Stone decoration board

A decorative panel and decorative panel technology, applied in the field of building decorative panels, can solve the problems of building settlement safety, affecting the progress of the project, hidden dangers, etc., and achieve the effects of easy construction, simple and reasonable structure, and weight reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

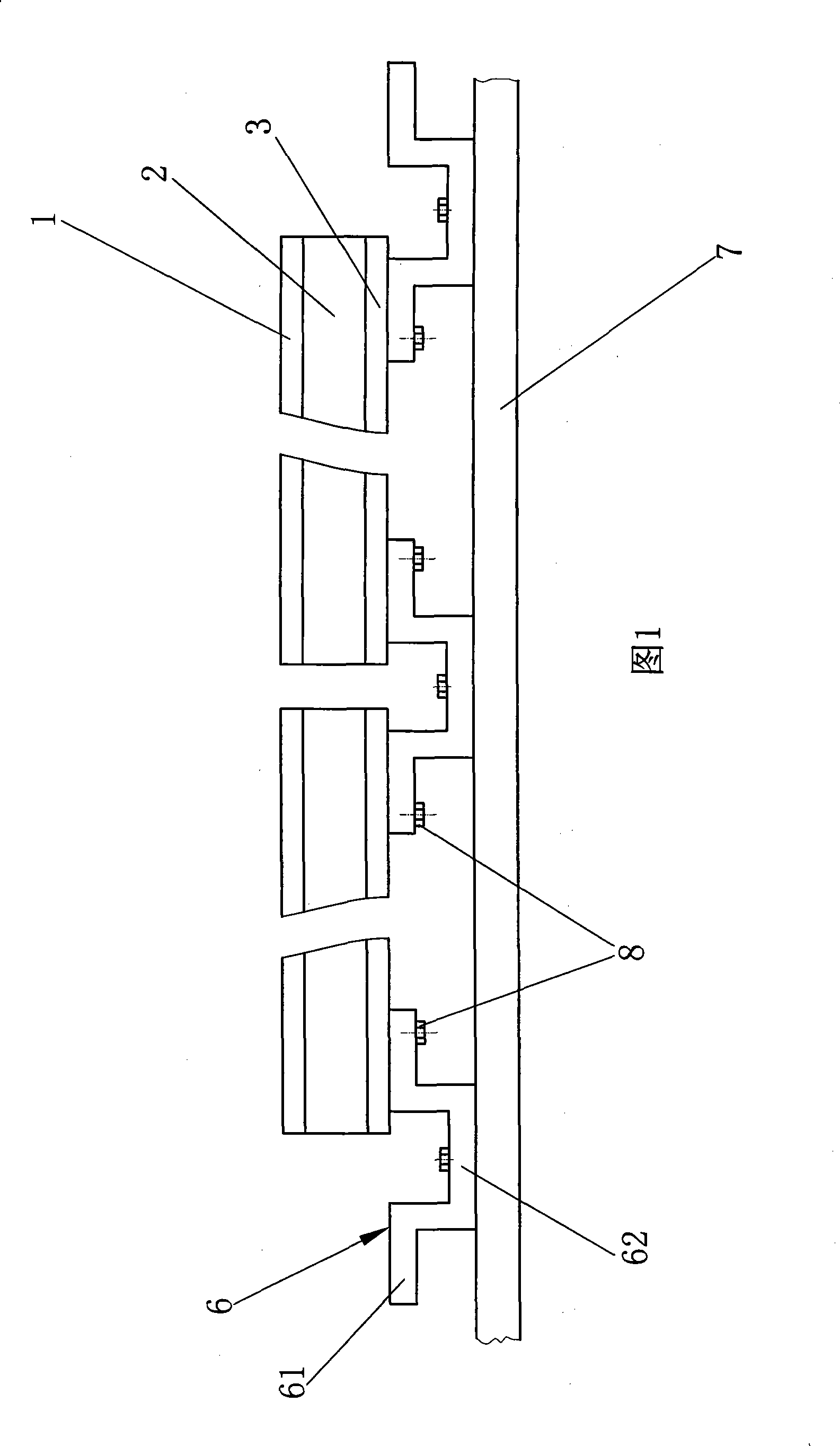

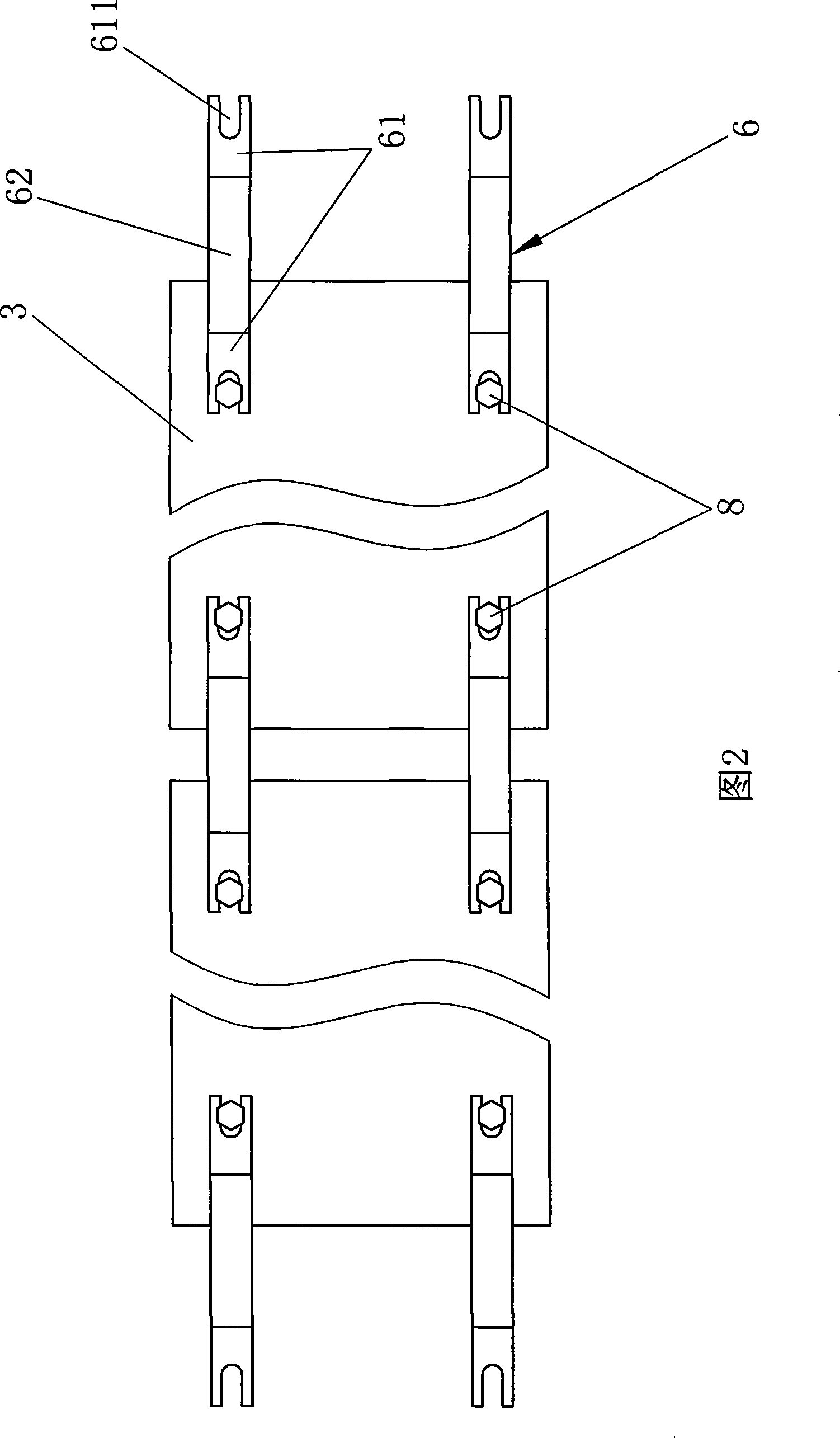

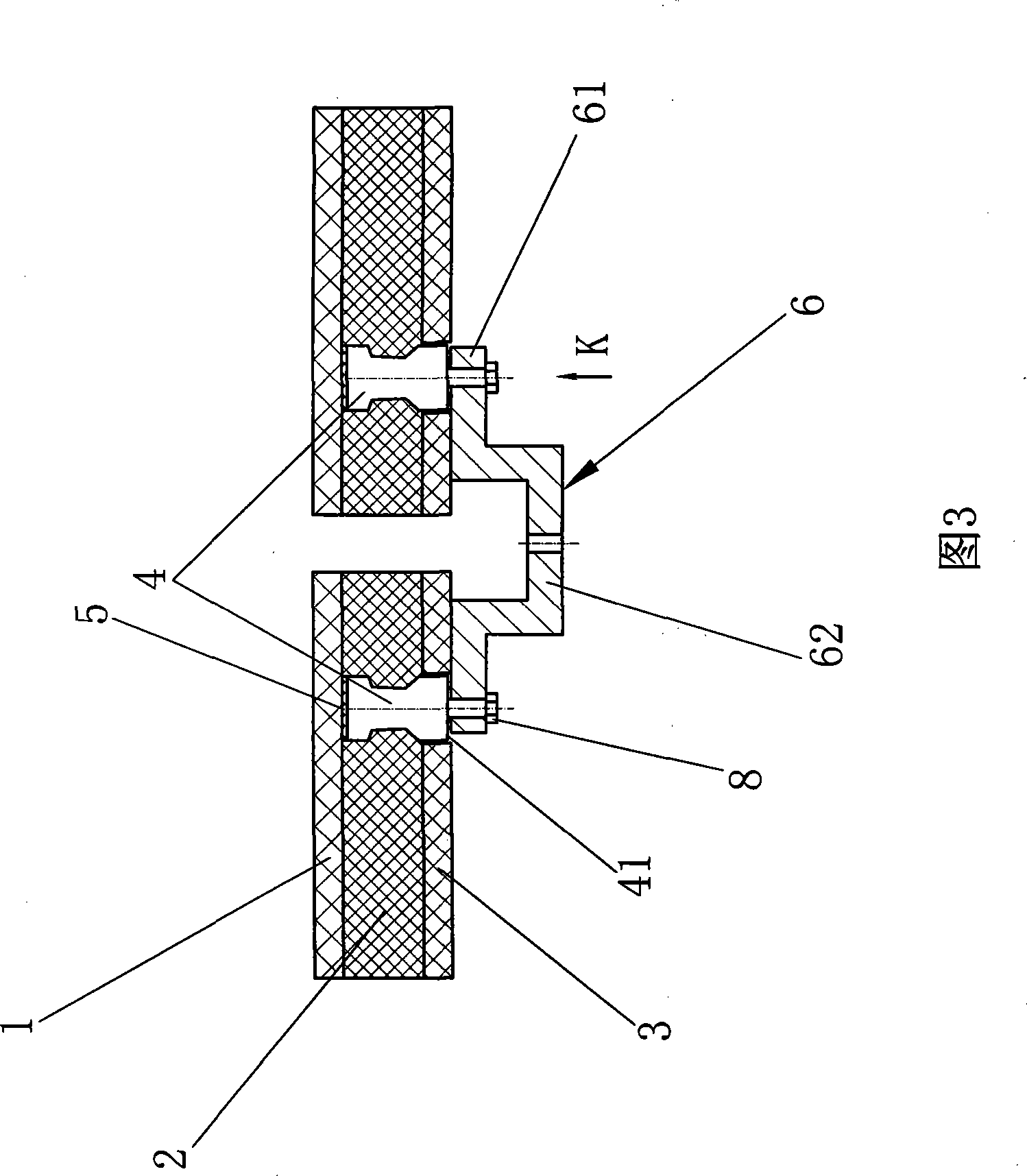

[0016] As shown in Figures 1, 2, and 3, a specific embodiment of the present invention is a stone decorative panel, which includes a stone decorative panel layer 1, an insulating layer 2, and a reinforcing layer 3 arranged sequentially from outside to inside. The stone decorative panel layer 1 is made of ultra-thin stone, and the thickness of the ultra-thin stone is 0.5-5mm. The material of the insulation layer 2 is a foam insulation material, and the material of the reinforcement layer 3 is an inorganic board. The four corners of the inner surface of the stone decorative panel layer 1 are respectively provided with four embedded nuts 4, one end of the embedded nut 4 is fixed on the inner surface of the stone decorative panel layer 1, and the other end penetrates the insulation layer 2 and the reinforcement layer 3, and the embedded The working end surface 41 of the nut 4 is flush with the outer surface of the reinforcing layer 3 . An adhesive 5 is provided on the embedded nu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com