High-performance ceramic-based epoxy modified organic silicon coating material, preparation method and application method thereof

A silicone coating, high-performance technology, used in epoxy resin coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems of easy scratches, hard to achieve hardness, yellowing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of the high-performance ceramic-based epoxy-modified organic silicon coating comprises the following steps:

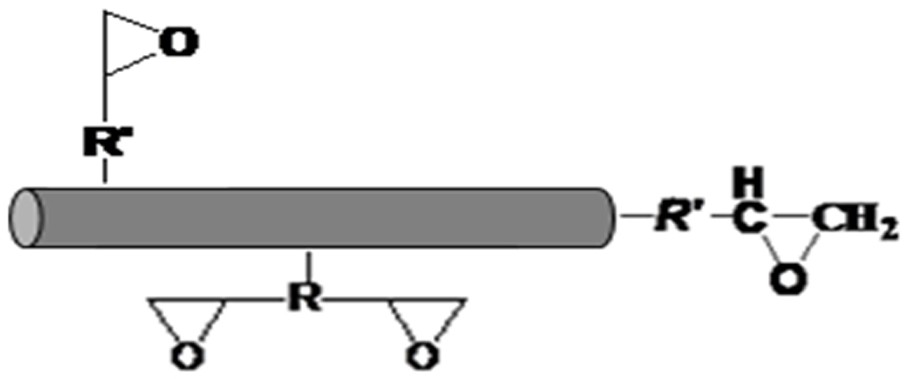

[0040] Step 1, the preparation of boehmite-modified epoxy resin solution, its preparation process is to react with epoxy resin by isocyanate as bridging at first, the preparation end group is the epoxy prepolymer of isocyanate group, then through dehydration The reaction removes the hydroxyl group in the boehmite, so that the boehmite is grafted into the epoxy segment, which specifically includes the following steps:

[0041] (1) According to the ratio of 1g / (1.5-3)ml, take the epoxy resin and the xylene solvent which has been dehydrated in advance and place them in a reactor with magnetic stirring. After fully stirring and mixing, the epoxy resin is prepared. Resin thinner, spare;

[0042] (2) At room temperature, according to the ratio of isocyanate and epoxy resin of 1mol / (16-25) g, take the bridging reactant isocyanate and slowly add ...

Embodiment 1

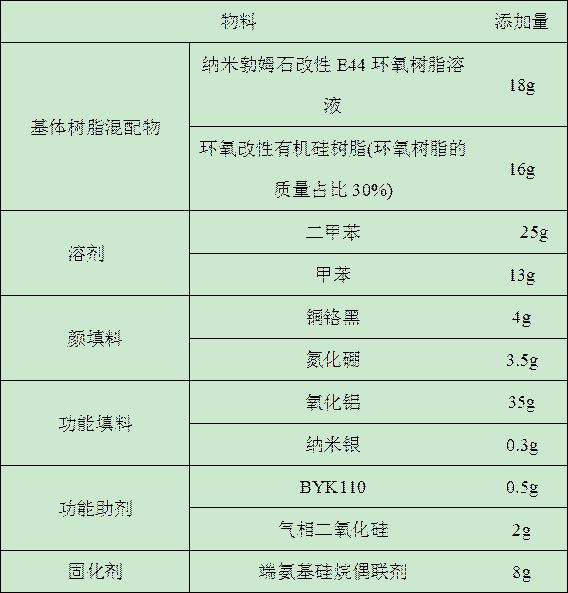

[0057] A kind of high-performance ceramic-based epoxy-modified organosilicon coating of the present embodiment, its specific batching table is:

[0058] The list of ingredients of table 1 embodiment 1

[0059]

[0060] The specific preparation method of a kind of high-performance ceramic-based epoxy-modified silicone coating of the present embodiment is:

[0061] Step 1, preparation of boehmite modified epoxy resin solution

[0062] (1) Take 20g of epoxy resin and 40ml of pre-dehydrated xylene solvent and place them in a reactor with magnetic stirring, stir and mix well to prepare epoxy resin dilution material, and then dilute to the epoxy resin Slowly add 1 mol of bridging reactant isocyanate into the material, polymerize at 120°C for 3.5 hours, and then heat up the reaction product to 140°C to remove the xylene solvent to obtain an epoxy prepolymer for future use;

[0063] (2) Take 1g of boehmite and 10ml of xylene solvent and mix them in a reactor with mechanical stirr...

Embodiment 2

[0075] A kind of high-performance ceramic-based epoxy-modified organosilicon coating of the present embodiment, its specific batching table is:

[0076] The list of ingredients of table 2 embodiment 2

[0077]

[0078] The specific preparation method of a kind of high-performance ceramic-based epoxy-modified silicone coating of the present embodiment is:

[0079] Step 1, preparation of boehmite modified epoxy resin solution

[0080](1) Take 20g of epoxy resin and 30ml of pre-dehydrated xylene solvent and place them in a reactor with magnetic stirring, stir and mix thoroughly to prepare epoxy resin dilution material, and then dilute to the epoxy resin Slowly add 1.25 mol of bridging reactant isocyanate into the material, polymerize at 130°C for 3 hours, and then heat up the reaction product to 140°C to remove the xylene solvent to obtain an epoxy prepolymer for later use;

[0081] (2) Take 1g of boehmite and 8ml of xylene solvent and mix them in a reactor with mechanical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com