Dumb thermoplastic polyurethane elastomer composition and preparation method thereof

A thermoplastic polyurethane and elastomer technology, applied in the field of matte thermoplastic polyurethane elastomer composition and its preparation, can solve the problems of poor effect, poor surface scratch resistance and the like, and achieve matte effect and surface scratch resistance effect Good, the effect of improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

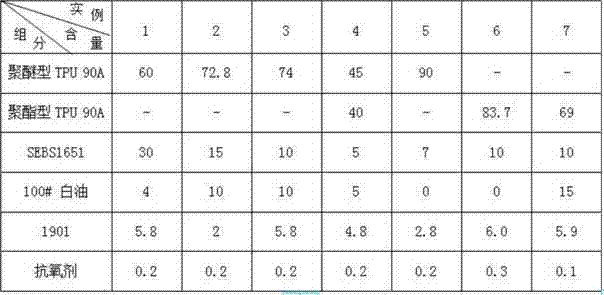

[0035] The raw material involved in embodiment 1~7 is:

[0036] TPU is the polyether type and polyester type of BASF's trade name Elastollan 90A;

[0037] SEBS 1651 is Kraton G from Kraton Polymers;

[0038] 100# white oil is naphthenic oil from Xinjiang Karamay Petrochemical;

[0039] The compatibilizer is Kraton 1901 of Kraton polymer;

[0040] The antioxidant is [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol, purchased from Ciba Specialty Chemicals, and the product model is Irganox 1010.

[0041] The components and mass percentages of each composition in Examples 1-7 are shown in Table 1. Add the components of each composition into a high-speed mixer, mix for 1 to 3 minutes to obtain a premix, and then put the fully mixed premix into a twin-screw extruder, preferably a twin-screw extruder The length-to-diameter ratio of the extruder is greater than 36:1, the twin-screw extruder rotates at 280-320rpm, and the processing temperature is controlled a...

Embodiment 8~11

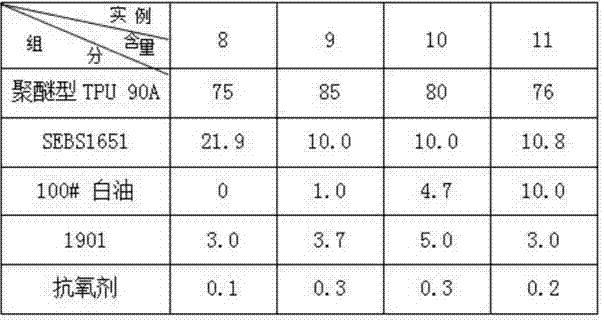

[0048] The raw materials involved in Examples 8 to 11 are the same as those in Examples 1 to 7, and the components and mass percentages of each composition in Examples 8 to 11 are as shown in Table 3. The preparation method of each embodiment composition is the same as in Example 1 ~7. The performance of the prepared composition was tested, and the results are shown in Table 4.

[0049] table 3

[0050]

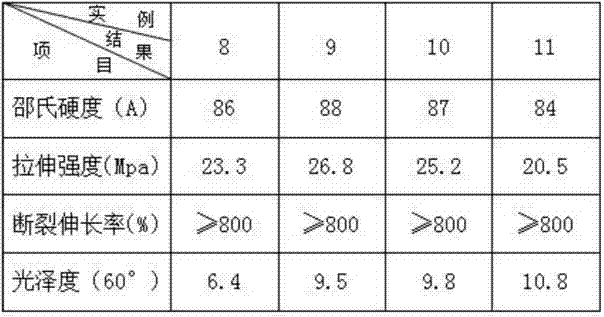

[0051] Table 4

[0052]

[0053] It can be seen from Table 4 that the tensile strengths of Examples 8-11 are all greater than 20 Mpa and have lower gloss, that is, the compositions of Examples 8-11 have better parameters in terms of tensile strength and gloss. , so that the product has lower gloss while ensuring the tensile strength, which can better meet the performance requirements of the product.

[0054] In summary, the matt thermoplastic polyurethane elastomer composition of the present invention has better product surface matte effect and surface scratch resist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com