Patents

Literature

42 results about "Carex meyeriana" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of carex meyeriana fiber

ActiveCN102660779AImprove degumming effectImprove performanceVegetable materialMechanical treatmentFiberSulfite salt

The invention discloses a production method of a carex meyeriana fiber. The production method adopts the following process flow: taking carex meyeriana raw grass, boiling, carrying out primary processing, carrying out pre-degumming treatment by an ultrasonic wave, carrying out primary washing, carrying out alkali oxidation and degumming bath, pickling, carrying out secondary washing, drying, feeding oil, opening and carding to obtain the carex meyeriana fiber, wherein water is used as a medium in the step of the pre-degumming treatment by the ultrasonic wave, when the frequency is 28-40HZ and the temperature is 50-70 DEG C, the pre-degumming treatment by the ultrasonic wave is carried out for 60-90 minutes, and NaOH is added when the treatment is carried out within 20-30 minutes so as to enable the alkali concentration of the solution to reach 5-15g / l; in the step of alkali oxidation and degumming bath process, carex meyeriana can be put in an alkali oxidation extracting solution to enable the temperature to rise to 90-100 DEG C, heat preservation and boiling are performed for 1-2 hours; the alkali oxidation extracting solution is prepared from the following ingredients: 6-9g / l of sodium hydroxide, 8-12g / l of hydrogen peroxide, 2-4% of sodium polyphosphate serving as an additive of carex meyeriana mass, 2-4% of magnesium sulfate and 1-3% of sodium sulfite.

Owner:TIANJIN POLYTECHNIC UNIV

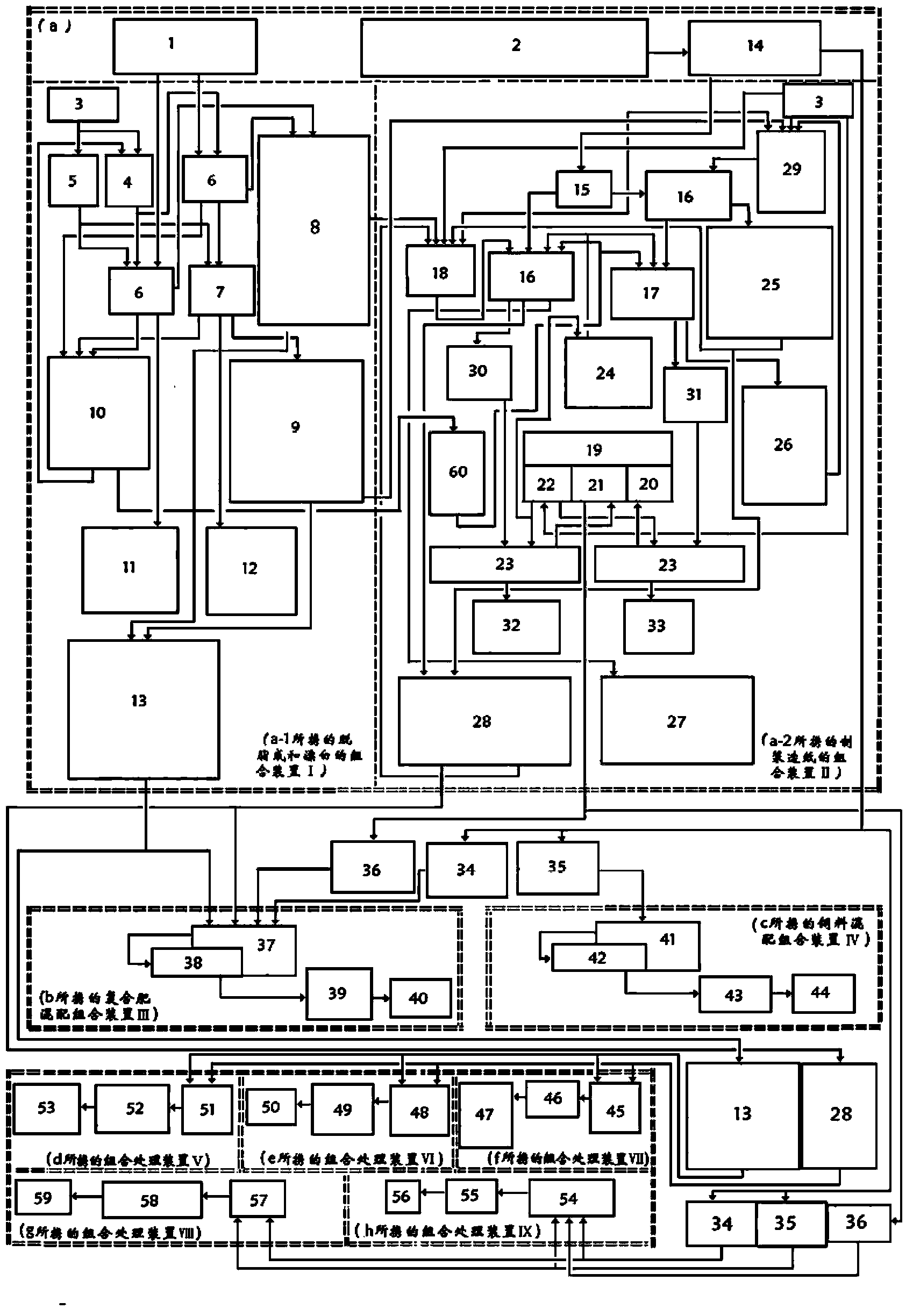

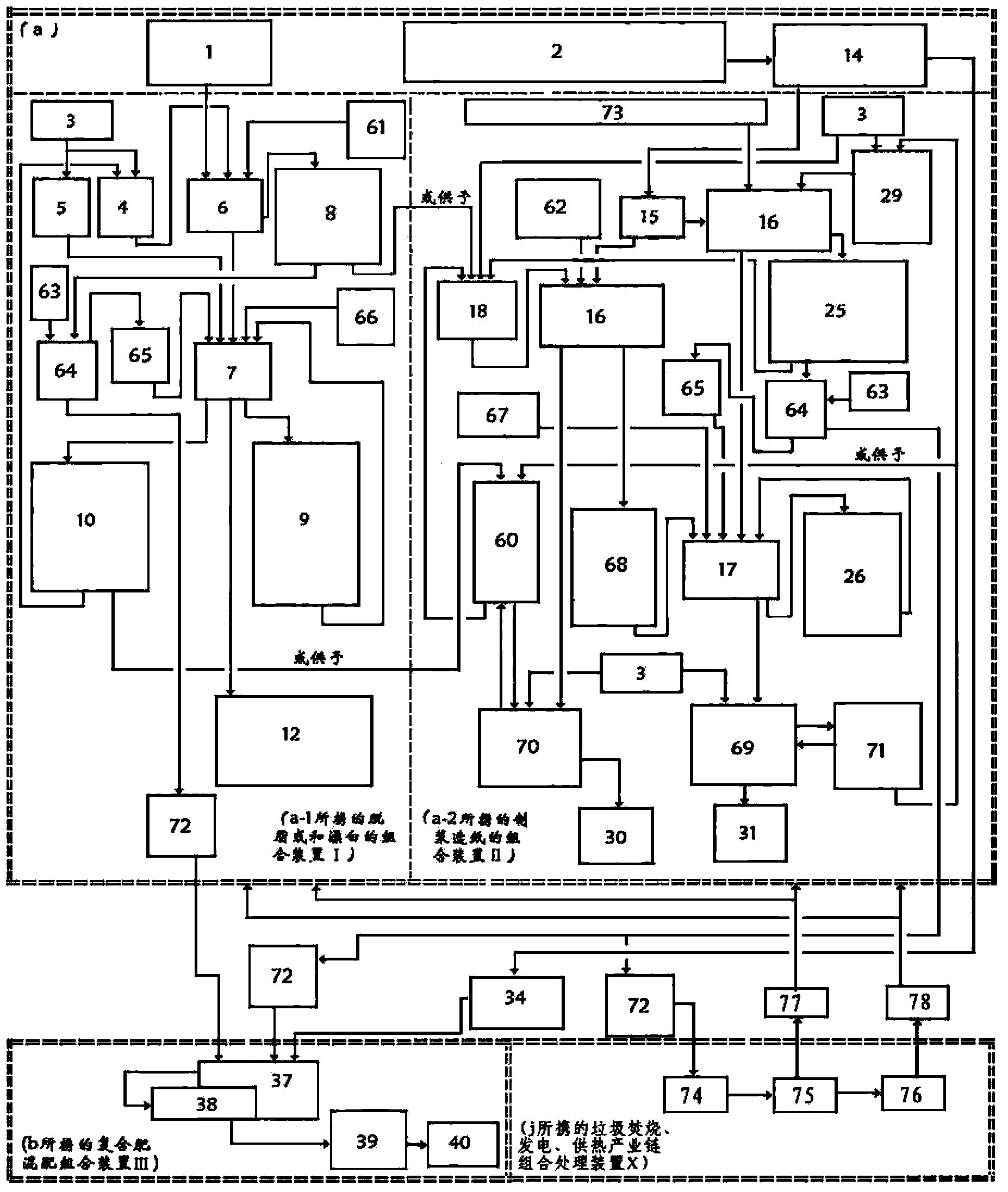

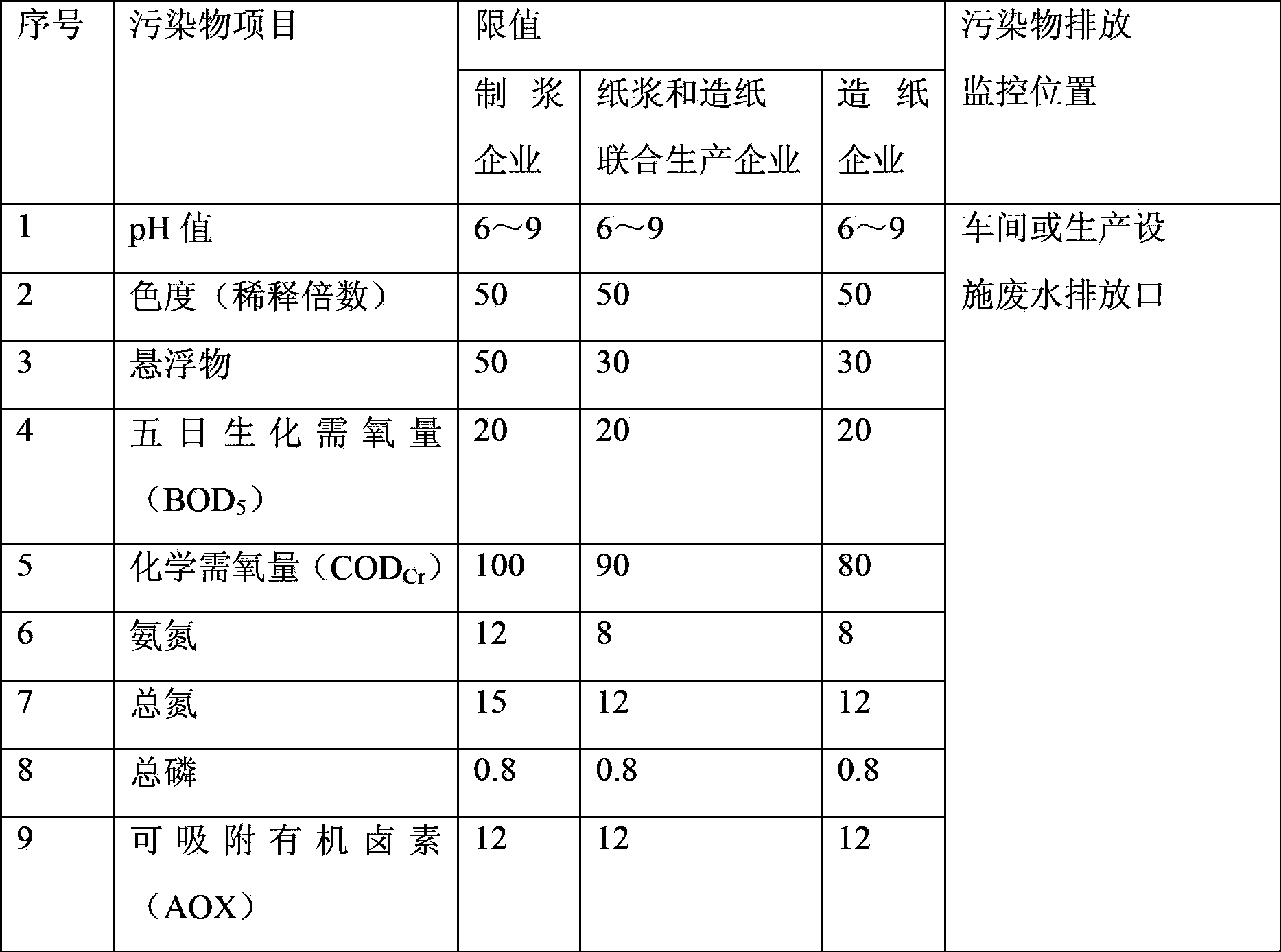

Clean production method of plant fiber product

InactiveCN103523945ARealize cleaner productionReduce processing costsMultistage water/sewage treatmentWaste water treatment from plant processingSludgeSugar industry

The invention discloses a clean production method of a plant fiber product, relating to the regeneration treatment on the black liquid generated by the deinking or degreasing or / and delignification in a production process of the plant fiber product or / and the implementation of interception-type recycling of the black liquid containing sodium ions, relating to the circulating water treatment and application in a production process in the field of different sub-products of the field of plant fiber products, relating to the treatment and utilization of the sludge obtained in black liquid regeneration and circulating water treatment processes, and relating to the blending treatment and utilization of drain water, wherein the plant fiber at least comprises any one of cotton and fibrilia crops, crop straw including any one of cotton straw, rice straw, wheat straw, reed, corn straw and the like, weed including any one of carex meyeriana, solidago decurrens and the like, broadleaf wood and the like including any one of poplar and eucalyptus, bagasse discarded by the sugar industry and any one of waste paper and old cotton or the combination of more than one waste plant fiber product and the like.

Owner:上海橡本永拓环保科技发展有限公司 +4

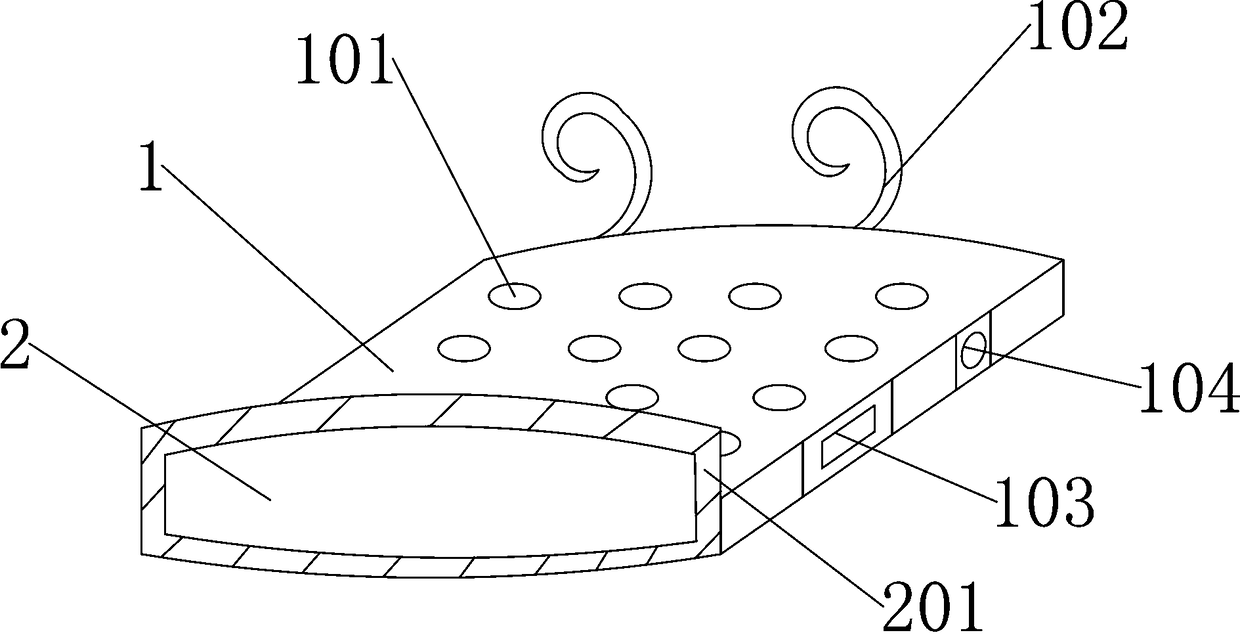

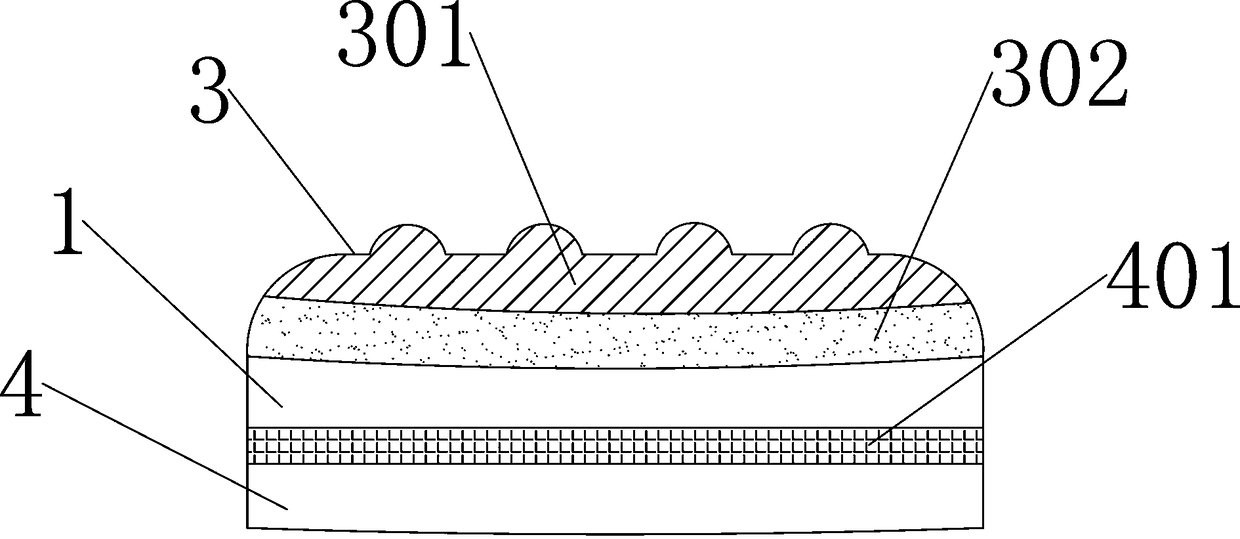

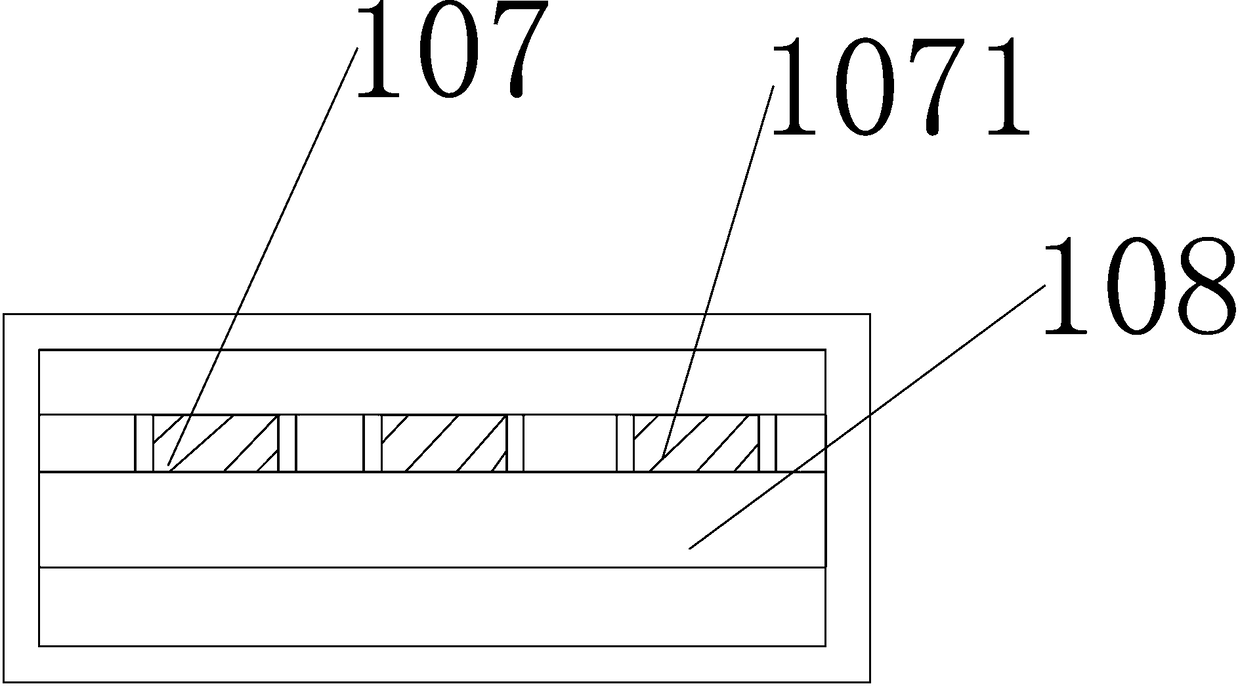

Health mattress made of Carex meyeriana Kunth

The invention discloses a kind of hygienic mattress made of uregrass. It comprises the following steps to make it: put the uregrass into the agitator and make it stifled by the vapor, to make the raw material mellow and difficult to broken; pave the raw material well and send it into the pressurized machine to sterilize at a high temperature, form by pressure, and set prominences in one end of the mattress uniformly; put the formed mattress into the traditional medicine to immerse and oversaw traditional medicine powder to the formed mattress, to make the mattress contains following features: heat and cold insulation, cold-proof and damp-proof, mellow texture, good air perviousness and the prevention and treat to the rheumatic disease. The mattress is made by the pressing of green plants, sticked without glue, having environmental protection function, and having chiropractic function with the arrangement of the prominences. The uregrass can also be made into hygienic shoe-pad, it can prevent beriberi.

Owner:任学明

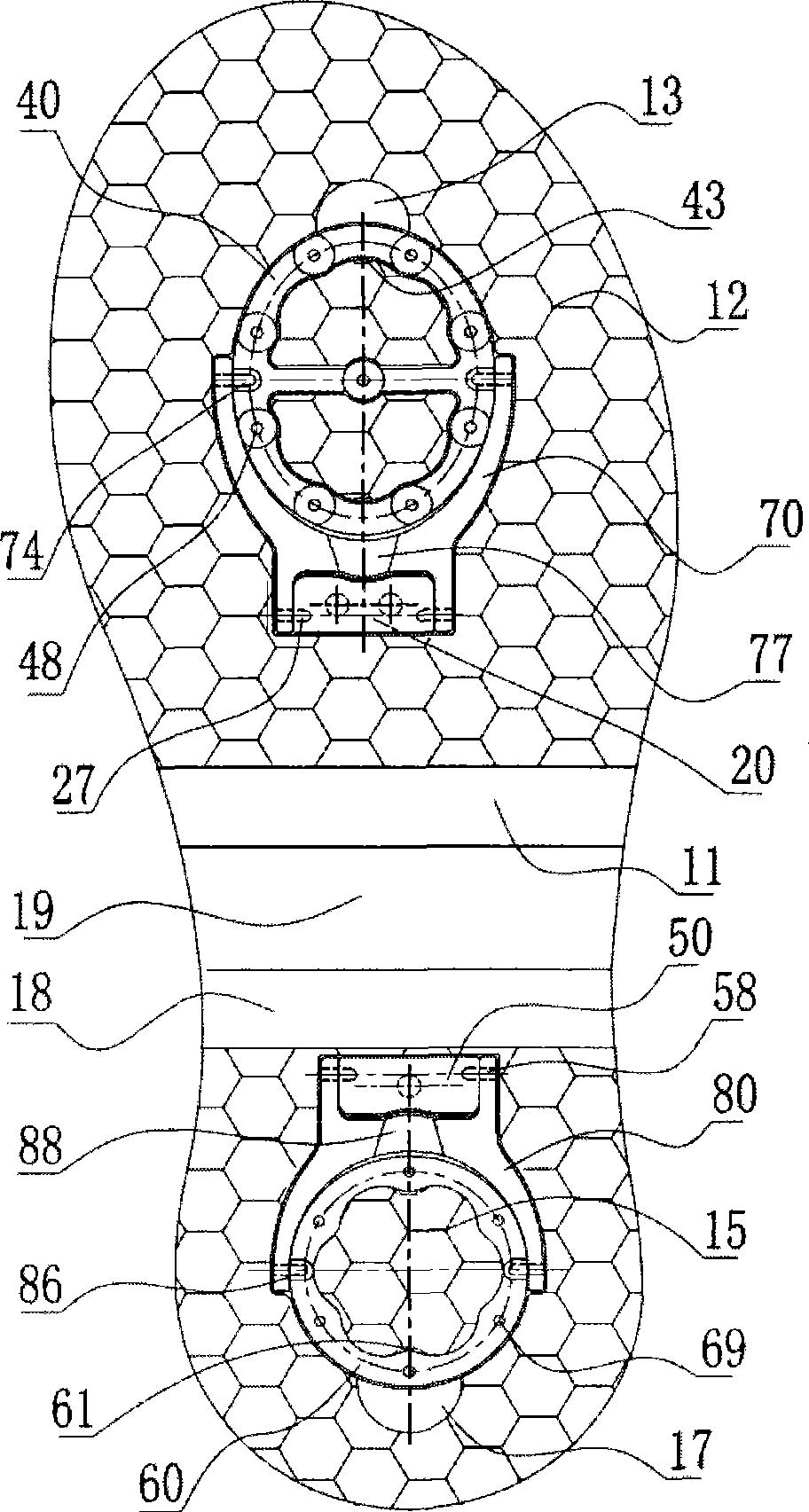

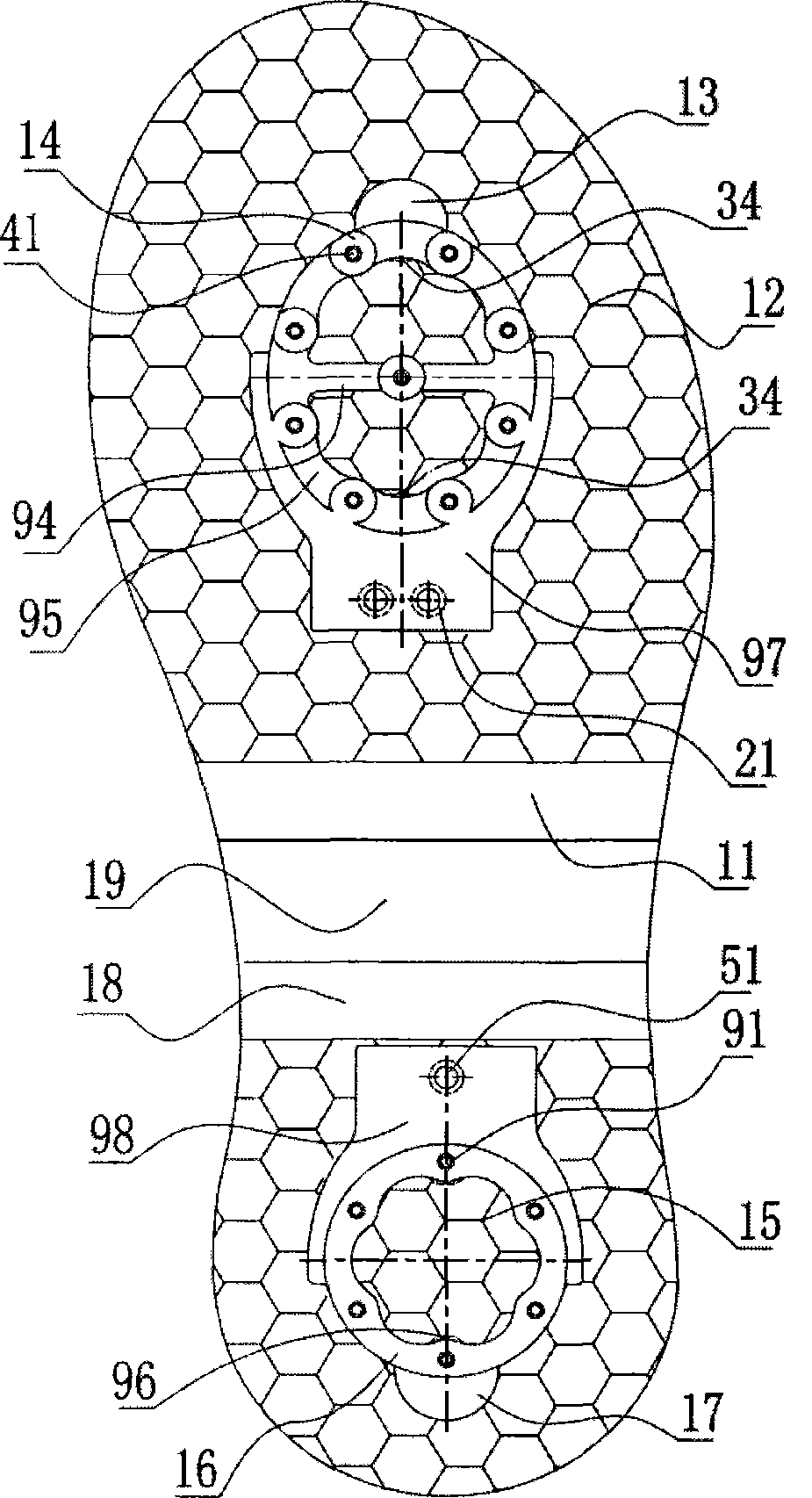

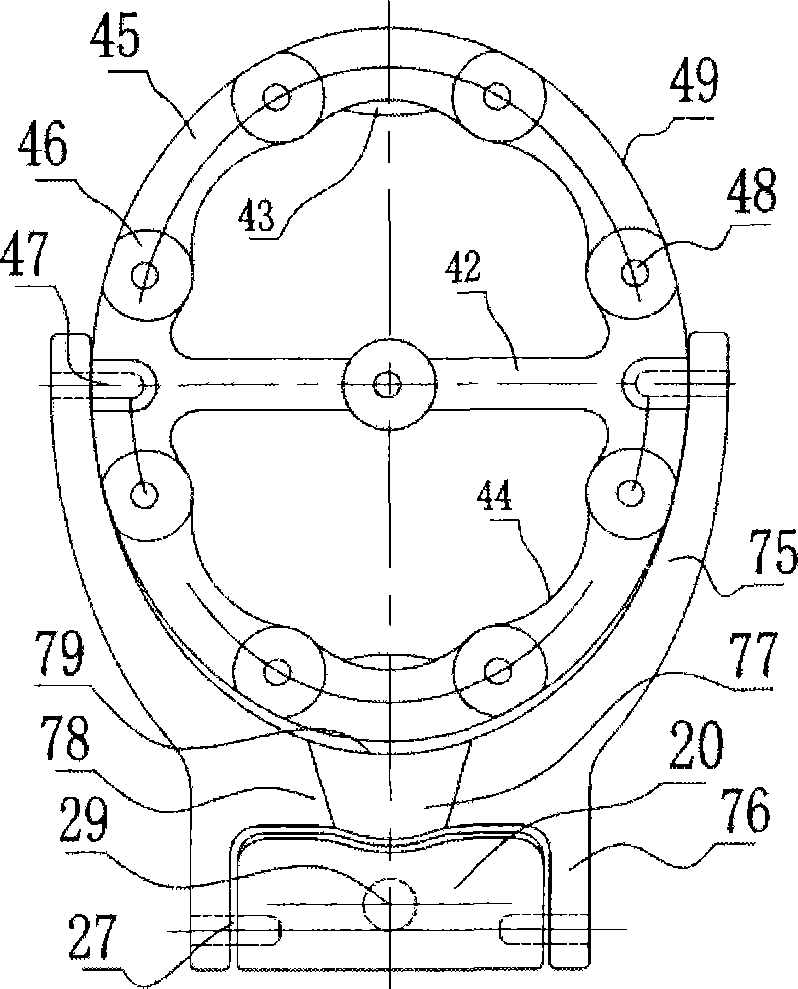

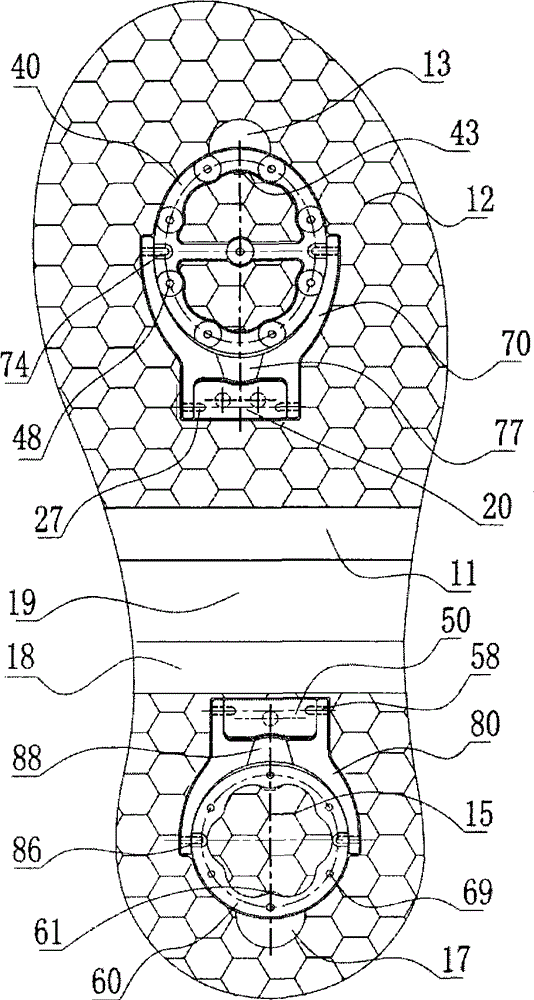

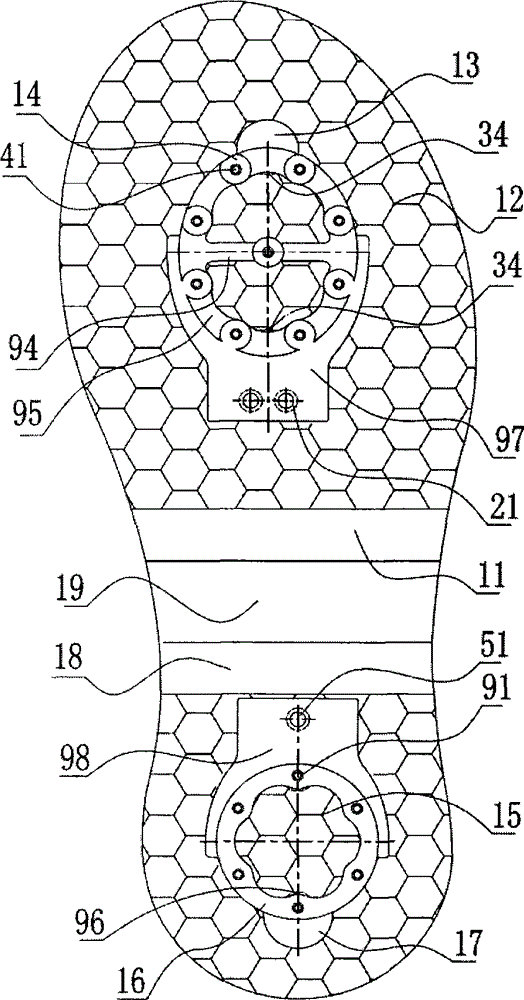

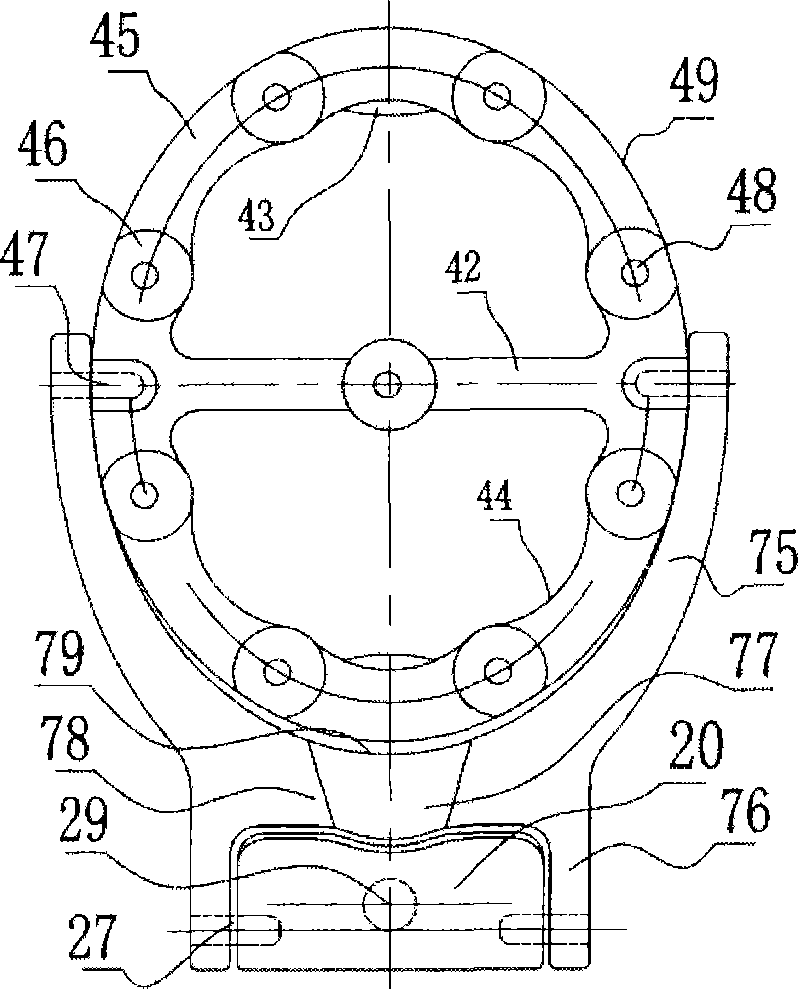

Warm keeping and skipping preventing shoes for internal use and external use

The invention provides warm keeping and skipping preventing shoes for internal use and external use. The warm keeping and skipping preventing shoes comprise surfaces, upper bottoms, half sole bottoms and heel flat bottoms, wherein the half sole bottoms have half sole curved surfaces; and the heel flat bottoms have heel flat surfaces. The warm keeping and skipping preventing shoes are characterized in that a thermal insulation flock sleeve layer is fixedly connected and clung to the inner side of each surface; a thermal insulating insole layer is clung onto the upper surface of each upper bottom and is connected with a thermal insulating insole into a whole in a sewing manner; mountain skipping preventing assemblies and ice land skipping preventing assemblies are respectively arranged on the half sole bottoms and heel bottoms; each mountain skipping preventing assembly comprises a bent plate forked base, an elliptic nail plate and a bent plate swinging fork; and each ice land skipping preventing assembly comprises a swinging fork base, a flat face round nail plate and a swinging fork. The warm keeping and skipping preventing shoes for the internal use and the external use enable stable walking on both a general road and an icy road to be possible, and also can be used for steadily climbing a mountain, and are convenient to adjust. The thermal insulation flock sleeves are made of woollen goods; the thermal insulating insoles are made of carex meyeriana materials which are known as one of Northeast Three Treasures and have sufficient thermal insulation effect.

Owner:山东润蒙应急救援装备有限公司

Production process of carex meyeriana Kunth fibre and product thereof

InactiveCN1558011AHighlight the characteristics of heat preservation and cold protectionImprove spinnabilityYarnYarnFiber

The present invention discloses one kind of Ula weed fiber yarn and its production process and product. The Ula weed fiber is produced with Ula weed and through soaking in water at normal temperature inside a spherical boiler, boiling in sodium hydroxide solution of 4-12 g / L at temperature of 60-100 deg.c and pressure of 0-10 Kg for 2-4 hr; washing to eliminate gelatine and other impurity, spinning and stoving. The The Ula weed fiber is then opened, carded, laid and spun into roving, spun yarn and Ula weed fiber yarn. The said Ula weed fiber has excellent warming performance and excellent spinnability.

Owner:王均有

Refined preparation method of Carex meyeriana fiber

InactiveCN106119980ASuitable for textile processingIncrease contact areaVegetable materialPectinaseSulfite salt

The invention discloses a refined preparation method of a Carex meyeriana fiber. The preparation method adopts the following technology: preparing a Carex meyeriana straw, dipping in water, cooking in water, carrying out preliminary processing, carrying out alkali treatment, washing with water, and carrying out bio-enzyme treatment, alkali-oxygen treatment, bath treatment, afterwashing with water, air drying and filament separation, thus obtaining the Carex meyeriana fiber. An alkali treatment technology is that the dosage of sodium hydroxide is 6-10g / L, and the dosage of urea is 2-4% of the mass of straw. In a bio-enzyme treatment technology, pectinase is adopted for degumming treatment. An alkali-oxygen one-bath technology is characterized in that 4-10g / L of sodium hydroxide, 2-8g / L of hydrogen peroxide and 1-3% of sodium sulfite are adopted, temperature is raised to 90 DEG C from room temperature, and constant temperature time is 30-90min. The fineness of the extracted Carex meyeriana fiber is 40-80mu m, and intensity is 110-230MPa. The problems of complexity in operation, long time consumption, environment pollution, poor fiber processing effect in a traditional preparation method of the Carex meyeriana fiber are solved, and an extraction process has the advantages of simple technology, good fiber performance and the like, and is clean and environmentally friendly.

Owner:TIANJIN POLYTECHNIC UNIV

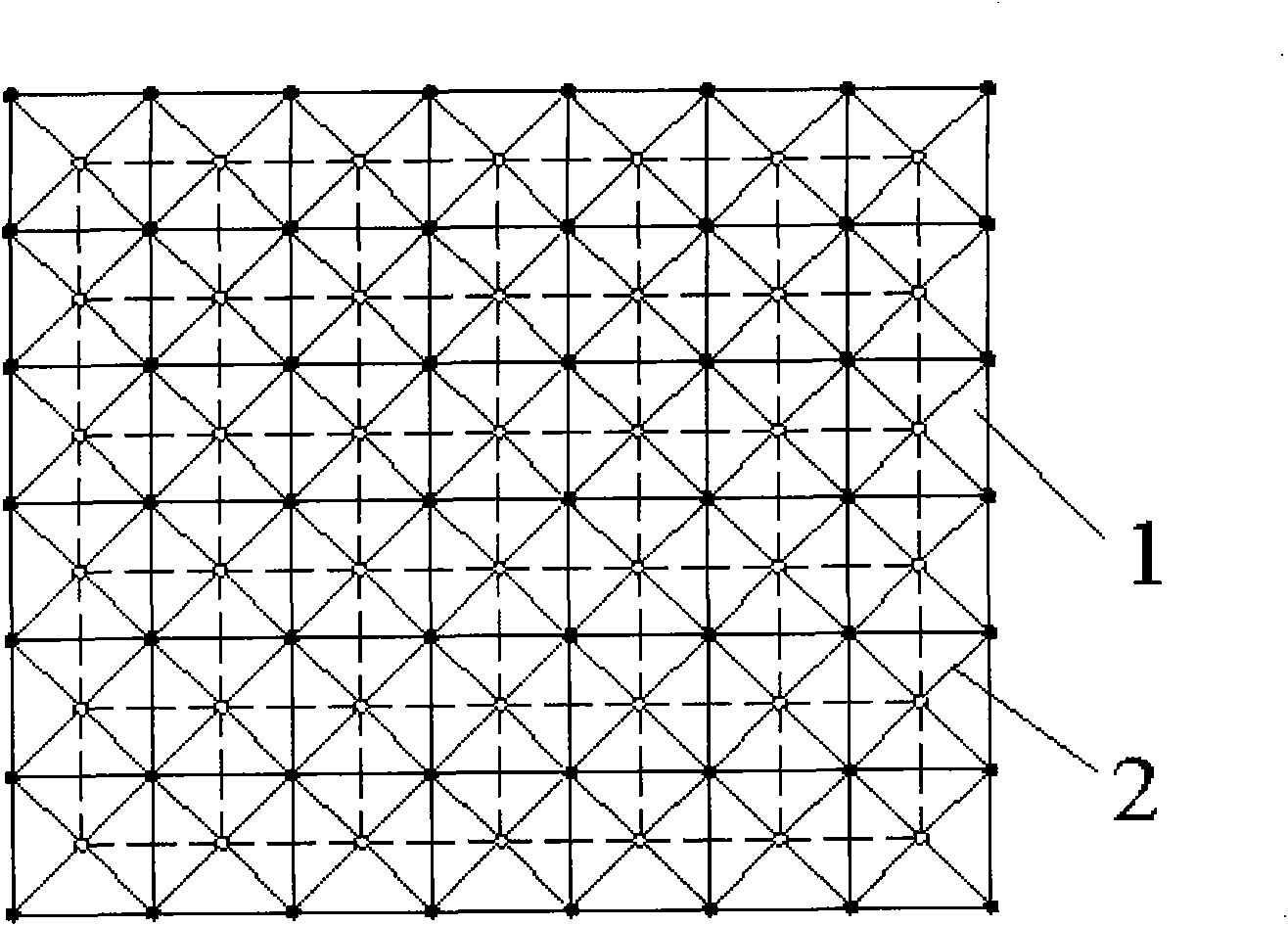

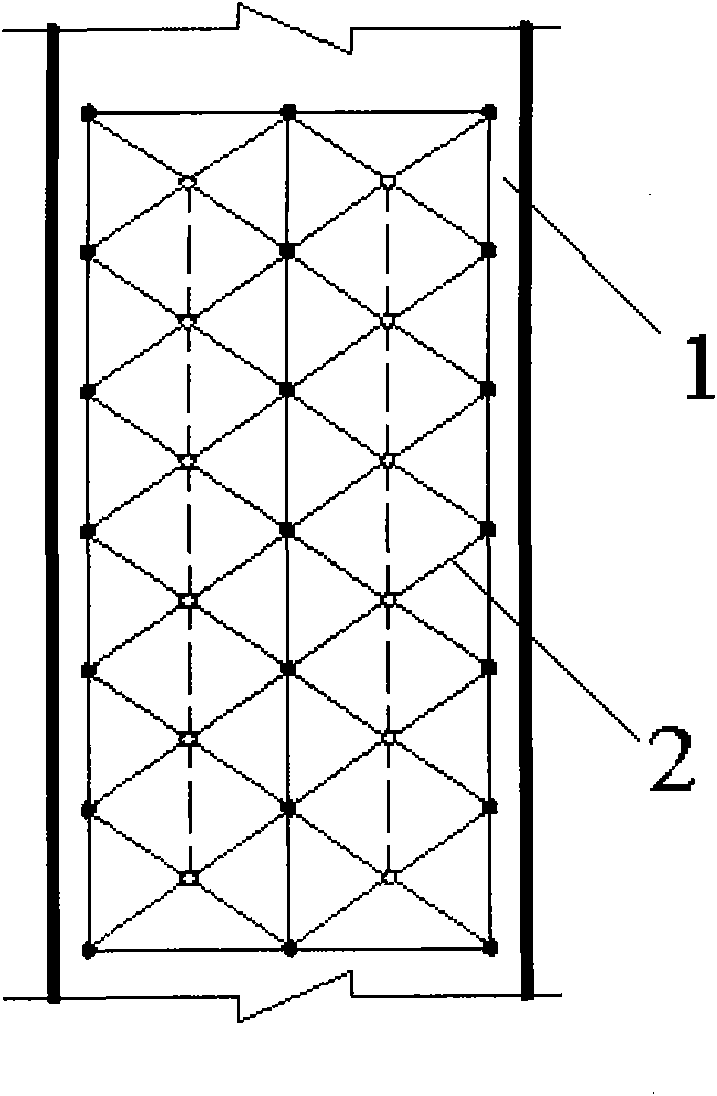

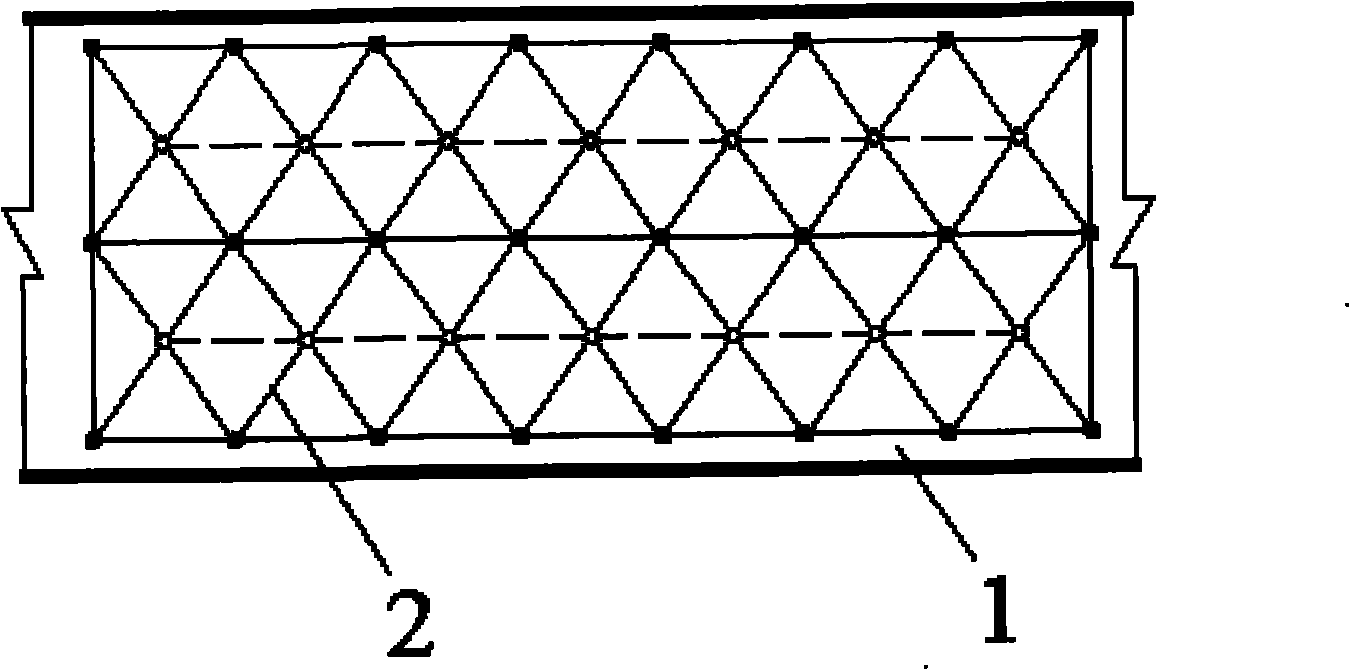

Spatial grid reinforcing environment-friendly heat insulation wallboard

InactiveCN101839037AHigh strengthImprove insulation effectConstruction materialSolid waste managementFiberMethyl cellulose

The invention discloses a spatial grid reinforcing environment-friendly heat insulation wallboard, the mortar thereof is prepared from cement, white lime, light filler, triple superphosphate powder, foamed PS particles, wood fiber, re-dispersible latex powder, methyl cellulose ether, Carex meyeriana or corn leaves and traditional Chinese medicine components. When in preparation, foaming is carried out after the wallboard mortar is formed but before solidification so as to enable a great number of bubbles to be generated in the wallboard. The spatial grid reinforcing environment-friendly heat insulation wallboard in the invention has the advantages of high strength and good heat insulation property, can remove methanal, purify air, has the efficacy of bring peace to mind of people, and is mainly used in building nonbearing walls.

Owner:纪瑞星

Medicinal herbals fiber soft cushion and production method thereof

InactiveCN101361931AAvoid degradationAvoid degradation, drug absorption is not affected by gastrointestinal factorsNervous disorderStuffed mattressesDiseaseFiber

The invention relates to a medical herbal fiber spongy pad body and a preparation method thereof, the medicinal herbal fiber spongy pad body is shaped by mixing the fibers and medicinal components extracted from such herbal plants as Carex meyeriana, ramuli mori, rhizoma homalonemae, phyllostachys pubescens, cortex eucommiae, radices dipsaci and Gynostemma pentaphylla, and the natural latex. The preparation method comprises the steps of: (1) ingredient cutting; (2) rolling and slicing; (3) digesting and splitting; (4) hydrolyzation; (5) neutralization and degreasing; and (6) processing and molding of the pad body. According to the principles of 'external treatment to internal diseases' and 'lower treatment to upper diseases', the pad body can be made into the shape of mattress, insole, knee pad, belly bank, and shoulder periphery or other needed shapes, which can be conveniently used and replace sponge as pad bodies widely used in sound insulation and heat insulation for health care.

Owner:黄 建华

Carex meyeriana volatile oil and application thereof

ActiveCN106726758AImprove securitySimple and fast operationAntibacterial agentsCosmetic preparationsEscherichia coliCarex

The invention discloses carex meyeriana volatile oil and application thereof. The preparation process of the carex meyeriana volatile oil comprises the following steps: crushing carex, soaking for 2-6 hours in water at 24-26 DEG C according to a material to liquid ratio of (1:10)-(1:50), performing stirring heating extraction for 5-9 hours by using a volatile oil extraction device at a rotation speed of 150-350rpm, cooling to the room temperature, and collecting a light yellow oil substance from the upper end of the volatile oil extraction device, thereby obtaining a crude carex meyeriana volatile oil extract. The carex meyeriana volatile oil disclosed by the invention has an antibacterial function and a mite elimination function on escherichia coli, staphylococcus aureus, bacillus pumilus and bacillus subtilis, can be developed into products for eliminating mites and preventing bacteria, and meanwhile can be applied to products for whitening skin, removing beverage and tendering skin.

Owner:吉林市一力乌拉草制品有限公司

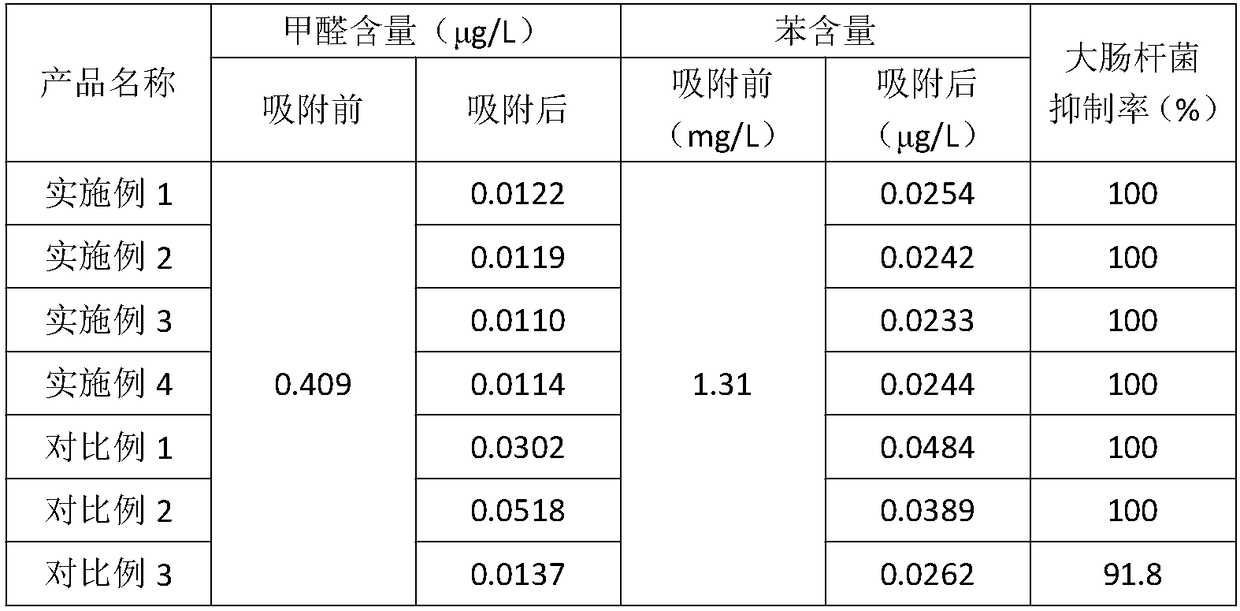

Preparation method of tear resistant silicone rubber mold

The invention provides a preparation method of a tear resistant silicone rubber mold. The method includes the steps of: (1) crushing Carex meyeriana fiber, adding ammonia water, conducting water bath stirring, taking the Carex meyeriana fiber out and performing washing, and then carrying out drying to a constant weight to obtain alkalized Carex meyeriana fiber; (2) mixing amino silicone oil, anhydrous ethanol and sodium hexadecyl benzene sulfonate to obtain a modified emulsion, adding the modified emulsion and alkalized Carex meyeriana fiber into a reaction kettle, introducing nitrogen to carry out reaction, then taking the material out and performing washing, and carrying out drying to a constant weight to obtain modified Carex meyeriana fiber; (3) adding siloxane, BR and the modified Carex meyeriana fiber into an open mill, performing mixing, then transferring the materials into a single screw extruder to conduct melt extrusion, thus obtaining a base material; and (4) adding a reinforcing agent, a heat-resistant agent, a crosslinking agent, a thixotropic agent, a stabilizer, weight increase filler into the base material, mixing the materials evenly by a kneader, adding a vulcanizing agent and a promoter, mixing the materials uniformly, carrying out vacuum degassing, then pouring the mixture into a die, and conducting solidification under room temperature, thus obtaining the tear resistant silicone rubber mold. The silicone rubber mold prepared by the method provided by the invention has good tear resistance.

Owner:DONGGUAN XINXING ORGANIC SILICON TECH

Chem-bio combined preparation method of carex meyeriana fibers

The invention discloses a chem-bio combined preparation method of carex meyeriana fibers, which includes the steps of: collection of straw of carex meyeriana, water-boiling, pre-processing, pre-alkaline boiling, water washing, alkali-peroxide one-bath treatment, water washing, post-alkaline boiling, water washing, treatment with laccase, water washing and oil addition to prepare the carex meyeriana fibers. In the pre-alkaline boiling, an alkaline solution in high concentration is employed, wherein urea is added to perform puffing and degumming treatment. In the alkali-peroxide one-bath treatment, a JFC penetrant is added so that effect of the alkali and peroxide is more complete. In the post-alkaline boiling, an alkaline solution in lower concentration is employed, wherein the JFC penetrant is added to further degum the product. In the laccase treatment, a shaking table vibration method is employed, wherein a beaker is arranged in a shaking table of which the temperature is 40-60 DEG C and the vibration speed is 40-90 r / min to degum the product for 15-30 min gently and uniformly. The method is simple, is high-effective, is clean and environment-friendly, wherein the degumming is gentle and uniform. The extracted carex meyeriana fibers are uniform and soft, and can be used in yarn spinning.

Owner:TIANJIN POLYTECHNIC UNIV

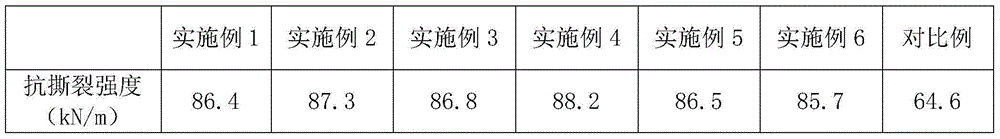

Sterilization type air purifying material and preparation method thereof

InactiveCN108126669AImprove adsorption capacityReduce adsorptionBiocideGas treatmentFiberChlorine dioxide

The invention provides a sterilization type air purifying material and a preparation method thereof. The preparation method comprises the following steps: firstly, mixing dolomite powder, a carbon molecular sieve and refined diatomite and grinding to obtain mixed powder; secondly, adding shaddock peel biochar, nanosized titania, fly ash, hydrochloric acid and one half deionized water, sealing by apreservative film, stirring and insulating; thirdly, filtering, drying, putting a dried substance into a grinding machine for grinding, passing a sieve with 200 meshes and removing large particles; fourthly, adding straw alkali lignin, soybean 11S globulin, a nettle leaf ethanol extract, carex meyeriana fiber, xanthic acid chitosan, chlorine dioxide, acrylic emulsion and residual deionized water,sealing by the preservative film and stirring; fifthly, filtering and drying to obtain a finished product. The sterilization type air purifying material provided by the invention has a good adsorption effect on formaldehyde and benzene, and can be used for effectively adsorbing the formaldehyde and the benzene in air; meanwhile, the sterilization type air purifying material also has a good antibacterial effect and can be used for effectively inhibiting reproduction of bacteria, thereby improving the decrease of the adsorption effect caused by the reproduction of the bacteria.

Owner:FOSHAN CITY ZHONGHUAN ENVIRONMENT CENT

Fabric preparation and dyeing method

ActiveCN108048977AGood antibacterialImprove dyeing efficiencySucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersFiberYarn

The invention discloses a fabric preparation and dyeing method. The method includes steps: S1, fabric preparation, to be more specific, using a twisting machine for twisting, by mass, 5-9 parts of artemisia argyi fibers, 12-23 parts of carex meyeriana fibers and 10-18 parts of acorus calamus fibers into artemisia argyi fiber strips, carex meyeriana fiber strips and acorus calamus fiber strips, andpreparing blended yarns from the artemisia argyi fiber strips, the carex meyeriana fiber strips, the acorus calamus fiber strips and cotton fiber strips to further obtain a fabric A. The prepared fabric not only has a fragrance efficacy but also has great antibacterial and odor removal functions and is high in comfort, low in dyeing agent residual amount and free of fading. In addition, the fabric produced according to the method is high in toughness and durability.

Owner:SHAOXING HAITONG PRINTING & DYEING CO LTD

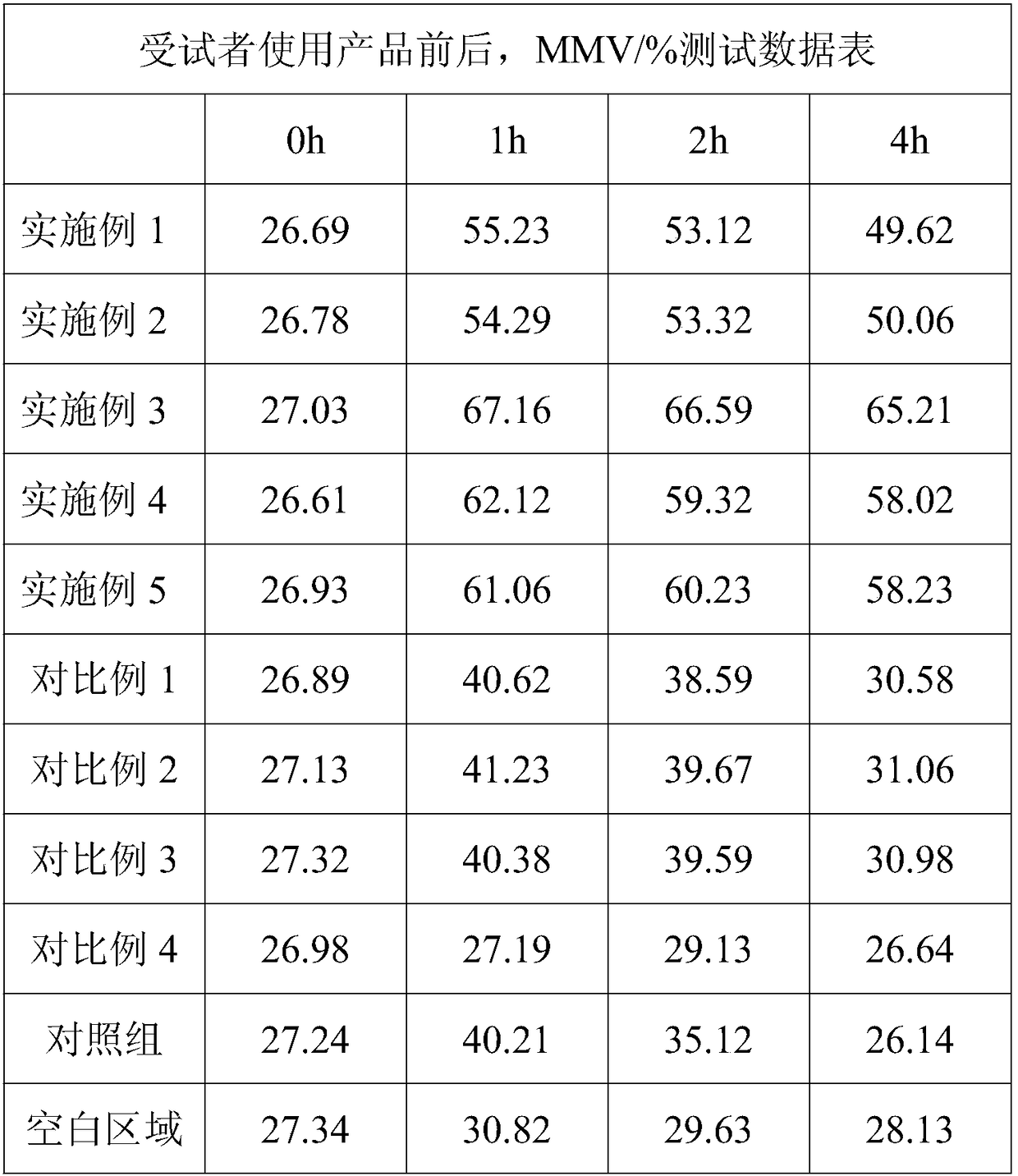

Anti-aging skin beautifying cream

InactiveCN108272703APromote circulationTo promote metabolismCosmetic preparationsToilet preparationsAdditive ingredientMedicine

The invention discloses anti-aging skin beautifying cream. The anti-aging skin beautifying cream is prepared from the following components by mass percent: 0.1-1% of Carex meyeriana extract, 0.1-1% ofCalyx seu Fructus Physalis extract, and 0.1-1% of passion fruit extract. The anti-aging cream contains the added plant components including the Carex meyeriana extract, the Calyx seu Fructus Physalisextract and the passion fruit extract that play a synergy role, thereby effectively promoting microcirculation, delaying aging, and nourishing and moisturizing the skin so as to achieve the effect ofpreventing the skin from aging and beatifying the skin.

Owner:FOSHAN SANSHUI DISTRICT JIAHUA CHEM RES INST GENERAL PARTNERSHIP

Novel plant composite shoe material

The invention discloses a novel plant composite shoe material, which comprises a plant composite material and a non-woven fabric, wherein the components of the plant composite material formula comprise 3-5 parts of carex meyeriana powder, 3-5 parts of tea leaf powder, 3-5 parts of platycladus orientalis leaf powder, 1-2 parts of antibacterial powder, 2-4 parts of zeolite powder, 2-4 parts of negative ion powder, 1-2 parts of fragrant powder, 2-4 parts of PVA, and 70-90 parts of deionized water. According to the present invention, by using the carex meyeriana powder, the tea leaf powder, the platycladus orientalis leaf powder and other plants, the produced shoe material has functions of strong odor adsorption and strong wet-liquid adsorption; the system contains the antibacterial powder, the negative ion powder, the fragrant powder and the zeolite powder so as to provide strong bacterial killing ability and strong odor decomposition ability and purify the inside-shoe environment; the mid-sole and the insole produced from the product of the present invention have excellent inside-shoe purification function and can achieve the effects of antibacterial effect and deodorization; and the novel plant composite shoe material has characteristics of simple process, low cost, and easy use.

Owner:JINHOU GRP WEIHAI SHOES

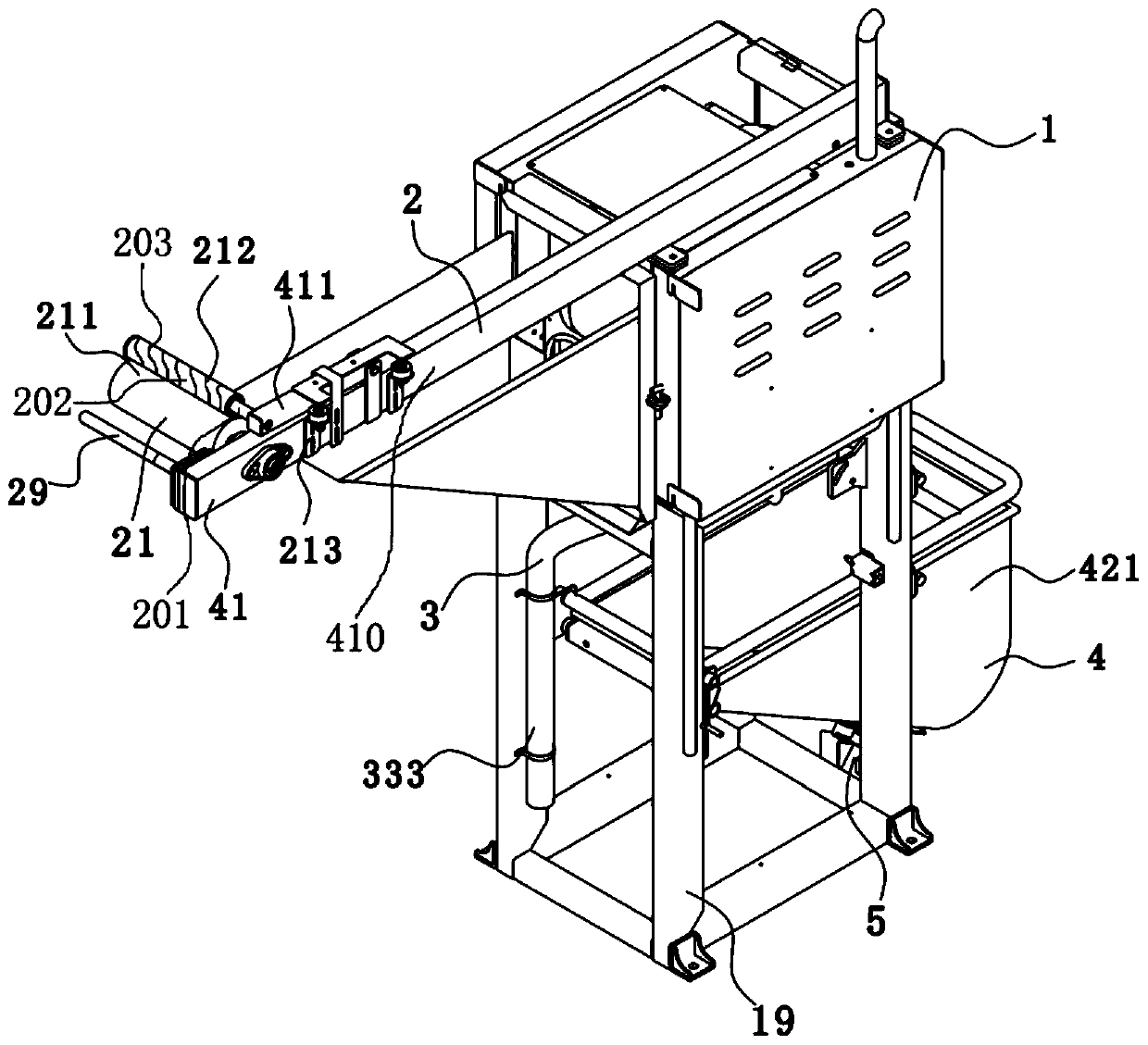

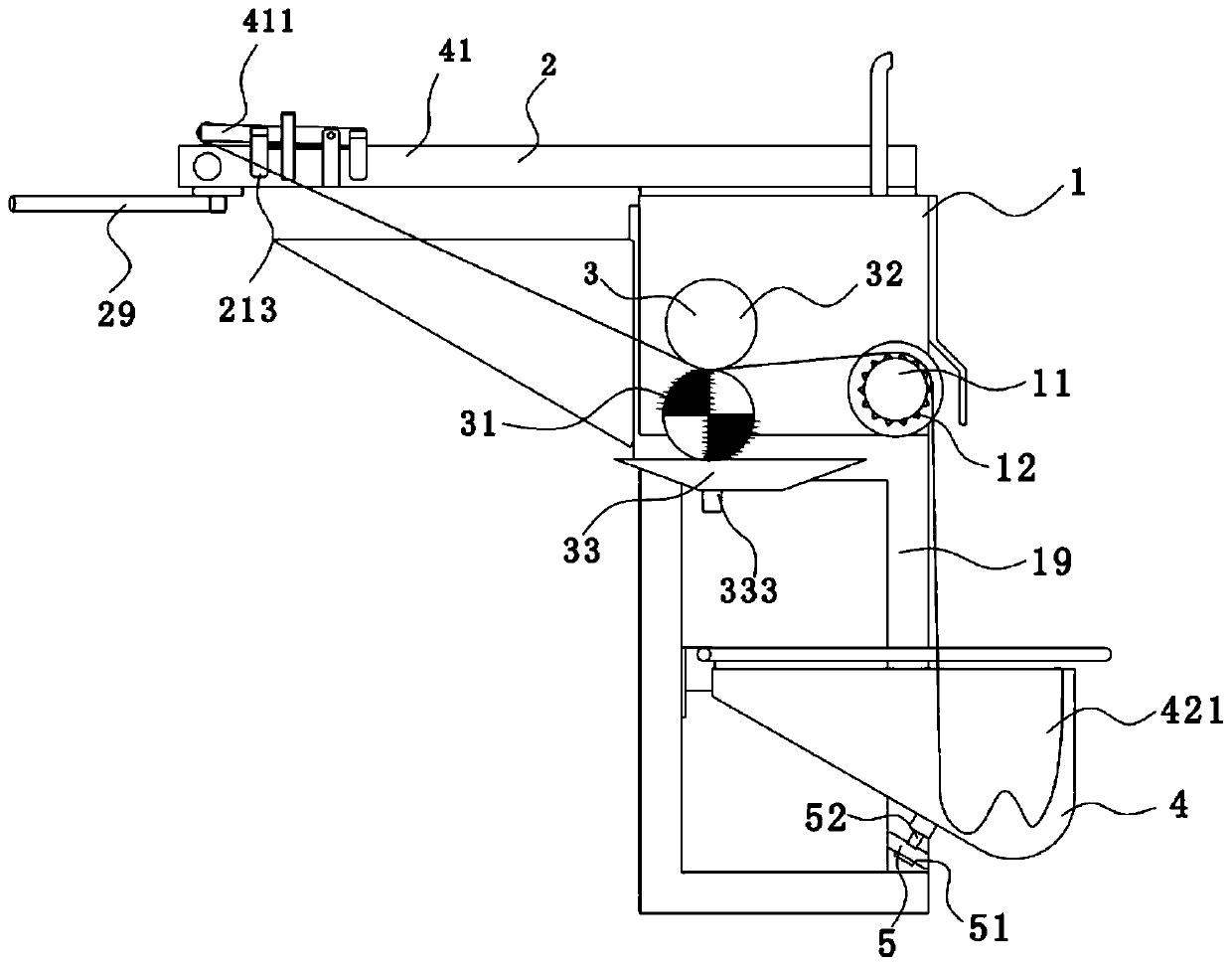

Manufacturing method of carex-meyeriana mattress

InactiveCN107518678AImprove the calming effectPlay a bactericidal effectStuffed mattressesSpring mattressesLavandulaUgni molinae

The invention discloses a manufacturing method of a carex-meyeriana mattress. The manufacturing method comprises the following steps of mixing, mincing and cooking carex meyeriana, artemisia argyi and lavandula angustifolia to obtain a mixture I; mixing and oven-drying matricaria chamomilla, a jasmine flower and a cape jasmine flower to obtain a mixture II; arranging the mixture I and the mixture II in sequence from bottom to top to obtain a mixture III; carrying out high temperature setting on the mixture III to obtain the carex-meyeriana mattress; carrying out latex spraying on the carex-meyeriana mattress. According to the manufacturing method, the promotion of the sleep quality of people is facilitated through adding the artemisia argyi, the lavandula angustifolia, the jasmine flower, the cape jasmine flower and the like into the carex-meyeriana mattress; the mattress is enabled to have a favorable mind tranquilization effect and the bactericidal effect on the mattress is achieved through adding the matricaria chamomilla.

Owner:ZHEJIANG ANJI MEI JIAQI HOME CO LTD

Manufacturing process of mattress

The invention discloses a manufacturing process of a mattress. The manufacturing process comprises the following steps: (1) mixing dried carex meyeriana, wormwood and acorus calamus in a weight ratio of 10 to 1 to 1 to obtain a mixture, tightly compacting the carex meyeriana, the wormwood and the acorus calamus, carrying out shearing, and sleeving the surface of the sheared mixture with a layer of non-woven fabric, so as to obtain a carex meyeriana layer; (2) mixing dried taxus chinensis leaves, lavender and chamomile in a weight ratio of 6 to 1 to 1 to obtain a mixture, tightly compacting the taxus chinensis leaves, the lavender and the chamomile together, carrying out shearing, and sleeving the surface of the sheared mixture with a layer of non-woven fabric, so as to obtain a taxus chinensis layer; and (3) putting the taxus chinensis layer on the carex meyeriana layer, tightly compacting the taxus chinensis layer and carex meyeriana layer together, and sleeving the surfaces of the taxus chinensis layer and carex meyeriana layer with a mattress cover. The carex meyeriana and the taxus chinensis leaves are taken as the raw materials and are added with the wormwood, the acorus calamus, the lavender and the chamomile, so that the manufactured mattress has the efficacies of soothing nerves, removing odor and killing and resisting bacteria and further has certain health functions.

Owner:ANJI YUANMO MECHANICS TECH CO LTD

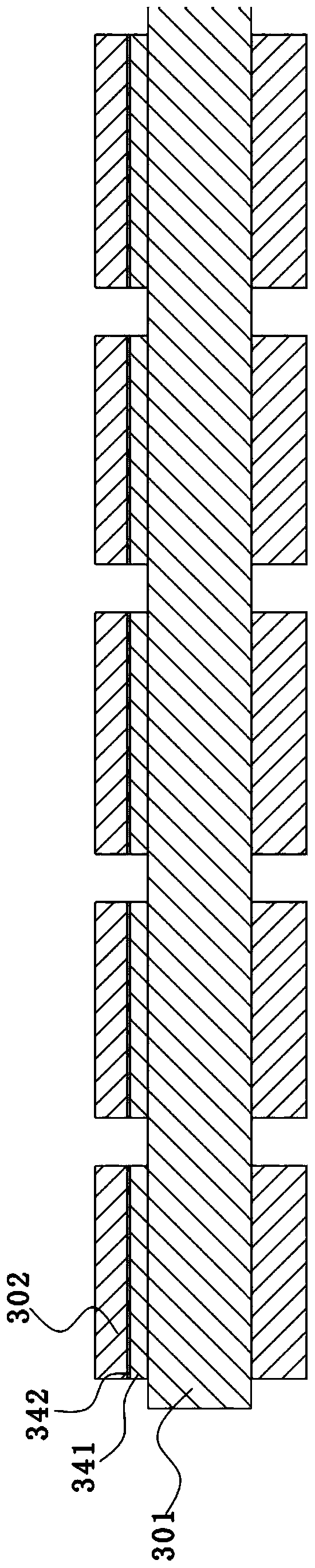

Carex meyeriana blended yarn production method

The invention discloses a Carex meyeriana blended yarn production method. Tencel fiber is regenerated cellulose fiber, sweat-absorbent, breathable and can keep warm and cool, the Tencel fiber is comfortable to wear, the strength elongation property is high, the Tencel fiber also has the handle of silk and is the most ideal material for light and thin fabric, so that the blended yarn with higher quality can be obtained by blending of Carex meyeriana fiber and the Tencel fiber. The Carex meyeriana / Tencel blended yarn explores a new space for the development of Carex meyeriana products. The technological process comprises blended materials, a blowing-carding unit, a drawing frame (three-lines) and an air-jet spinning machine in sequence. The method is characterized in that raw materials are pre-processed, a reasonable raw material blending technology is chose, a reasonable technological process is determined, parameters of all fore-spinning working procedures are configured accurately, and optimized air-jet spinning technology parameters are determined. According to the Carex meyeriana / Tencel blended yarn produced through air-jet spinning, the blended yarn with a good balance between all performance indexes such as even yarn, little hairy yarn, even strength, good anti-friction, anti-pilling property is obtained.

Owner:QIQIHAR UNIVERSITY

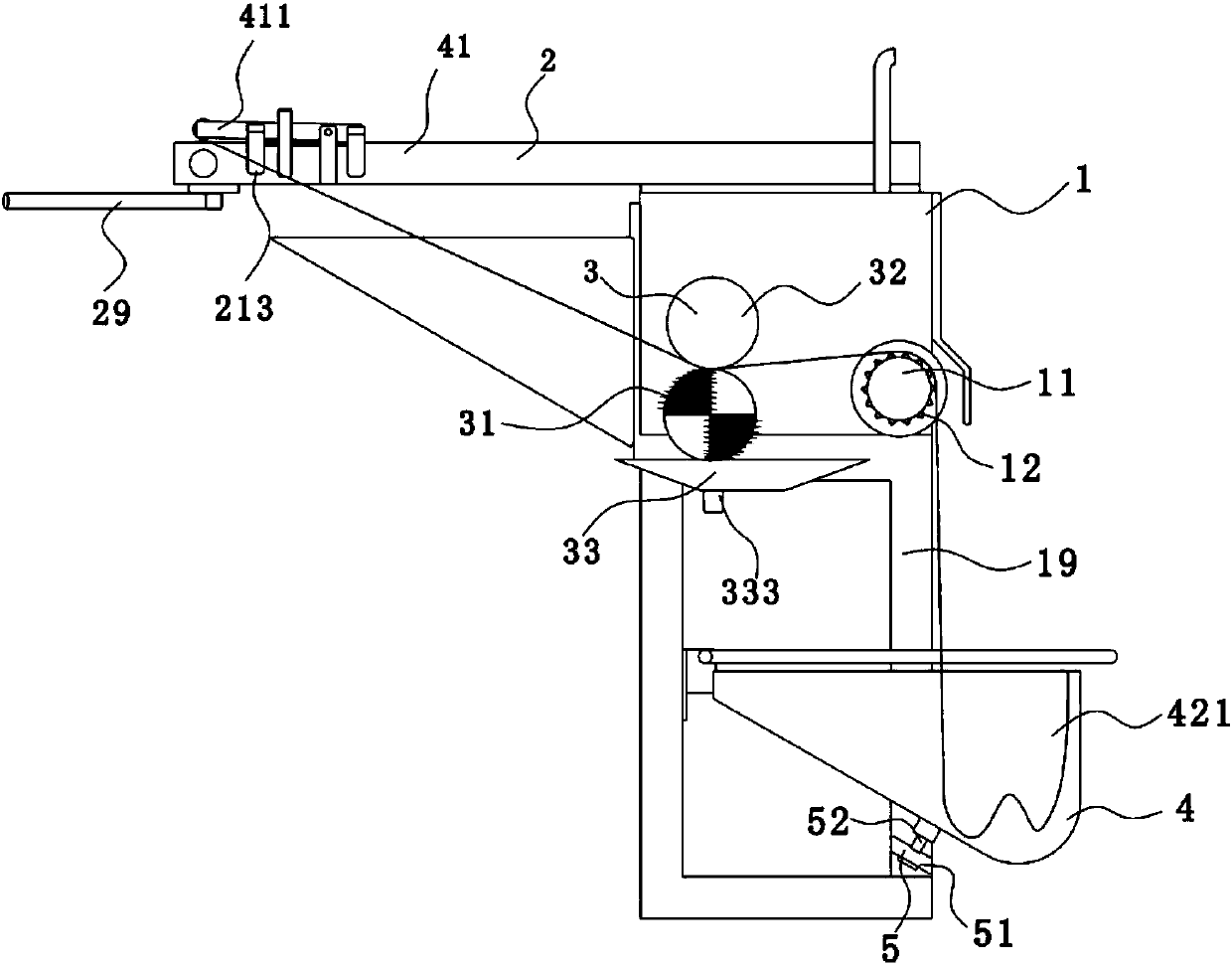

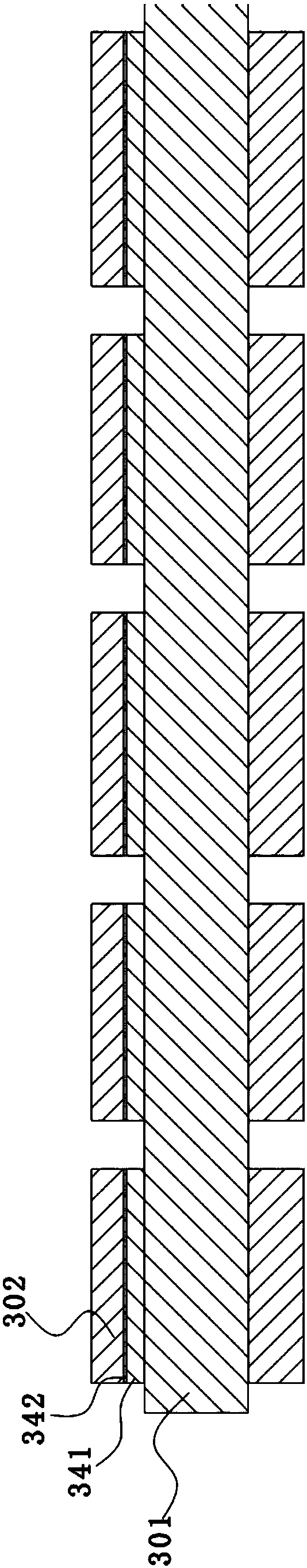

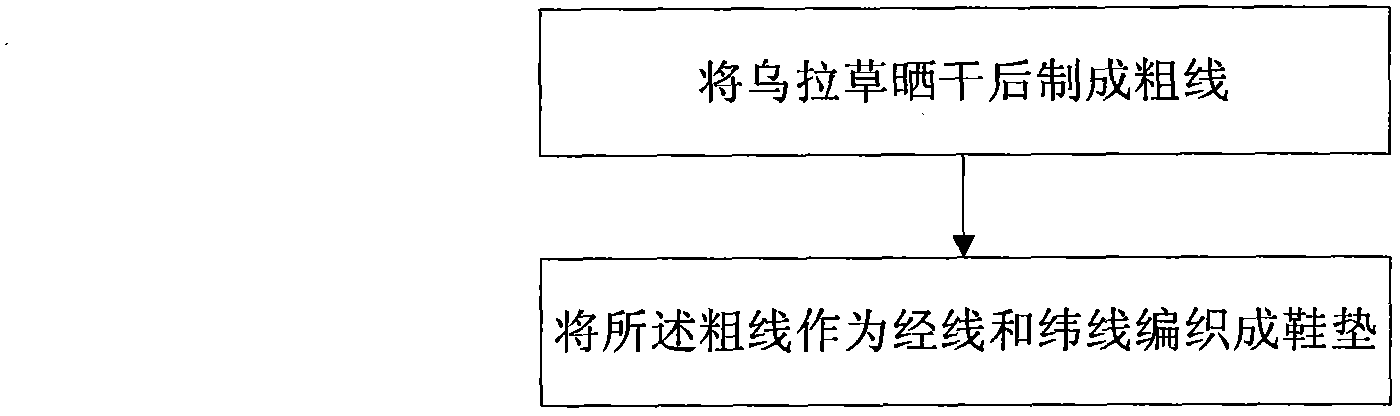

Insole and manufacturing method

The invention provides an insole and a manufacturing method. The insole is woven through dried carex meyeriana. The method includes producing thick threads through the dried carex meyeriana; adopting the thick threads as weft yarns and warp yarns to weave to obtain the insole. According to the scheme, the carex meyeriana is adopted to produce the insole. Thus, the fine cold proof effect can be achieved, and freezing injure can be prevented; meanwhile, attractiveness and comfort are provided; the insole made of the carex meyeriana is low in cost and has fine cold proof effect.

Owner:蔡燕春

Health care mattress production process

Owner:ANJI YUANMO MECHANICS TECH CO LTD

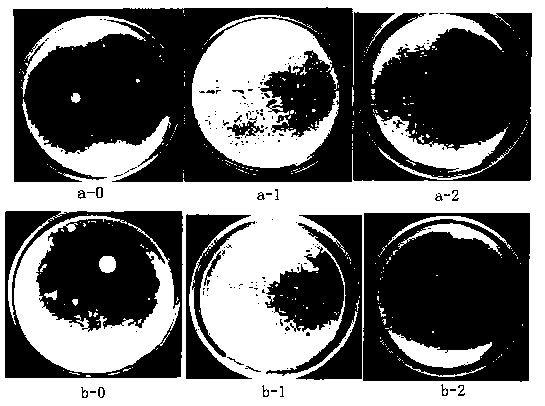

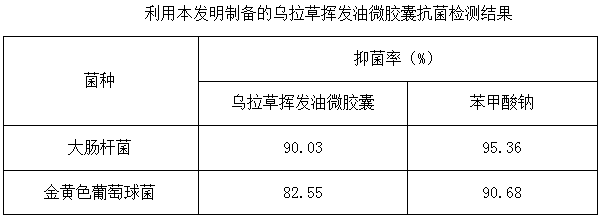

Preparation method of carex meyeriana volatile oil microcapsule

The invention relates to a preparation method of a carex meyeriana volatile oil microcapsule and relates to the technical field of microcapsule preparation. The preparation method comprises the operation steps of pretreatment, distillation, extraction, emulsification and granulation. By using the preparation method of the carex meyeriana volatile oil microcapsule, the prepared microcapsule has smaller particle size, the average particle diameter is 3.5 microns, and particle size distribution is more uniform. Then, staphylococcus aureus and escherichia coli are inhibited by adding the carex meyeriana volatile oil microcapsule and sodium benzoate which are equal in adding amount, its bacteriostasis rate is slightly lower than that of the sodium benzoate. However, the sodium benzoate is a chemical agent, its food safety is poorer than that of the carex meyeriana volatile oil microcapsule and the carex meyeriana volatile oil microcapsule has good continuity and meanwhile has better fragrance, so that the carex meyeriana volatile oil microcapsule has a wider application prospect.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

Production process of carex-meyeriana mattress

InactiveCN107518677AImprove breathabilityPlay a protective effectStuffed mattressesSpring mattressesLavandulaUgni molinae

The invention discloses a production process of a carex-meyeriana mattress. The production process comprises the following steps of mixing, mincing and cooking carex meyeriana, artemisia argyi and lavandula angustifolia to obtain a mixture I; mixing, mincing and cooking a palm filament, a bamboo filament and schoenoplectus trigueter to obtain a mixture II; mixing and oven-drying matricaria chamomilla, a jasmine flower and a cape jasmine flower to obtain a mixture III; arranging the mixture II, the mixture III and the mixture I in sequence from bottom to top to obtain a mixture IV; carrying out high temperature setting on the mixture IV to obtain the carex-meyeriana mattress; carrying out latex spraying on the carex-meyeriana mattress. In conclusion, according to the production process, the promotion of the sleep quality of people is facilitated through adding the artemisia argyi, the lavandula angustifolia, the matricaria chamomilla, the jasmine flower, the cape jasmine flower and the like into the carex-meyeriana mattress; the air permeability of the mattress is increased by the palm filament, the bamboo filament and the schoenoplectus trigueter; the latex is sprayed outside the carex-meyeriana mattress; the protection effect on the mattress can be achieved and the service life is prolonged.

Owner:ZHEJIANG ANJI MEI JIAQI HOME CO LTD

Health mattress made of Carex meyeriana Kunth

The invention discloses a kind of hygienic mattress made of uregrass. It comprises the following steps to make it: put the uregrass into the agitator and make it stifled by the vapor, to make the raw material mellow and difficult to broken; pave the raw material well and send it into the pressurized machine to sterilize at a high temperature, form by pressure, and set prominences in one end of the mattress uniformly; put the formed mattress into the traditional medicine to immerse and oversaw traditional medicine powder to the formed mattress, to make the mattress contains following features: heat and cold insulation, cold-proof and damp-proof, mellow texture, good air perviousness and the prevention and treat to the rheumatic disease. The mattress is made by the pressing of green plants, sticked without glue, having environmental protection function, and having chiropractic function with the arrangement of the prominences. The uregrass can also be made into hygienic shoe-pad, it can prevent beriberi.

Owner:任学明

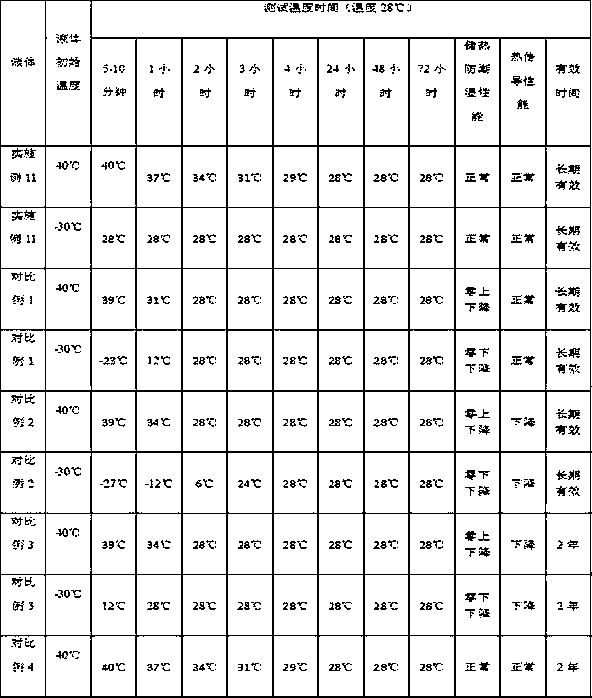

28 DEG C liquid and preparation method thereof

InactiveCN109536139AMaintain temperature effectImprove temperature performanceHeat-exchange elementsStrontiumGraphite

The invention discloses 28 DEG C liquid, which is prepared from the following raw materials in parts by weight: 0.5 to 1.5 parts of graphite, 5 to 10 parts of ice apron, 5 to 10 parts of tourmaline, 5to 10 parts of plant active carbon, 15 to 25 parts of cinerite, 20 to 30 parts of carex meyeriana volatile oil, 8 to 15 parts of calamine, 0.1 to 2 parts of strontium peroxide, 0.02 to 1 part of strontium and 80 to 120 parts of water. The 28 DEG C liquid can realize the heat absorption and heat release, has no need of external power or energy; when the environment temperature is higher than 30 DEG C, heat absorption can be performed, so that the environment temperature is lowered to 28+ / -3 DEG C; when the environment temperature is lower than 27.5 DEG C, through heat release, the temperatureis raised to 28+ / -3 DEG C; the energy or power provided by outside is not needed; the cooling or heating is performed; the heat absorption process and the heat release process can be performed in a cyclic repeated way; the energy sources are saved.

Owner:北京二十八度天空新材料科技有限公司

Sweat-removing dehumidification cushion for bodybuilding

InactiveCN108926169AFast water absorptionQuick dehumidificationStuffed mattressesSynthetic resin layered productsFiberSurface layer

The invention discloses a sweat-removing dehumidification cushion for bodybuilding, and belongs to the field of accessories for bodybuilding apparatuses. The cushion comprises a cushion body, a baffleplate, a cushion surface layer and a cushion supporting body, the cushion surface layer is closely laminated to the cushion body, the cushion supporting body is fixedly connected to the bottom of thecushion body, the cushion body includes water absorption holes and a drying groove, the water absorption holes are connected to the top of the drying groove in a penetrating manner, every water absorption hole is filled with a water absorption agent, the drying groove is connected to the bottom of the cushion body in a penetrating manner, and a Carex meyeriana layer and a sponge layer are arranged below the cushion surface layer. Fibers of the sponge layer are soft and flexible, so the cushion is comfortable to lean and sit on; Carex meyeriana can quickly absorb and drain moisture, so the cushion has good sweat absorption and moisture removal effects, and is hygienic to use; and the water absorption agent in the water absorption holes of the cushion body can absorb water in the cushion body, and the drying groove can dry the moisture in the cushion to achieve the effects of dehumidification and sweat removal, and the use cost is low.

Owner:DONGGUAN SONGYAN ZHIDA IND DESIGN CO LTD

Manufacturing method of health-care mattress

InactiveCN107518676AHave sleepDeodorantStuffed mattressesSpring mattressesPhysical well beingCarex meyeriana

The invention discloses a manufacturing method of a health-care mattress. The manufacturing method comprises the following steps: manufacturing a coconut fiber layer, manufacturing a carex meyeriana layer, manufacturing a mat rush layer, carrying out hot pressing and curing, trimming and sleeving. According to the manufacturing method disclosed by the invention, the mattress produced by the coconut fiber layer, the carex meyeriana layer and the mat rush layer has a very good sterilization effect and a very good odor-removing capability and is used for effectively inhibiting the breeding of bacteria in the mattress; the health-care mattress is good for body health of people; furthermore, the smell of the mattress can also keep fresh for long time and the sleeping quality is improved.

Owner:ZHEJIANG ANJI MEI JIAQI HOME CO LTD

Warm keeping and bacteria resisting fitted cover based on carex meyeriana composite non-woven cloth

InactiveCN106671521AFirmly connectedImprove fitLamination ancillary operationsSynthetic resin layered productsFiberSurface layer

The invention discloses a warm keeping and bacteria resisting fitted cover based on carex meyeriana composite non-woven cloth. The warm keeping and bacteria resisting fitted cover is mainly formed by ramie cloth, the carex meyeriana composite non-woven cloth and a flannel / coral velvet surface layer. The warm keeping and bacteria resisting fitted cover integrates the warm keeping and bacteria inhibiting effects of carex meyeriana and environment-friendly, ventilate, soft and skin-friendly functions of flannel / coral fabric, so that the warm keeping and bacteria resisting fitted cover is stronger in functions and is more innovative; carex meyeriana fiber but not a carex meyeriana raw material is adopted, so that the flexibility and the comfort of the warm keeping and bacteria resisting fitted cover are greatly improved; by adding the carex meyeriana composite non-woven cloth between flannel and coral velvet, so that the warm keeping and bacteria resisting functions can be enhanced.

Owner:李林

Fabric preparation and printing and dyeing methods

ActiveCN108048977BStrong comfortWon't fadeSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersFiberYarn

The invention discloses a fabric preparation and dyeing method. The method includes steps: S1, fabric preparation, to be more specific, using a twisting machine for twisting, by mass, 5-9 parts of artemisia argyi fibers, 12-23 parts of carex meyeriana fibers and 10-18 parts of acorus calamus fibers into artemisia argyi fiber strips, carex meyeriana fiber strips and acorus calamus fiber strips, andpreparing blended yarns from the artemisia argyi fiber strips, the carex meyeriana fiber strips, the acorus calamus fiber strips and cotton fiber strips to further obtain a fabric A. The prepared fabric not only has a fragrance efficacy but also has great antibacterial and odor removal functions and is high in comfort, low in dyeing agent residual amount and free of fading. In addition, the fabric produced according to the method is high in toughness and durability.

Owner:SHAOXING HAITONG PRINTING & DYEING CO LTD

Warm keeping and skipping preventing shoes for internal use and external use

The invention provides warm keeping and skipping preventing shoes for internal use and external use. The warm keeping and skipping preventing shoes comprise surfaces, upper bottoms, half sole bottoms and heel flat bottoms, wherein the half sole bottoms have half sole curved surfaces; and the heel flat bottoms have heel flat surfaces. The warm keeping and skipping preventing shoes are characterized in that a thermal insulation flock sleeve layer is fixedly connected and clung to the inner side of each surface; a thermal insulating insole layer is clung onto the upper surface of each upper bottom and is connected with a thermal insulating insole into a whole in a sewing manner; mountain skipping preventing assemblies and ice land skipping preventing assemblies are respectively arranged on the half sole bottoms and heel bottoms; each mountain skipping preventing assembly comprises a bent plate forked base, an elliptic nail plate and a bent plate swinging fork; and each ice land skipping preventing assembly comprises a swinging fork base, a flat face round nail plate and a swinging fork. The warm keeping and skipping preventing shoes for the internal use and the external use enable stable walking on both a general road and an icy road to be possible, and also can be used for steadily climbing a mountain, and are convenient to adjust. The thermal insulation flock sleeves are made of woollen goods; the thermal insulating insoles are made of carex meyeriana materials which are known as one of Northeast Three Treasures and have sufficient thermal insulation effect.

Owner:山东润蒙应急救援装备有限公司

Plant fiber fabric for balancing oil secretion and preparation method thereof

InactiveCN108950723ASoft lusterFeel smoothConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsYarnProtein fiber

The invention discloses a plant fiber fabric for balancing oil secretion, and the plant fiber fabric is composed of the following components by weight: 20-30 parts of terephthalic acid, 5-8 parts of Carex meyeriana, 2-3 parts of lavender, 2-3 parts of of calendula, 40 to 60 parts of ethylene glycol, 4 to 6 parts of eucalyptus, 0.2-0.5 part of vitamin E, 5 to 8 parts of tea tree, 2 to 3 parts of flores aurantii, 0.5 to 1.2 parts of ethylene glycol antimony, 40-80 parts of Lyocell Bamboo fiber, 20-30 parts of silkworm pupa protein fiber, 10-20 parts of corn starch and 0.5-2 parts of a spinning aid. The plant fiber fabric is green and environmentally friendly, and the raw materials are made of renewable resources. The production process of yarns does not pollute the environment, and waste canbe partially degraded under natural conditions.

Owner:冯园园

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com