Spatial grid reinforcing environment-friendly heat insulation wallboard

A technology of thermal insulation wall panels and net frames, applied in the field of building materials, can solve the problems of application limitations, no data display application, no prefabricated panels, etc., and achieve good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Take the following ingredients:

[0030] Cement 30 kg

[0031] 2 kg slaked lime

[0032] Limestone 45kg

[0033] Heavy Calcium Powder 13kg

[0034] Foamed PS granules 5kg

[0035] Wood fiber (Arbocel) 0.5 kg

[0036] Redispersible latex powder (RE5044) 4.3 kg

[0037] Methyl cellulose ether (MKX15000PP20) 0.2 kg

[0038] 60 mesh Ulagrass 2kg

[0039] Cloves 1.5 kg

[0040] Radix Paeoniae Alba 3 kg.

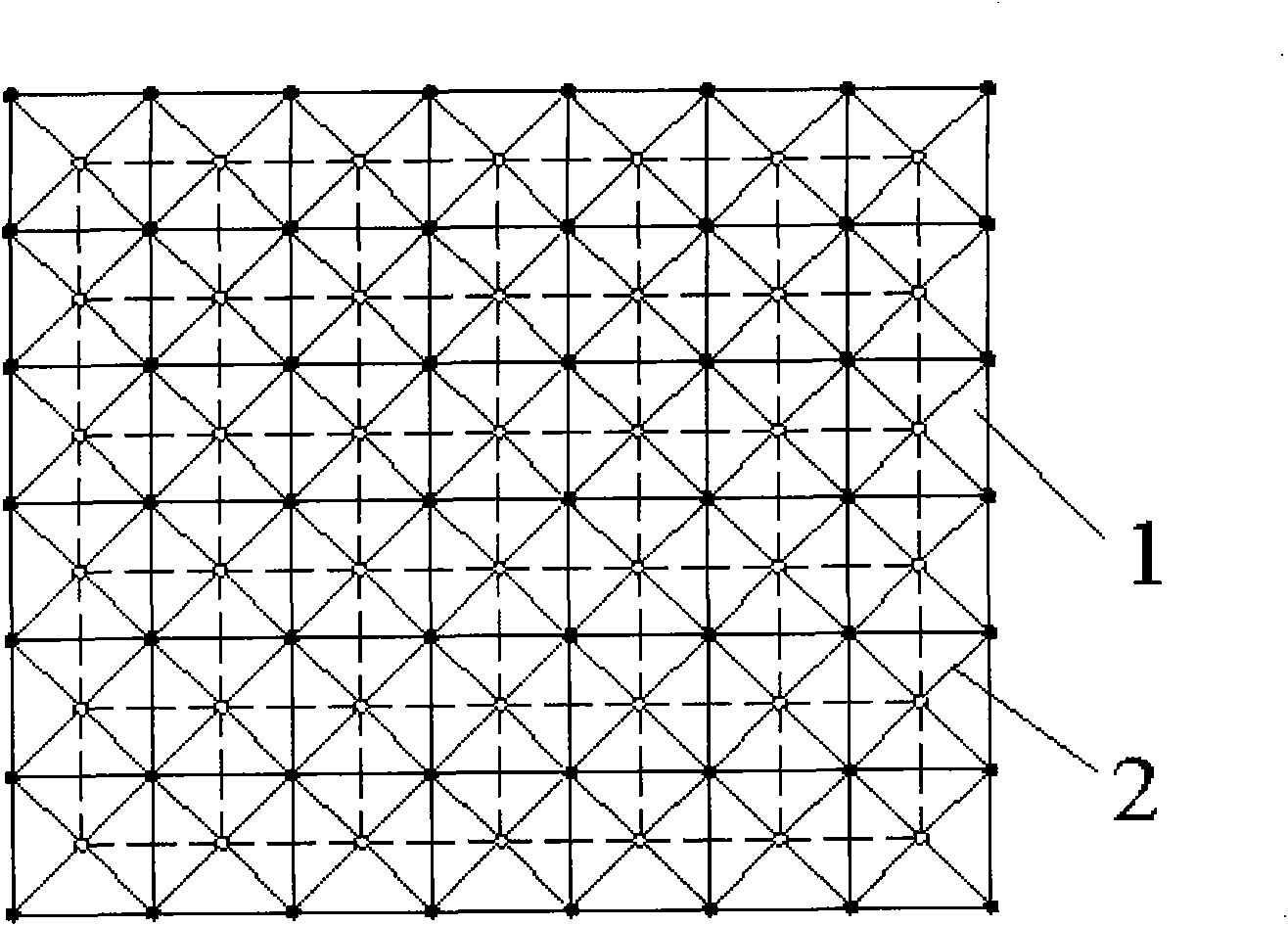

[0041] Such as figure 1 As shown, a steel wire mesh 2 is placed on the board main body 1 . After the above raw materials are mixed evenly, they are foamed after the wallboard mortar is formed and before solidification, so that a large number of air bubbles are generated in the wallboard, and the steel wire mesh is embedded in the wallboard mortar to obtain the thermal insulation wallboard.

Embodiment 2

[0043] Take the following ingredients:

[0044] Cement 25kg

[0045] 3 kg slaked lime

[0046] Limestone 40 kg

[0047] Heavy Calcium Powder 15kg

[0048] Foamed PS granules 3kg

[0049] Wood fiber (Arbocel) 0.5 kg

[0050] Redispersible latex powder (RE5044) 5kg

[0051] Methyl cellulose ether (MKX15000PP20) 0.1 kg

[0052] 60 mesh corn leaves 1kg

[0053] Albizia julibrissin 2kg

[0054] Pueraria 1 kg.

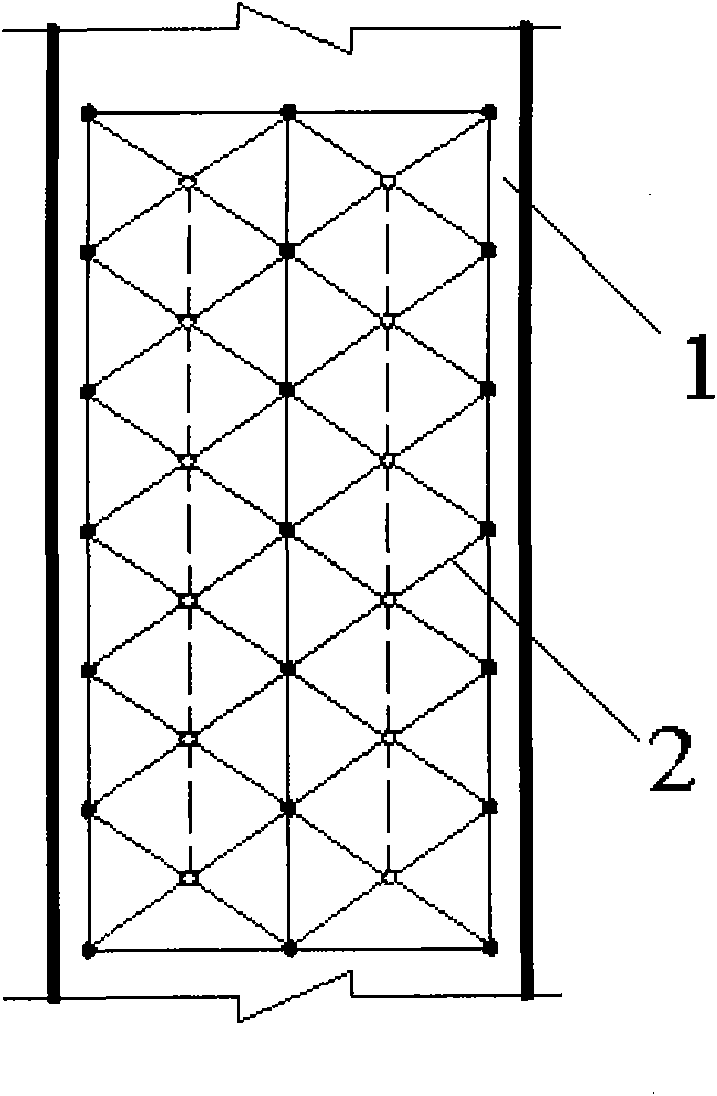

[0055] Such as figure 2 As shown, a steel wire mesh 2 is placed on the board main body 1 . After the above raw materials are mixed evenly, they are foamed after the wallboard mortar is formed and before solidification, so that a large number of air bubbles are generated in the wallboard, and the steel wire mesh is embedded in the wallboard mortar to obtain the thermal insulation wallboard.

Embodiment 3

[0057] Take the following ingredients:

[0058] Cement 35 kg

[0059] 1 kg slaked lime

[0060] Limestone 50 kg

[0061] Heavy Calcium Powder 10kg

[0062] Foamed PS granules 8kg

[0063] Wood fiber (Arbocel) 0.2 kg

[0064] Redispersible latex powder (RE5044) 3kg

[0065] Methyl cellulose ether (MKX15000PP20) 0.2 kg

[0066] 60 mesh corn leaves 3kg

[0067] Woody incense 1 kg

[0068] White Fuzi 5 kg.

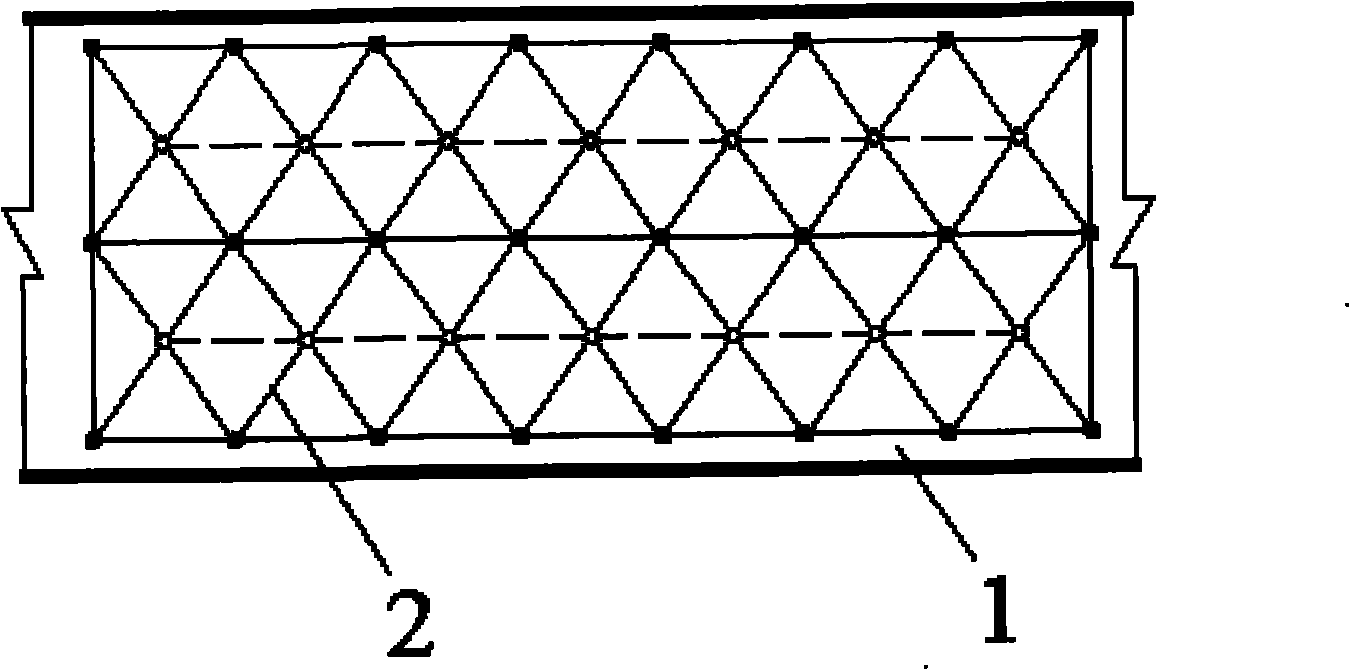

[0069] Such as image 3 As shown, a steel wire mesh 2 is placed on the board main body 1 . After the above raw materials are mixed evenly, they are foamed after the wallboard mortar is formed and before solidification, so that a large number of air bubbles are generated in the wallboard, and the steel wire mesh is embedded in the wallboard mortar to obtain the thermal insulation wallboard.

[0070] The thermal insulation wall panels obtained in Examples 1 to 3 have excellent thermal insulation and thermal insulation properties, high strength, air purification, tranq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com