Finishing agent for preventing fluffiness of embroideries and preparation method and utilization method of finishing agent

A finishing agent and anti-fluffing technology, which is applied in the direction of textiles and papermaking, fiber treatment, wear-resistant fibers, etc. It can solve the problems of affecting the beauty and durability of embroidery, troublesome use methods, and difficult to control the composition, and achieves an obvious anti-fluffing effect. , simple preparation method and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

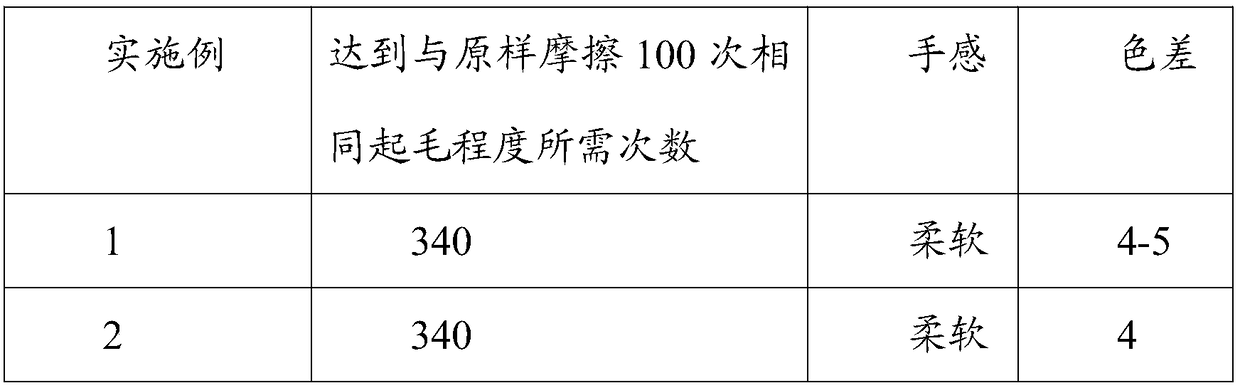

Embodiment 1

[0022] A finishing agent for preventing fluffing of embroidery, comprising polyvinyl alcohol, polyacrylic acid, crosslinking agent borax, colorless water-soluble penetrating agent, colorless water-soluble softener and deionized water, proportioned by weight as follows: poly 2 parts of vinyl alcohol, 5 parts of polyacrylic acid, 0.2 part of cross-linking agent borax, 0.5 part of colorless water-soluble penetrating agent, 0.3 part of colorless water-soluble softener, add deionized water to make a solution of 100 parts in total.

[0023] The preparation method of the finishing agent for preventing fluffing of embroidery comprises the following steps:

[0024] (1) According to the weight ratio, weigh 2 parts of polyvinyl alcohol and appropriate amount of deionized water to swell, and then heat to dissolve;

[0025] (2) Add 5 parts of polyacrylic acid, 0.5 part of colorless water-soluble fast penetrating agent, and 0.3 part of colorless water-based softener polyethylene glycol olea...

Embodiment 2

[0031] A finishing agent for preventing fluffing of embroidery, comprising polyvinyl alcohol, polyacrylic acid, crosslinking agent borax, colorless water-soluble penetrating agent, colorless water-soluble softener and deionized water, proportioned by weight as follows: poly 3.5 parts of vinyl alcohol, 3.5 parts of polyacrylic acid, 0.2 part of cross-linking agent borax, 0.5 part of colorless water-soluble penetrating agent, 0.3 part of colorless water-soluble softener, adding deionized water to make a solution of 100 parts in total.

[0032] The preparation method of the finishing agent for preventing fluffing of embroidery comprises the following steps:

[0033] (1) According to the weight ratio, weigh 2 parts of polyvinyl alcohol and appropriate amount of deionized water to swell, and then heat to dissolve;

[0034] (2) According to the weight ratio, add 5 parts of polyacrylic acid, 0.5 part of colorless water-soluble fast penetrating agent R, and 0.3 part of colorless water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com