Polyester resin for aluminum coil ceiling board and preparation method thereof

A polyester resin and ceiling technology, which is applied in the field of polymer materials, can solve the problems of difficulty in promotion and high cost, and achieve the effects of improving machinability, flexibility and processability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. A saturated polyester resin for aluminum ceiling paint, which is made of the following raw materials in percentage by weight: 5% neopentyl glycol, 20% methylpropanediol, 15% adipic acid, 5% methanediol Phthalic acid, 25% dimethyl terephthalate, 0.05% n-butyl titanate, 3% xylene, 30% S150, 7% butyl acetate.

[0030] 2, the preparation method of saturated polyester resin for coil aluminum topcoat, it comprises the following steps:

[0031] (1) Put 5% neopentyl glycol, 20% methylpropanediol, 25% dimethyl terephthalate, and 0.05% n-butyl titanate into the reaction kettle by weight percentage, and stir to make the materials mix uniformly;

[0032] (2) Then feed nitrogen, remove the oxygen in the reactor, and start to heat up; heat up to 240°C, keep warm for 0.5 hours, (in the process of heating up, the distillation temperature is controlled at no higher than 68°C), cool down to 160°C and wait use.

[0033] (3) Then add 15% adipic acid and 5% isophthalic acid according t...

Embodiment 2

[0041] 1. A saturated polyester resin for aluminum ceiling paint, which is made of the following raw materials in percentage by weight:

[0042] Dimethyl Terephthalate 30%, Methyl Propylene Glycol 25%, Neopentyl Glycol 10%, Adipic Acid 20%, Isophthalic Acid 10%, n-Butyl Titanate 0.05%, Xylene 3%, S150 Aromatics 35%, butyl acetate 10%.

[0043] 2, the preparation method of saturated polyester resin for coil aluminum topcoat, it comprises the following steps:

[0044] (1) Put 10% neopentyl glycol, 25% methylpropanediol, 30% dimethyl terephthalate, and 0.05% n-butyl titanate into the reaction kettle by weight percentage, and stir to make the materials mix uniformly;

[0045] (2) Then feed nitrogen, remove the oxygen in the reactor, and start to heat up; heat up to 240°C, keep warm for 0.5 hours, (in the process of heating up, the distillation temperature is controlled at no higher than 68°C), cool down to 160°C and wait use.

[0046] (3) Then add 20% adipic acid and 10% isopht...

Embodiment 4

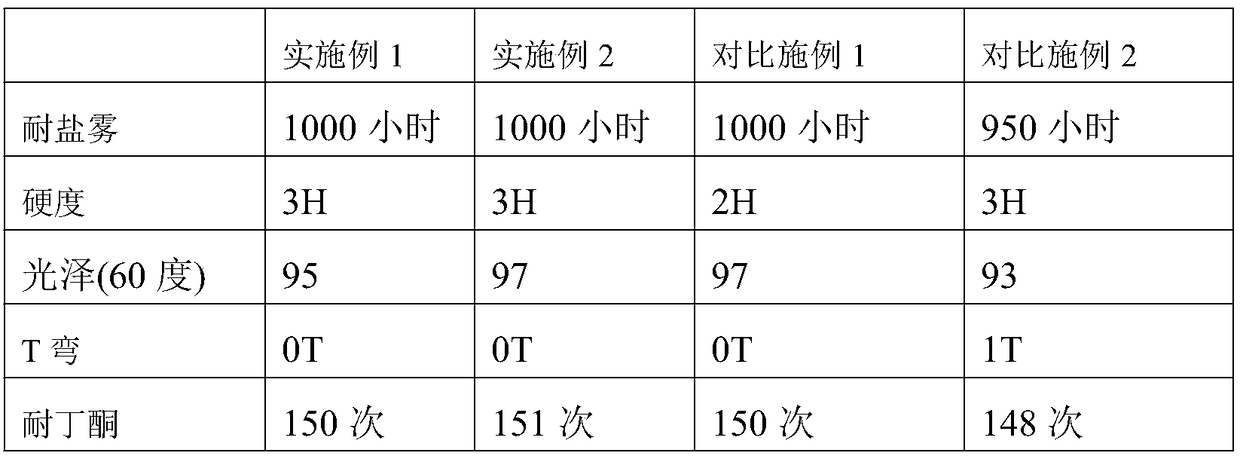

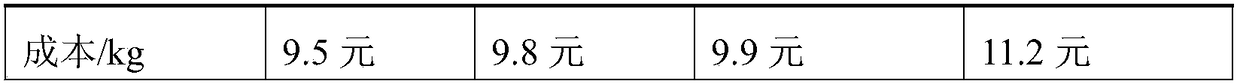

[0058] Embodiment 4 performance test

[0059]

[0060]

[0061] The above performance testing results show that the present invention screens through a large number of experiments, and adopts the saturated polyester resin for coiled aluminum ceiling paint prepared by the preferred raw material. Its hardness, processability and polyester resin of the prior art are equivalent, but the weather resistance is lower There are now technically saturated polyesters which are superior. Moreover, the cost is lower than that of the prior art, the environmental protection is better, and a very good technical effect has been achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com