High-elasticity silicon rubber heat transfer film and preparation method thereof

A silicone rubber and high elasticity technology, applied in the field of lettering film, can solve the problems of short service life, reduced appearance, poor softness, etc., and achieve high tear resistance, improved scratch resistance and formability, and good stretch Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

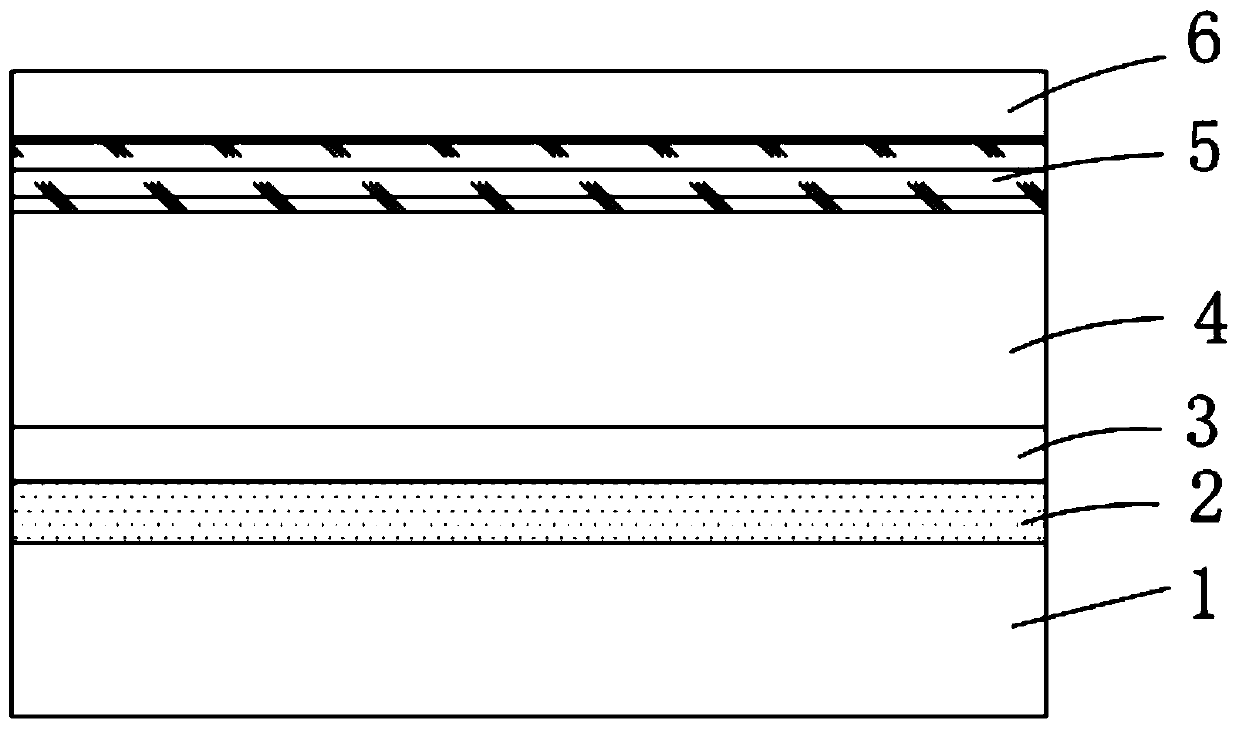

[0021] see figure 1 , the present invention provides a high-elastic silicone rubber lettering film, comprising a base substrate 1, a release layer 2 is provided above the base substrate 1, a scratch-resistant coating 3 is provided above the release layer 2, and the A rubber ink layer 4 is arranged above the scratch-resistant coating 3 , an adhesive layer 5 is arranged above the rubber ink layer 4 , and a TPU hot-melt adhesive film 6 is attached to the adhesive layer 5 .

[0022] Specifically, the rubber ink layer 4 has a thickness of 100 microns.

[0023] Specifically, the adhesive layer 5 is a thermoplastic resin structure, and the adhesive layer 5 and the TPU hot-melt adhesive film 6 are seamlessly bonded.

[0024] Specifically, the release layer 2 is a PTE release film, and the release layer 2 is coated with silicone oil.

[0025] A preparation method of highly elastic silicon rubber lettering film, comprising the steps of:

[0026] S1. Production of release liquid: Take...

Embodiment 2

[0033] see figure 1 , the present invention provides a high-elastic silicone rubber lettering film, comprising a base substrate 1, a release layer 2 is provided above the base substrate 1, a scratch-resistant coating 3 is provided above the release layer 2, and the A rubber ink layer 4 is arranged above the scratch-resistant coating 3 , an adhesive layer 5 is arranged above the rubber ink layer 4 , and a TPU hot-melt adhesive film 6 is attached to the adhesive layer 5 .

[0034] Specifically, the rubber ink layer 4 has a thickness of 100-200 microns.

[0035] Specifically, the adhesive layer 5 is a thermoplastic resin structure, and the adhesive layer 5 and the TPU hot-melt adhesive film 6 are seamlessly bonded.

[0036] Specifically, the release layer 2 is a PTE release film, and the release layer 2 is coated with silicone oil.

[0037] A preparation method of highly elastic silicon rubber lettering film, comprising the steps of:

[0038] S1. Production of release liquid: ...

Embodiment 3

[0045] see figure 1 , the present invention provides a high-elastic silicone rubber lettering film, comprising a base substrate 1, a release layer 2 is provided above the base substrate 1, a scratch-resistant coating 3 is provided above the release layer 2, and the A rubber ink layer 4 is arranged above the scratch-resistant coating 3 , an adhesive layer 5 is arranged above the rubber ink layer 4 , and a TPU hot-melt adhesive film 6 is attached to the adhesive layer 5 .

[0046] Specifically, the rubber ink layer 4 has a thickness of 200 microns.

[0047] Specifically, the adhesive layer 5 is a thermoplastic resin structure, and the adhesive layer 5 and the TPU hot-melt adhesive film 6 are seamlessly bonded.

[0048] Specifically, the release layer 2 is a PTE release film, and the release layer 2 is coated with silicone oil.

[0049] A preparation method of highly elastic silicon rubber lettering film, comprising the steps of:

[0050] S1. Preparation of release liquid: Tak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com