Glass and glass product

A glass product and glass technology, applied in the field of glass and glass products, can solve problems such as poor thermal shock resistance, low thermal shock resistance, glass mold bursting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

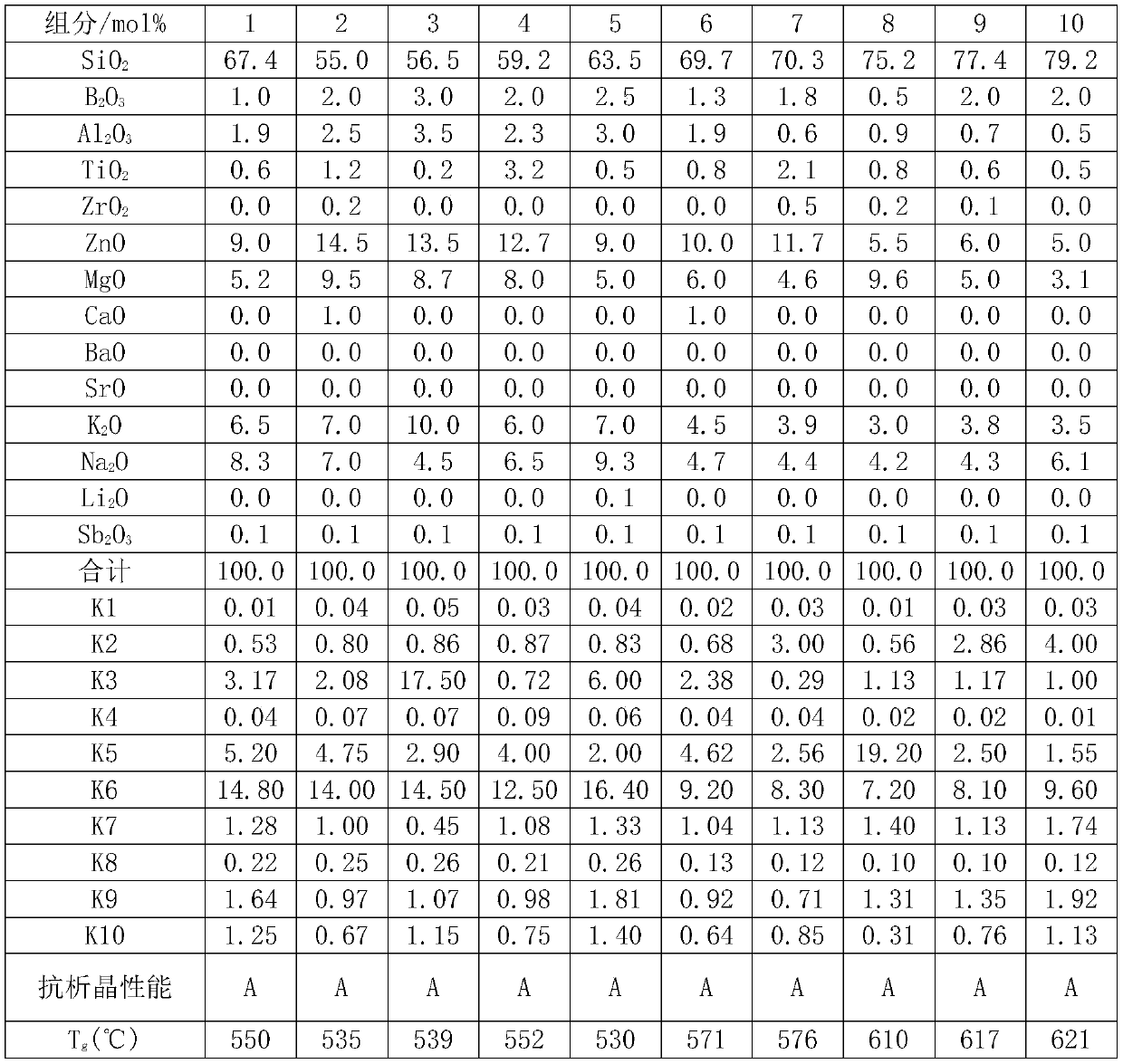

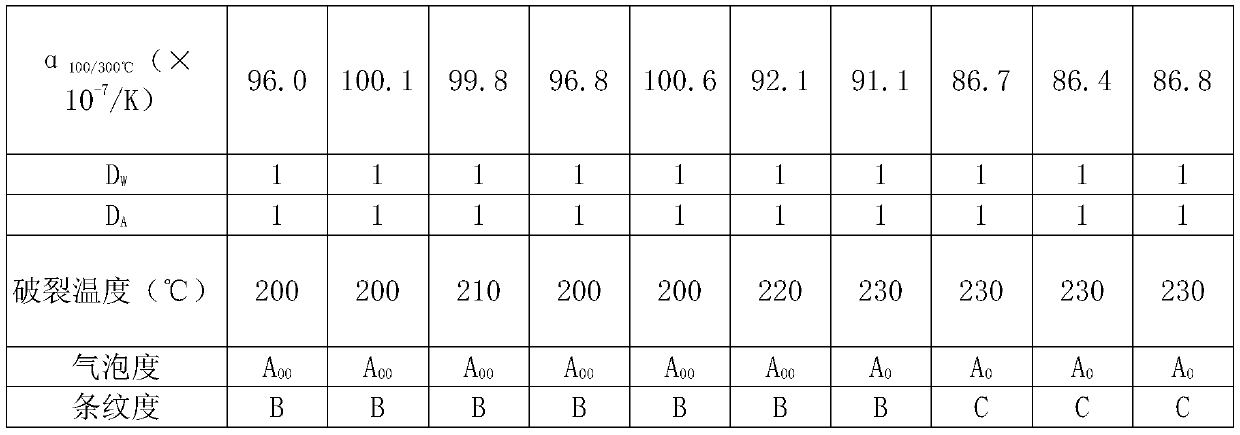

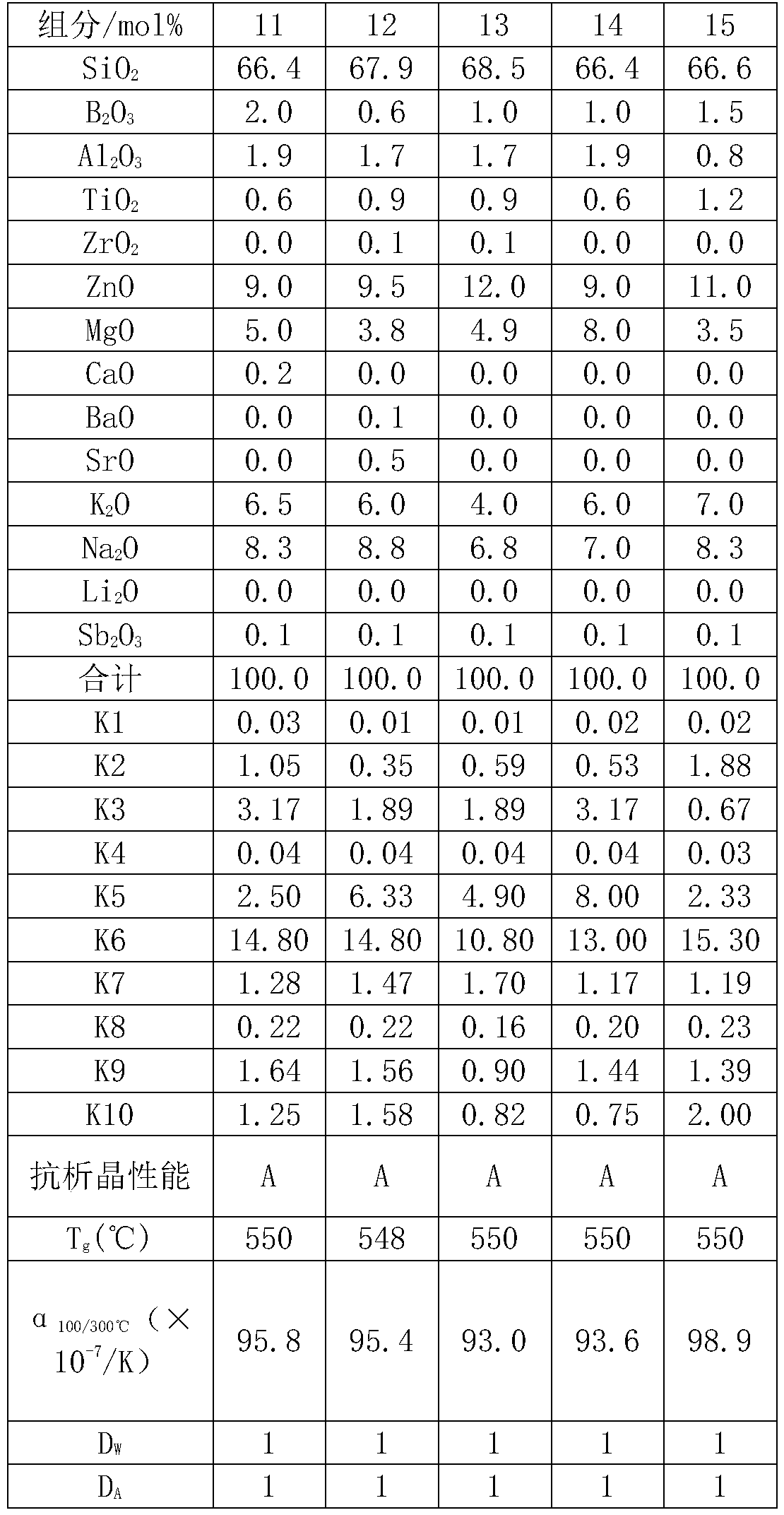

[0125] In order to further understand the technical solution of the present invention, examples of glass and glass products of the present invention will now be described. It should be noted that these examples do not limit the scope of the present invention.

[0126]

[0127] In this embodiment, the glass with the composition shown in Table 1-Table 2 was obtained by using the above glass manufacturing method. In addition, the performance of each glass is measured by the test method described in the present invention, and the measurement results are shown in Table 1-Table 2, the composition of Examples 1-15 of the present invention, wherein K1 is B 2 o 3 / SiO 2 value; K2 is B 2 o 3 / Al 2 o 3 The value of; K3 is Al 2 o 3 / TiO 2 The value of; K4 is (Al 2 o 3 +TiO 2 ) / SiO 2 The value of; K5 is MgO / B 2 o 3 The value of; K6 is Li 2 O+Na 2 O+K 2 The value of O; K7 is Na 2 O / K 2 The value of O; K8 is (Na 2 O+K 2 O) / SiO 2 value; K9 is (Na 2 O+K 2 O) / ZnO valu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| membrane rupture temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| surface stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com