Nano kaoline fire-resistant synergistic halogen-free non-phosphor cable sheath material

A nano-kaolin, cable sheathing material technology, applied in the field of halogen-free, low-smoke, non-phosphorus polyolefin flame retardant cable sheathing material, can solve the problem of unsatisfactory flame retardant performance and mechanical properties, complex manufacturing process, low purity, etc. problems, to achieve the effect of increased tensile strength, convenient material acquisition, high purity and whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

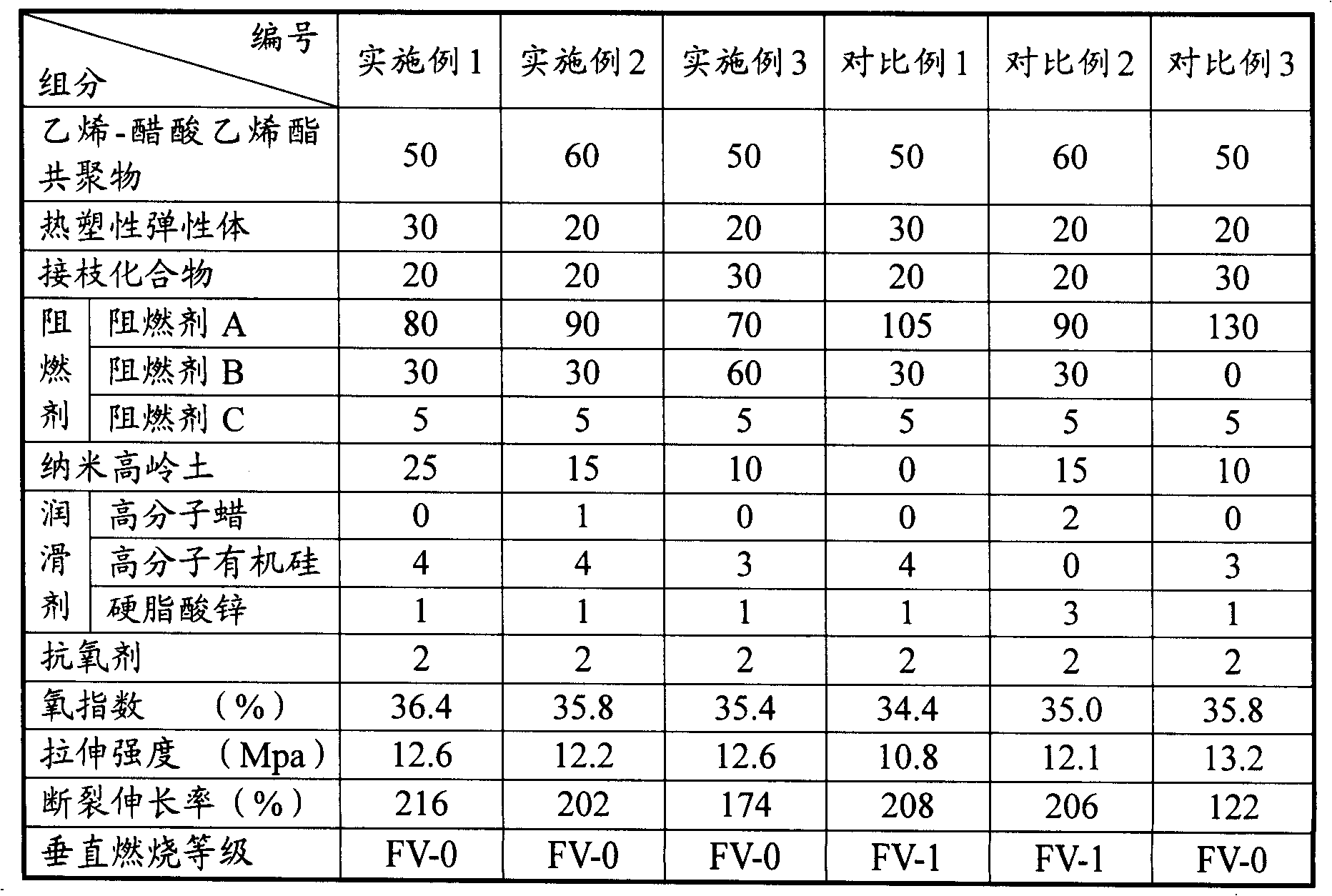

Embodiment 1

[0040] Example 1: 50 parts of ethylene-vinyl acetate copolymer, 30 parts of ethylene-octene copolymer, 20 parts of maleic anhydride grafted polyethylene, 80 parts of silane-treated aluminum hydroxide, and 30 parts of polymer-coated magnesium hydroxide 5 parts, 5 parts of zinc borate, 25 parts of nano-kaolin, 4 parts of polymer silicone, 1 part of zinc stearate, and 2 parts of antioxidant were added to a high-speed mixer and mixed for 10 minutes. Then the obtained mixture is melted and granulated in a twin-screw extruder at 120-150 DEG C, and dried to obtain the flame-retardant cable sheath material of the present invention. Test results: the oxygen index is 36.4, the tensile strength is 12.6Mpa, the elongation at break is 216%, and the vertical combustion reaches the FV-0 level.

Embodiment 2

[0041] Example 2: 60 parts of ethylene-vinyl acetate copolymers, 20 parts of ethylene-butene copolymers, 20 parts of maleic anhydride grafted ethylene-vinyl acetate copolymers, 90 parts of silane-treated aluminum hydroxide, polymer package 30 parts of coated aluminum hydroxide, 5 parts of zinc borate, 15 parts of nano-kaolin, 4 parts of polymer silicone, 1 part of polymer wax, 1 part of zinc stearate, and 2 parts of antioxidant were added to the high-speed mixer and mixed for 10 minutes . Then the obtained mixture is melted and granulated in a twin-screw extruder at 120-150 DEG C, and dried to obtain the flame-retardant cable sheath material of the present invention. Test results: the oxygen index is 35.8, the tensile strength is 12.2Mpa, the elongation at break is 202%, and the vertical combustion reaches the FV-0 grade.

Embodiment 3

[0042] Embodiment 3: With 50 parts of ethylene-vinyl acetate copolymers, 20 parts of low-density polyethylenes, 20 parts of maleic anhydride grafted polyethylenes, 10 parts of maleic anhydride grafted ethylene-vinyl acetate copolymers, silane treatment hydrogen 70 parts of alumina, 60 parts of polymer-coated aluminum hydroxide, 5 parts of zinc borate, 10 parts of nano-kaolin, 3 parts of polymer silicone, 1 part of zinc stearate, and 2 parts of antioxidant are added to a high-speed mixer and mixed 10 minutes. Then the obtained mixture is melted and granulated in a twin-screw extruder at 120-150 DEG C, and dried to obtain the flame-retardant cable sheath material of the present invention. Test results: the oxygen index is 35.4, the tensile strength is 12.6Mpa, the elongation at break is 174%, and the vertical combustion reaches the FV-0 grade.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com