A kind of cationic water-based antirust agent composition

A water-based rust inhibitor and cation technology, applied in the field of rust inhibitor compositions, can solve problems such as harm to human health and environmental damage, and achieve the effects of easy removal, simple operation and good rust prevention effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

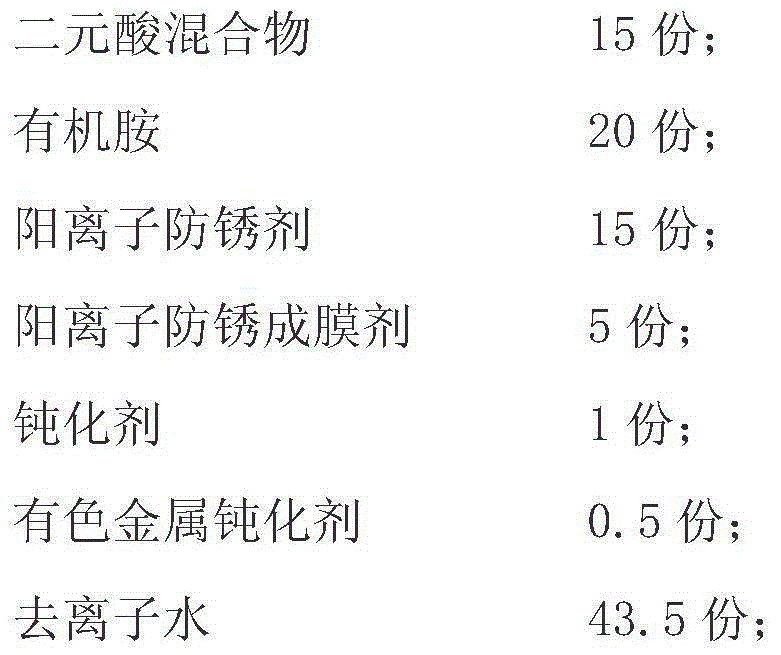

[0025] Present embodiment one concrete raw material and weight are:

[0026]

[0027] The steps of the preparation method for making the cationic water-based antirust agent composition are as follows: Weigh 43.5 kg of ionized water, put 10 kg each of triethanolamine and monoisopropanolamine into deionized water, stir well and mix the dodecyl carbon binary Put 10 kg of acid and 5 kg of undecanedibasic acid into the above mixed solution, heat it to 40-60°C while stirring, stir evenly and react completely, and put in 15 kg of bis-imidazoline quaternary ammonium salt after no visible particles, carbon Add 5 kg of quaternary ammonium salt, stir and stir evenly, then add 1 kg of sodium molybdate and 0.5 kg of benzotriazole into the above mixture, and stir evenly to obtain the finished product.

[0028] The above-mentioned carbonate quaternary ammonium salt is didecyldimethylammonium carbonate.

[0029] After the antirust solution prepared according to the implementation example ...

Embodiment 2

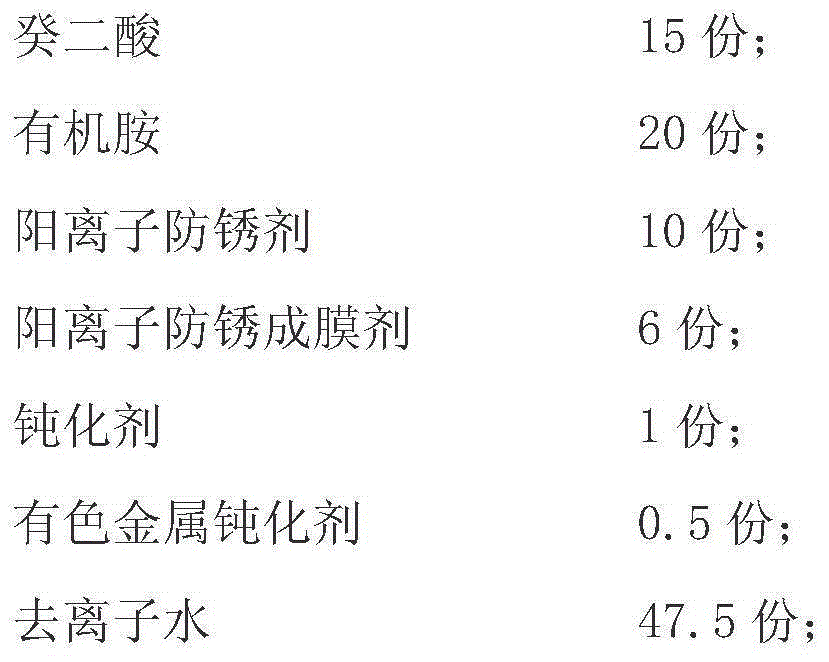

[0033] The concrete raw material of present embodiment two and weight are

[0034]

[0035] The steps of the preparation method for making the cationic water-based antirust agent composition are as follows: Weigh 47.5 kilograms of ionized water, put 10 kilograms of monoethanolamine and triisopropanolamine into deionized water, stir well and add 15 kilograms of sebacic acid Put into the above mixed solution, heat to 40-60°C while stirring, stir evenly and react completely, after no visible particles, put in 10 kg of bis-imidazoline quaternary ammonium salt, 6 kg of carbonate quaternary ammonium salt, stir and stir evenly, Then put 1 kg of sodium molybdate and 0.5 kg of tolyltriazole into the above mixture, and stir evenly to obtain the finished product.

[0036] The above-mentioned carbonate quaternary ammonium salt is didecyldimethylammonium carbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com