Shaft machining technology capable of reducing heat treatment bend amount

A technology of processing technology and bending amount, which is applied in the field of shaft processing technology, can solve the problems of large thermal deformation and long grinding time, and achieve the effects of increasing surface stress, reducing time required and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

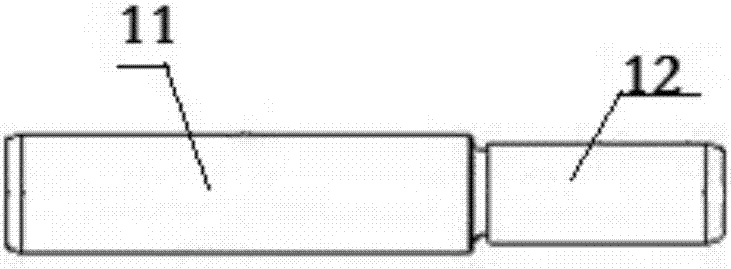

[0034] Example 1 Shaft machining to reduce heat treatment curvature (eg figure 1 , the outer diameter of the large shaft 11 is the large outer diameter, and the outer diameter of the small shaft 12 is the small outer diameter)

[0035] (1) The blanking material adopts cold drawn cylindrical bar, raw material Gcr15 (special steel for making bearings, the same below), bar length 6000mm, diameter Hardness HBW179-250, automatic feeding by punching and shearing machine, automatic punching and cutting according to the set length, the length of the shaft is 153mm, the diameter is not processed, it is still

[0036] (2) Turning uses CNC numerical control machine tool to bar material outside diameter turned to Turn one end face and chamfer, re-clamp, the outer diameter of the large shaft 11 is the large outer diameter, the outer diameter of the small shaft 12 is the small outer diameter, and the small outer diameter is machined Length 50mm (length-diameter ratio is 4), right ...

Embodiment 2

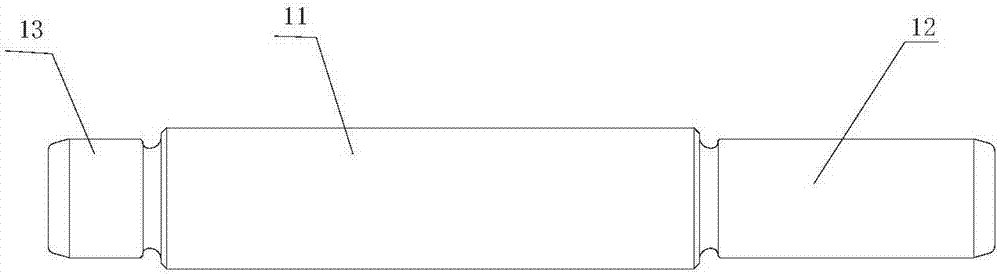

[0040] Example 2 Shaft machining to reduce heat treatment curvature (eg figure 2 As shown, the outer diameter of the large shaft 11 is the large outer diameter, the outer diameter of the small shaft 12 is the small diameter 1, and the outer diameter of the second small shaft 13 is the small diameter 2)

[0041] (1) The blanking material adopts the cold drawn cylindrical bar with a length of 6000mm and a diameter of 6000mm. Hardness HBW179-250, automatic feeding by punching and shearing machine, automatic punching and cutting according to the set length, the length of the shaft is 139mm, the diameter is not processed, it is still

[0042] (2) Turning uses CNC numerical control machine tools to process the bar Outer diameter turning to Trail 1 is The length of the small diameter 1 is 19mm (±0.05), the end face and chamfer of the small diameter are processed by turning, re-clamping, and the small diameter is turned Small diameter 2 length 52mm, right Chamfering, mach...

Embodiment 3

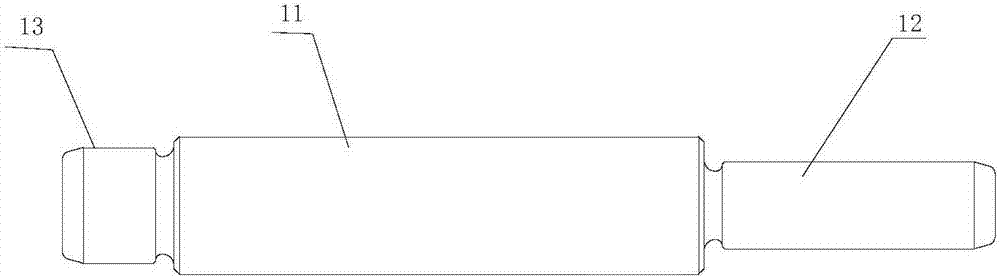

[0045] Embodiment 3 reduces the shaft processing of heat treatment curvature (such as image 3 As shown, the outer diameter of the large shaft 11 is the large outer diameter, the outer diameter of the small shaft 12 is the small diameter 1, and the outer diameter of the second small shaft 13 is the small diameter 2)

[0046] (1) The blanking adopts the cold-drawn cylindrical bar, the length is 6000mm, the diameter Hardness HBW179-250, automatic feeding by punching and shearing machine, automatic punching and cutting according to the set length, the length of the shaft is 129mm, the diameter is not processed, it is still

[0047] (2) Turning uses CNC numerical control machine tools to process the bar Outer diameter turning to Trail 1 is The length of trail 1 is 15.5mm (±0.05), turn the end face and chamfer of trail 1, re-clamp, turn the trail Minor diameter 2 length 66mm (length-to-diameter ratio is 5, belongs to the slender shaft), for Chamfering, the total length...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com