Kraft paper large ink position printing method and kraft paper for packaging

A printing method and technology of kraft paper, applied in printing, biological packaging, printing devices, etc., can solve the problems of kraft paper through-ground color, limited effect, thin thickness, etc., and achieve the effect of smooth pattern, strong texture and uniform ink color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

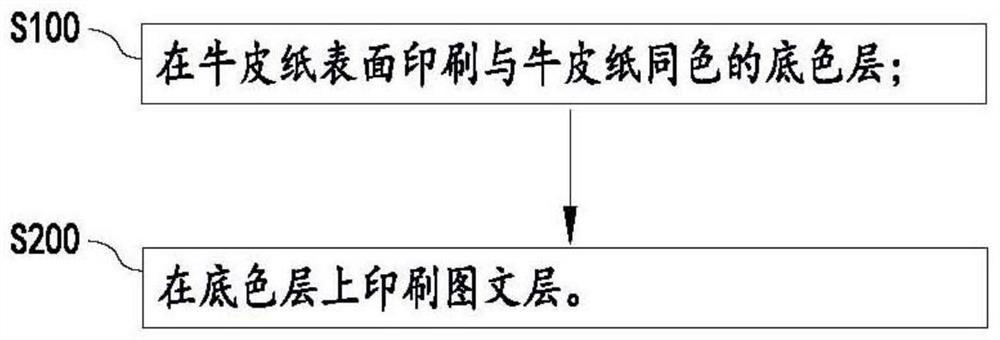

[0030] like figure 1 As shown, a large ink level printing method for kraft paper according to a preferred embodiment of the present invention can perform large ink level printing on kraft paper with excellent effect, and the amount of ink when printing graphics and texts is also greatly reduced, reducing production costs.

[0031] Based on the above technical solution, the present embodiment provides a large ink level printing method for kraft paper, comprising the following steps:

[0032] S100, printing a base color layer of the same color as the kraft paper on the surface of the kraft paper;

[0033] Before printing on the surface of the kraft paper in step S100, the kraft paper is pretreated. First, remove the damaged paper and the paper with uneven surface, then clean the impurities on the surface of the paper, and then hang it to dry for 48 hours, so that the temperature and humidity of the kraft paper are consistent with the temperature and humidity of the printing wor...

Embodiment 2

[0040] The steps of this embodiment are the same as those of Embodiment 1, except that steps S100 and S200 are large ink level printing. Compared with the traditional printing method of printing smaller images and texts, the display effect of images and texts on kraft paper is improved.

[0041] Preferably, in step S100, spot-color ink is used for printing. Compared with four-color printing, spot-color printing has a high degree of color reproduction. The spot-color ink can improve the printing effect of kraft paper printing, and can effectively retain the original kraft paper. The background color and texture make the choice of printing colors of kraft paper wider, suitable for the printing of various graphics and texts.

[0042] Specifically, by performing one printing on the surface of the kraft paper in step S100, the situation of powder removal and hair loss that will occur during the printing process of the graphic layer due to the poor surface smoothness of the kraft pap...

Embodiment 3

[0052] Preferably, the ink components used in printing are:

[0053] Organic pigments, accounting for 28 to 32% by mass;

[0054] Connecting material, the mass ratio is 22 to 24%;

[0055] Soybean oil, 14% to 16% by mass;

[0056] Vegetable oils other than soybean oil, accounting for 8% by mass;

[0057] Mineral oil, 18% to 22% by mass;

[0058] Filler, accounting for 1% to 3% by mass;

[0059] Wax, 3% to 5% by mass;

[0060] The ink viscosity was adjusted to 72 to 74 Pa·s using silicone oil, and the pH value was 8.2 to 9.5.

[0061] Among them, the connecting material includes high molecular resin, plasticizer and low molecular resin. The polymer resin is chlorinated natural rubber. The plasticizer adopts dibutyl phthalate, dioctyl phthalate, and butyl stearate. The low molecular weight resin adopts natural rosin ester and dimerized rosin pentaerythritol ester.

[0062] Wherein, the filler is talcum powder;

[0063] Specifically, the percentage content of each compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com