Scratch-resistant grain lettering film and manufacturing method thereof

A production method, scratch-resistant technology, applied in the direction of copying/marking method, temperature recording method, printing, etc., can solve the problem of poor scratch resistance of textured lettering film, achieve broad market value and social value, improve mechanical strength, clear texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

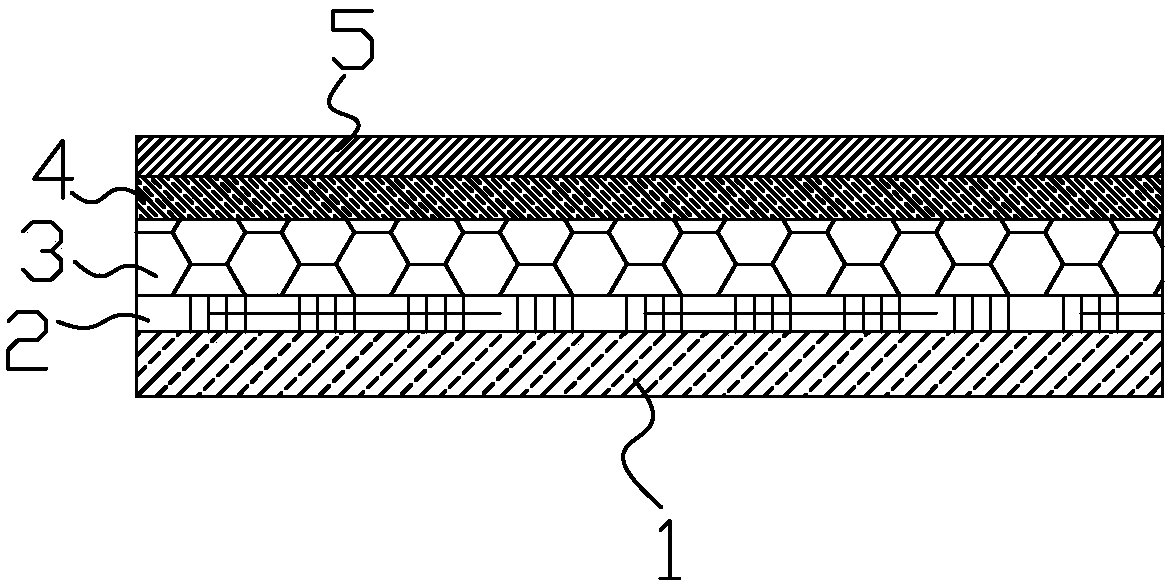

[0037] A scratch-resistant texture lettering film, such as figure 1 As shown, from bottom to top are PET release film 1, silicone oil release layer 2, resin molding layer 3, texture layer 4, and hot melt adhesive layer 5. The raw material component of the resin molding layer is polyester TPU 60KG, ABS15KG, stearic acid modified wollastonite powder 20KG (average particle size 4μm-6μm), ABS-G 3KG, polysiloxane 1KG, acrylic leveling agent 1KG.

[0038] The preparation method of the stearic acid-modified wollastonite powder is as follows: 25KG of wollastonite powder with an average particle size of 4 μm-6 μm, add 0.25 KG of stearic acid, stir, the speed is 900 r / min, the temperature is 80 ° C, and the time is 20 min , and then cooled to room temperature to remove larger particles to obtain stearic acid modified wollastonite powder.

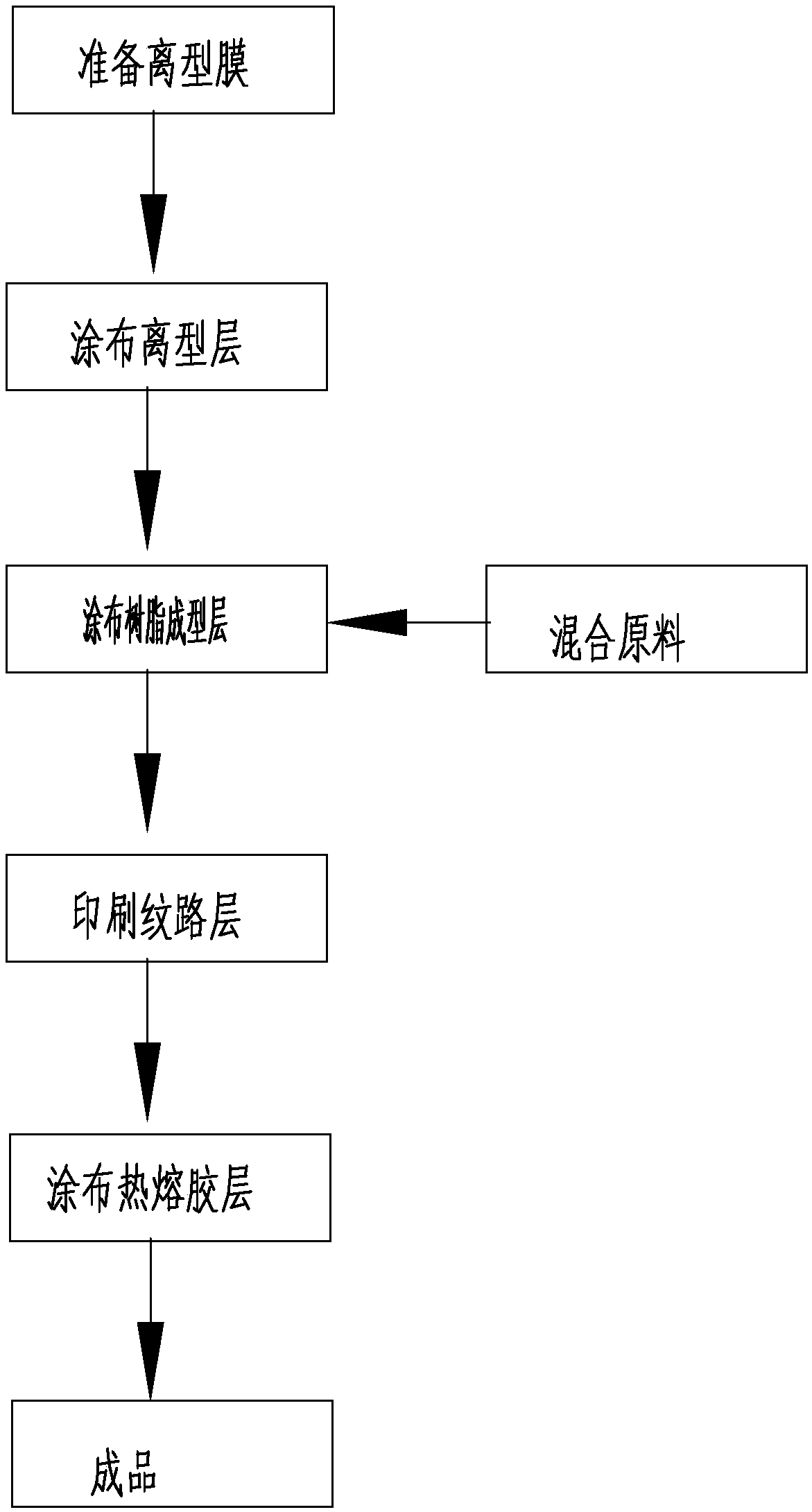

[0039] refer to figure 2 , the preparation method of the scratch-resistant pattern lettering film is:

[0040] Coat a layer of silicone oil on a ...

Embodiment 2

[0042] A scratch-resistant textured lettering film, from bottom to top are PET release film, silicone oil release layer, resin molding layer, texture layer, hot melt adhesive layer, the raw material component of the resin molding layer is polyester TPU 60KG , ABS5KG, stearic acid modified wollastonite powder 10KG, ABS-G 1KG, polysiloxane 1KG, acrylic leveling agent 5KG.

[0043] The preparation method of the stearic acid modified wollastonite powder is as follows: 15KG of wollastonite powder with an average particle size of 4 μm-6 μm, add 0.18 KG of stearic acid, stir at a speed of 1000 r / min, a temperature of 120 ° C, and a time of 30 min. Then cool to room temperature, remove larger particles, and obtain stearic acid modified wollastonite powder.

[0044] The preparation method of the scratch-resistant pattern lettering film is as follows:

[0045]Coat a layer of silicone oil on a PET release film with a width of 1000mm and a thickness of 5c as a release layer; fully mix th...

Embodiment 3

[0047] A scratch-resistant textured lettering film, from bottom to top are PET release film, silicone oil release layer, resin molding layer, texture layer, hot melt adhesive layer, the raw material component of the resin molding layer is polyester TPU 70KG , ABS10KG, stearic acid modified wollastonite powder 10KG, ABS-G 5KG, polysiloxane 4.9KG, acrylic leveling agent 0.1KG.

[0048] Its preparation method is:

[0049] Coat a layer of silicone oil on a PET release film with a width of 1000mm and a thickness of 7.5c as a release layer; fully mix the raw material components of the above-mentioned resin molding layer to obtain a mixture, and send the mixture into a twin-screw extruder , the material is fully fused under the shearing, mixing and conveying of the screw to form a coating liquid, which is extruded from the gap of the extrusion nozzle under pressure, the temperature of each section of the twin-screw is 200°C-220°C, and the screw speed is 300r / min; The extrusion coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com