Surface treating process of multiple sheet alloy

A surface treatment and alloy plate technology, applied in the field of materials, can solve the problems that the surface treatment process of various alloy plates cannot meet the needs, and achieve a highly practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

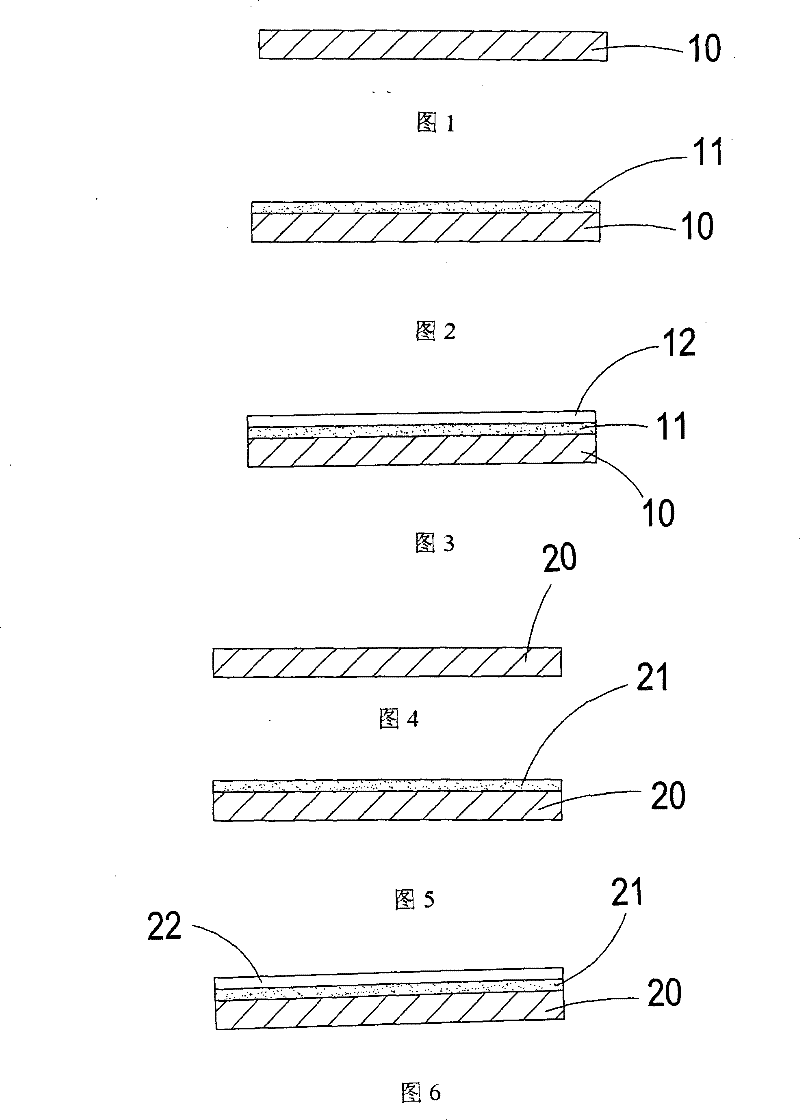

[0025] as attached figure 1 As shown in accompanying drawing 3, the present invention firstly provides a base material 10 to be surface-treated, and the base grid 10 is a magnesium alloy, and a transparent film layer 11 is formed on the surface of the base material 10 by chemical or electrochemical methods. The thin film layer 11 can reduce or block the chemical reaction between the substrate 10 and the post-treatment chemicals and retain the original conductive properties. Method of Coating The transparent conductive layer 11 on the surface of the substrate 10 is dyed one or more times to form the dyed layer 12 .

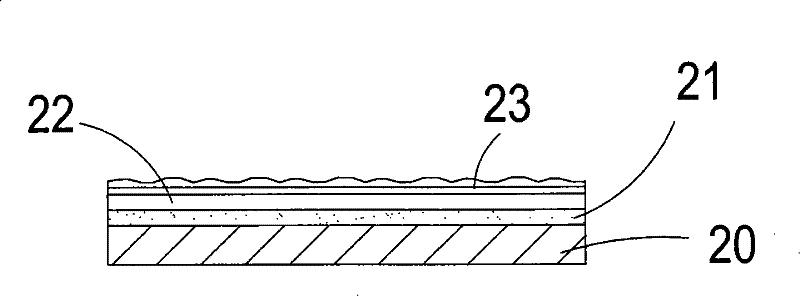

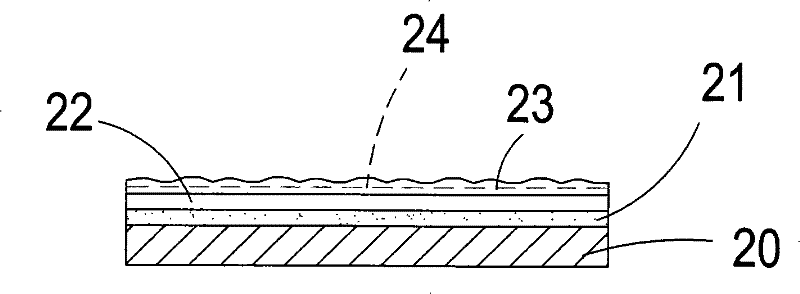

[0026] as attached Figure 4 to attach Figure 12 Shown, another embodiment of the present invention, it first provides a base material 20 to be surface treated, and this base material 20 is magnesium alloy, utilizes chemical or electrochemical method to form transparent film layer 21 on the surface of base material 20, transparent The thin film layer 21 can red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com