Composite material veneer containing carbon fiber weaving cloth and its preparation method

A plywood and carbon fiber technology, applied in the field of plywood, can solve the problems of low thickness and high strength and toughness, increase the thickness of plywood, limit the application level of products, etc., and achieve the effect of high strength and toughness appearance and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A composite plywood with carbon fiber woven cloth and wood veneer and its manufacturing method are disclosed by the preferred embodiment of the present invention. Persons familiar with the art can understand the present invention according to the description of the preferred embodiments of the present invention, and implement the present invention in detail without departing from the spirit and scope of the present invention.

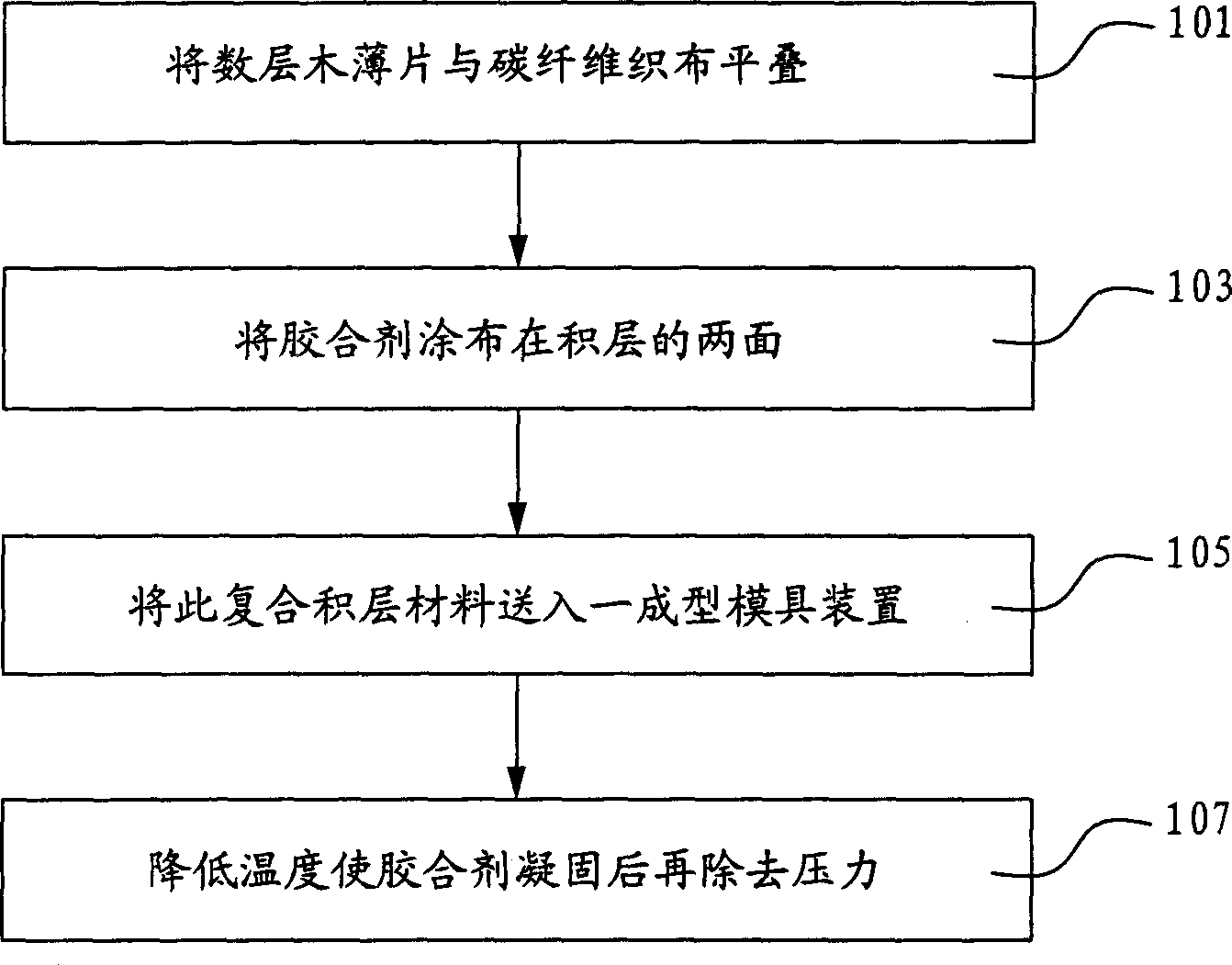

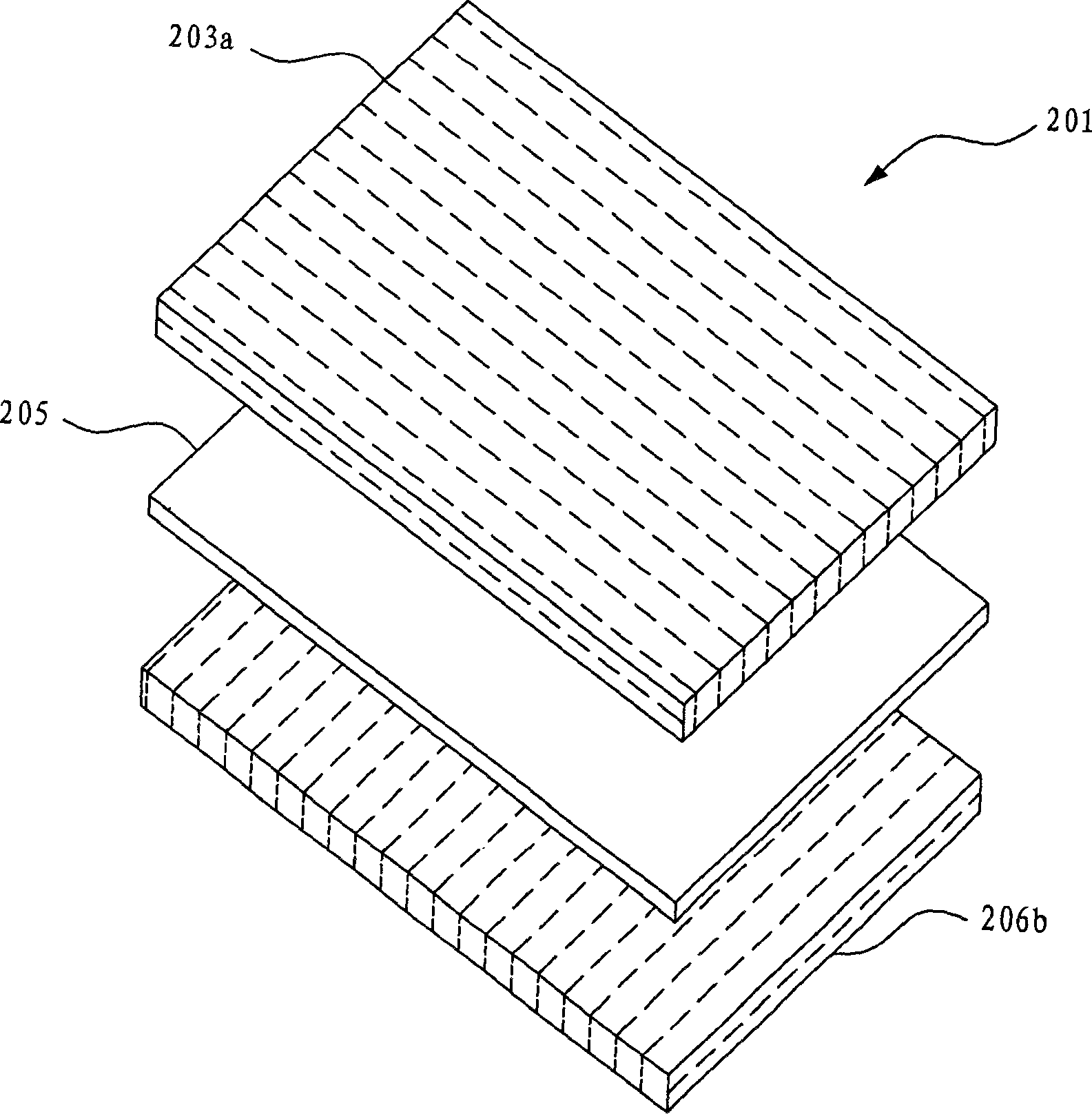

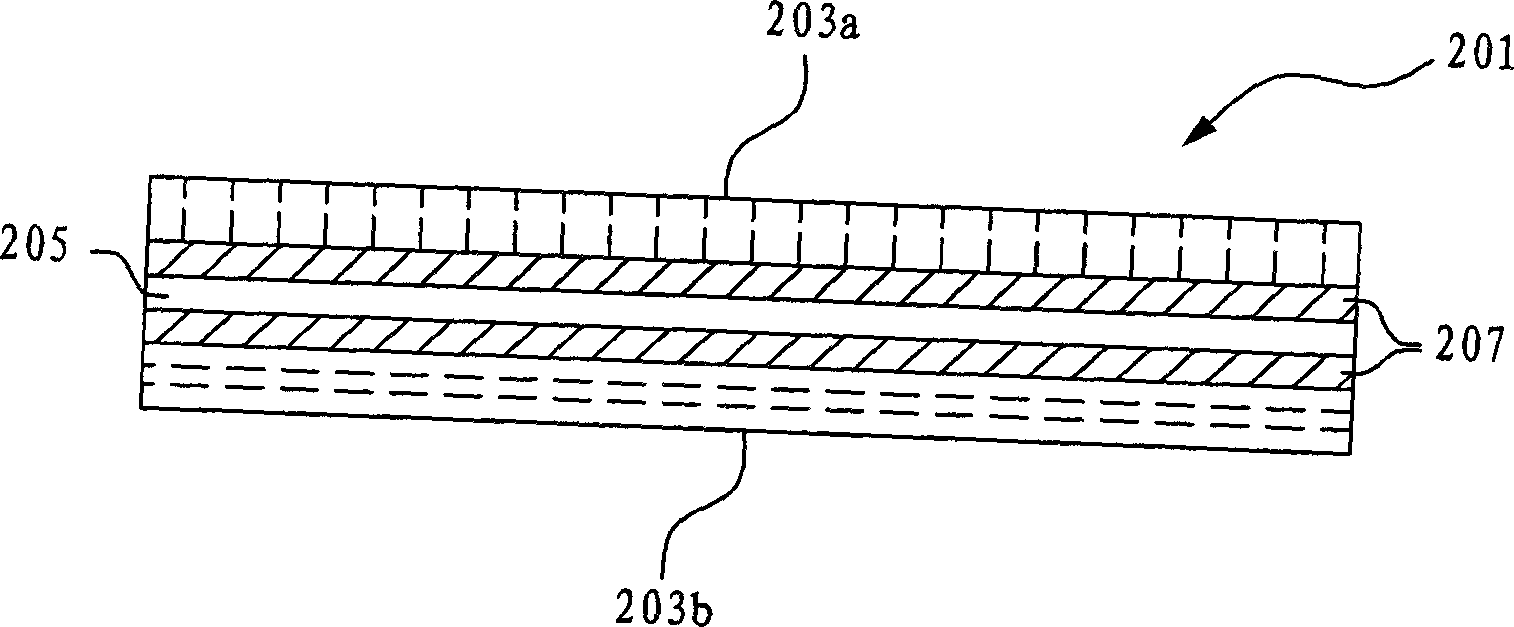

[0014] Please refer to figure 1 , which is a manufacturing flow chart according to a preferred embodiment of the present invention, used to illustrate the manufacturing process of the composite plywood. In the 101st step, firstly, odd-numbered layers of wood veneers and even-numbered layers of carbon fiber woven cloth are laid parallel to each other to form a composite laminated material. Among them, the upper and lower layers and the middle layer of the composite laminated material are wood veneers, while the remaining wood veneers are laid sym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com