Preparation method of tear resistant silicone rubber mold

A technology of tear resistance and silicone rubber, applied in the field of silicone rubber, can solve the problems of poor tear resistance and tear resistance, and achieve the effect of improving tear resistance, eliminating tear stress and improving environmental protection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

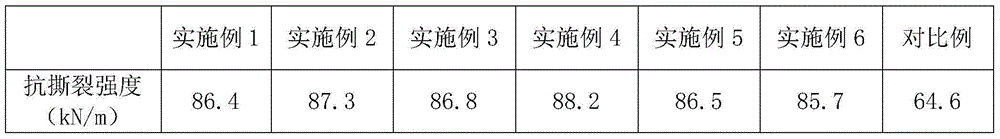

Examples

Embodiment 1

[0025] The preparation method of tear-resistant mold silicone rubber, its step is as follows:

[0026] (1) Pulverize the Ulagrass fiber with a pulverizer, add ammonia water with a mass concentration of 9%, stir in a water bath at 70°C for 80 minutes, take it out, wash it with absolute ethanol until neutral, and dry it in a vacuum oven at 85°C To constant weight, obtain the basalt fiber of alkalization, wherein, the weight ratio of fiber of sage fiber and ammoniacal liquor is 1:25;

[0027] (2) Amino silicone oil, dehydrated alcohol, and sodium cetylbenzenesulfonate were mixed and stirred for 1 hour to obtain a modified emulsion with a weight ratio of 1:1:4, and the modified emulsion was mixed with the obtained product of step (1). Alkalized Ulagrass fibers were added to the reaction kettle together, reacted at 150°C for 4 hours after being ventilated with nitrogen, washed 5 times with deionized water after being taken out, and dried to constant weight at 75°C in a vacuum dryin...

Embodiment 2

[0031] The preparation method of tear-resistant mold silicone rubber, its step is as follows:

[0032] (1) Pulverize the Ulagrass fiber with a pulverizer, add ammonia water with a mass concentration of 9%, stir in a water bath at 70°C for 80 minutes, take it out, wash it with absolute ethanol until neutral, and dry it in a vacuum oven at 85°C To constant weight, obtain the basalt fiber of alkalization, wherein, the weight ratio of fiber of sage fiber and ammoniacal liquor is 1:25;

[0033] (2) Amino silicone oil, dehydrated alcohol, and sodium cetylbenzenesulfonate were mixed and stirred for 1 hour to obtain a modified emulsion with a weight ratio of 1:1:4, and the modified emulsion was mixed with the obtained product of step (1). Alkalized Ulagrass fibers were added to the reaction kettle together, reacted at 150°C for 4 hours after being ventilated with nitrogen, washed 5 times with deionized water after being taken out, and dried to constant weight at 75°C in a vacuum dryin...

Embodiment 3

[0037] The preparation method of tear-resistant mold silicone rubber, its step is as follows:

[0038] (1) Pulverize the Ulagrass fiber with a pulverizer, add ammonia water with a mass concentration of 9%, stir in a water bath at 70°C for 80 minutes, take it out, wash it with absolute ethanol until neutral, and dry it in a vacuum oven at 85°C To constant weight, obtain the basalt fiber of alkalization, wherein, the weight ratio of fiber of sage fiber and ammoniacal liquor is 1:25;

[0039] (2) Amino silicone oil, dehydrated alcohol, and sodium cetylbenzenesulfonate were mixed and stirred for 1 hour to obtain a modified emulsion with a weight ratio of 1:1:4, and the modified emulsion was mixed with the obtained product of step (1). Alkalized Ulagrass fibers were added to the reaction kettle together, reacted at 150°C for 4 hours after being ventilated with nitrogen, washed 5 times with deionized water after being taken out, and dried to constant weight at 75°C in a vacuum dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com