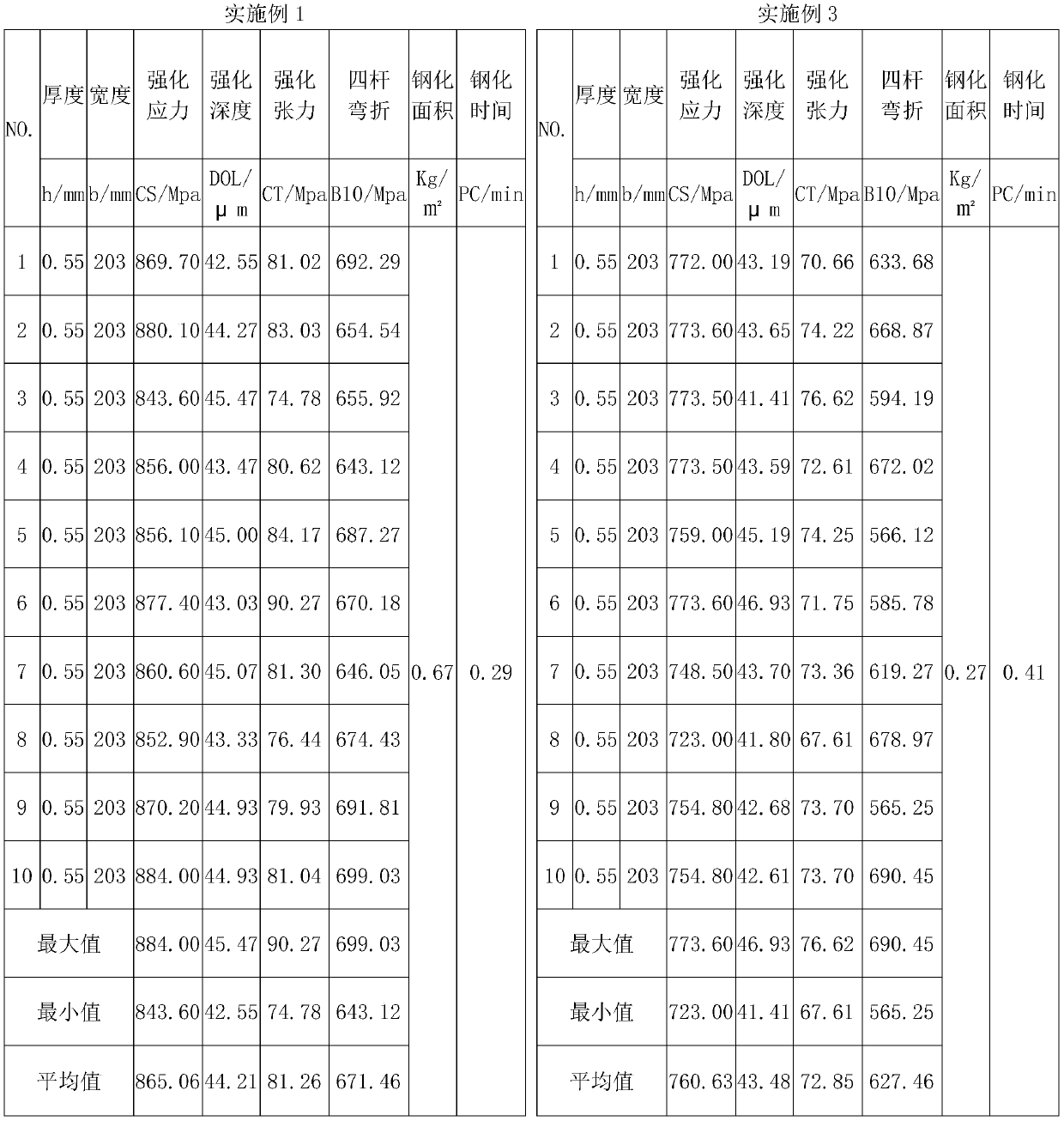

Embodiment 1

[0021] (1) Preheating for the first time: place the 0.55mm thick glass to be tempered in the preheating furnace of the automatic tempering furnace equipment, and preheat for 1 hour at a temperature of 300°C to obtain the first preheated piece;

[0022] (2) The first tempering: immerse the preheated parts for the first time in the potassium nitrate molten salt of the tempering furnace of the automatic tempering furnace equipment, in which sodium ions account for 0 wt% of the total amount of metal ions, and the first time is carried out at a temperature of 410 ° C. Ion exchange for 6 hours to obtain the first tempered piece;

[0023] (3) The first drop of salt: raise the first tempered piece and drop the salt for 10 minutes;

[0024] (4) The first annealing: After the salt drop is completed, move the first tempered piece to the annealing furnace of the tempering furnace equipment, anneal for 2 hours, reduce the temperature to below 100°C, and take it out of the furnace to obtain...

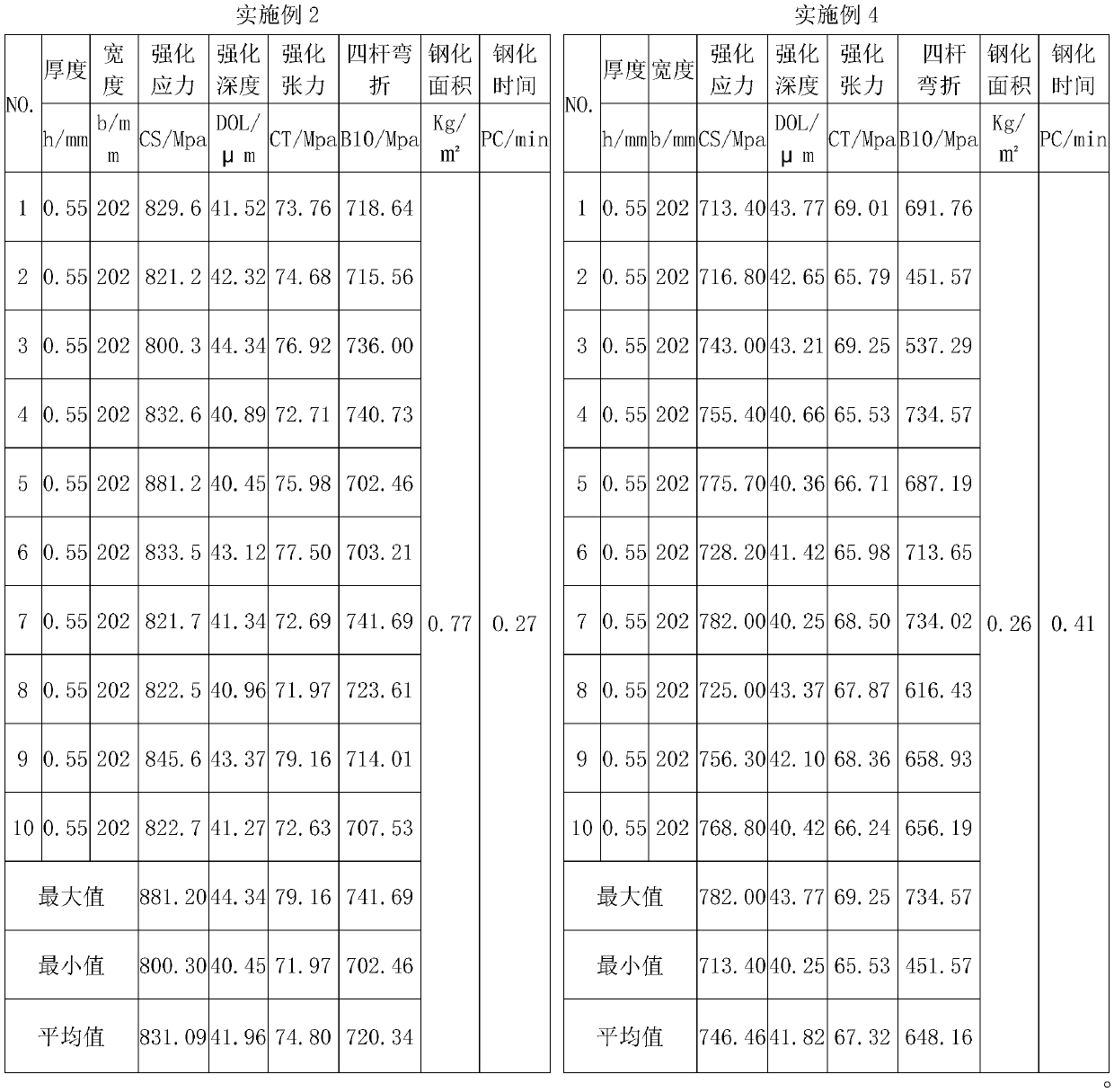

Embodiment 2

[0030] (1) Preheating for the first time: place the 0.55mm thick tempered glass in the preheating furnace of the automatic tempering furnace equipment, preheat for 3 hours at a temperature of 100°C, and obtain the first preheated part;

[0031] (2) The first tempering: the first preheated piece is immersed in the potassium nitrate molten salt of the tempering furnace of the automatic tempering furnace equipment, wherein sodium ions account for 0.6wt% of the total amount of metal ions, and the temperature is 420°C. One time of ion exchange for 5 hours to obtain the first tempered piece;

[0032] (3) The first drop of salt: raise the first tempered piece and drop the salt for 20 minutes;

[0033] (4) The first annealing: After the salt drop is completed, move the first tempered piece to the annealing furnace of the tempering furnace equipment, anneal for 3 hours, reduce the temperature to below 100°C, and take it out of the furnace to obtain the first annealed piece;

[0034] (...

Embodiment 3

[0039] This embodiment is comparative example one

[0040] (1) Preheating: Put the 0.55mm thick Corning 2320 glass to be tempered into a preheating furnace, and preheat for 3 hours at a temperature of 200°C.

[0041] (2) Tempering: transfer the preheated Corning 2320 glass into a tempering furnace containing molten salt (potassium nitrate containing 0.1% sodium ions), and perform ion exchange at a temperature of 420°C for 6h30min.

[0042](3) Dropping salt: drop salt on the tempered Corning 2320 glass for 30 minutes

[0043] (4) Annealing: Transfer the Corning 2320 glass after dripping salt to an annealing furnace, cool slowly to 320°C, and after 3.5 hours, take it out of the furnace for salt washing test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com