High-alumina glass with rapid ion exchange

A high-alumina glass and ion exchange technology, applied in the field of glass materials, can solve the problems of reduced ion exchange efficiency and low compressive stress layer, and achieve the effects of improving chemical toughening performance and melting performance, high surface stress, and increasing intrinsic strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

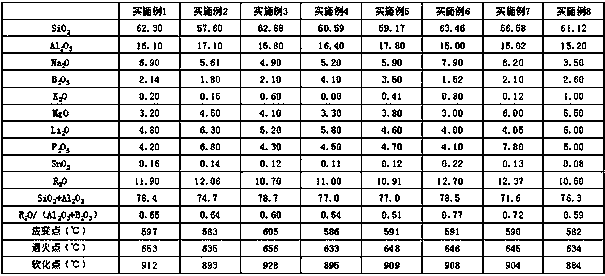

[0036] 1) Test sample preparation

[0037] According to the formula in Table 1, weigh the glass raw materials and mix them respectively (in order to obtain more stable measurement results, chemical-grade raw materials should be selected); In the furnace, gradually raise the temperature to 1650°C, keep it warm for 3 to 8 hours, and accelerate the discharge of bubbles and homogenize the glass to eliminate them by stirring. After melting, pour the molten liquid into a heat-resistant stainless steel mold for molding, then take out the glass block and move it into a box-type annealing furnace, heat treatment at 600°C for 2 hours, and then lower it to 550°C at a rate of less than 1°C / min , and then naturally cooled to room temperature.

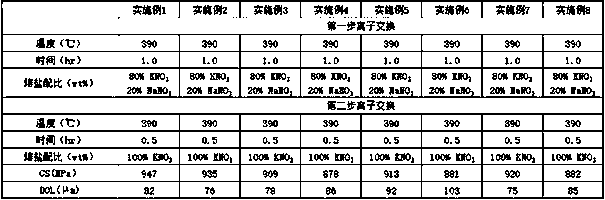

[0038] 2) Ion exchange method

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com